I’ve seen too many people waste money on the wrong CNC machine. Either they buy a cheap one that breaks down or overspend on features they don’t need.

The right CNC machine is an investment—it should pay for itself.

That’s why I wrote this guide. I’ve spent years working with CNC equipment, testing machines, and learning what actually works. The goal is simple: find machines that balance cost, power, and ease of use.

In this article, you’ll find a handpicked list of 7 CNC milling machines that deliver real value. Whether you’re working with wood, metal, or plastic, there’s an option here for you.

By the end, you’ll have the knowledge to choose wisely—so your CNC machine works for you, not against you.

So let’s get down to it!

Quick Comparison Chart

Choosing the best CNC milling machine for your small business depends on your needs, budget, and workspace. Each of these 7 machines offers something different—whether it’s power, affordability, or precision. Here’s how they compare:

| Machine Name | Cutting Area (mm) | Spindle Speed (RPM) | Motor Power | Material Compatibility | Standout Point |

| SYIL X7 | 400 x 300 | Up to 12,000 | 3.2 kW | Wood, plastic, aluminum, soft steels | Compact size and supports basic workshop tasks |

| Haas Mini Mill | 406 x 305 x 254 | Up to 6,000 | 5.6 kW (7.5 hp) | Aluminum, plastics, light steel | Known brand with simple controls and solid construction |

| Blue Elephant ELECNC-1212 | 1200 x 1200 | Up to 24,000 | 3.2 kW | Wood, plastics, foam, soft aluminum | Large working area, smooth cutting, easy setup, and dedicated business support from Blue Elephant |

| Bantam Tools Desktop Mill | 228 x 178 x 89 | Up to 26,000 | 0.25 hp | Aluminum, brass, plastics, wood | Preloaded software for quick learning and small-scale jobs |

| Pocket NC V2-50 | 116 x 127 x 87 | Up to 50,000 | 0.25 hp | Aluminum, composites, plastics | Offers 5-axis control for small, detailed prototypes |

| TAIG 2019 CNC Micro Mill | 305 x 140 x 152 | Up to 10,000 | 0.25 hp | Aluminum, brass, plastics, wood | Durable build for everyday light milling |

| SainSmart 3018 PROVer | 300 x 180 x 45 | Up to 10,000 | Low (not specified) | Wood, acrylic, soft metals | Entry-level option for learning and small engraving tasks |

1. SYIL X7 CNC Mill

A small business owner told me, “Every machine we buy has to earn its keep.” That’s the reality for many shops. You need something reliable, affordable, and space-efficient.

That’s where the SYIL X7 stands out. It’s compact but powerful, offering the precision you need without taking over your workspace—or your budget.

Key Features

- Cutting Area: 400 x 300 mm, Big enough for small-to-medium projects.

- Motor Power: 3.2 kW, Strong enough for clean, precise cuts.

- Spindle Speed: Up to 12,000 RPM, Handles detailed work with ease.

- Supported Materials: Wood, plastic, aluminum, and some softer steels.

- Software Compatibility: Runs on Mach3, LinuxCNC, and Fusion 360—no need to switch your current setup.

Pros & Cons

✅ Pros

- Simple controls, no steep learning curve.

- A strong machine without a high price tag.

- Get up and running quickly.

❌ Cons

- Not the best for hardened steel.

- Better suited for smaller runs.

Best For

- Craft enthusiasts creating custom pieces.

- Furniture makers producing one-of-a-kind designs.

- Hobbyists who want a reliable machine without complications.

Why Choose This?

You don’t have time to wrestle with complicated setups, and the SYIL X7 gets that. It’s built to be user-friendly, with beginner-friendly software preloaded so you can get to work fast. If you’re looking for a CNC mill that balances cost, performance, and space efficiency, the SYIL X7 is a solid option worth considering.

2. Haas Mini Mill

“I need something reliable, compact, and powerful—but I can’t afford to waste money on the wrong machine,” a business owner told me while searching for a CNC mill. He wasn’t alone. Many small shops and repair businesses face the same issue.

That’s where the Haas Mini Mill comes in. It delivers precision, fits into tight spaces, and works within a reasonable budget—making it a smart choice for growing operations.

Key Features

- Cutting Area: 16″ x 12″ x 10″ (406 x 305 x 254 mm) handles most small-to-medium projects.

- Spindle Speed: Up to 6,000 RPM smooth cuts without excessive heat buildup.

- Motor Power: 7.5 hp (5.6 kW) vector drive strong enough for aluminum, plastics, and light steel work.

- Tool Capacity: 10-station automatic tool changer faster job completion with minimal manual input.

Pros & Cons

✅ Pros

- Haas controls are simple to learn.

- Built to last with solid construction.

- Haas offers great customer service and resources.

❌ Cons

- Not ideal for large projects.

- Some jobs may require faster cutting speeds.

- Upgrades can raise the price quickly.

Best For

- Machine dealers need a reliable, well-known brand to resell.

- Spare parts dealers producing small, custom components.

- Machine repairers who need precision cutting for modifications.

- Rental companies offering mills for short-term use.

- Craft enthusiasts working in furniture, mold making, and advertising.

Why Choose This?

The Haas Mini Mill is compact, affordable, and reliable—ideal for businesses that need precision without complexity. It offers solid performance in a space-saving design and fits within tighter budgets. If you’re looking for a CNC mill that delivers consistent results without taking up too much room, this machine is worth considering.

3. Blue Elephant ELECNC-1212 Desktop CNC Milling Machine

Running a small shop doesn’t mean you have to settle for basic tools. If you’re working with wood, foam, acrylic, or even soft aluminum, you probably need something that cuts clean, works fast, and doesn’t take up your whole garage.

That’s where the Blue Elephant ELECNC-1212 fits in.

I’ve seen this model used in small furniture workshops and sign-making studios. It’s simple to set up and easier to maintain than bigger machines. If you’re just starting out or looking to expand your side hustle, this one is worth a serious look.

Key Features

- Working Area: 1200 x 1200 mm of working space.

- Spindle Power: 3.2 kW

- Top Speed: Up to 24,000 RPM

- Software Compatibility: You won’t have to learn new software. It works with Mach3, LinuxCNC, ArtCAM, Fusion 360, and more.

Supported Materials

- Wood (MDF, plywood, hardwood)

- Acrylic and plastics

- Foam

- Soft aluminum

Pros and Cons

✅ Pros

- Easy to operate—even for first-timers

- Affordable compared to larger models

- Fits well in compact spaces

- Trusted customer support from Blue Elephant

❌ Cons

- Might not suit factories needing high-volume output

Best For

- Woodworkers building custom furniture

- Sign makers needing sharp detail

- Small shops doing in-house prototypes

- Hobbyists stepping up from DIY routers

Why Choose this?

The Blue Elephant ELECNC-1212 is a smart choice for small businesses. It offers strong cutting power, a spacious work area, and works with popular software. You don’t need a large space or big budget to get started. It’s great for signs, furniture parts, or custom work—and helpful support makes it even easier to get going.

4. Bantam Tools Desktop CNC Milling Machine

You might think that desktop CNC mills are just for hobbyists. But that’s not always the case. If you need a precise, compact, and easy-to-use machine for prototyping, small production runs, or training purposes, the Bantam Tools Desktop CNC Milling Machine is worth considering.

I’ve seen small manufacturers, repair technicians, and even machine dealers use this mill for quick, high-accuracy jobs. It’s not built for heavy production, but if you need a desktop-sized machine that delivers real results, this one checks a lot of boxes.

Key Features

- Cutting Area: 9″ x 7″ x 3.5″ – Best for small precision parts.

- Spindle Speed: Up to 26,000 RPM – Handles fine details with smooth finishes.

- Motor Power: ¼ hp – Enough for aluminum, brass, and plastics.

- Material Compatibility: Works with soft metals, wood, composites, and plastics.

- Software: Preloaded with Bantam Tools’ intuitive software—no complex setup required.

Pros & Cons

✅Pros

- Fits in tight workspaces.

- Minimal learning curve with user-friendly software.

- Ideal for small, precision-focused tasks.

❌ Cons

- Works best for small, shallow parts.

- Optimized for aluminum, brass, and plastics.

- lower material removal than larger machines.

Best For

- Machine dealers looking for a small CNC option to offer clients.

- Spare parts manufacturers creating precision components in small batches.

- Machine repairers needing a portable mill for quick modifications.

- Rental companies that lease CNC mills for training and prototyping.

- Craft, furniture, and advertising businesses working on custom designs and engraving.

Why Choose This?

The Bantam Tools Desktop CNC Mill is compact, affordable, and built for small, high-precision work. If your business needs prototyping or engraving without the size or cost of a full system, it’s a smart option. It fits on a workbench, runs quietly, and delivers reliable results—making it a practical choice for professionals working in tight spaces.

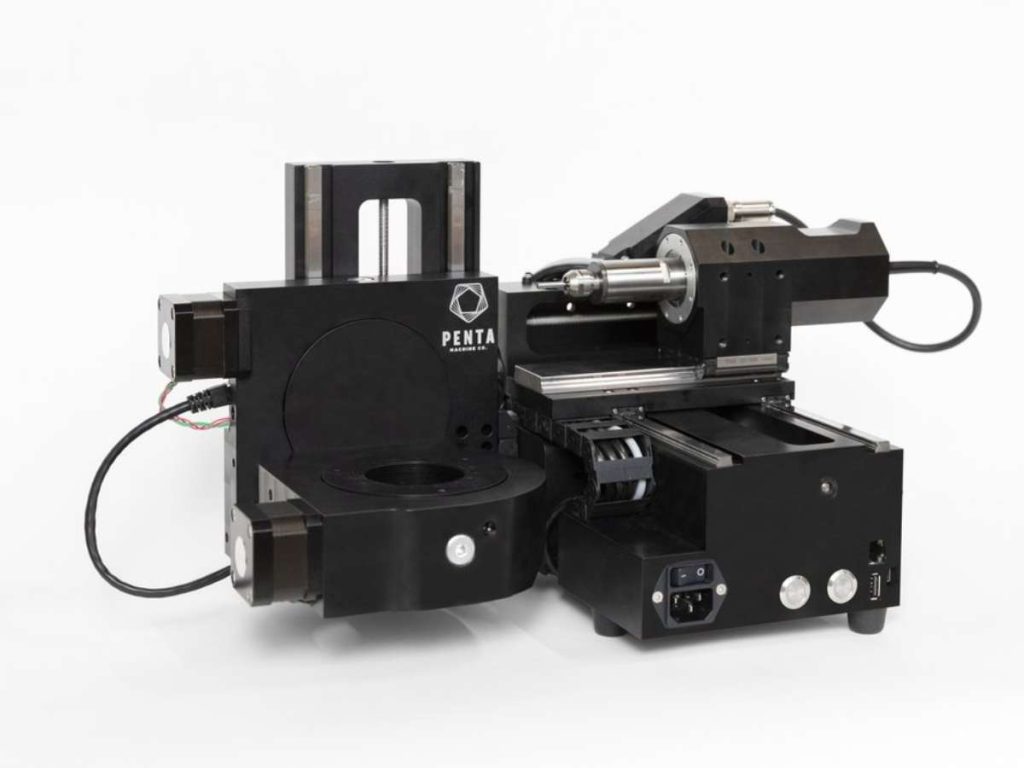

5. Pocket NC V2-50 Desktop 5-Axis Machine

You know the limitations of a 3-axis CNC mill. Some designs demand more—complex angles, undercuts, and curved surfaces. But upgrading to a 5-axis machine usually means huge costs, more space, and a steep learning curve.

That’s where the Pocket NC V2-50 comes in. It brings multi-axis machining into small shops, repair businesses, and prototyping labs without massive investment. You get precision, flexibility, and compact size—all in one machine.

Key Features

- Cutting Area: 4.55″ x 5.00″ x 3.45″ – Ideal for small precision parts.

- Spindle Speed: Up to 50,000 RPM – High-speed cutting with clean finishes.

- Motor Power: ¼ hp – Designed for aluminum, composites, and plastics.

- 5-Axis Capability: Enables multi-angle machining in a single setup.

- Software Compatibility: Works with Fusion 360, G-code-based software, and standard CAM programs.

Pros & Cons

✅ Pros

- Cuts complex angles in fewer setups.

- Smooth cutting for intricate designs.

- Fits in small workshops.

❌Cons

- Best for small parts and prototypes.

- Optimized for aluminum and composites.

- 5-axis machining requires practice.

Best For

- Machine dealers looking for an affordable 5-axis CNC to recommend.

- Spare parts manufacturers producing custom, high-precision components.

- Machine repairers needing advanced cutting for complex modifications.

- Rental companies offering CNC mills for training and prototyping.

- Craft, furniture, and advertising businesses creating high-detail engravings and 3D designs.

Why Choose This?

If you need better precision, more cutting flexibility, and fewer setups—without the cost and footprint of a full-size machine—this is a strong choice. If you’re ready to expand your machining capabilities, the Pocket NC V2-50 helps you take on more complex projects without breaking your budget.

6. TAIG 2019 CNC Micro Mill

A spare parts manufacturer once told me he was tired of outsourcing small jobs but couldn’t justify a large, costly machine. He said, “I needed something reliable that wouldn’t drain my budget or take over my shop.”

That’s when he found the TAIG 2019 CNC Micro Mill. Compact, accurate, and affordable, it gave him full control over production in just a few weeks.

Key Features

- Cutting Area: 12″ x 5.5″ x 6″ , Large enough for small to medium-sized projects.

- Spindle Speed: Up to 10,000 RPM, Allows for smooth, detailed cutting.

- Motor Power: 1/4 hp, Handles aluminum, brass, plastics, and wood with precision.

- Construction: Heavy-duty aluminum and steel frame for durability.

- Software Compatibility: Runs on Mach3, LinuxCNC, and standard CAM software.

Pros & Cons

✅ Pros

- One of the best-priced CNC mills for small businesses.

- Steel and aluminum built for long-term use.

- Larger than most micro mills.

❌Cons

- Best for small to medium-sized parts.

- Slower on harder metals like stainless steel.

- Some fine-tuning needed for optimal results.

Best For

- Machine dealers looking for a budget-friendly CNC option for small businesses.

- Spare parts manufacturers producing custom, high-precision components.

- Machine repairers needing a compact CNC for quick modifications.

- Rental companies offering CNC mills for training or prototyping.

- Craft, furniture, and advertising businesses creating small, detailed designs.

Why Choose This?

The TAIG 2019 CNC Micro Mill is compact, precise, and budget-friendly—ideal for small businesses starting with CNC machining. It delivers quality results without the high cost or large footprint. If you want reliable milling on a tight budget, this machine offers great value and performance, making it a smart investment for shops with limited space or funds.

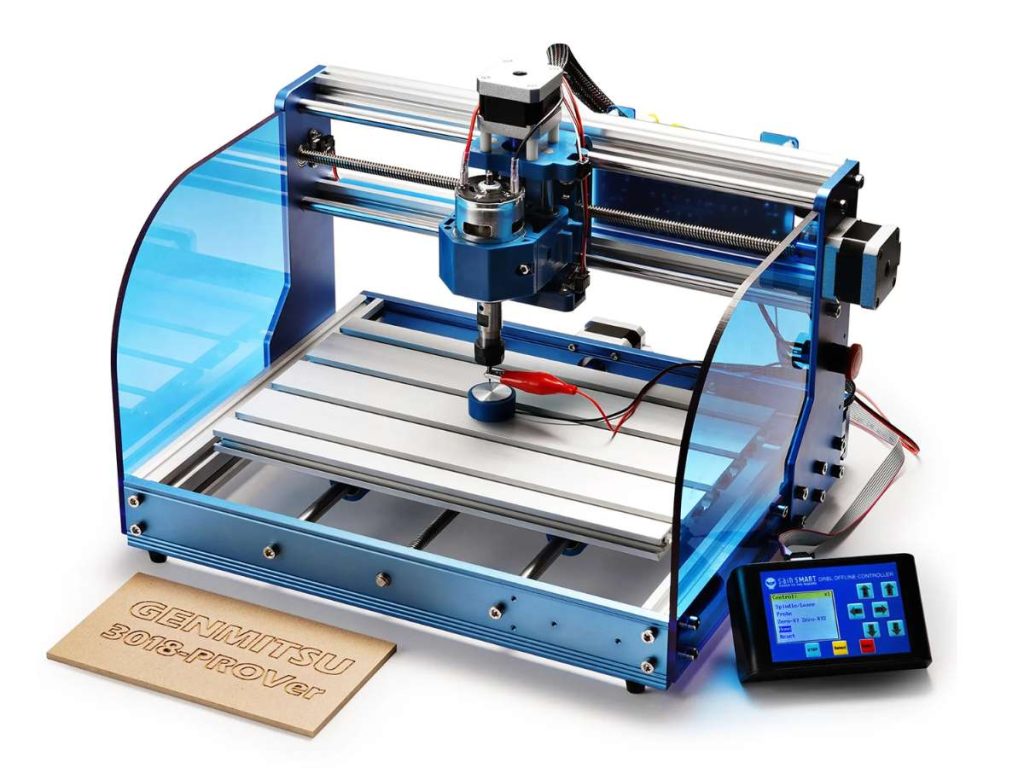

7. SainSmart Genmitsu 3018 PROVer

You need a CNC mill that’s affordable, reliable, and easy to operate. Maybe you’re looking for a starter machine to test CNC machining before committing to a larger investment. Or perhaps you need a compact engraving solution for custom parts.

That’s why many small businesses turn to the SainSmart Genmitsu 3018 PROVer—a starter-friendly CNC mill that delivers real results without the cost and complexity of larger machines.

Key Features

- Cutting Area: 11.8″ x 7.1″ x 1.8″ , Ideal for small engravings and detailed cuts.

- Spindle Speed: Up to 10,000 RPM, Smooth cutting for wood, plastics, and soft metals.

- Frame: Aluminum body with rigid construction for stability.

- Software Compatibility: Works with GRBL-based programs like Candle and Easel.

- Offline Controller: Run jobs directly from a USB stick—no need for a dedicated computer.

Pros & Cons

✅ Pros

- A practical first investment.

- Easy to learn and operate.

- Doesn’t require a dedicated workshop.

❌Cons

- Best for engraving and light-duty milling.

- Works best with wood, acrylic, and aluminum.

- Slower speeds on tougher materials.

Best For

- Machine dealers looking for a budget-friendly CNC mill to offer customers.

- Spare parts manufacturers testing prototypes and engraving custom parts.

- Machine repairers creating small, detailed modifications.

- Rental companies offering CNC mills for training and small-scale production.

- Furniture makers, crafters, and advertising businesses producing engraved designs and decorative elements.

Why Choose This?

The SainSmart Genmitsu 3018 PROVer is a compact, affordable CNC mill ideal for small parts, precision work, and engraving. It’s a smart, low-risk way to get started with CNC milling. Built for more than just hobby use, it fits well in small shops and offers solid results without taking up space or draining your budget.

Conclusion

In 7 CNC milling machines, we explored tools that balance cost, performance, and efficiency. The right choice depends on your workflow, materials, and growth plans.

So what’s your next step? Will you keep outsourcing, or will you bring production in-house? Every successful business reaches a point where they have to decide—stay where you are or scale up.

The next move is yours.

What could you achieve with the right setup? How much time and money could you save?

Contact us today so that we can help your business.