Every CNC machine looks great on paper. But which ones actually deliver?

I’ve spent years in manufacturing, sourcing machines, testing performance, and working with suppliers. I’ve seen machines that run for years without a problem. I’ve also seen ones that start strong, then break down just when you need them most.

If you’re here, you’re probably trying to make a smart decision. Maybe you’re starting a business or you’re upgrading your current setup. Either way, you want a CNC machine that meets your needs, without regrets later.

That’s exactly what this guide will help you do.

Inside, I’ve reviewed 7 of the best CNC machines, breaking down their features, performance, and real-world reliability. By the end, you’ll know which one fits your needs best.

Let’s get started!

Quick Comparison

You wouldn’t buy a car without checking the specs first, right? CNC machines are no different.

Before we get into the details of each machine, here’s a side-by-side comparison to help you spot the key differences and narrow down your choices.

| Machine Name | Type | Work Area | Material Compatibility | Spindle/Laser Power | Speed | Price Range | Best For |

| Fiber Laser Metal Cutting Machine ELECNC-1530F | Fiber Laser Cutter | 1515 x 3030 mm | Carbon steel, stainless steel, aluminum, brass | 1kW – 6kW | High-speed cutting | $20,000 – $50,000 | Industrial manufacturers, sheet metal fabrication |

| Shapeoko 4 CNC Router | CNC Router | 33 x 33 in (XXL model) | Wood, plastics, soft metals | Router-based | Variable, depends on material | $1,700 – $2,300 | Hobbyists, small businesses |

| Maslow CNC Router | CNC Router | 4′ x 8′ | Wood, plastics, foam | Router-based | Moderate | $500 – $700 | DIY enthusiasts, makers |

| Tormach PCNC 440 CNC Mill | CNC Mill | 10 x 6.25 x 10 in | Metals, plastics, composites | 0.75 HP spindle | 135 IPM (X/Y), 110 IPM (Z) | $8,994+ | Small workshops, prototyping |

| Bantam Tools Desktop CNC Milling Machine | CNC Mill | 7 x 9 x 3.3 in | Aluminum, brass, plastics | 28,000 RPM spindle | 250 IPM | $6,999 | Prototyping, small-scale metal milling |

| OMTech AF2028-60 60W CO2 Laser Engraver | Laser Engraver | 20 x 28 in | Wood, acrylic, glass, leather | 60W CO2 laser | 600 mm/s | $2,899.99 | Custom engraving, small businesses |

| Avid CNC PRO60120 | CNC Router | 5′ x 10′ | Wood, plastics, composites, non-ferrous metals | Customizable | 600 IPM (cut), 1200 IPM (rapid) | $8,085 – $17,380 | Large-scale production, fabrication |

Now that you’ve got a big-picture comparison, let’s go deeper.

Next, we’ll break down each machine one by one so you can see which one truly fits your needs.

1. Fiber Laser Metal Cutting Machine ELECNC-1530F

If you work with metal, you know precision matters.

A small error can lead to wasted material, costly reworks, or parts that just don’t fit. That’s why choosing the right cutting machine is critical.

The ELECNC-1530F Fiber Laser Metal Cutting Machine is designed for businesses that demand accuracy, speed, and efficiency. Whether you’re in sheet metal fabrication, automotive part production, or metal signage, this machine delivers clean cuts with minimal waste.

Who is this machine best for?

- Industrial manufacturers that require high-precision metal cutting.

- Businesses producing automotive parts, signage, or sheet metal components.

- Workshops looking to improve cutting efficiency while reducing waste.

This machine is designed specifically for carbon steel, stainless steel, aluminum, and brass. However, if your work involves non-metal materials like wood or plastic, you’ll need a different cutting solution.

Key Features

- Intelligent Automatic Focusing Laser Head: Reduces manual adjustments. Achieves a focusing speed of 10m/min with 50-micron positioning accuracy.

- Aviation Aluminum Beam: Corrosion-resistant and lightweight. High rigidity ensures fast and precise cutting.

- High-Quality Thick Wall Carbon Steel Bed: Treated at 600℃ for durability. Reduces vibration and maintains accuracy over time.

- Large Volume Dust Removal System: Clears smoke and debris. Keeps the work area clean and safe.

- Automatic Lubrication System: Reduces manual maintenance. Increases machine lifespan and efficiency.

Performance & Capabilities

- Precision Cutting: Suitable for intricate patterns and detailed metalwork.

- High-Speed Operation: Cuts thin metal sheets quickly and efficiently.

- Continuous Use: Designed for long working hours without loss of performance.

Specifications

- Model: ELECNC-1530F

- Machine Size: 4320 × 2250 × 1950 mm

- Working Area: 1515 × 3030 mm

- Positioning Accuracy: ±0.03 mm

- Repositioning Accuracy: ±0.02 mm

- Maximum Acceleration: 1.5G

- Laser Power: 1 kW – 6 kW (configurable)

- Focusing Method: Auto / Manual

- Servo Motor & Driver: YASKAWA / FUJI

- Reducer: Shimpo

Pricing & Cost Efficiency

- Base Price: $15,000 per set.

- Price Range: $20,000 – $50,000 per set, depending on power and configuration.

- Low Maintenance: Fiber laser systems need less upkeep than CO2 models.

- Energy Efficient: Uses less power while delivering high-quality results.

Pros & Cons

✅ Pros

- High-speed and high-precision cutting.

- Works with multiple metal types.

- Stable structure with low vibration.

- User-friendly control system.

❌ Cons

- Not suitable for non-metals like wood or plastic.

2. Shapeoko 4 CNC Router

If your business needs a compact yet powerful CNC router, the Shapeoko 4 is a solid choice. Designed for hobbyists, small businesses, and educators, it provides precision cutting with a user-friendly setup.

Whether you’re crafting custom signs, furniture, or prototypes, this machine offers versatility without a steep learning curve.

Applications

- Custom woodworking and engraving

- Small-scale signage production

- Educational training in CNC machining

- Prototyping and light manufacturing

Compatible with wood, plastics, and soft metals, this router is best suited for non-industrial applications. For heavy-duty metalwork or large-scale manufacturing, alternative models may be more appropriate.

Key Features

- Heavy-duty V-wheels enhance machine stability and smooth operation.

- 15mm belts provide increased stiffness for improved cutting precision.

- Inductive homing switches ensure reliable and accurate positioning.

- Integrated T-slot table offers multiple work-holding options.

- Leadscrew-driven Z-axis delivers precise depth control for detailed cutting.

Performance & Capabilities

- High precision for detailed woodworking, plastics, and light metal applications.

- Carbide Create software simplifies the design-to-cutting process.

- Expandable with compatibility for different routers and spindles.

Specifications

- Available sizes:

- Standard: 16″ x 16″ cutting area

- XL: 16″ x 33″ cutting area

- XXL: 33″ x 33″ cutting area

- Footprint:

- Standard: 28.75″ x 24.75″ x 16″

- XL: 44.75″ x 24.75″ x 16″

- XXL: 44.75″ x 40.75″ x 16″

- Weight: Approximately 150 lbs (varies by size)

Pricing & Cost Efficiency

- Base prices:

- Standard: $1,800

- XL: $2,150

- XXL: $2,400

- Included accessories:

- Sweepy 65mm V2 Dust Boot

- Carbide Create software

- Assembly tools

- Optional add-ons:

- Carbide Compact Router ($80)

- Endmill Starter Pack ($195)

- Clamp Set ($58)

Pros & Cons

✅ Pros

- Multiple size options for various workspace requirements

- Strong community support and manufacturer resources

- Durable construction for long-term use

❌ Cons

- Assembly required, which may take time for first-time users

- Not designed for heavy-duty industrial applications

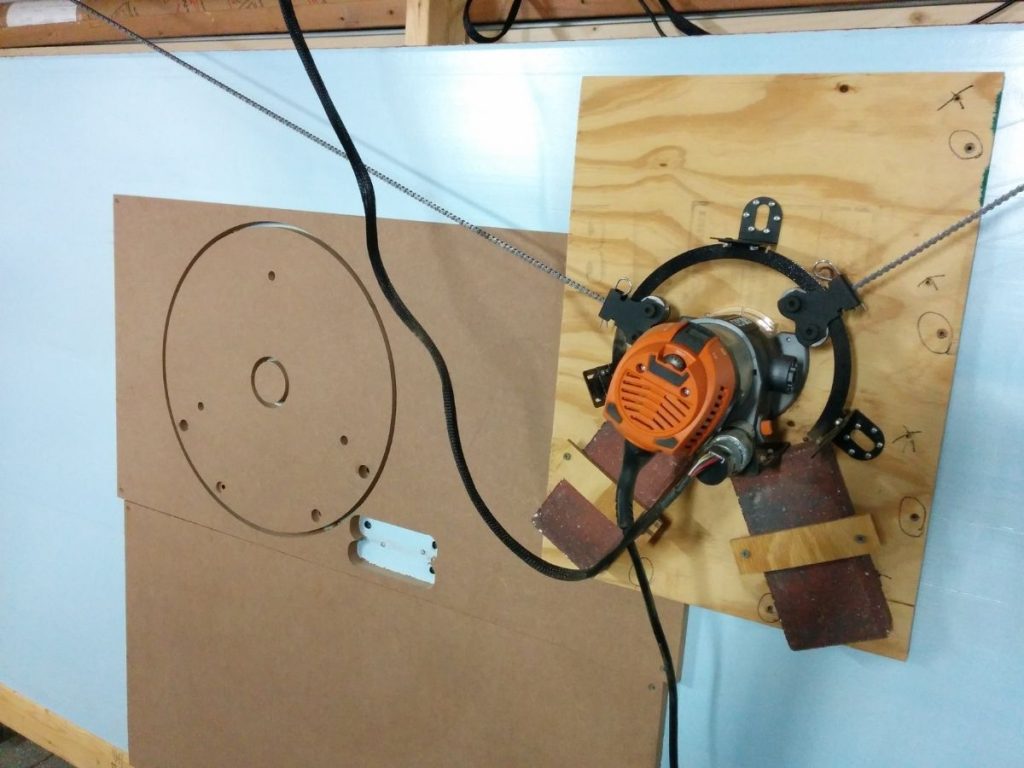

3. Maslow CNC Router

Large-format CNC machines are usually expensive and take up significant space. The Maslow CNC Router changes that. It provides an affordable, space-saving solution for those who need to cut large materials without the cost of an industrial machine.

Unlike traditional CNC routers, Maslow’s vertical cutting design saves space while still handling 4′ x 8′ sheet materials. It’s an open-source machine, which means you can customize and upgrade it based on your needs.

It’s also one of the most affordable CNC kits available.

Applications

- Custom Furniture Production: Cuts large wood panels for furniture pieces, cabinets, and home decor.

- Sign Making: Suitable for creating large-scale signage with intricate designs.

- DIY & Hobbyist Projects: Ideal for home workshops, personal CNC projects, and makerspaces.

- Educational Training: Useful for teaching digital fabrication and CNC machining in schools and universities.

It works with wood, plastics, and some soft metals. However, if you need a machine for high-speed production or heavy-duty metal cutting, this may not be the best option.

Key Features

- Vertical Cutting Orientation: Uses a hanging plotter-style design that supports full 4′ x 8′ sheet cutting while reducing floor space use.

- Open-Source Platform: Allows custom modifications and upgrades based on specific needs.

- Affordable Kit: Priced lower than most CNC routers, making it accessible to small businesses and hobbyists.

- Large Cutting Area: Despite its compact design, it can cut large panels efficiently.

Performance & Capabilities

- Cutting Speed: Reaches up to 40 inches per minute, making it suitable for detailed woodworking and light metalwork.

- Precision Cutting: Offers a resolution of ±0.4mm, delivering accurate cuts for large-scale projects.

- Scalability: Can be upgraded and customized, with community support available for modifications.

Specifications

- Cutting Area: 4 feet x 8 feet

- Footprint: 10 feet wide x 19 inches deep

- Motor System: Geared motors with closed-loop feedback system

- Controller: Arduino Mega microprocessor

- Power Requirements: 120-240 volts, 50-60Hz, consuming less than 1 Amp

Pricing & Cost Efficiency

- Base Kit Price: Around $500

- Total Setup Cost: Estimated at $800, including the router, frame materials, and a computer for operation

- Low Cost per Square Foot: Provides a large-scale CNC solution at a fraction of the cost of comparable machines

Pros & Cons

✅ Pros

- Low cost compared to other large-format CNC machines

- Vertical design saves space

- Strong community support for upgrades and troubleshooting

❌ Cons

- Assembly required, including building the frame

- Cutting speed is slower than traditional CNC routers

- Manual calibration can take time to fine-tune

4. Tormach PCNC 440 CNC Mill

Not every workshop has the space or budget for a full-sized CNC mill. The Tormach PCNC 440 offers a solution.

It’s compact, powerful, and built for precision. Whether you’re running a small business, making custom parts, or teaching CNC machining, this machine provides industrial-level control without the industrial footprint.

I’ve seen small shops struggle with space and machinists outgrow beginner-level machines.

The PCNC 440 fits right in the middle.

It’s big enough to handle serious work but small enough to fit in a garage or classroom.

Applications

- Small business owners making precision parts without the need for a massive machine.

- Educators and students looking for an accessible, hands-on CNC training tool.

- Makers and hobbyists who want something more powerful than entry-level CNC routers.

This machine is built for metals, plastics, and composites, making it a versatile tool for different projects.

Key Features

- Compact design fits into tight spaces without sacrificing power.

- High-speed spindle runs at 10,000 RPM, allowing for clean, detailed cuts.

- User-friendly PathPilot® system makes programming and operation easier.

- Heavy-duty cast iron frame and table reduce vibration for stable machining.

Performance & Capabilities

- Travel dimensions:

- X-axis: 10 in.

- Y-axis: 6.25 in.

- Z-axis: 10 in.

- Feed rates:

- X and Y axes: 135 inches per minute (IPM)

- Z-axis: 110 IPM

- Expandable with accessories like tool changers, enclosures, and probing systems.

Specifications

- Table size: 18 in. × 6.3 in.

- Spindle power: 0.75 hp (0.56 kW)

- Power requirements: Single-phase 115 Vac, 50/60 Hz, 15A breaker

- Machine weight: About 450 lbs

Pricing & Cost Efficiency

- Base price: $8,994, with financing options available.

- Included features:

- 64GB program storage

- Conversational programming

- Coordinate rotation

- Lifetime PathPilot updates

For what it offers, it’s a strong investment for shops that need precision without spending six figures on an industrial mill.

Pros & Cons

✅ Pros

- Perfect for small workspaces while still handling real machining.

- Handles metals, plastics, and composites with ease.

- Upgradeable with add-ons to grow with your needs.

❌ Cons

- Smaller work area, so larger parts may need multiple setups.

- Requires assembly, which might take some time.

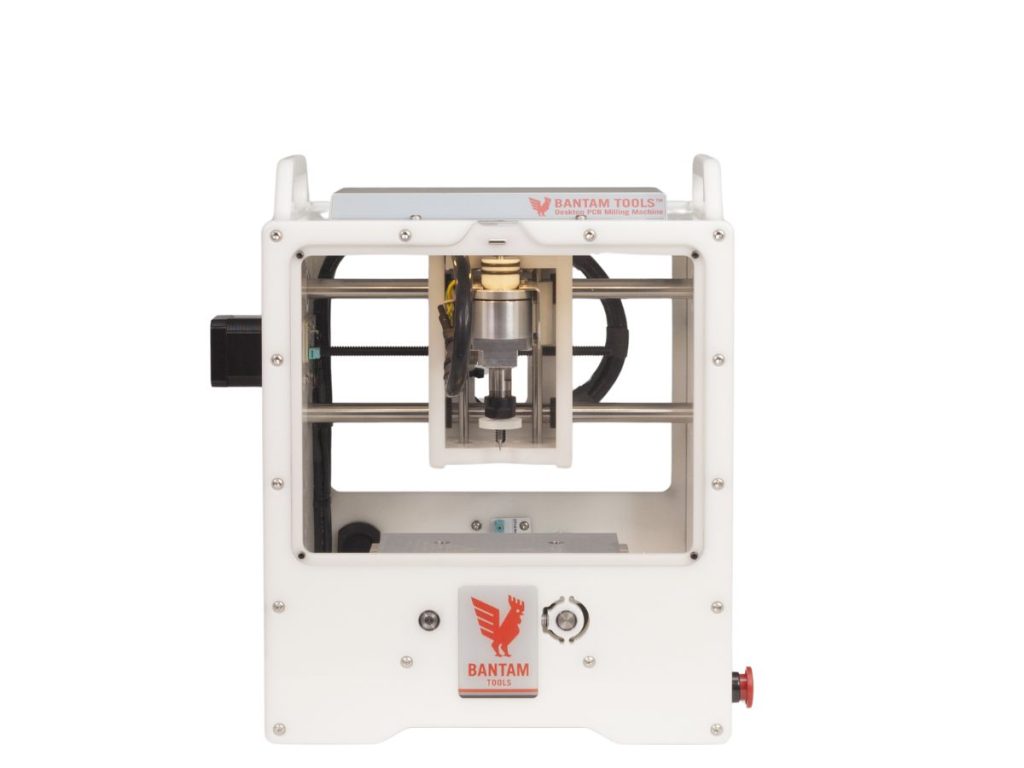

5. Bantam Tools Desktop CNC Milling Machine

If you’ve ever worked with a small CNC machine that couldn’t handle aluminum, you know the frustration.

Wasted material, uneven cuts, limited speeds. It all adds up.

The Bantam Tools Desktop CNC Milling Machine is built to solve those issues. It’s a desktop mill that actually delivers high-speed precision, making it perfect for small workshops, engineers, and educators who need real machining power without the industrial-scale equipment.

Applications

- Prototyping and Product Development: Ideal for engineers and designers creating prototypes in materials like aluminum and plastics.

- Educational Institutions: Suitable for teaching CNC machining principles in classrooms and labs.

- Hobbyists and Makers: Perfect for individuals interested in precision machining for personal projects.

This machine is optimized for machining aluminum but also handles other soft metals and plastics efficiently.

Key Features

- High-Speed Spindle: Operates at up to 28,000 RPM, enabling precise and efficient material removal.

- ER-11 Collet: Supports tooling up to 1/4″ in diameter, offering versatility for various milling tasks.

- Build Volume: Provides a working area of 7″ x 9″ x 3.3″, accommodating a range of project sizes.

- Fully Enclosed Design: Features a powder-coated steel frame with safety interlocks and an emergency stop button for enhanced safety.

- User-Friendly Software: Comes with Bantam Tools Milling Machine Software, compatible with Mac OS X 10.9 or higher and Windows 7 or higher.

Performance & Capabilities

- Material Compatibility: Optimized for aluminum; also capable of milling brass, copper, engineering plastics, machining wax, and FR-1.

- Material Removal Rate (MRR): Achieves up to 0.4 cubic inches per minute in aluminum 6061, facilitating rapid prototyping.

- Repeatability: Maintains a repeatability of +/- 0.001″, ensuring consistent precision across projects.

- Dry Milling: Designed for dry milling operations, eliminating the need for lubrication or coolants.

Specifications

- Overall Dimensions: 19.8″ × 20.9″ × 19.4″ (503 mm x 531 mm x 493 mm)

- Max Traverse Speed: 250 inches per minute (6350 mm/min)

- Spindle Motor Power: 250 W

- Power Requirements: 100–240 V AC, 50/60 Hz, 350 W

- Machine Weight: Approximately 80 lbs (36 kg)

Pricing & Cost Efficiency

- Base Price: $6,999.00 USD

- Included Accessories:

- Power cable

- USB cable

- Collet wrench

- Allen key (4 mm)

- Collet nut

- ER-11 collet (1/4″)

- Flat end mill (1/4″)

- Probing pin (1/4″)

- Right-angle alignment bracket (L-bracket)

- Toe clamps (2)

- Aluminum stock for the Tool Holder project

The Bantam Tools Desktop CNC Milling Machine offers a cost-effective solution for those seeking high-quality machining capabilities without the expense and space requirements of larger machines.

Pros & Cons

✅ Pros

- Compact design suitable for limited spaces.

- High spindle speed allows for precise and efficient milling.

- User-friendly software simplifies the machining process.

- Compatible with various materials, enhancing versatility.

❌ Cons

- Limited build volume may not accommodate larger projects.

- Optimized for aluminum; extended machining of harder materials like steel is not recommended.

6. OMTech AF2028-60 60W CO2 Laser Engraver Cutting Machine

Laser engraving can feel intimidating, especially if you’re new to the process. Too many machines require complicated setup, endless adjustments, and trial-and-error learning.

The OMTech AF2028-60 simplifies things.

With autofocus, a large 20” x 28” work area, and intuitive software compatibility, it removes the hassle and lets you focus on creating.

Applications

- Small Businesses: Ideal for custom engraving services on wood, acrylic, and glass.

- Educational Institutions: Suitable for teaching laser cutting and engraving techniques.

- Hobbyists and Makers: Perfect for personal projects requiring precision and creativity.

Key Features

- Autofocus Function: Automatically adjusts the laser head for optimal focus, enhancing precision and ease of use.

- Spacious Work Area: Offers a 20″ x 28″ (500 x 700 mm) workbed, accommodating various project sizes.

- High-Speed Operation: Engraving speeds up to 23.6 inches per second (600 mm/s) for efficient project completion.

- Compatible Software: Supports popular design software like LightBurn, CorelDRAW, and AutoCAD, providing flexibility in design workflows.

Performance & Capabilities

The OMTech AF2028-60 excels in delivering precise engravings and clean cuts on non-metal materials. Its 60W laser tube allows for engraving depths up to 0.4 inches (10 mm), making it suitable for various applications. The autofocus feature simplifies setup, ensuring consistent results without manual adjustments. Additionally, the machine’s high-speed capabilities enable efficient processing of intricate designs.

Specifications

- Laser Power: 60W

- Workbed Size: 20″ x 28″ (500 x 700 mm)

- Engraving Speed: Up to 23.6 inches per second (600 mm/s)

- Compatible Materials: Wood, acrylic, glass, leather, and other non-metal materials

- Software Compatibility: LightBurn, CorelDRAW, AutoCAD

Pricing & Cost Efficiency

The OMTech AF2028-60 is competitively priced at approximately $2,899.99, offering a balance between affordability and functionality. Its robust feature set and performance capabilities provide excellent value for small businesses, educational institutions, and hobbyists seeking a reliable laser engraving solution.

Pros & Cons

Pros:

- Autofocus simplifies operation, reducing setup time.

- Large work area accommodates diverse project sizes.

- High-speed engraving enhances productivity.

- Compatibility with various design software offers flexibility.

Cons:

- Limited to non-metal materials, restricting its use for metal engraving or cutting.

- Requires adequate ventilation due to fume generation during operation.

7. Avid CNC PRO60120

Scaling up production often means choosing between affordability and performance. Many businesses outgrow their entry-level CNC machines but aren’t ready to invest in a fully custom industrial setup.

The Avid CNC PRO60120 is built for that middle ground.

It provides a large work area, durable construction, and precise motion control, making it an ideal choice for workshops that need to handle larger materials without sacrificing accuracy.

Applications

- Custom Fabrication: Perfect for cutting large pieces of wood, metal, and plastics.

- Prototyping & Manufacturing: Reliable for creating custom parts and testing designs.

- Education & Training: A valuable tool for universities and trade schools teaching CNC machining.

This machine is designed for precision and efficiency, making it a solid choice for businesses, schools, and advanced makers.

Key Features

- Large Work Area: Handles materials up to 5′ x 10′, ideal for full sheets of plywood or aluminum.

- Modular Frame: Can be expanded or modified as your needs grow.

- Heavy-Duty Construction: Built with steel and aluminum components for stability and accuracy.

- High-Speed Operation: Capable of cut speeds up to 600 inches per minute (IPM) for efficient production.

- Precision Components: Uses linear guide rails and ballscrew Z-axis for smooth, repeatable movement.

Performance & Capabilities

- Repeatability of ±0.002 inches ensures consistent results.

- Rapid movements up to 1,200 IPM improve workflow efficiency.

- Customizable setup with options for different spindles, control systems, and accessories.

- Versatile material compatibility, works with wood, plastics, composites, and non-ferrous metals.

Specifications

- Work Area:

- X-axis: 61-3/8 inches

- Y-axis: 124-1/4 inches

- Z-axis: 8-12 inches (adjustable gantry height)

- Footprint:

- Width: 78-3/4 inches (or 88-3/4 inches with an extended gantry)

- Length: 141 inches

- Height: 43-3/8 inches (or 77-1/2 inches with leg kit)

- Machine Weight: Approx. 708 lbs

Pricing & Cost Efficiency

- Base price starts at $8,085.

- With additional upgrades (spindle, control system, etc.), costs can reach $17,380.

- Modular upgrades help extend machine lifespan, making it a long-term investment.

While the upfront cost is higher than some smaller CNC routers, the scalability, durability, and performance justify the price for businesses that need high-precision large-format cutting.

Pros & Cons

Pros

- Large work area for big projects.

- Modular design allows for future expansion.

- High cutting speeds improve productivity.

- Sturdy construction reduces vibration and increases accuracy.

Cons

- Requires a large workspace, making it unsuitable for tight areas.

- Higher initial cost than smaller CNC routers.

- Assembly takes time and technical knowledge.

Conclusion

Not every machine is built for the same job. Some are designed for heavy-duty production, while others are better for hobbyists and small businesses. The key is knowing which one aligns with your needs.

Now that you’ve seen the comparisons, what stood out to you?

The right CNC machine will help you work faster, reduce waste, and increase profits. So don’t wait. Take action today.

Have questions? Reach out to us now. We’ll help you make the right call.