Is your CNC software helping your business—or slowing it down? The right software can streamline production, reduce errors, and cut downtime. The wrong one? It leads to missed deadlines, costly mistakes, and frustrated operators.

With years of experience as a CNC machinist and software consultant, I’ve seen what works well—and what doesn’t. The best tools support your workflow, not slow it down.

In this guide, you’ll find the 10 best CNC software options based on performance, ease of use, and business value. Whether you need a solution for operating, programming, simulating, or optimizing CNC machines, you’ll walk away with a clear choice.

So let’s start!

Quick Comparison Chart

Choosing the right CNC software depends on your business needs, machine type, and budget. Some software is best for high-precision industrial machining, while others are perfect for woodworking, engraving, or DIY CNC setups.

This chart breaks down the top 10 CNC software options, including their type, best use case, key features, and pricing model. Whether you’re a machine dealer, repair technician, or manufacturer, this chart will help you find the right fit.

| Software | Type | Best For | Key Features | Pricing Model |

| Fusion 360 | CAD/CAM | Professionals & Small Businesses | 3D Modeling, Advanced Toolpath Strategies, Cloud-Based Collaboration | Subscription |

| Mach3 & Mach4 | CNC Control | Hobbyists & Small Shops | Custom Macros, Works with Many Controllers, Mach4 Offers Better Speed | One-Time Purchase |

| SolidWorks CAM | CAD/CAM | Engineers & Manufacturers | Integrated with SolidWorks, Advanced Simulation, Automates Toolpath Creation | Subscription |

| VCarve Pro | CAD/CAM | Woodworkers & Sign Makers | 2D & 3D Carving Tools, Drag-and-Drop Design, Works with Many CNC Machines | One-Time Purchase |

| GRBL & UGS | CNC Control | DIY CNC Machines | Lightweight, Runs on Arduino, Simple G-Code Handling | Free |

| Mastercam | CAD/CAM | Large-Scale Manufacturing | Supports 2D/3D & Multi-Axis, High-End Toolpath Optimization, Custom Post-Processing | Subscription |

| EstlCAM | CAM & CNC Control | Hobbyists & Small Businesses | Simple Toolpath Creation, Works with Arduino Controllers, One-Time Purchase | One-Time Purchase |

| AutoCAD | CAD | Architectural & Mechanical Design | Industry-Standard 2D Drafting, Precise Measurement, CAM Compatibility | Subscription |

| Aspire by Vectric | CAD/CAM | 3D Carving & Engraving | 3D Modeling, Powerful Toolpath Control, Supports Various File Imports | One-Time Purchase |

| LinuxCNC | CNC Control | Advanced Users with Linux-Based Systems | Runs on Linux, Supports 3 to 9-Axis, Free & Open-Source | Free |

1. Fusion 360

I remember the first time I tried Fusion 360. I was overwhelmed. Too many buttons. Too many tools. But once I got the hang of it, everything changed.

Fusion 360 is CAD/CAM software designed for both professionals and small businesses. Whether you’re making furniture, molds, or custom machine parts, it has the tools you need. It’s packed with features but still easy to learn.

Key Features

- 3D Modeling and Simulation: Design complex parts, test assemblies, and catch mistakes before machining.

- Advanced Toolpath Strategies: Generate precise and efficient cutting paths for different materials and machine types.

- Cloud-Based Collaboration: Access your projects from anywhere and share designs with team members in real time.

Pros and Cons

Pros

- All-in-one CAD and CAM solution

- Cloud-based access for easy collaboration

- Affordable compared to other professional-grade software

- Free version available for non-commercial use

- Strong community support and learning resources

Cons

- Requires an internet connection for cloud features

- Subscription-based pricing for businesses

- Can have a learning curve for advanced features

Why Choose Fusion 360?

Fusion 360 is an ideal solution for CNC businesses looking for a cost-effective, feature-rich CAD/CAM platform. It allows machine shops, manufacturers, and repair services to improve design accuracy, reduce machining time, and optimize workflows. If you need reliable, scalable software for CNC operations, Fusion 360 is worth considering.

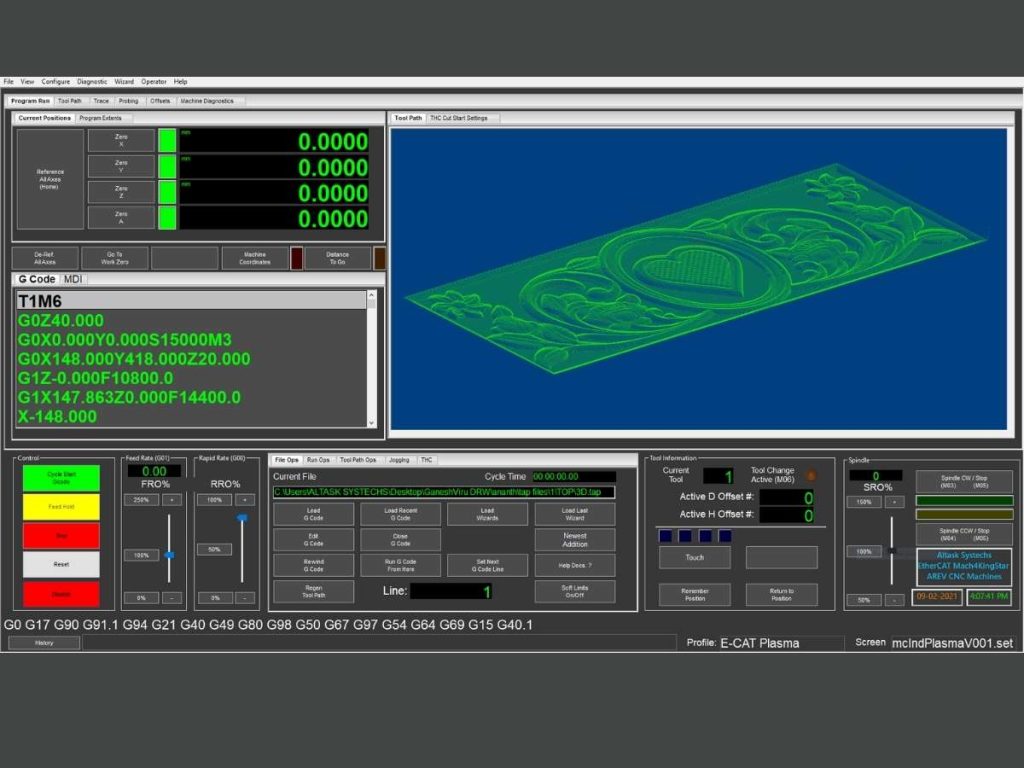

2. Mach3 & Mach4

You can almost hear the buzz of the spindle and feel the tension as you try to make the software behave. Every shop owner has faced it—solid machine, frustrating control system. That’s where Mach3 and Mach4 step in.

Mach3 brought flexibility to the floor with simple setup and smooth performance. Mach4 sharpened that experience—faster, more stable, and ready for serious customization.

Key Features

- Custom Macros and Scripts: Automate repetitive processes to improve efficiency.

- Broad CNC Compatibility: Works with parallel port controllers and external motion devices.

- Mach4 Offers Smoother Motion Control: Faster processing and better machine response.

Pros and Cons

Pros

- User-friendly interface, making it easy to train operators

- Compatible with a wide range of CNC machines

- Allows for deep customization through scripting

- Strong online community for troubleshooting and setup support

Cons

- Mach3 is outdated and lacks support for modern systems

- Mach4 requires a paid license, with different versions unlocking specific features

- Some businesses find initial setup tricky without prior experience

Why Choose Mach3 & Mach4?

For small manufacturers, machine repair services, and independent CNC operators, Mach3 is a budget-friendly workhorse, while Mach4 provides better performance for shops that need reliability and faster processing. If your shop needs cost-effective, customizable CNC control software, Mach3 and Mach4 are worth considering.

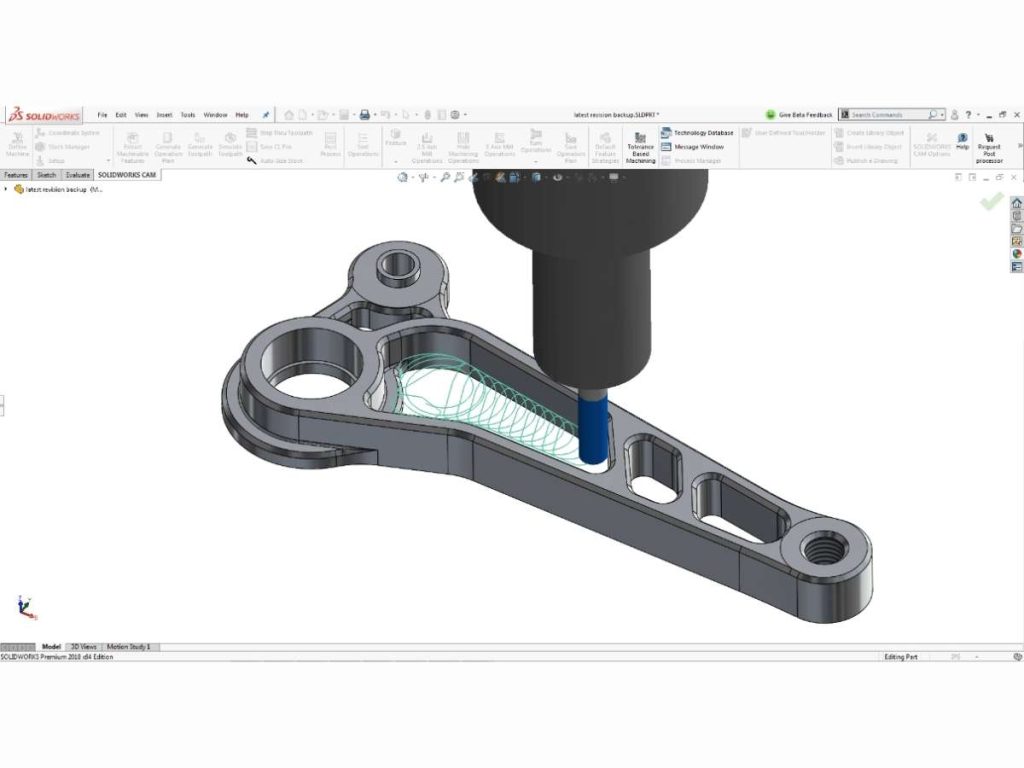

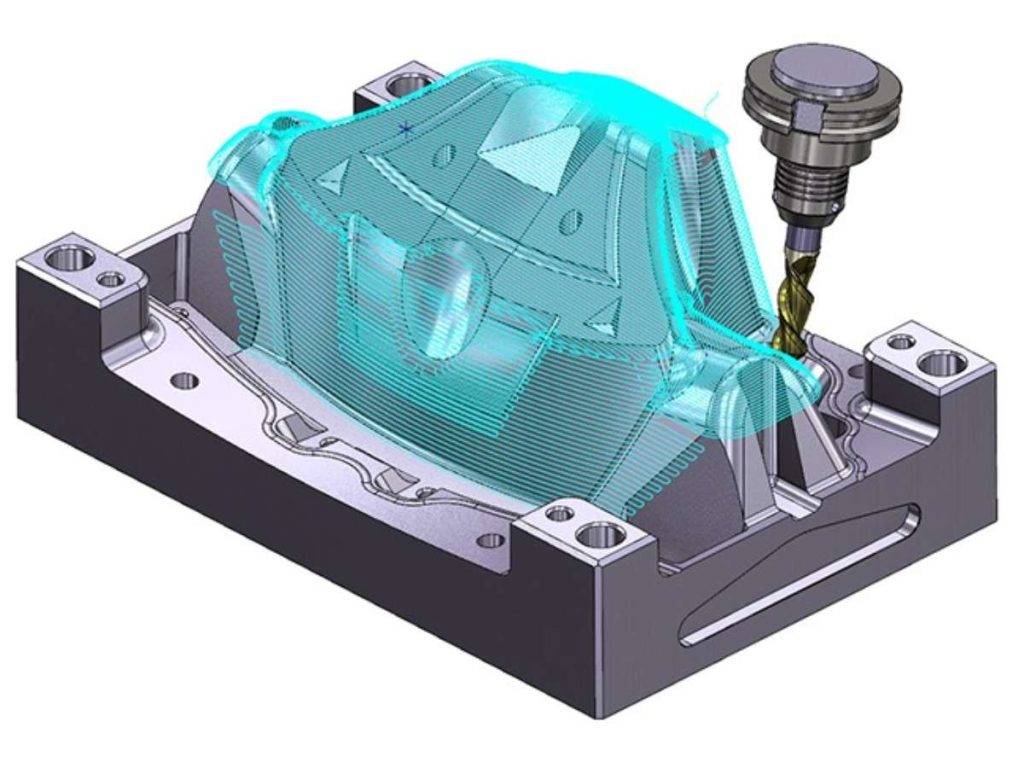

3. SolidWorks CAM

If you already use SolidWorks, then SolidWorks CAM might be the easiest way to integrate CAD and CAM into your business workflow. Instead of jumping between different programs, you can design and program toolpaths in one place.

SolidWorks CAM is built for precision and automation. It helps reduce manual programming by automating toolpath creation, which saves time and minimizes human error. It also comes with advanced simulation tools, allowing you to test a job before making a single cut.

Key Features

- Integrated CAM with SolidWorks: No need to export files; design and machine with the same software.

- Advanced Simulation Tools: Identify errors before machining to avoid wasted materials.

- Automated Toolpath Creation: Generates optimized cutting paths based on the part’s design.

Pros and Cons

Pros

- Works seamlessly within SolidWorks, eliminating extra steps

- Automates many machining tasks, saving time

- Ideal for complex machining and multi-axis work

- Improves workflow efficiency for professional manufacturers

Cons

- Only works with SolidWorks—no standalone version

- Requires a paid license, making it more expensive than other CAM options

- Learning curve for those unfamiliar with SolidWorks

Why Choose SolidWorks?

If your shop already uses SolidWorks, this CAM integration is a no-brainer. It keeps everything in one system, speeds up programming, and helps manufacturers create accurate, efficient toolpaths. For businesses that demand precision and automation, SolidWorks CAM is a strong choice.

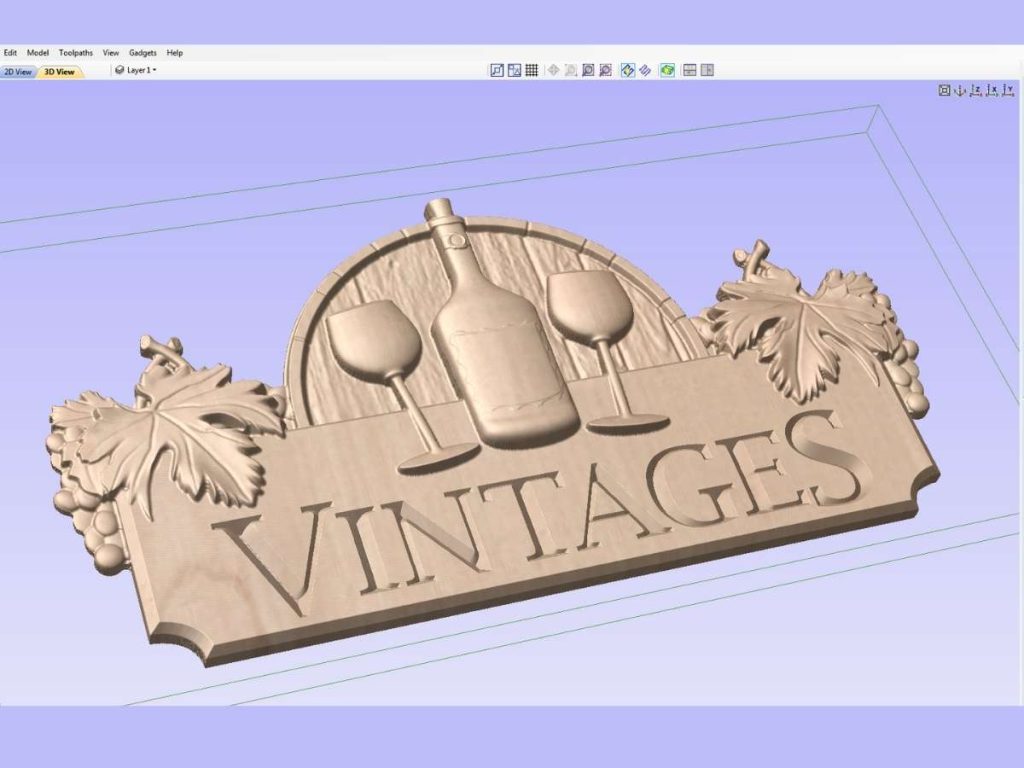

4. VCarve Pro

Need CNC software that’s easy to use but still powerful enough for professional work? If you’re in woodworking, sign making, or custom engraving, VCarve Pro is built for you. It’s a favorite among small businesses and independent CNC operators because it balances simplicity and capability.

Unlike industrial-level software, VCarve Pro doesn’t overwhelm you with complicated features. The interface is straightforward, with drag-and-drop tools that make designing quick and easy. Whether you’re carving intricate 3D designs or cutting simple shapes, it has the tools to get the job done.

Key Features

- 2D and 3D Carving Tools: Create anything from basic engravings to detailed 3D reliefs.

- User-Friendly Interface: No steep learning curve—just intuitive design tools.

- Wide Compatibility: Works with many CNC routers and supports STL, DXF, and other file formats.

Pros and Cons

Pros

- Ideal for woodworkers and sign makers

- Easy to learn, even for beginners

- One-time purchase—no ongoing subscriptions

- Works with a variety of popular CNC routers

- Large online community for tutorials and support

Cons

- Lacks advanced CAD tools for complex engineering projects

- Not as powerful as high-end industrial CAM software

- Limited automation tools compared to other professional options

Why Choose VCarve Pro?

Do you use a CNC router for woodworking or sign making? If so,the VCarve Pro is one of the best tools for the job. It works with many CNC machines, supports various file formats, and lets you buy it once without monthly fees. For small businesses and professionals who need reliable, easy-to-use CNC software, VCarve Pro is a smart investment.

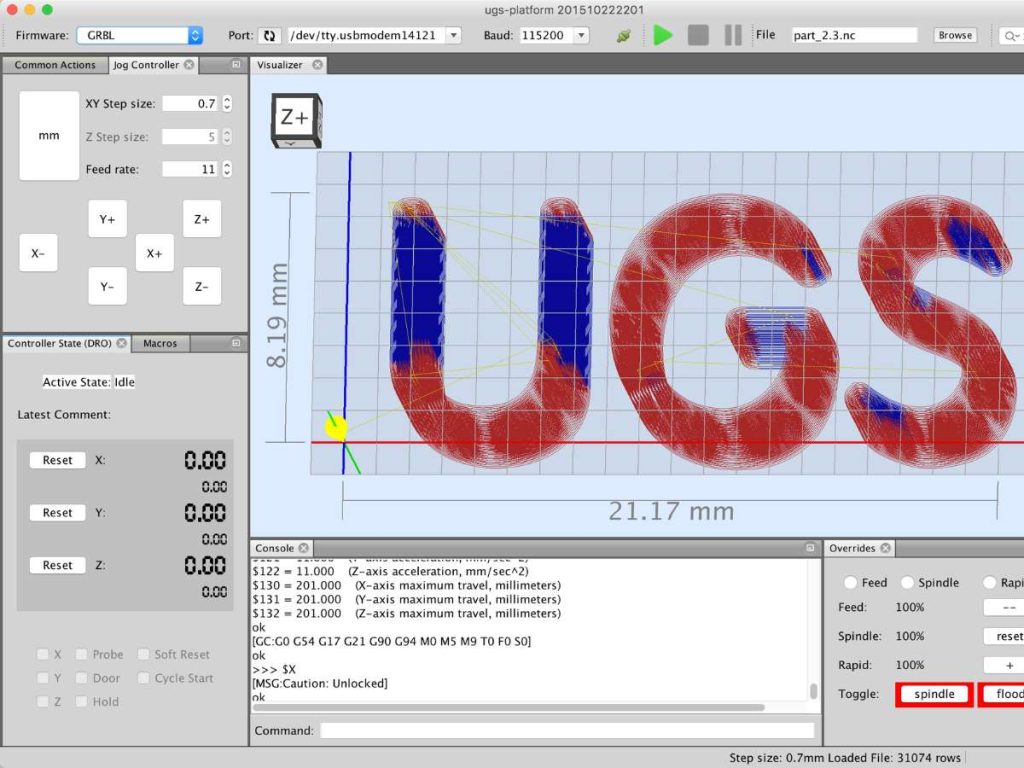

5. GRBL & Universal Gcode Sender

“I just need something that works—no extra costs, no headaches,” a shop owner once told me while setting up his new router. That’s exactly what GRBL and Universal Gcode Sender (UGS) offer. For small machine shops and repair businesses, they provide reliable control without expensive software or bulky systems.

I thought open-source tools would be complicated, but after using GRBL and UGS myself, I realized how smooth and efficient they are. Simple setup, clean interface, and zero stress.

Key Features

- Lightweight and Efficient: Runs smoothly on small Arduino boards.

- Compatible with Many CNC Machines: Works with open-source and custom-built systems.

- Simple G-code Handling: Processes commands quickly without delays.

Pros and Cons

Pros

- Free and open-source—no ongoing costs

- Runs on low-cost Arduino controllers

- Easy to install and operate

- Works well for small-scale production and repairs

- Large online support community

Cons

- Limited to three-axis control—no multi-axis support

- Requires separate CAD/CAM software for design

- Not suited for high-speed or industrial-grade machining

Why Choose GRBL and UGS?

For machine dealers, repair shops, and businesses working with custom CNC builds, GRBL and UGS offer an affordable, practical solution. They cut costs without sacrificing precision, making them a great choice for shops that need reliable CNC control without big investments.

6. Mastercam

The shop was falling behind. Orders were piling up, and their old software just couldn’t keep pace. Complex parts, tight deadlines, and constant tweaks had everyone frustrated. “We needed something built for real production,” the manager said.

That’s when they switched to Mastercam. Setup time dropped. Toolpaths ran clean. Errors dropped to near zero. Mastercam handled everything—from 2D cuts to multi-axis jobs—keeping the spindle moving and the shop on schedule. For them, it wasn’t just software. It was the fix.

Key Features

- Supports 2D, 3D, and Multi-Axis Machining: Handles everything from simple cuts to 5-axis precision work.

- High-End Toolpath Optimization: Reduces cycle times, increases tool life, and improves surface finish.

- Advanced Post-Processing Customization: Generates optimized G-code tailored to specific CNC machines.

Pros and Cons

Pros

- Designed for industrial-grade machining

- Handles complex, multi-axis toolpaths

- Reduces cycle times with high-efficiency toolpath strategies

- Strong customer support and training programs

- Compatible with a wide range of CNC machines

Cons

- Expensive, making it a big investment for smaller shops

- Steep learning curve for new users

- Requires a high-performance computer for smooth operation

Why Choose Mastercam?

For large-scale manufacturing, aerospace, automotive, and high-precision machining, Mastercam is one of the most trusted solutions on the market. It supports complex CNC processes, reduces downtime, and comes with extensive customer support and training.

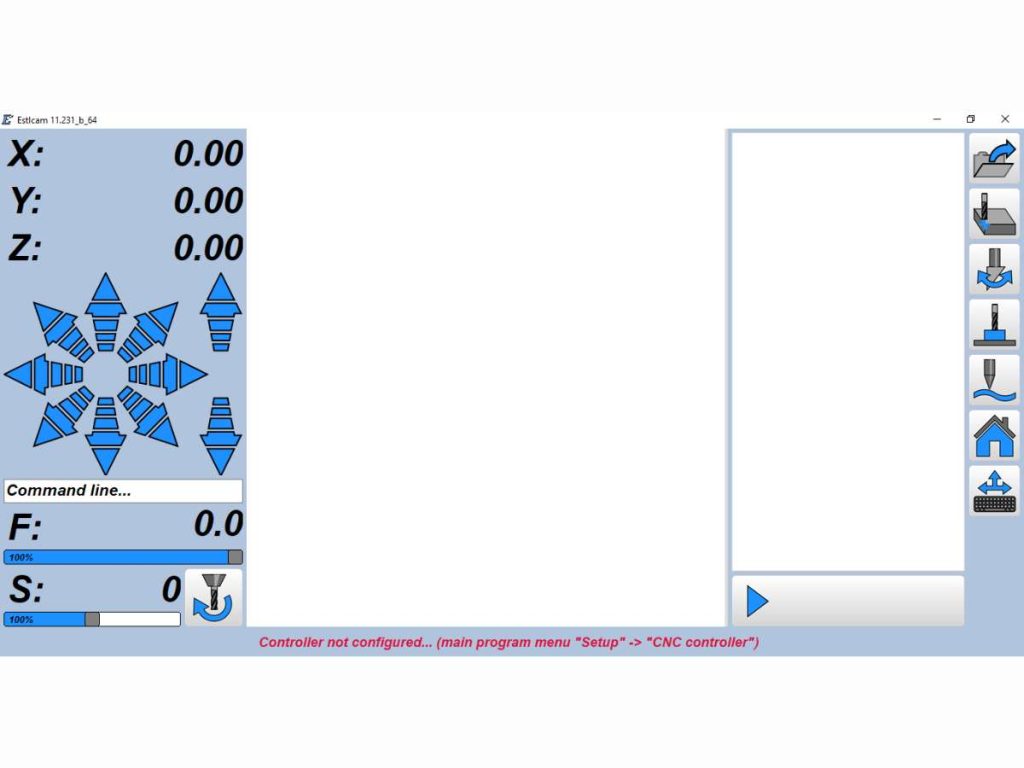

7. EstlCAM

The shop owner looked at the screen and sighed, “I just want something simple that works.” He didn’t need advanced features—just clean cuts and less hassle.

That’s where EstlCAM came in. With its clear interface and smooth setup, he was cutting parts within hours. No complex menus, no confusion—just reliable performance for 2D and 3D jobs. For furniture, signs, or custom builds, EstlCAM turned frustration into steady, confident machining.

Key Features

- Simple 2D and 3D Toolpath Creation: Easily generate cutting paths without hassle.

- Works with Arduino-Based CNC Controllers: Great for custom and budget CNC setups.

- One-Time Purchase: No subscriptions, just a single payment for lifetime use.

Pros and Cons

Pros

- Easy to learn, even for beginners

- Affordable compared to other CAM software

- Generates clean, optimized G-code

- Lightweight—runs on most computers without issues

- Strong online community for support and tutorials

Cons

- Limited advanced machining features for industrial work

- It only supports Windows—no Mac or Linux version

- Best suited for small-scale CNC projects, not heavy-duty machining

Why Choose EstlCAM?

If you need budget-friendly, easy-to-use CAM software, EstlCAM is a solid choice. It’s great for beginners, works with affordable CNC controllers, and doesn’t lock you into a subscription model. For small businesses, repair shops, and DIY CNC builders, it offers a practical, no-frills solution that just works.

8. AutoCAD

If you’re working with CNC machines, you know how important precision is. Whether you’re creating custom parts or mechanical layouts, you need drawings that are accurate down to the last millimeter. That’s where AutoCAD comes in—it’s trusted by engineers and machinists for a reason.

AutoCAD helps you draft clean, exact 2D files that connect easily with CAM software. It reduces mistakes, saves material, and keeps your workflow smooth from design to production. It’s built to support how you work.

Key Features

- Industry-Standard 2D Drafting Tools: Used in manufacturing, machining, and engineering.

- Precise Measurement and Dimensioning: Ensures accuracy in technical drawings.

- Seamless Integration with CAM Software: Exports files easily for CNC programming.

Pros and Cons

Pros

- Trusted across engineering, manufacturing, and construction industries

- Works with most CNC-compatible CAM software

- Highly customizable with scripting and automation tools

- Reduces design errors and improves machining accuracy

- Extensive training and documentation for businesses

Cons

- Higher cost compared to basic CAD programs

- Focused on 2D design, making it less useful for complex 3D modeling

- Requires training for first-time users in CNC workflows

Why Choose AutoCAD?

For businesses that depend on precision and seamless CNC integration, AutoCAD remains one of the most trusted CAD solutions. It’s widely used in large-scale manufacturing, machining, and engineering, ensuring compatibility with CAM software and CNC production workflows. If accuracy, efficiency, and industry-standard compatibility matter to your operation, AutoCAD is a proven investment.

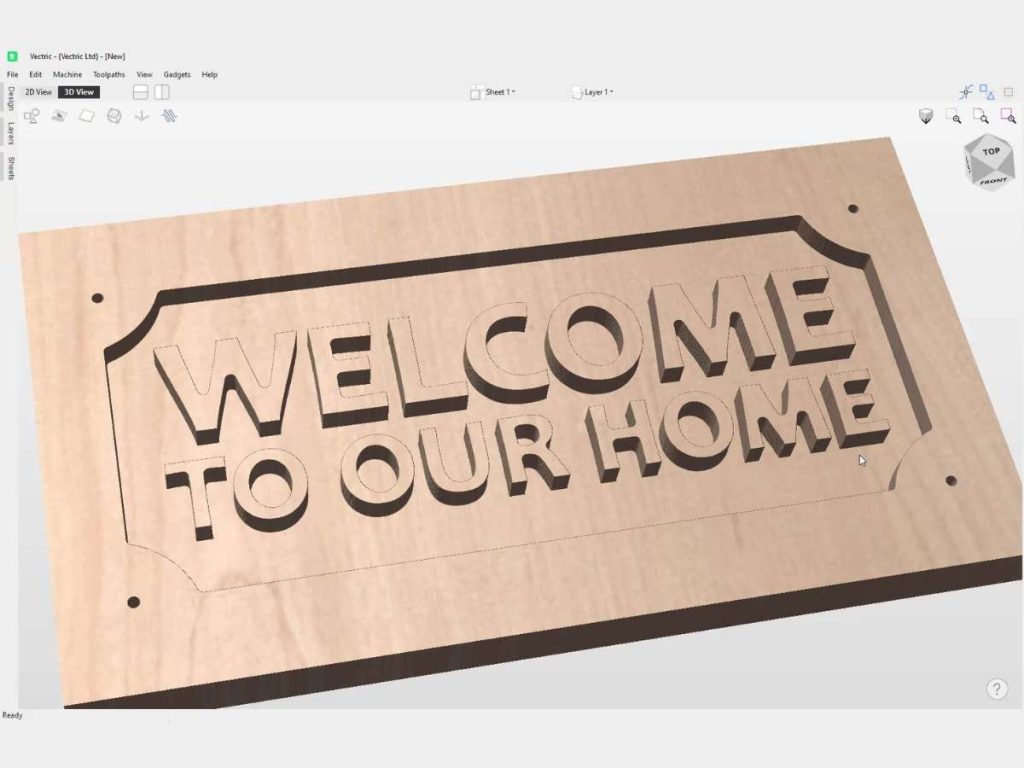

9. Aspire by Vectric

If you use CNC for more than just cutting—if you care about detail, design, and craft—Aspire by Vectric is made for you. Whether you’re carving signs, shaping furniture accents, or adding texture to wood, Aspire helps you turn creative ideas into real, polished pieces.

You don’t need to be a software expert. Aspire’s clean layout, 3D tools, and file support make it easy to create artistic work that looks as good as it feels.

Key Features

- 3D Modeling & Sculpting Tools: Create intricate carvings, engravings, and artistic designs.

- Powerful Toolpath Control: Generate smooth, efficient toolpaths for CNC routing.

- Supports Multiple File Formats: Import STL, DXF, bitmap images, and more.

Pros and Cons

Pros

- Perfect for 3D carving, engraving, and sign making

- User-friendly interface with a short learning curve

- One-time purchase—no ongoing subscription fees

- Compatible with many CNC routers

- Strong community support with tutorials and project-sharing

Cons

- More expensive than some entry-level CNC software

- Focuses on artistic projects, not industrial machining

- Requires powerful hardware for complex 3D modeling

Why Choose Aspire by Vectric?

If your CNC work is more about creativity than mass production, Aspire is a smart choice. It’s perfect for artistic carving, sign making, and decorative engraving. The software is easy to learn, works with various CNC routers, and doesn’t lock you into a subscription.

10. LinuxCNC

One shop owner once told me, “Once you get LinuxCNC dialed in, it just works. No surprises. No expensive updates.” That’s the biggest advantage—you’re in full control. If you like custom-built CNC machines, LinuxCNC lets you modify, script, and fine-tune settings however you need.

LinuxCNC has been around for years. It’s trusted by machinists, engineers, and DIY CNC builders who want precision and flexibility. Since it runs on Linux, it’s more stable than many Windows-based controllers. It doesn’t crash easily, and it handles complex multi-axis machining with ease.

Key Features

- Runs on Linux OS: More stable and crash-resistant than many commercial alternatives.

- Supports 3 to 9-Axis CNC Machines: Works for everything from basic mills to complex machining centers.

- Free and Open-Source: No licensing fees, no subscriptions, and fully customizable.

Pros and Cons

Pros

- Completely free with no hidden costs

- Highly customizable with Python scripting and configuration options

- Works with multi-axis machines

- Stable performance, even for demanding jobs

- Strong community support with active forums and resources

Cons

- Requires Linux OS, which may be a barrier for Windows users

- Has a steeper learning curve than plug-and-play software

- Initial setup can be complex, especially for beginners

Why Choose LinuxCNC?

For businesses and professionals who need stability, flexibility, and full CNC control, LinuxCNC is a great alternative to commercial software. It’s ideal for custom-built CNC machines, supports advanced configurations, and costs nothing to use.

Looking for a CNC Machine That’s Compatible With Your Software?

Any software is useful only if it connects well with your CNC machine. Whether you’re using Fusion 360, VCarve Pro, or Mach3, the right machine makes all the difference. Smooth communication between software and hardware helps you avoid errors, reduce downtime, and get clean, accurate results.

That’s where Blue Elephant comes in. Our machines are compatible with major CNC software and built for real production work.

Here’s what you can expect:

- Works with Fusion 360, VCarve, Mach3/4, and more

- Handles wood, plastic, metal, and composites

- Supports G-code and standard post-processors

- Easy setup for beginners and professionals

- Backed by solid technical support

Contact us today to find a machine that works with the software you already trust.

Conclusion

You’ve explored the best CNC software for machining, engraving, design, and control. Now, the decision is yours. Which one fits your business needs?

A small change in software can lead to fewer errors, faster turnaround times, and a more efficient workflow. Don’t settle for a tool that holds you back.

Take a step today. Try a demo, test a free version, or upgrade to a better solution. The right software can change everything.

Contact us today to get started!