I’ve seen it happen too many times. A company invests in a fiber laser machine, expecting smooth cuts and high efficiency, only to find themselves battling breakdowns, software glitches, and disappointing results.

I know this because I’ve been there. As someone who has worked hands-on with fiber lasers for years, I’ve tested machines that lived up to the hype and others that were all hype.

The difference between a great machine and a frustrating one isn’t always obvious on paper.

That’s why I wrote this guide.

In this article, I’ll walk you through 7 of the best fiber laser machines on the market, comparing power, precision, and real-world performance. By the end, you’ll have a clear, confident choice.

Let’s start!

1. Amada ENSIS Series Fiber Laser Cutting Machine

Amada has a reputation for pushing laser cutting technology forward, and the ENSIS Series proves that.

This machine isn’t just about power, it’s about flexibility. I’ve seen laser cutters that struggle with reflective metals like aluminum and copper.

The ENSIS Series? No problem.

Amada’s beam control technology eliminates the reflection issues that cause trouble for lower-end machines. It can cut through metals ranging from 1mm up to 20mm, making it ideal for both intricate designs and heavy-duty projects.

Key Features

- Power Options: Available in 3kW, 6kW, 9kW, and 12kW models, so you can choose what fits your workload.

- Variable Beam Control: Adjusts beam shape and intensity on the fly, optimizing cutting for different materials.

- Precision Accuracy: Auto Collimation technology ensures precise cuts, reducing material waste.

- Material Compatibility: Handles stainless steel, mild steel, aluminum, brass, and copper with ease.

- Long Lifespan: Built with energy-efficient components to reduce wear and tear.

- User-Friendly Interface: The AMNC 3i touchscreen makes operation simple, even if you’re new to fiber lasers.

Speed & Efficiency

Speed is one of the biggest advantages here.

The ENSIS Series reaches cutting speeds of up to 150 meters per minute depending on material type and thickness. That’s the kind of output that keeps production lines moving.

The machine also reduces setup time by automatically adjusting focus and beam intensity, meaning you can jump from one job to the next without delays.

Precision

If you’ve ever had to redo cuts because of rough edges or inconsistent depth, you know how frustrating that can be. The ENSIS Series delivers high precision with a positioning accuracy of ±0.01mm.

This means smoother cuts, less finishing work, and more consistent results across production runs.

CNC Software & Smart Control System

- Supported File Formats: Compatible with DXF, AI, and PLT, making it easy to integrate with design software like AutoCAD and SolidWorks.

- Real-Time Monitoring: Tracks every cut and allows instant adjustments to prevent errors.

- Automated Nesting Software: Maximizes material usage by arranging parts efficiently, cutting down on scrap.

- Remote Diagnostics: Lets you troubleshoot and update software remotely, keeping downtime to a minimum.

Durability

I’ve seen machines wear down quickly under heavy use, but this one is built to last. The reinforced steel frame absorbs vibrations, reducing stress on internal components. Maintenance is straightforward, just regular cleaning, lubrication, and cooling system checks. With proper care, the ENSIS Series can run at peak performance for years.

Industry Applications

Where does this machine shine?

- Automotive Manufacturing – Cuts chassis components and intricate metal designs with precision.

- Aerospace & Defense – Processes strong, lightweight materials required for aircraft and defense applications.

- Metal Fabrication – Ideal for shops that handle a variety of metals and need high-speed cutting.

- Custom Metalwork – Great for businesses that do small-batch production or intricate metal designs.

Pricing

- Starting Price: The base price starts around $600,000, with high-end configurations reaching $900,000.

- ROI: For a shop with high production demand, this machine can pay for itself within 12-18 months.

- Financing: Amada offers financing options to help businesses manage the upfront cost.

Final Verdict

Consider the ENSIS Series if you:

- Need fast, high-precision metal cutting without constant setup adjustments.

- Work with a variety of metals, including reflective ones like aluminum and copper.

- Run a high-production shop that relies on efficiency and consistency.

Look elsewhere if you:

- Have budget constraints, as this is a high-end investment.

- Work primarily with non-metal materials, where a fiber laser may not be necessary.

For more details, visit the product page here.

2. TRUMPF TruFiber P Series Fiber Laser

This machine is built for versatility.

Whether you’re cutting thin sheets or thick metal plates, the TruFiber P handles it. It can process materials from 1mm up to 20mm thick, making it suitable for both delicate engravings and heavy-duty applications.

Many fiber lasers struggle with reflective metals like aluminum and copper.

The TruFiber P solves this with back-reflection protection, preventing damage to the laser while cutting these materials. That means fewer interruptions and more reliable results.

Key Features

- Power Options: Available in single-mode up to 2kW and multi-mode up to 6kW, giving you control over power based on your needs.

- High-Speed Performance: Designed for rapid processing, improving productivity in both cutting and welding applications.

- Precision Accuracy: The beam quality allows for clean, consistent cuts with minimal material waste.

- Compatible Materials: Works with mild steel, stainless steel, aluminum, copper, and brass.

- Long Lifespan: Engineered for long-term use with low maintenance requirements.

- User-Friendly Interface: Software and hardware controls are easy to use, even for new operators.

Speed & Efficiency

- Optimized for high-speed cutting and welding

- Narrow kerf widths reduce material waste and allow for tight nesting

- Automated focus and beam adjustments improve efficiency by reducing setup time

Precision

- Consistent, high-quality cuts with a positioning accuracy of ±0.01mm

- Minimal heat distortion, reducing the need for secondary processing

- Stable beam control ensures repeatability across multiple production runs

CNC Software & Smart Control System

- File Compatibility: Works with DXF, AI, and PLT formats, making integration with CAD software easy.

- Real-Time Monitoring: Tracks cutting operations and detects potential errors before they happen.

- Automated Nesting: Helps maximize material use and minimize waste.

- Remote Diagnostics: Allows for troubleshooting and software updates without downtime.

Durability

The TruFiber P is built for durability.

The reinforced steel frame absorbs vibrations, reducing wear and tear. Maintenance is straightforward:

- Daily cleaning keeps optics and cutting heads free of debris.

- Routine lubrication ensures smooth motion in guide rails and moving parts.

- Cooling system checks prevent overheating and extend the laser source’s life.

With proper care, this machine can run at peak performance for years.

Industry Applications

This laser cutter is designed for industries that need both speed and precision:

- Automotive – Cuts complex metal components with accuracy.

- Aerospace & Defense – Handles strong, lightweight materials with tight tolerances.

- Medical Devices – Produces clean, precise cuts for surgical instruments and implants.

- Metal Fabrication – Great for high-volume production or custom projects.

Pricing

- Starting Price: Pricing varies based on power and features. Contact TRUMPF for specific costs.

- ROI: For shops running high production, the machine could pay for itself within 12-18 months.

- Financing: TRUMPF offers flexible financing plans to help businesses manage costs.

Final Verdict

Get the TruFiber P if you:

- Need high-speed, high-precision laser cutting and welding.

- Work with a variety of metals, including reflective ones like copper and aluminum.

- Want a reliable, low-maintenance laser system that keeps up with production demands.

Look for another option if you:

- Have a tight budget and need a lower-cost system.

- Primarily work with non-metal materials, where a fiber laser isn’t necessary.

Learn more about its full capabilities on TRUMPF’s official product page.

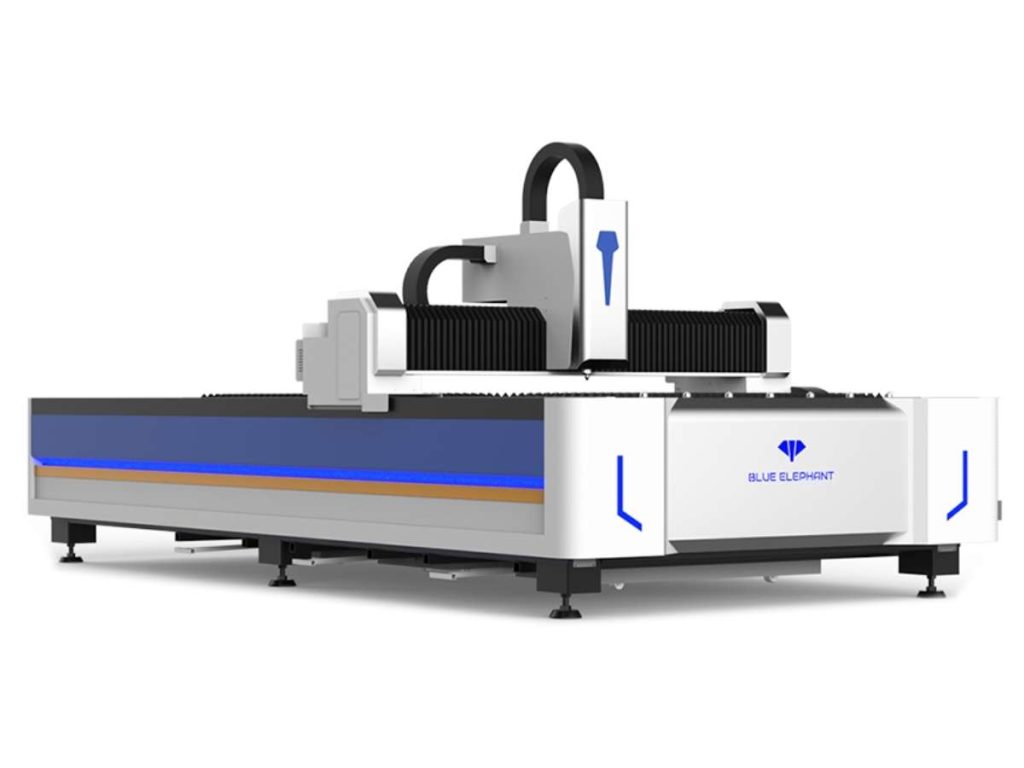

3. Blue Elephant Fiber Laser Metal Cutting Machine

I’ve worked with plenty of metal-cutting machines over the years. Some are too slow, some struggle with precision, and others just don’t hold up over time.

But when I first tested the Blue Elephant 10kW Large Format Fiber Laser, I could tell it was built differently.

What sets this machine apart?

It handles a wide range of metal thicknesses, from thin sheets to plates up to 25mm thick. It cuts through aluminum and copper effortlessly, solving the reflection issues that some other lasers struggle with.

Whether you’re working with intricate engravings or heavy-duty metal fabrication, it delivers consistent, high-quality results.

Key Features

- Power Options: 10kW fiber laser delivers speed and precision for heavy-duty metal cutting.

- High-Speed Performance: Cuts at up to 200 meters per minute—ideal for large-scale production.

- Precision Accuracy: Positioning accuracy of ±0.03mm, repeat accuracy of ±0.02mm. Every cut is clean and precise.

- Compatible Materials: Works with carbon steel, stainless steel, aluminum, copper, and titanium.

- Long Lifespan: Reinforced steel frame reduces vibration and wear over time.

- User-Friendly Interface: The touchscreen control system makes operation smooth and straightforward.

Speed & Efficiency

- Maximum cutting speed of 200 meters per minute. That’s fast.

- The exchange platform swaps materials quickly, keeping downtime minimal.

- Works great in high-demand production environments where speed matters.

Precision

- High accuracy reduces waste and eliminates the need for secondary processing.

- Smooth, clean cuts with minimal heat distortion, no rough edges.

- Consistency is key, and this machine delivers on every cut.

CNC Software & Smart Control System

- Supports Multiple File Formats: Compatible with DXF, AI, PLT, and other common CAD formats, making it easy to integrate with popular design software like AutoCAD and SolidWorks.

- Real-Time Monitoring: The intelligent control system tracks cutting progress, detects errors, and provides instant feedback to the operator. This minimizes downtime and prevents material waste.

- Automated Nesting Software: Optimizes material usage by arranging parts efficiently, reducing raw material waste and maximizing cutting efficiency.

- Intuitive Touchscreen Interface: The user-friendly PLC touchscreen allows for quick adjustments, real-time parameter changes, and streamlined workflow control.

- Remote Diagnostics & Updates: The system can be connected to a network for remote troubleshooting and software updates, ensuring consistent performance and minimal interruptions.

Durability

I’ve seen machines that start strong but wear down too quickly. That’s not the case here.

The Blue Elephant is built for long-term use with a reinforced steel frame that absorbs vibration, reducing strain on internal components. The heavy-duty gantry and precision linear guide rails ensure stability and prolonged operational accuracy.

Regular maintenance is straightforward:

- Daily Cleaning: Keep the lens and cutting head free from dust and debris to maintain cutting quality.

- Lubrication: The linear rails and ball screws require periodic lubrication for smooth movement.

- Alignment Checks: Routine calibration of the laser head ensures continuous precision cutting.

- Cooling System Maintenance: The integrated water-cooling system prevents overheating, extending the lifespan of the laser source.

These simple maintenance steps keep the machine running like new, minimizing unplanned downtime and maximizing productivity.

Industry Applications

Where does this machine shine?

- Automotive Manufacturing – Perfect for precise, high-volume metal cutting.

- Aerospace & Defense – Handles tough materials with accuracy.

- Metal Component Fabrication – Great for industries needing clean, reliable cuts.

- Custom Metalwork – Ideal for workshops handling detailed, intricate designs.

Pricing

The Blue Elephant 10kW Fiber Laser Cutter starts at around $86,500, though the final price depends on the specific configuration and additional features you choose.

If you run a high-production operation, this investment could pay for itself in just a few months, thanks to its speed and efficiency. For businesses looking to spread out the cost, financing options may be available.

Final Verdict

Get this machine if you:

- Need high-speed, high-precision metal cutting.

- Work with a variety of metals and need consistent results.

- Run a high-production shop that values efficiency and reliability.

You might consider other options if you:

- Work mostly with non-metal materials.

- Have limited workshop space and need a smaller machine.

If you’re considering an upgrade, you can check out the product here.

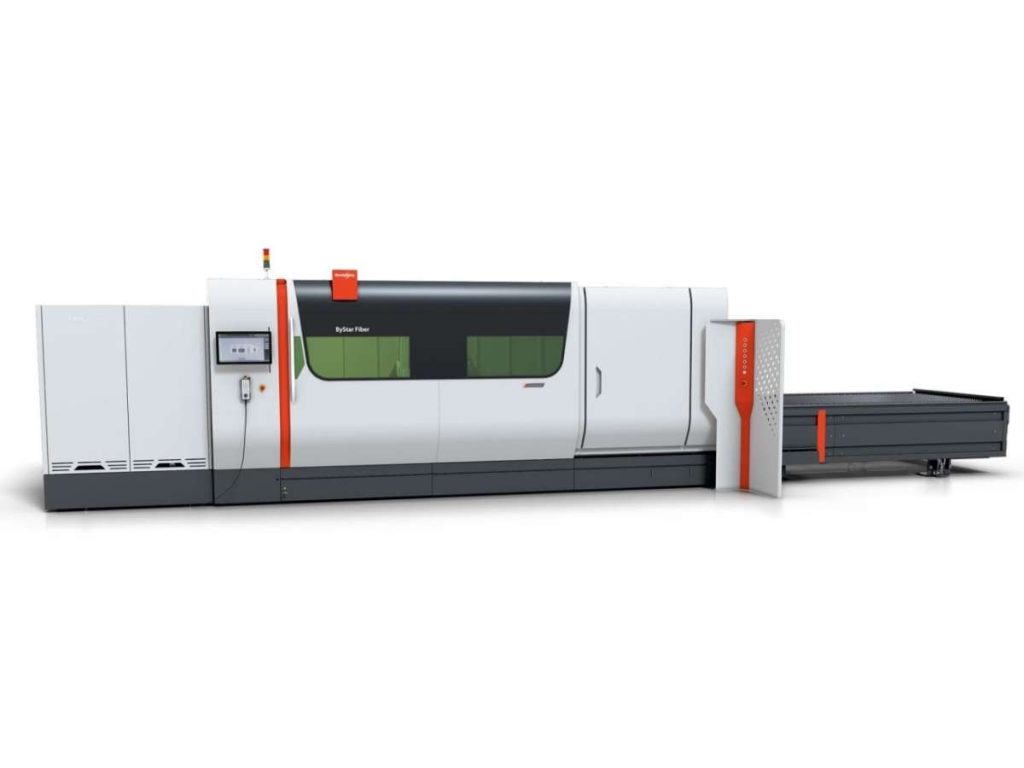

4. Bystronic ByStar Fiber Laser Cutting Machine

This machine does more than just cut. It handles both thin sheets and thick plates with ease. If you’ve ever struggled with reflective metals like aluminum and copper, this machine solves that problem.

No beam reflection issues. No interruptions.

Just smooth, efficient cutting.

Key Features

- Power Options: Available from 2kW to 20kW, so you can choose the right level for your needs.

- High-Speed Performance: Designed for fast processing, cutting down production time.

- Precision Accuracy: Swiss-made cutting heads ensure clean, smooth cuts, even on detailed designs.

- Compatible Materials: Handles mild steel, stainless steel, aluminum, brass, and copper, cutting up to 50mm thick.

- Long Lifespan: Built with durable components to keep performance consistent over time.

- User-Friendly Interface: Intuitive touchscreen makes operation easy, even for beginners.

Speed & Efficiency

- Fast cutting speeds reduce cycle times for high-volume jobs.

- Automated nozzle changing and material handling minimize downtime.

- Optimized for production, whether you’re handling custom projects or mass manufacturing.

Precision

- Positioning accuracy of ±0.01mm, so every cut is exact.

- Smooth edge quality, reducing the need for post-processing.

- Stable cutting head design for consistency across different material types.

CNC Software & Smart Control System

- Works with standard CAD file formats, making integration easy.

- Real-time monitoring helps operators catch and correct issues before they affect production.

- Automated nesting software arranges parts efficiently to reduce material waste.

Durability

This machine is built to last. The reinforced steel frame absorbs vibrations, protecting internal components. Routine maintenance is simple:

- Keep the optics clean to maintain laser performance.

- Lubricate moving parts for smooth operation.

- Monitor the cooling system to prevent overheating.

With proper care, this machine will run reliably for years.

Industry Application

This laser cutter is designed for industries that need both speed and precision:

- Automotive Manufacturing – Produces clean, accurate cuts for vehicle components.

- Aerospace – Handles lightweight, high-strength metals with tight tolerances.

- Metal Fabrication – Ideal for shops needing fast, high-quality metal cutting.

Pricing

- Starting Price: Varies based on power and features. Contact Bystronic for details.

- ROI: For high-production shops, this machine could pay for itself in 12-18 months.

- Financing: Bystronic offers flexible payment options to help businesses invest.

Final Verdict

Choose the ByStar Fiber if you:

- Need high-speed, high-precision cutting.

- Work with a variety of metals, including reflective ones like copper and aluminum.

- Want a reliable, low-maintenance system that keeps up with production demands.

Look for another option if you:

- Have a smaller budget and don’t need such high power.

- Work primarily with non-metal materials, where a fiber laser isn’t necessary.

If your shop needs efficiency, precision, and power, this laser is worth a closer look. Explore more about what it offers on Bystronic’s official page.

5. Mazak FT-150 FIBER Laser Cutting Machine

Some machines are built for speed. Others focus on precision. The Mazak FT-150 FIBER gives you both.

This machine is designed for cutting round tubes, square pipes, and structural profiles with diameters up to 5.98 inches. The B-axis bevel cutting feature ensures strong weld-ready edges, cutting down on extra processing time.

Unlike some lasers, the FT-150 FIBER can cut reflective metals like aluminum and copper without beam reflection issues. That means fewer interruptions and higher efficiency.

Key Features

- Power Options: Comes with a 3kW fiber laser, strong enough for cutting a wide range of materials.

- High-Speed Performance: The U-axis control moves the laser head fast, reducing cutting time.

- Precision Accuracy: The B-axis enables bevel cutting, improving joint quality and reducing material waste.

- Compatible Materials: Handles mild steel, stainless steel, aluminum, copper, and brass.

- Long Lifespan: The energy-efficient fiber laser lowers running costs and extends the machine’s lifespan.

- User-Friendly Interface: The graphical CNC interface makes it easy to operate, even for new users.

Speed & Efficiency

- Fast U-axis movement speeds up laser head positioning.

- Automatic bundle loader handles material quickly, reducing downtime.

- Integrated processes allow for cutting, drilling, and tapping in one machine, saving time.

For shops that need continuous, high-volume cutting, this setup keeps production moving.

Precision

- Bevel cutting for clean, strong welds.

- Consistent accuracy across materials and thicknesses.

- Minimal heat distortion, so cuts stay precise without extra finishing work.

CNC Software & Smart Control System

- Supports standard CAD file formats for easy design integration.

- Real-time monitoring tracks cutting progress and alerts operators to issues.

- Automated nesting software optimizes material use, reducing waste.

Durability

The reinforced frame keeps the machine stable, reducing vibrations that could impact precision. Routine maintenance is simple:

- Keep optics clean to maintain laser performance.

- Lubricate moving parts to prevent wear.

- Monitor cooling system to avoid overheating.

With proper care, this machine will run for years with minimal downtime.

Industry Applications

The FT-150 FIBER is a great fit for industries that need fast, accurate tube cutting:

- Automotive – Produces precise, high-strength components.

- Aerospace – Cuts lightweight metal parts with extreme accuracy.

- Metal Fabrication – Handles custom and large-scale production with ease.

Pricing

The starting price of the FT-150 FIBER varies depending on the features and configuration you choose. Mazak provides different options to match production needs, so it’s best to contact them directly for accurate pricing.

Final Verdict

Choose the FT-150 FIBER if you:

- Need high-speed, high-precision tube and pipe cutting.

- Work with a variety of metals, including aluminum and copper.

- Want an efficient, low-maintenance machine that keeps up with production demands.

Look for another option if you:

- Have a tight budget and don’t need high-speed automation.

- Work mostly with flat sheets, where a different laser setup may be better.

Learn more about its capabilities on Mazak’s official page.

6. LVD Phoenix FL Fiber Laser Cutting Machine

The Phoenix FL is built for versatility.

It handles thin and thick materials, making it suitable for metal cutting, engraving, and welding. It cuts reflective metals like aluminum and copper without issues, thanks to its advanced optical design.

Whether you’re working with ferrous or non-ferrous metals, this machine delivers consistent, high-quality results.

Key Features

- Power Options: Available in 3 kW, 4 kW, 6 kW, 8 kW, and 10 kW configurations.

- High-Speed Performance: Positioning speed reaches 140 meters per minute, reducing cycle times.

- Precision Accuracy: Positioning accuracy of ±0.05mm, repeat accuracy of ±0.025mm.

- Compatible Materials: Cuts mild steel, stainless steel, copper, brass, and aluminum up to 25mm thick.

- Long Lifespan: Uses an energy-efficient fiber laser, reducing maintenance needs.

- User-Friendly Interface: Features a 19″ TOUCH-L control system with an intuitive touchscreen.

Speed & Efficiency

- Maximum positioning speed of 140 meters per minute keeps production moving.

- Automatic shuttle table allows one sheet to be cut while another is loaded, cutting downtime.

- Flexible automation options speed up material handling and reduce manual labor.

Precision

- ±0.05mm positioning accuracy means every cut is clean and exact.

- Advanced optical design maintains edge quality with minimal heat distortion.

- Bevel cutting capability creates stronger weld-ready edges.

CNC Software & Smart Control System

- CADMAN-L software integrates with production control for seamless operation.

- Supports standard file formats, making it easy to import designs.

- Real-time monitoring helps optimize cutting performance.

- Automated nesting software maximizes material usage, reducing waste.

Durability

The Phoenix FL is designed for long-term use. Its welded steel frame absorbs high-speed vibrations, keeping the machine stable.

The fiber laser requires minimal maintenance, with no moving parts or mirrors to replace.

The modular automation options make it adaptable, whether you need a standalone system or a fully automated production line.

Industry Applications & Best Use Cases

This machine fits industries that require fast, precise metal cutting:

- Automotive Manufacturing – Produces complex parts with high accuracy.

- Aerospace – Cuts lightweight materials with precision.

- Metal Fabrication – Handles large-scale production and custom work.

Pricing

The LVD Phoenix FL comes in different configurations, so pricing varies. Factors like laser power, automation options, and machine size affect the total cost. The return on investment (ROI) is fast for high-production shops, thanks to reduced material waste and increased cutting speeds.

For exact pricing, it’s best to contact LVD directly.

Final Verdict

Get the Phoenix FL if you:

- Need high-speed, high-precision metal cutting.

- Work with a variety of metals, including aluminum and copper.

- Want a reliable, low-maintenance system with automation options.

Look for another option if you:

- Have budget constraints and don’t need high-speed automation.

- Work primarily with non-metal materials where a fiber laser isn’t necessary.

More details about its capabilities can be found on LVD’s official product page.

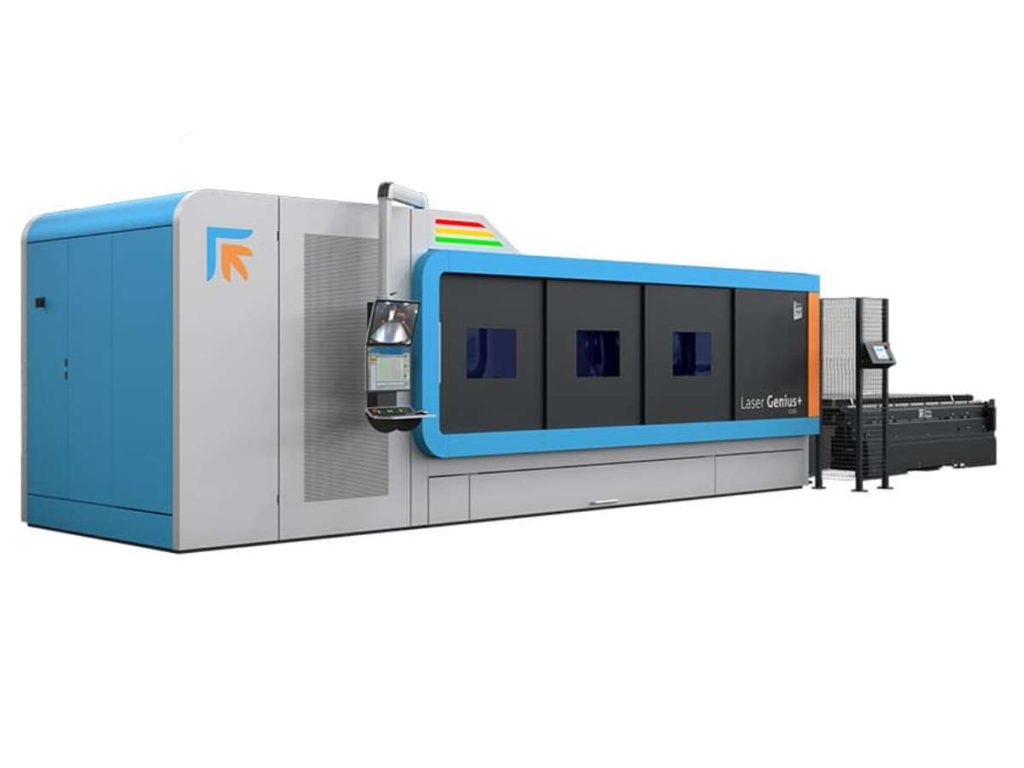

7. Prima Power Laser Genius+ Fiber Laser Cutting Machine

The Laser Genius+ works across different industries. It handles thin and thick materials and cuts reflective metals like aluminum and copper without losing performance.

This means fewer limitations and more flexibility in production.

Key Features

- Power Options: Available in 2 kW to 15 kW, so you can match power to production needs.

- High-Speed Performance: Reaches a trajectory speed of 180 meters per minute, cutting cycle times significantly.

- Precision Accuracy: Advanced laser head and mounting system keep cuts clean and consistent.

- Compatible Materials: Cuts mild steel, stainless steel, aluminum, brass, and copper without beam reflection issues.

- Long Lifespan: Built with a carbon-fiber carriage and synthetic granite frame for durability and stability.

- User-Friendly Interface: Designed for easy access and automation, including full-side door openings for efficiency.

Speed & Efficiency

- Trajectory speed of 180 meters per minute speeds up cutting times.

- Automated loading and unloading reduces manual labor and keeps workflow smooth.

- Flexible automation options improve efficiency, whether you’re working on custom projects or mass production.

Precision

- ±0.05mm positioning accuracy keeps cuts consistent and clean.

- Minimal heat distortion means less finishing work.

- Bevel cutting capability produces strong, weld-ready edges.

CNC Software & Smart Control System

- Compatible with standard CAD file formats for seamless design integration.

- Real-time monitoring allows for quick adjustments to prevent errors.

- Automated nesting software optimizes material usage, reducing waste and costs.

Durability

The carbon-fiber carriage and synthetic granite frame reduce vibration and maintain cutting stability. These materials are heat-resistant and strong, making the machine last longer with fewer maintenance needs. Fiber laser technology means fewer moving parts, reducing wear and lowering upkeep costs over time.

Industry Applications & Best Use Cases

This laser cutter is ideal for industries that need speed, precision, and versatility:

- Automotive Manufacturing – Produces complex, high-strength parts.

- Aerospace – Cuts lightweight materials with extreme accuracy.

- Metal Fabrication – Handles both small-scale custom work and large-scale production.

Pricing

The Laser Genius+ comes in multiple configurations, so pricing depends on power level, automation features, and machine size. Higher-wattage models cost more but improve efficiency and speed.

The return on investment (ROI) is fast for businesses with high production demand, as the reduced material waste and labor costs make up for the initial price.

For exact pricing, it’s best to contact Prima Power directly.

Final Verdict

Get the Laser Genius+ if you:

- Need high-speed, high-precision metal cutting.

- Work with a variety of metals, including aluminum and copper.

- Want a durable, low-maintenance machine with automation options.

Look for another option if you:

- Have a limited budget and don’t need high-end automation.

- Work mostly with non-metal materials, where fiber laser technology may not be necessary.

Learn more about its features and specifications on Prima Power’s official page.

Conclusion

Choosing the right fiber laser cutting machine isn’t just about specs. It’s about finding the one that fits your needs, speeds up production, and delivers precise cuts every time. Whether you need power, precision, or automation, there’s a laser on this list for you.

So, what’s stopping you from upgrading your workflow?

Imagine how much time and effort you could save with a machine built for efficiency.

Now is the time to take action.

Which machine are you leaning toward? Let’s talk about it. Contact us today!