We learned the hard way. A cheap laser welder nearly ruined an entire batch of high-value components. The welds were weak, and rework costs piled up fast.

That mistake pushed us to find reliable machines that deliver consistent, high-quality welds.

This guide is built on firsthand experience, industry insights, and extensive testing. We’ve cut through the noise so you don’t have to.

Inside, you’ll find the 7 best laser welding machines, with details on performance, durability, and ROI. No gimmicks, just the facts.

Let’s break it down!

Quick Comparison Chart

Choosing the right laser welding machine can significantly impact efficiency, precision, and overall production costs. Below is a detailed comparison of seven top laser welding machines to help businesses find the best fit for their specific needs.

| Laser Welding Machine | Type | Power Output | Key Features | Best For | Automation Level | Portability | Industries |

| TRUMPF TruLaser Weld 5000 | Automated Laser Welding System | Varies based on configuration | Automated robotic welding, FusionLine technology, adaptable welding processes | High-volume production, automotive, aerospace, metal fabrication | Fully automated | Fixed, industrial setup | Automotive, aerospace, industrial manufacturing, metal fabrication |

| Han’s Laser W Series | Versatile Laser Welding Series | Varies based on model | Advanced laser technology, versatile applications, user-friendly interface | Electronics, automotive, medical device manufacturing | Semi-automated to fully automated (varies by model) | Fixed, industrial setup | Electronics, automotive, medical, precision manufacturing |

| Blue Elephant 3D Automatic Laser Welding Machine | 3D Automatic Laser Welding Machine | Customizable | 3D welding capability, automated welding, high precision | Automotive, aerospace, robotics, complex metal fabrications | Fully automated | Fixed, industrial setup | Automotive, aerospace, industrial robotics, tool making |

| Amada FLW-ENSIS Series | High-Speed Fiber Laser Welding | ENSIS technology (adjustable power) | ENSIS beam adjustment, high-speed processing, integrated automation | Sheet metal processing, automotive, aerospace, high-speed manufacturing | Fully automated | Fixed, industrial setup | Automotive, sheet metal, industrial manufacturing |

| Coherent StarFiber 100-600 Series | Precision Fiber Laser Welding | 100W – 600W | SmartWeld technology, versatile optics, energy-efficient | Precision welding, medical devices, electronics, fine mechanics | Fully automated | Fixed, compact design | Medical, electronics, jewelry, fine mechanics, automotive |

| Jenoptik JENOPTIK-VOTAN BIM | 3D Laser Cutting & Welding System | High-power laser | Integrated beam guidance, compact design, high-speed operation | 3D laser welding & cutting, automotive, consumer electronics, aerospace | Fully automated | Fixed, robotic integration | Automotive, aerospace, consumer electronics, industrial production |

| Baison Laser Handheld Fiber Laser Welder | Handheld Fiber Laser Welding Machine | Typically 1000W – 2000W | Portable, flexible operation, low heat distortion | Small workshops, repair operations, custom metal fabrications | Manual operation with some automation | Highly portable, handheld | Automotive repairs, aerospace maintenance, metal fabrication, artistic metalwork |

1. TRUMPF TruLaser Weld 5000

The TruLaser Weld 5000 is a high-performance laser welding system built for automated precision welding. It seamlessly integrates advanced robotics, laser technology, and intelligent processing optics, ensuring a streamlined welding process.

Applications

- Automotive Manufacturing

- Metal Fabrication

- Aerospace Components

- Heavy Machinery

- Electronics Industry

Key Features

- Flexible Welding Processes: The TruLaser Weld 5000 is equipped to perform heat conduction welding, deep penetration welding, and FusionLine technology. Whether you need strong, deep welds for structural integrity or seamless surface welds for aesthetics, this system can handle it all.

- User-Friendly Operation: The rotatable control panel and additional status monitor make it easy to oversee the welding process. Operators can monitor and adjust settings with minimal effort, reducing training time and increasing productivity on the shop floor.

- Improved Accessibility: The machine features a rotary module for shield gas guidance, ensuring optimal access to complex parts. This means fewer obstacles during welding, allowing for faster and more precise operations, even on challenging geometries.

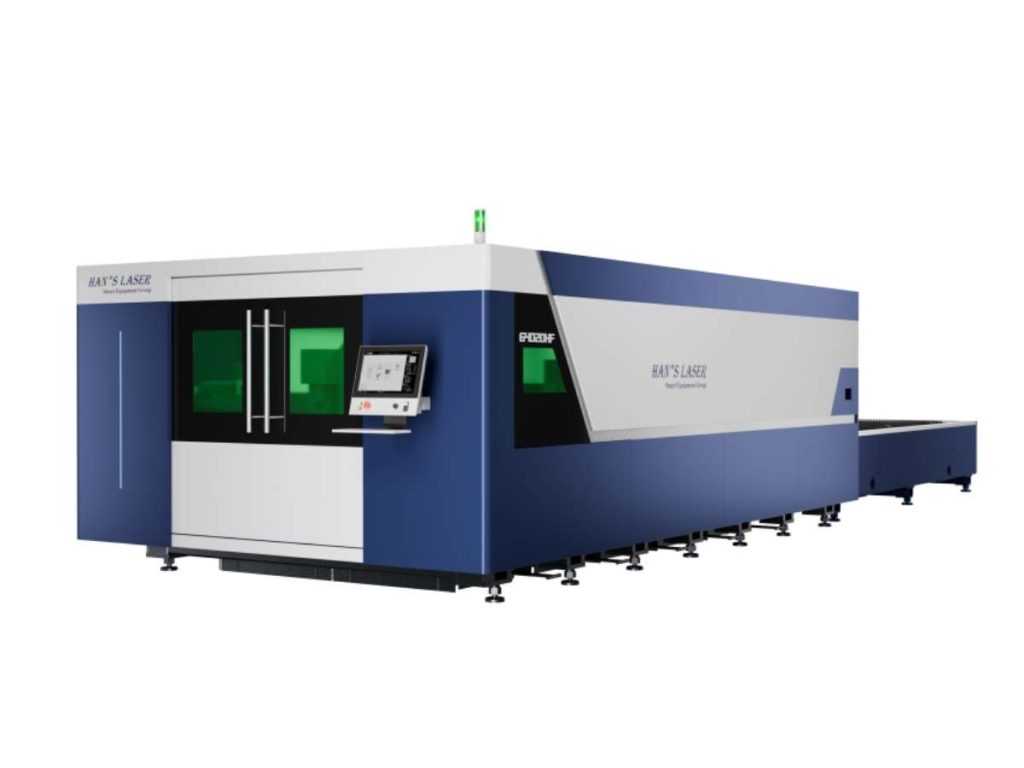

2. Han’s Laser W Series

The Han’s Laser W Series is a collection of high-precision laser welding machines built for efficiency and durability. Designed to meet the demands of modern industrial applications, these machines offer reliable and consistent welding solutions across various industries.

Applications

- Electronics Manufacturing

- Automotive Industry

- Medical Device Manufacturing

- Aerospace Applications

- Industrial Equipment Fabrication

Key Features

- Advanced Laser Technology: The W Series incorporates some of the most advanced laser systems available, ensuring clean, high-quality welds every time. With precise energy control and focused laser beams, you can achieve seamless joins with minimal heat distortion, even on sensitive materials.

- Versatile Applications: This machine isn’t limited to one industry, it’s designed to work across various sectors, from automotive and aerospace to electronics and medical device manufacturing. Whether you’re welding stainless steel, aluminum, or specialized alloys, it offers the flexibility to adapt to different materials and production needs.

- User-Friendly Interface: With an intuitive control panel and easy-to-use software, the W Series minimizes the learning curve for operators. This means faster setup times, fewer errors, and increased productivity, allowing businesses to focus on production rather than troubleshooting complex settings.

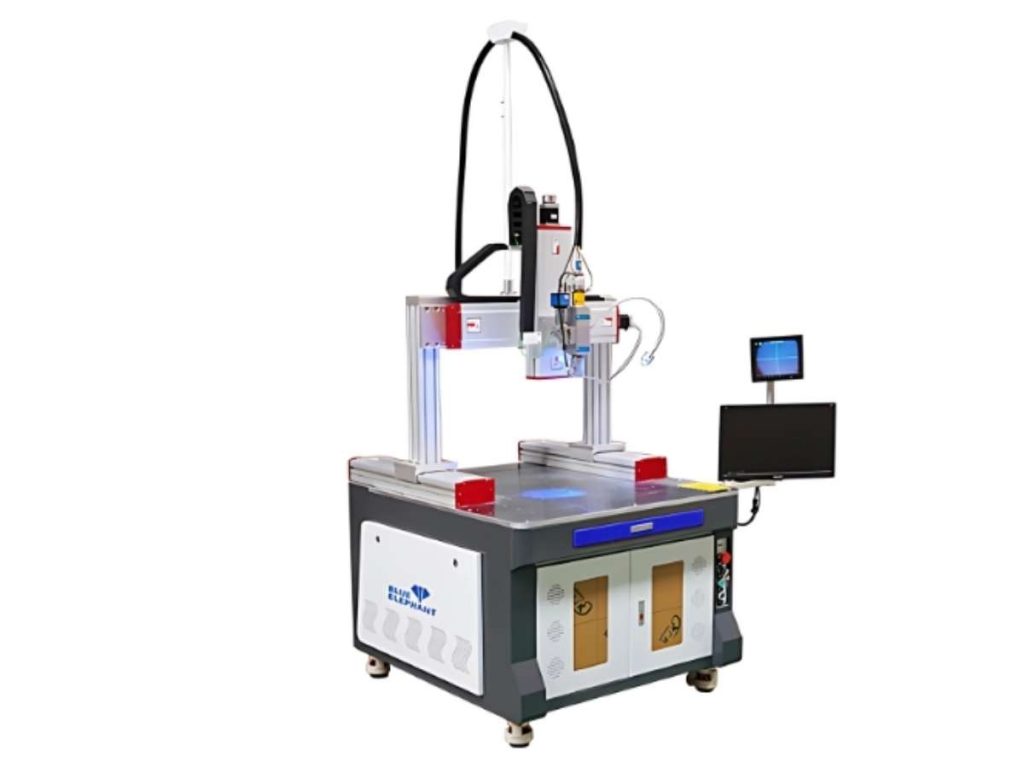

3. Blue Elephant 3D Automatic Laser Welding Machine

The Blue Elephant 3D Automatic Laser Welding Machine is designed for high-precision welding in three-dimensional applications. Whether you’re dealing with intricate components, curved surfaces, or multi-layered structures, this machine offers the automation and precision required for complex welding tasks.

Applications

- Automotive Industry

- Aerospace Sector

- Robotics and Automation

- Industrial Metal Fabrication

- Tool and Mold Making

Key Features

- 3D Welding Capability: Unlike conventional welding machines that struggle with non-flat surfaces, this system is designed specifically for three-dimensional welding tasks. Whether you’re working with automotive frames, or intricate metal fabrications, it ensures a seamless and consistent weld every time.

- Automation: This machine takes welding precision to the next level by integrating automated processes that reduce manual intervention. Automation not only speeds up production but also ensures every weld meets strict quality standards, eliminating inconsistencies in mass production.

- Precision Welding: Accuracy is crucial in industries where even the smallest welding defects can cause product failures. This machine provides fine control over the welding process, ensuring that each joint is flawless, even when working with delicate or high-tolerance components.

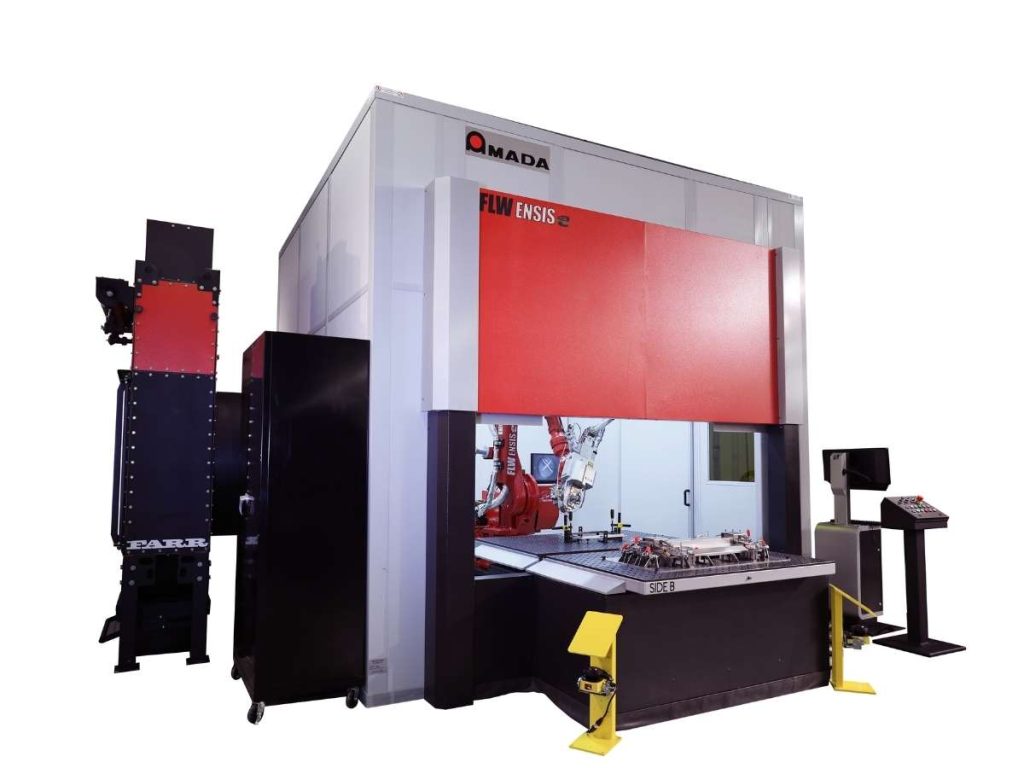

4. Amada FLW-ENSIS Series

The Amada FLW-ENSIS Series is a state-of-the-art laser welding system designed for high-speed, high-precision welding. It combines Amada’s innovative ENSIS technology with advanced automation to optimize welding quality across a variety of materials and thicknesses.

Applications

- Automotive Manufacturing

- Aerospace Engineering

- Heavy Equipment Production

- Sheet Metal Fabrication

- Appliance Manufacturing

Key Features

- ENSIS Technology: The FLW-ENSIS Series automatically modifies the laser beam shape and intensity to match the material being welded. This means you can switch between thin and thick materials without adjusting the setup, saving time and increasing efficiency.

- High-Speed Welding: This system is built for fast-paced production environments where speed matters. With high-powered fiber laser technology, it delivers fast, clean welds without sacrificing accuracy, making it ideal for mass production.

- Integrated Automation: The machine includes robotic integration and advanced motion control, reducing manual labor and ensuring consistent weld quality. With its automated features, businesses can achieve higher output with lower operational costs, improving overall profitability.

5. Coherent StarFiber 100-600 Series

The Coherent StarFiber 100-600 Series is a powerful and versatile fiber laser welding system designed for precision and efficiency. Whether you’re working on fine, intricate welds or larger industrial components, this machine offers flexibility with power options ranging from 100W to 600W.

Applications

- Electronics Industry

- Medical Device Manufacturing

- Fine Mechanics & Jewelry

- Automotive Sector

- Industrial Manufacturing

Key Features

- High Efficiency: The StarFiber Series delivers exceptional welding performance with optimized laser power usage, reducing energy consumption while maintaining strong, high-quality welds. This not only cuts operational costs but also minimizes heat-affected zones, preserving the integrity of the welded materials.

- Versatile Optics: Available with both scanner and fixed optics, this machine can be adapted to suit different welding applications. This means businesses can tailor the system to their specific needs, whether they require fast, automated production or detailed manual control.

- SmartWeld™ Technology: With Coherent’s SmartWeld™ technology, the system improves seam quality, reduces porosity, and enhances joint strength. This ensures that each weld is not only visually perfect but also structurally durable, making it ideal for applications where reliability is critical.

6. Jenoptik JENOPTIK-VOTAN BIM

The Jenoptik JENOPTIK-VOTAN BIM is a highly advanced laser welding and cutting system designed for precision and flexibility in industrial manufacturing. Unlike traditional laser systems, this machine features an innovative robotic beam-guiding technology that allows for seamless 3D processing of metals and plastics.

Applications

- Automotive Manufacturing

- Aerospace Industry

- Consumer Electronics

- Medical Equipment Production

- Industrial Equipment Fabrication

Key Features

- Integrated Beam Guide: Unlike conventional systems that use fiber optic cables, this machine employs an internal mirror system to guide the laser beam. This design eliminates wear and tear on fiber optics, reducing maintenance costs and ensuring long-term reliability in demanding production environments.

- Compact and Lightweight Design: The streamlined and space-saving design allows for greater mobility and flexibility in manufacturing plants. It can easily be incorporated into robotic workstations, enabling smooth operation in automated production lines with minimal disruption.

- High-Speed Processing: With its precision control and dynamic beam adjustments, businesses can achieve better efficiency without sacrificing accuracy or strength in the final product.

7. Baison Laser Handheld Fiber Laser Welder

The Baison Laser Handheld Fiber Laser Welder is a portable yet powerful welding solution designed for businesses that need flexibility and ease of use. Unlike bulky industrial welding machines, this handheld model allows operators to weld in hard-to-reach areas while still maintaining precision and efficiency.

Applications

- Metal Fabrication

- Automotive Repairs and Manufacturing

- Aerospace Component Repair

- Artistic Metalwork & Custom Manufacturing

- Maintenance & Repair Operations

Key Features

- Portability & Flexibility: This lightweight handheld design allows welders to move freely and work on large or irregularly shaped components without restrictions. Whether you’re welding metal furniture, automotive parts, or machinery frames, this welder gives you the freedom to handle diverse projects.

- Fiber Laser Technology: Unlike traditional welding machines, this fiber laser welder provides precise and efficient energy transfer, ensuring deep penetration and high-strength welds. The minimal heat-affected zone prevents material distortion, making it ideal for thin metals and delicate projects.

- User-Friendly Interface: Designed with simplicity in mind, the intuitive controls make it easy for both experienced and novice welders to operate. Quick setup and minimal maintenance requirements mean your team can focus on production rather than troubleshooting complex welding parameters.

Conclusion

I’ve been where you are, scrolling through machines, wondering which one will actually deliver.

That’s why I created this list. Seven laser welders that are worth your time.

And if you’re eyeing advanced 3D welding? Blue Elephant is one to seriously consider.

Don’t sit on this decision. Your production line deserves better.

Contact us today, we’ll walk you through your options.