When I started my small business, I thought any CNC router would do the job. I quickly learned that not all machines are built the same. Some break down fast, while others run for years with minimal maintenance.

Your CNC router is an investment. The right one will save you money, increase productivity, and keep your customers happy.

That’s why I created this guide. After years of working with CNC machines, testing different models, and learning from other business owners, I’ve figured out what separates the best from the rest.

In this guide, you’ll see the seven best CNC routers for small businesses. I’ll break down their features, explain their strengths and weaknesses, and help you find the right fit for your needs.

By the end, you’ll know which CNC router fits your shop, your budget, and your goals.

So let’s jump in!

Comparison Table

Not all CNC routers are built the same—some prioritize precision, others focus on speed and automation. This quick comparison table breaks down specifications, materials, and performance to help you find the best fit for your business needs:

| CNC Router | Cutting Area | Frame | Spindle | Drive System | Software Compatibility | Supported Materials | Key Capabilities |

| Carbide 3D Shapeoko 4 | ~33″ x 33″ x 4″ | Heavy-duty aluminum extrusion | Supports Carbide Compact Router | Belt-driven X/Y, ball screw Z | Carbide Create & Carbide Motion | Wood, plastics, soft metals | Precision cutting, batch production, upgradable |

| VEVOR CNC 3018-PRO | 11.8” x 7.1” x 1.8” | Aluminum & Bakelite | 775 spindle motor (10,000 RPM) | Lead screw drive | GRBL (Candle, Easel, Universal Gcode Sender) | Wood, acrylic, PCB, plastic, leather | Fine engraving, small batch production, customizable |

| Blue Elephant ELECNC2646ATC-4A | 102″ x 181″ x 20″ | Heavy-duty steel structure | 9.0kW ATC spindle (24,000 RPM) | Servo motors | Syntec industrial CNC control | Wood, MDF, plastics, aluminum, stone | Automated tool changing, high-speed cutting, 3D carving |

| SainSmart Genmitsu 3020-PRO MAX | 11.8” x 7.9” x 2.8” | All-aluminum construction | 300W high-speed spindle (12,000 RPM) | Lead screw-driven | GRBL (Candle, Easel, Fusion 360) | Wood, acrylic, aluminum, PCB, carbon fiber | High-precision engraving, soft metal machining, low noise |

| BobsCNC Quantum | 24” x 24” x 3.3” | Laser-cut Baltic birch plywood | Supports DeWalt 611 router | Belt-driven X/Y, lead screw Z | Universal Gcode Sender, Easel | Wood, MDF, acrylic, plastics, soft metals | Large work area, lightweight yet stable, great for woodworking |

| ShopSabre IS-M Series | 48” x 96” and larger | Fully welded, stress-relieved steel | 10HP to 15HP HSD spindle (24,000 RPM) | Ball screw with servo motors | Advanced CNC motion control software | Wood, aluminum, plastic, composites | Heavy-duty cutting, 24/7 operation, extreme accuracy |

| Inventables X-Carve Pro | 4′ x 4′ or 4′ x 2′ | Heavy-duty aluminum extrusion | 1.5kW (2HP) spindle (24,000 RPM) | Precision ball screw | Easel Pro, Fusion 360 | Wood, plastics, MDF, soft metals | Fast and efficient, easy-to-use software, small-batch production |

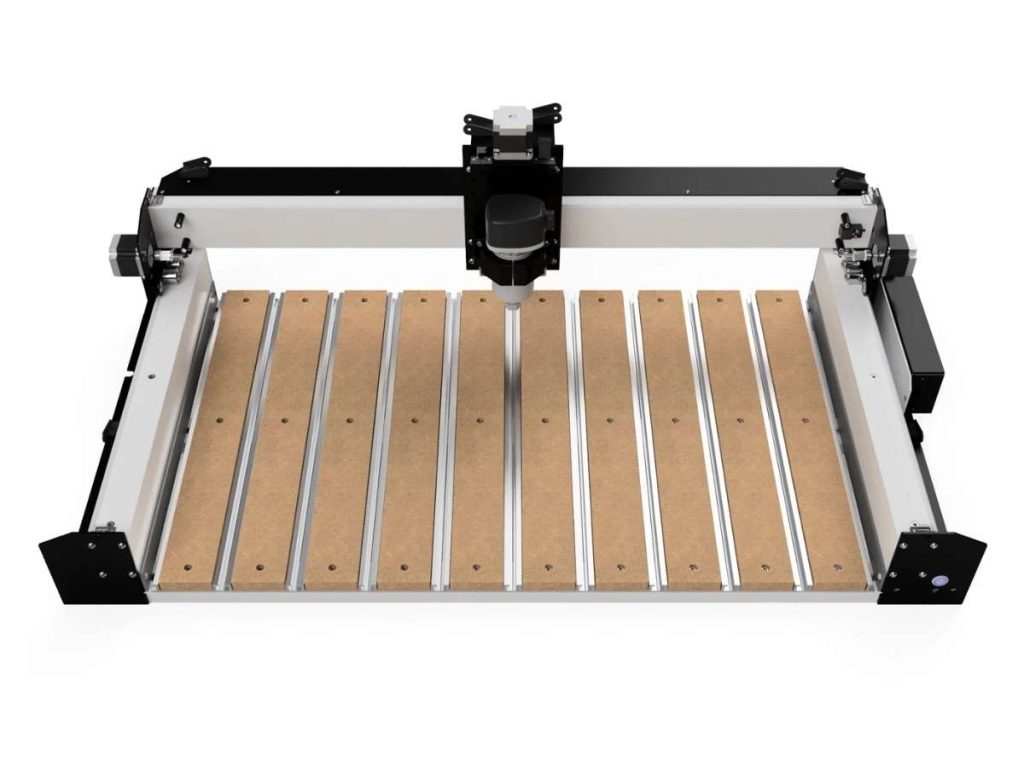

1. Carbide 3D Shapeoko 4

When I first worked with Carbide 3D Shapeoko 4, I knew it was different. It had the strength, accuracy, and reliability that small business owners needed. Whether you’re cutting wood, plastic, or aluminum, this machine delivers.

With a sturdy frame, upgraded motion system, and an easy-to-use interface, this CNC router offers a solid balance of performance and affordability. It’s a step up from hobbyist machines, making it a smart choice for small businesses ready to scale.

Specifications

Before choosing a CNC router, you need to know the hard facts. Here’s what the Shapeoko 4 brings to the table:

- Cutting Area: ~33″ x 33″ x 4″ (varies by model size)

- Spindle Compatibility: Works with routers like the Carbide Compact Router or a standard trim router

- Frame: Heavy-duty aluminum extrusion with a hybrid table for better stability

- Drive System: Belt-driven for X and Y axes, ball screw-driven Z-axis for more accuracy

- Software: Comes with Carbide Create (CAD/CAM) and Carbide Motion (controller software)

- Supported Materials: Wood, plastics, composites, soft metals (aluminum, brass)

- Upgrades Available: Can be fitted with a Z-plus leadscrew system and dust collection accessories

Capabilities

The Shapeoko 4 isn’t just another desktop CNC router—it’s built for real work.

- Precision Cutting: Achieve tight tolerances on wood, acrylic, and even soft metals like aluminum.

- Batch Production: With its large cutting area, you can process multiple parts in a single run.

- Versatile Material Support: From MDF to carbon fiber, this router handles a wide range of materials.

- Expandable & Upgradable: Need more power? You can add a spindle upgrade, an enclosure, or a dust collection system for cleaner cuts.

- User-Friendly: With Carbide Create, even first-time users can design and cut without needing expensive software.

The result? More productivity, less frustration.

Maintenance Tips

A well-maintained CNC router is a profitable CNC router. If you want to get the most out of your Shapeoko 4, follow these simple maintenance steps:

- Check Belt Tension Weekly: Loose belts can cause imprecise cuts. Keep them tight but not overstretched.

- Clean the Rails & Bearings: Dust buildup affects accuracy. Wipe down the rails and bearings after every use.

- Secure the Workpiece Properly: Always check your clamps or tape to avoid material shifting mid-cut.

- Lubricate the Z-Axis Lead Screw: This prevents wear and ensures smooth vertical movement.

- Keep Software & Firmware Updated: Carbide 3D releases updates to improve performance—don’t skip them.

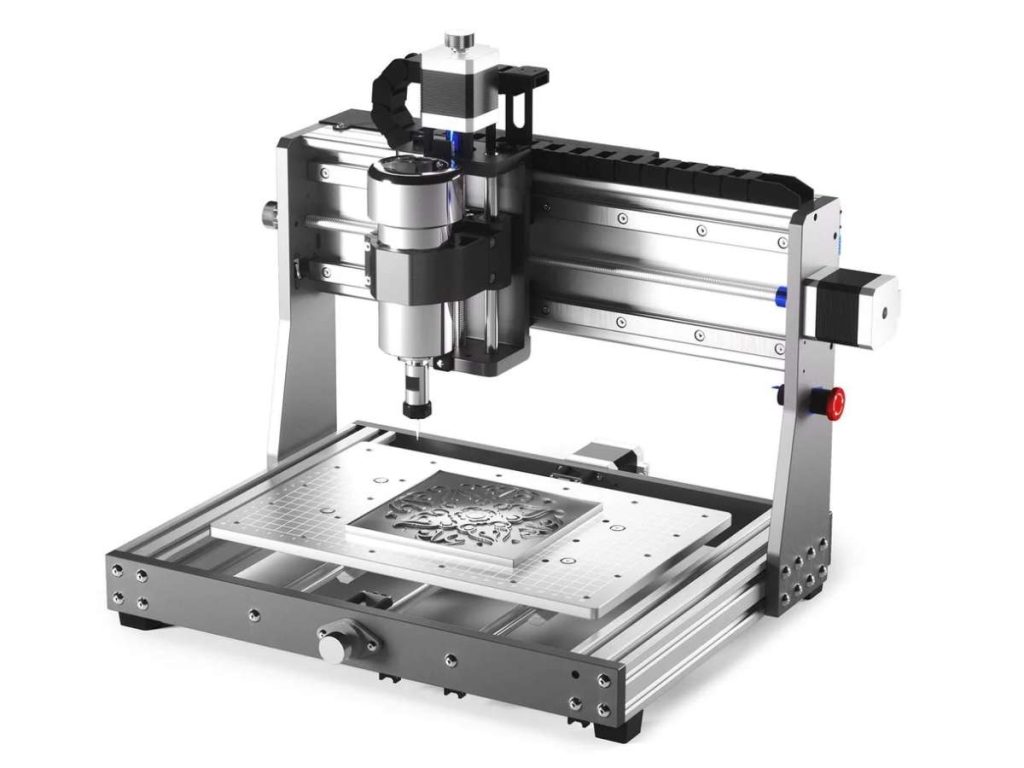

2. VEVOR CNC 3018-PRO

Ever felt like a CNC router was too much machine for your small projects? Like you were paying for power you didn’t actually need?

That’s exactly how I felt—until I found the VEVOR CNC 3018-PRO. It’s a compact, affordable CNC router designed for small businesses that need precision without the bulk. It won’t replace an industrial machine, but it’s perfect for light-duty cutting, engraving, and prototyping.

This machine is perfect for prototyping and low-volume production. If you work with wood, acrylic, or soft metals, it can handle intricate designs with ease. And because of its size, it fits in workshops with limited space—no need for a massive setup.

Specifications

The VEVOR CNC 3018-PRO might be small, but it packs a punch. Here’s what you’re working with:

- Cutting Area: 11.8” x 7.1” x 1.8” (300mm x 180mm x 45mm)

- Frame: Aluminum & Bakelite for stability and durability

- Spindle: 775 spindle motor (10,000 RPM)

- Software Compatibility: Supports GRBL control and works with software like Candle, Easel, and Universal Gcode Sender

- Supported Materials: Wood, acrylic, PCB, soft aluminum, plastic, and leather

- Laser Module Compatibility: Can be upgraded with a laser engraver module

Capabilities

Unlike larger CNC routers, the VEVOR CNC 3018-PRO shines in detail work and customization rather than bulk production. Here’s what it does best:

- Fine Engraving: Create intricate designs on wood, plastic, and soft metals with high precision.

- Small Batch Production: Ideal for engraving logos, jewelry, and electronic components.

- Rapid Prototyping: Test your designs without investing in a large, expensive machine.

- Laser Engraving (With Upgrade): Convert it into a laser engraver for extra versatility.

- Customizable & Hackable: Many business owners modify this router for better precision and expanded capabilities.

If your business focuses on customization and precision, this CNC router gives you the flexibility you need.

Maintenance Tips

The VEVOR CNC 3018-PRO is a low-maintenance machine, but regular care prevents errors and extends its lifespan. Here’s how to keep it in peak condition:

- Tighten Screws & Fasteners Regularly: Due to vibrations, bolts can loosen over time. Check them before each use.

- Keep the Spindle Motor Clean: Dust buildup can cause overheating. Use compressed air to clear debris.

- Check Belt Tension Monthly: A loose belt affects cutting precision. Adjust it as needed for consistent results.

- Use a Vacuum or Dust Extraction System: Fine dust from wood and plastic can clog moving parts. Keep your work area clean.

- Lubricate the Lead Screws: Apply a small amount of machine oil to keep the movement smooth and prevent wear.

3. Blue Elephant ELECNC2646ATC-4A

When production demands increase, you need a CNC router that can keep up. Slow tool changes, limited cutting areas, and weak motors can bottleneck your workflow, costing you time and money.

I was impressed when I came across the Blue Elephant ELECNC2646ATC-4A. This industrial-grade CNC router is built for high-speed, precision cutting with an automatic tool changer (ATC) that makes switching bits effortless. If you need power, speed, and reliability, this machine delivers.

Specifications

Here’s what makes the ELECNC2646ATC-4A stand out:

- Cutting Area: 2600mm x 4600mm x 500mm (102″ x 181″ x 20″)

- Spindle: 9.0kW air-cooled ATC spindle (up to 24,000 RPM)

- Tool Changer: 8-12 position automatic tool changer

- Frame: Heavy-duty steel structure for vibration-free operation

- Drive System: Yaskawa servo motors for high-speed precision

- Controller: Syntec industrial CNC control system

- Supported Materials: Wood, MDF, plastics, aluminum, acrylic, composites, stone

This machine is built for high-volume work—if you’re scaling up, it’s an investment that pays off.

Capabilities

Unlike compact CNC routers, the ELECNC2646ATC-4A is made for high-speed, high-precision, and large-scale production. Here’s what it can do:

- Automated Tool Changes: The ATC system lets you switch between cutting, engraving, and drilling without stopping production.

- Large-Scale Cutting: The oversized worktable supports full sheets of plywood, aluminum panels, and thick materials.

- Heavy-Duty Performance: Designed for continuous operation, it runs smoothly for long hours without overheating.

- Multi-Axis Precision: The 4-axis system allows for 3D carving, contour cutting, and advanced milling.

- Fast Production Speeds: Servo motors ensure rapid movement without sacrificing accuracy.

If you need a CNC router that can handle bulk orders and complex designs without slowing down, this one is built for the job.

Maintenance Tips

This is a high-performance machine, and keeping it in top shape is key to maximizing its lifespan and efficiency. Here’s how:

- Calibrate the Tool Changer Weekly: Ensure the ATC system picks up and drops tools correctly to avoid alignment issues.

- Check Spindle Bearings Regularly: The high-speed spindle works hard; inspect for wear and replace bearings as needed.

- Keep the Rails & Ball Screws Clean: Dust and debris can slow down movement—use compressed air and a dry cloth for cleaning.

- Lubricate the Servo Motors & Bearings: Smooth motion prevents breakdowns; apply the recommended lubrication every month.

- Monitor the Vacuum System: If using a vacuum table, ensure it maintains suction to keep materials stable during cutting.

At the end of the day, machines like these are only as reliable as the care we give them. I treat mine like part of the team—because when it’s dialed in and well-maintained, it gives me consistent results and fewer surprises.

4. SainSmart Genmitsu 3020-PRO MAX

Not every business needs an industrial-sized CNC router. Sometimes, what matters most is precision, ease of use, and a machine that fits your workspace.

I’ve worked with large CNC routers, but I’ve also seen the power of compact machines that deliver high-quality results. The SainSmart Genmitsu 3020-PRO MAX is one of those machines. It’s built for accuracy, small-batch production, and intricate detailing, making it perfect for businesses that need a reliable desktop CNC router.

Specifications

Here’s what the 3020-PRO MAX brings to the table:

- Cutting Area: 300mm x 200mm x 70mm (11.8” x 7.9” x 2.8”)

- Frame: All-aluminum construction for durability and vibration reduction

- Spindle: 300W high-speed spindle (up to 12,000 RPM)

- Drive System: Lead screw-driven for increased accuracy

- Controller: GRBL-based control system

- Supported Materials: Wood, acrylic, aluminum, PCB, plastics, carbon fiber

- Software Compatibility: Works with Candle, Easel, Fusion 360, and other G-code-based software

This machine is designed for precision and reliability, making it a strong option for small businesses looking for consistent performance.

Capabilities

The 3020-PRO MAX is not about size—it’s about detail and precision. Unlike large industrial routers, this machine is built for intricate work and fine engravings.

- High-Precision Engraving: Perfect for logos, circuit boards, and fine details on wood, metal, and acrylic.

- Custom Prototyping: Ideal for small-batch production and testing designs before full-scale manufacturing.

- Soft Metal Machining: Cuts aluminum and brass with better accuracy than belt-driven CNCs.

- Low Noise, High Stability: The lead screw drive system reduces vibration, improving cutting accuracy.

- Easy Upgrades: Supports laser engraving and other accessories for expanded functionality.

If your business requires fine, accurate cuts rather than heavy-duty production, this machine delivers.

Maintenance Tips

Unlike industrial CNCs, the 3020-PRO MAX is low-maintenance, but regular care ensures precision and longevity.

- Check Lead Screws for Debris: Dust and small metal shavings can affect movement. Clean them after each session.

- Reinforce Workpiece Clamping: A small machine means tight material holding is critical. Secure materials properly to prevent misalignment.

- Monitor Spindle Wear: High-speed spindles wear over time. Listen for changes in sound—this may indicate the need for a replacement.

- Keep Electronics Dust-Free: A small router means more exposure to dust in tight spaces. Use a soft brush to clear control boards and cooling fans.

- Align the Gantry Periodically: Even on a sturdy frame, repeated use can shift alignment slightly. Check for squareness every few weeks.

A little maintenance goes a long way, keeping your SainSmart Genmitsu 3020-PRO MAX running smoothly and accurately.

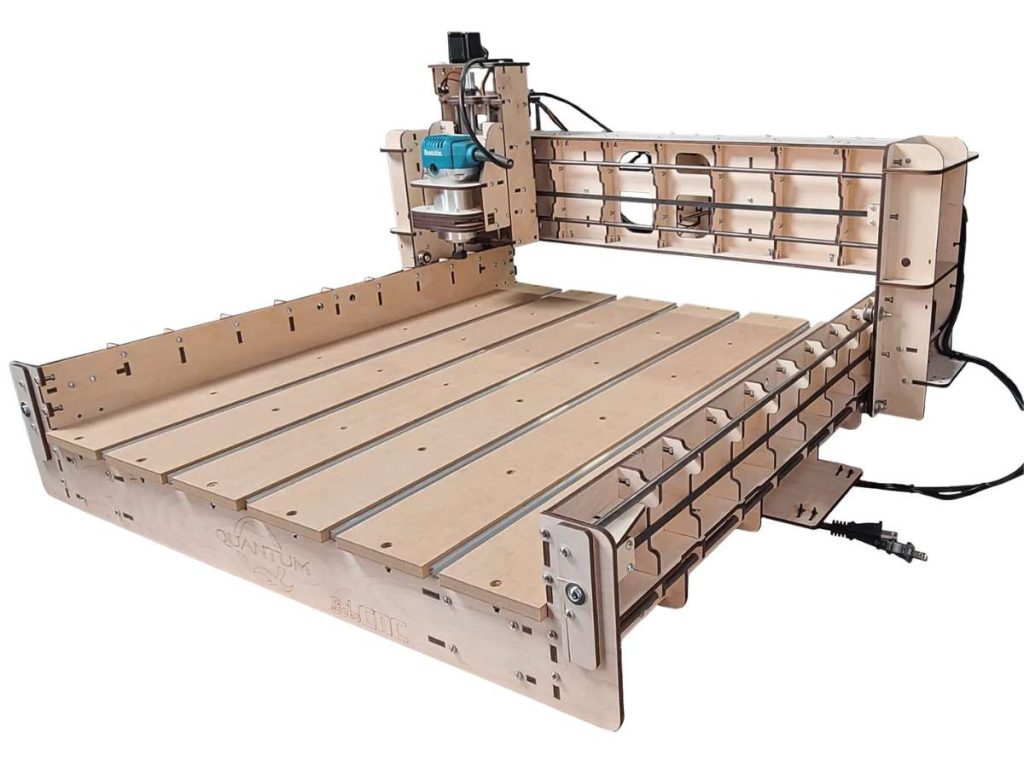

5. BobsCNC Quantum

Some CNC routers look high-tech, made from heavy steel and aluminum. The BobsCNC Quantum is different. At first glance, its wooden frame might make you question its durability. I had the same doubts—until I saw it in action.

This CNC router is lightweight, affordable, and powerful for its price. It’s designed for businesses that need large cutting areas without the weight and cost of metal-frame machines. If you want a versatile CNC that’s easy to customize, this could be a great fit.

Specifications

The Quantum is known for its large work area and lightweight design. Here’s what you get:

- Cutting Area: 24” x 24” x 3.3” (610mm x 610mm x 85mm)

- Frame: Laser-cut Baltic birch plywood for flexibility and vibration absorption

- Spindle: Supports DeWalt 611 router (not included)

- Drive System: Belt-driven X and Y axes, lead screw-driven Z-axis

- Controller: GRBL-based control system with Arduino support

- Supported Materials: Wood, MDF, acrylic, plastics, and soft metals like aluminum

- Software Compatibility: Works with Universal Gcode Sender, Easel, and other CNC software

This machine is ideal for businesses that prioritize affordability and a large work area over industrial-level power.

Capabilities

The BobsCNC Quantum is all about size, affordability, and customization. It’s not the most powerful machine, but it excels in areas where other routers fall short.

- Large Work Area for the Price: One of the biggest cutting areas in this price range, making it perfect for sign makers and furniture businesses.

- Lightweight, Yet Stable: The wooden frame absorbs vibration, reducing chatter and improving cut quality.

- Great for Woodworking: Ideal for carving, engraving, and detailed cuts on wood and MDF.

- Easy to Upgrade: Since it uses a standard DeWalt 611 router, you can easily swap out parts or upgrade the spindle.

- Good Learning Machine: Its GRBL-based control system makes it beginner-friendly while allowing for advanced customizations.

If you want a CNC router with a big workspace at a low cost, the Quantum delivers.

Maintenance Tips

Since the BobsCNC Quantum has a wooden frame, it requires different maintenance than metal-frame CNC routers. Here’s how to keep it in top shape:

- Check for Frame Expansion & Contraction: Wood can shift slightly with temperature and humidity changes. Re-tighten screws monthly to maintain accuracy.

- Lubricate the Lead Screws: Apply light machine oil to the Z-axis lead screw to ensure smooth vertical movement.

- Clean Dust & Debris Regularly: Fine sawdust can collect in the belts and lead screws. Use a small vacuum or soft brush to remove buildup.

- Inspect the Belt Tension: The X and Y axes use belts, which can stretch over time. Tighten them as needed for precise cuts.

- Secure the Router Mounting: Since the spindle is user-installed, check its mounting screws to prevent vibration during cutting.

6. ShopSabre IS-M Series

Not all CNC routers are built the same. Some are made for hobbyists, others for small businesses. But when you need industrial-grade performance, you need a machine that can handle heavy workloads, long production hours, and extreme precision.

The ShopSabre IS-M Series is a powerful, high-end CNC router designed for businesses that demand speed, accuracy, and durability. I’ve seen machines struggle with high-volume production, but this one was built to keep running, day after day, without compromise.

Specifications

The ShopSabre IS-M Series is packed with industrial-grade components to ensure flawless operation. Here’s what you get:

- Cutting Area: Customizable sizes, starting from 48” x 96” and larger

- Frame: Fully welded, stress-relieved steel frame for zero flex

- Spindle: 10HP to 15HP HSD spindle (up to 24,000 RPM)

- Drive System: Industrial ball screw and servo motor system for ultra-precise cuts

- Control System: High-end CNC control with advanced motion control software

- Supported Materials: Wood, aluminum, plastic, acrylic, composites, and more

- Vacuum Hold-Down System: Keeps materials stable during high-speed cutting

This CNC router is built for industrial production, not occasional use.

Capabilities

The ShopSabre IS-M Series is in a league of its own. It’s designed to handle massive workloads with pinpoint accuracy.

- Heavy-Duty Cutting: Easily cuts through hardwood, aluminum, acrylic, and even dense composites.

- High-Speed Production: The servo-driven system allows for faster cycle times without losing precision.

- Extreme Accuracy: Ball screw technology ensures tight tolerances, even on intricate designs.

- 24/7 Operation: Built for non-stop production with minimal maintenance.

- Integrated Vacuum Table: Holds materials in place, reducing vibration and improving cut quality.

If you need a CNC router that can handle large-scale projects with absolute precision, the IS-M Series is a machine you can rely on.

Maintenance Tips

With a machine this powerful, proper maintenance is crucial. A well-maintained ShopSabre IS-M Series can run flawlessly for years.

- Inspect Ball Screws & Rails Weekly: Clean off dust and lubricate to prevent wear.

- Check Vacuum System Performance: Ensure proper suction for maximum material hold-down stability.

- Monitor Spindle Bearings: High-speed spindles endure stress; check for unusual noise or overheating.

- Keep the Dust Collection System Clean: Prevent buildup that can affect machine performance.

- Update Control Software Regularly: ShopSabre provides firmware updates to improve efficiency and accuracy.

7. Inventables X-Carve Pro

Every small business reaches a turning point. You start with a machine that gets the job done, but as demand grows, so do your needs. You need faster production, better accuracy, and a CNC router that keeps up.

That’s where the Inventables X-Carve Pro comes in. I remember working with entry-level CNC routers that took forever to complete projects. The X-Carve Pro changes that. It’s fast, precise, and easy to use, making it a great choice for businesses scaling up their production.

Let’s dive into what makes this machine stand out.

Specifications

The X-Carve Pro is designed for businesses that want industrial-like performance without the high price tag.

- Cutting Area: 4′ x 4′ or 4′ x 2′ models available

- Frame: Heavy-duty aluminum extrusion for stability

- Spindle: 1.5kW (2HP) spindle, variable speed up to 24,000 RPM

- Drive System: Precision ball screw for smooth, accurate cuts

- Controller: Integrated with Inventables’ Easel Pro software

- Supported Materials: Wood, plastics, MDF, composites, soft metals

- Software Compatibility: Works with Easel Pro, Fusion 360, and other G-code-based software

This machine is designed to reduce setup time while providing consistent, high-quality results.

Capabilities

The X-Carve Pro is about speed and precision. It’s built for businesses that need consistent results with minimal learning curves.

- Fast and Efficient: Cuts twice as fast as standard entry-level CNC routers.

- User-Friendly Software: Comes with Easel Pro, making it one of the easiest CNC routers to operate.

- Perfect for Small-Batch Production: Ideal for custom furniture, signage, and engraving businesses.

- Smart Dust Collection System: Keeps work areas clean while improving cut accuracy.

- Plug-and-Play Setup: No complicated installation—ready to use out of the box.

If you want a professional CNC router without the industrial complexity, the X-Carve Pro is a strong choice.

Maintenance Tips

- Check Belt Tension Weekly: Unlike some routers, the X-Carve Pro uses belts that need occasional tightening for precision cuts.

- Clean Dust from Ball Screws & Rails: Sawdust buildup can reduce accuracy—wipe rails clean after each session.

- Update Software Regularly: Easel Pro updates improve functionality—install them as soon as they’re available.

- Secure Workpieces Properly: A loose board or shifting material can cause mistakes. Use clamps or a vacuum hold-down system.

- Inspect the Spindle Cooling System: A well-cooled spindle runs more efficiently. Check for airflow obstructions monthly.

Conclusion

We’ve explored seven of the best options for small businesses, from compact engravers to industrial powerhouses. Each one offers something unique, whether it’s precision, speed, or scalability.

I remember struggling with my first CNC purchase. If I had known then what I know now, I would’ve made a smarter choice. Now, you can.

Looking for a trusted CNC router supplier? Consider Blue Elephant. We help small businesses win with reliable, affordable machines.

Take the next step and contact us today!