Let’s be honest, buying a CNC machine isn’t cheap. And when you’re looking at tabletop models, the last thing you want is to spend money on the wrong one.

I’ve made that mistake before. I thought I was saving money by going for a budget-friendly option. But after countless breakdowns, software crashes, and ruined materials, I had to admit it. A cheap machine that doesn’t work is more expensive than a good machine that does.

That’s why I put together this guide, I’ll walk you through 7 of the best tabletop CNC machines, ones that balance precision, reliability, and efficiency without wasting your time or money.

Let’s find the right one for you!

Quick Comparision

Before we dive deep into each machines, here’s a quick side-by-side comparison to help you get a feel for what each machine offers:

| Machine | Spindle Power | Work Area | Supported Materials | Accuracy & Speed | Software Compatibility | Price Range |

| Shapeoko 4 | Up to 1.25HP | 33” x 17.5” x 4” | Wood, plastics, aluminum | High precision, lead screw Z-axis | Carbide Create, Fusion 360, Vectric | $1,500 – $2,300 |

| BobsCNC Evolution 4 | 600W (1HP) Makita RT0701C Router | 24” x 24” x 3” | Wood, plastics, soft metals | Up to 0.002” repeatability | GRBL, UGS, Fusion 360, VCarve | $900 – $1,200 |

| Blue Elephant 1212 | 1.5kW – 2.2kW water-cooled spindle | 47” x 47” | Wood, acrylic, PVC, soft metals | High precision, ball screw transmission | DSP control system, ArtCAM, Type3, UG, Fusion 360 | $3,500 – $5,500 |

| Genmitsu 3018-PRO | 775 motor (10,000 RPM) | 11.8” x 7.1” x 1.8” | Wood, acrylic, PCB, soft aluminum | 0.1mm accuracy | GRBL, LaserGRBL, Fusion 360 | $250 – $400 |

| Axiom Iconic-4 | 1HP electro spindle | 24” x 24” x 4” | Wood, plastics, aluminum | High precision, ball screw drive | VCarve, Aspire, Fusion 360 | $3,500 – $4,500 |

| Sherline 12” Deluxe | 90V DC motor | 13” x 2.75” x 5.38” | Aluminum, brass, wood, plastic, light steel | 0.001” accuracy, 70–2800 RPM | Mach3, LinuxCNC, Fusion 360 | $2,000 – $3,000 |

| Bantam Tools Desktop CNC | 28,000 RPM spindle | 7” x 9” x 3.3” | Aluminum, brass, wood, plastic | ±0.001” repeatability | Bantam Tools Software, G-code, SVG | $6,999 |

You’ve got the side-by-side view, now it’s time for the hands-on details.

Let’s explore each CNC machine to see which one meets your needs.

1. Shapeoko 4 CNC Router

I remember when I first started looking for a tabletop CNC machine. I wanted something powerful but not complicated. Affordable but not flimsy. And most importantly, I wanted a machine that wouldn’t make me regret my purchase a month later.

That’s what led me to the Shapeoko 4 CNC Router. It’s one of those machines that finds the right balance, powerful enough for serious work, yet approachable enough for beginners.

But is it right for you? Let’s break it down.

Specifications

| Feature | Details |

| Spindle Power | Supports up to 1.25HP routers (like the Carbide Compact Router) |

| Work Area | 33” x 17.5” x 4” (varies by model) |

| Supported Materials | Wood, plastics, aluminum, and soft metals |

| Accuracy & Speed | High precision with lead screw-driven Z-axis |

| Software Compatibility | Carbide Create (included), Fusion 360, Vectric, etc. |

Performance

- The rigid aluminum frame makes cutting smooth and consistent.

- With ball bearings and precision-milled components, movement feels solid.

- It’s fast without sacrificing accuracy, ideal for sign-making, furniture, and small parts.

But like any CNC, it has limits. If you plan to cut thick steel, this isn’t the right machine.

Maintenance & Longevity

- Easy to clean, just clear out dust and debris.

- Parts like belts and V-wheels may wear over time, but replacements are easy to find.

- With good care, expect 5+ years of use before major upgrades are needed.

Price & Value

The Shapeoko 4 costs around $1,500 to $2,300, depending on the size and accessories you choose. Compared to industrial CNCs, it’s an affordable option that still delivers professional results. However, you may need to budget for extras like clamps, cutting bits, and software upgrades, which can increase the total cost.

For what it offers, the Shapeoko 4 provides great value for those who need a mix of power, precision, and usability without breaking the bank.

Who It’s Best For

The Shapeoko 4 is a great choice for hobbyists, small business owners, and makers who need precision without the steep learning curve. It’s particularly well-suited for woodworkers, sign-makers, and designers who want to create detailed cuts and engravings.

But, it does have some limitations.

If you need a plug-and-play experience, be prepared for some assembly, it takes a few hours to set up. While it cuts soft metals, it’s not built for thick or heavy-duty metalworking. If your main focus is machining steel, you’ll want to look at other options.

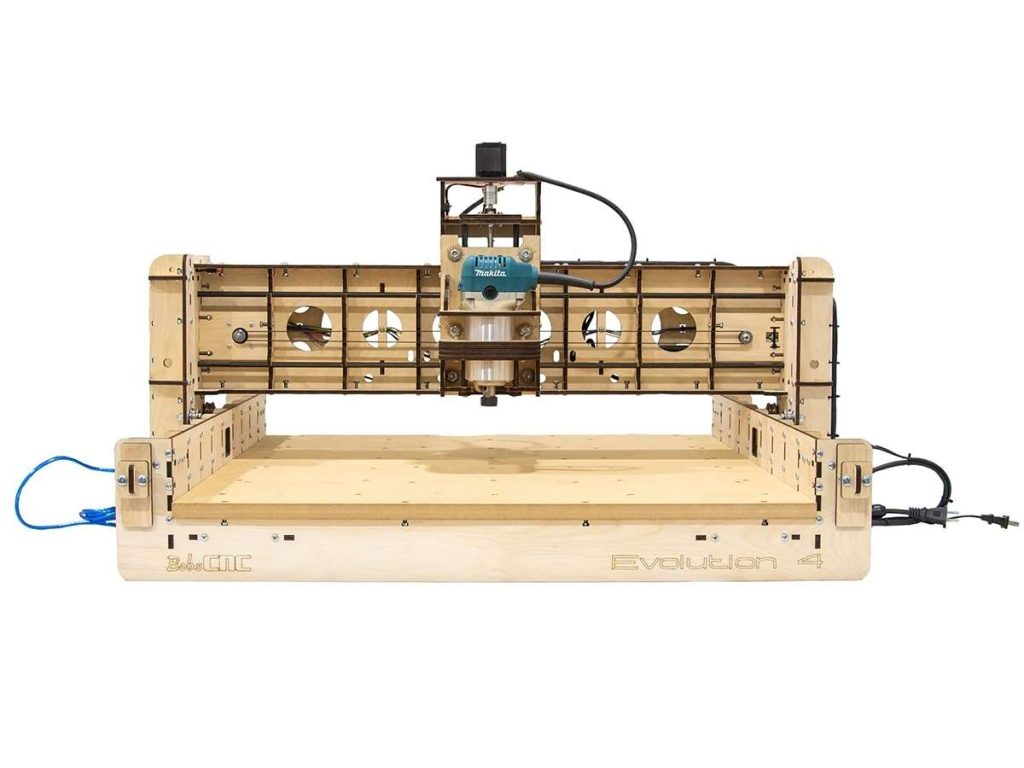

2. BobsCNC Evolution 4

The first time I saw the BobsCNC Evolution 4, I wasn’t sure what to think. It looked different from most CNC machines, a wooden frame instead of metal? But after using it, I realized something. This machine isn’t trying to look high-tech. It’s built for functionality, precision, and affordability.

If you’re someone who enjoys hands-on assembly and learning how machines work, the Evolution 4 might be a great fit.

But is it right for you? Let’s take a closer look.

Specifications

| Feature | Details |

| Spindle Power | 600W (1HP) Makita RT0701C Router |

| Work Area | 24” x 24” x 3” |

| Supported Materials | Wood, plastics, soft metals |

| Accuracy & Speed | Up to 0.002” repeatability |

| Software Compatibility | GRBL-based software, works with UGS, Fusion 360, VCarve |

Performance

For a machine with a wooden frame, the BobsCNC Evolution 4 is surprisingly stable and accurate. The rigid plywood design absorbs vibrations well, which helps maintain smooth cutting paths. However, because it’s not made of metal, it requires careful assembly to keep everything aligned.

- Cutting precision is excellent for wood and plastic, though aluminum cutting requires slow speeds.

- The Makita RT0701C router is powerful enough for hobbyists and small businesses.

- It runs at a reasonable speed but prioritizes stability and precision over raw cutting power.

For woodworking, sign-making, and engraving, it’s a solid performer at its price point.

Maintenance & Longevity

Keeping this CNC in good condition isn’t difficult, but it does require some extra care due to its wooden frame.

- Store it in a dry environment to prevent warping.

- Belts and bearings need occasional adjustments to maintain accuracy.

- Parts like the router and stepper motors are easily replaceable.

- With proper care, the Evolution 4 can last 5+ years before needing major repairs.

Unlike metal-frame machines, the wooden structure needs to be kept stable, but as long as it’s well-maintained, it holds up well.

Price & Value

The BobsCNC Evolution 4 is priced in the $900 to $1,200 range, making it one of the most affordable tabletop CNC machines. While it doesn’t come pre-assembled, its lower price and solid performance make up for the extra effort.

- Hidden costs: You may need to buy additional router bits, clamps, and software upgrades.

- Assembly trade-off: You’re saving money, but you’ll need to put in the time to build and calibrate the machine.

- Worth it? If you enjoy DIY projects, absolutely. If you prefer plug-and-play, maybe not.

For its price, the Evolution 4 offers great value for those willing to put in the effort.

Who It’s Best For

The Evolution 4 is a great choice for DIY enthusiasts, hobbyists, and small business owners who enjoy hands-on projects. If you like understanding how your CNC works inside and out, this machine gives you that opportunity. It’s ideal for:

- Woodworkers and sign makers who need a budget-friendly CNC.

- Makers and hobbyists who don’t mind assembling their machine.

- Small business owners looking for an entry-level CNC that delivers precision at a lower cost.

However, it’s not the best option for someone looking for a plug-and-play CNC. Assembly takes time, and since the frame is wooden, it requires more careful handling. If you need a machine that’s ready to go out of the box, this may not be the best fit.

3. Blue Elephant 1212 Desktop Advertising CNC Machine

When I first started working with desktop CNC machines, I wanted something compact but still powerful enough to handle detailed engraving and cutting jobs.

That’s when I came across the Blue Elephant 1212 Desktop Advertising CNC Machine.

Unlike some entry-level models that struggle with precision, this machine is built to handle advertising, signage, and small-scale manufacturing with accuracy and efficiency.

If you’re looking for a machine that delivers professional-grade results without taking up too much space, this one is worth considering.

Specifications

| Feature | Details |

| Spindle Power | 1.5kW to 2.2kW water-cooled spindle |

| Work Area | 1200mm × 1200mm (47” x 47”) |

| Supported Materials | Wood, acrylic, PVC, MDF, aluminum composite panel |

| Accuracy & Speed | Positioning accuracy: ±0.02mm; Cutting speed: up to 25,000mm/min |

| Software Compatibility | DSP control system, compatible with ArtCAM, Type3, UG, Fusion 360 |

Performance

For a desktop CNC, the Blue Elephant 1212 packs impressive precision. The ball screw transmission system helps eliminate backlash, ensuring that cuts are sharp and consistent. The water-cooled spindle allows for long work sessions without overheating, making it great for businesses handling bulk orders.

- Cutting precision is excellent for engraving, acrylic cutting, and sign-making.

- The frame is rigid and stable, reducing vibrations and improving accuracy.

If you’re working with fine engravings, this machine does an excellent job of delivering clean, intricate results. However, if you’re planning to cut thick aluminum or steel, it may not have enough power for heavy-duty metalworking.

Maintenance & Longevity

Like any CNC machine, keeping it in good shape requires regular upkeep.

- Cleaning the spindle and work area after each use prevents material buildup.

- Lubricating the ball screws and rails ensures smooth movement and long-term accuracy.

- Water-cooling maintenance is simple, but you’ll need to monitor the coolant levels.

With proper care, the Blue Elephant 1212 can last 7+ years without major issues, making it a solid long-term investment.

Price & Value

This machine falls within the $3,500 to $5,500 price range, depending on the spindle power and additional features. While it’s more expensive than hobbyist models, it delivers professional-quality results.

- Additional costs may include specialized router bits, software, and a dust collection system.

- For business use, the price is reasonable, given its precision and durability.

- For hobbyists, it might be overkill unless you’re producing high-end projects.

For the right user, this machine is worth every dollar due to its accuracy, stability, and ability to handle commercial work.

Who It’s Best For

This CNC is ideal for small business owners, advertising professionals, and workshop operators who need a machine that can handle both engraving and cutting on a variety of materials. If you’re making signs, acrylic displays, or detailed engravings, this machine can save you time while delivering clean, professional results.

It’s not the best fit for complete beginners since the DSP control system requires some learning. If you’re new to CNC, you may need time to get comfortable with the software and settings before achieving perfect results.

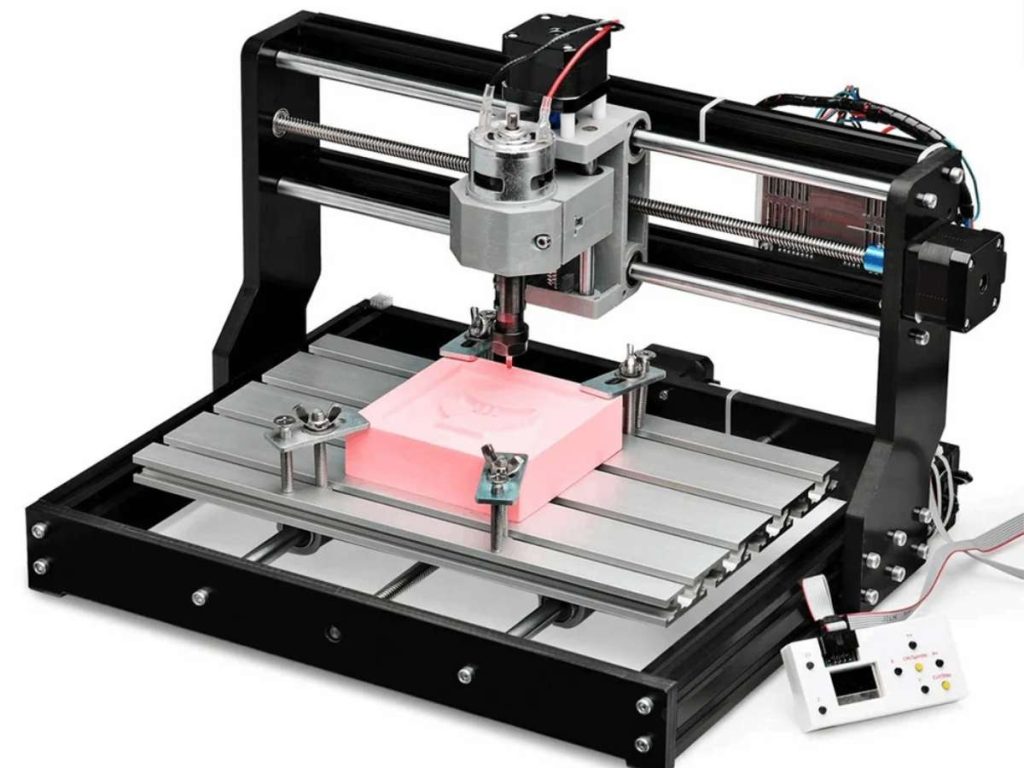

4. Genmitsu CNC 3018-PRO

The first time I saw the Genmitsu CNC 3018-PRO, I wasn’t sure what to expect. It looked smaller than other tabletop CNC machines I had worked with, and I wondered if it could actually handle real projects. But after setting it up and running my first test cut, I realized something. This little machine punches above its weight.

If you’re new to CNC machining and want something affordable to learn the ropes, this is a great place to start. It’s compact, budget-friendly, and surprisingly capable for small-scale projects.

Specifications

| Feature | Details |

| Spindle Power | 775 motor (10,000 RPM) |

| Work Area | 300mm x 180mm x 45mm (11.8” x 7.1” x 1.7”) |

| Supported Materials | Wood, acrylic, PVC, PCB, soft aluminum |

| Accuracy & Speed | High precision with lead screw drive |

| Software Compatibility | GRBL-based, works with Candle, Fusion 360, and Easel |

Performance

For a budget CNC, the Genmitsu 3018-PRO is surprisingly capable. It’s not meant for heavy-duty cutting, but for engraving and small-scale projects, it does a great job.

- The lead screw drive system provides good precision, reducing backlash for accurate cuts.

- Frame durability is decent, with a mix of aluminum and plastic, but it’s not as rigid as larger machines.

- It’s not the fastest CNC, but it delivers clean engravings when set at the right speed.

For working with wood, plastics, and soft metals, this machine performs well. However, if you need to cut thick aluminum or harder materials, you’ll need a stronger spindle upgrade.

Maintenance & Longevity

Keeping this CNC in good shape is simple since it has fewer moving parts than larger models.

- Regularly check the lead screws and linear bearings to keep movements smooth.

- Clean dust and debris after each use to prevent clogging.

- Spindle maintenance is minimal, but upgrading it over time may improve performance.

With proper care, the 3018-PRO can last 3 to 5 years, making it a solid beginner-friendly investment.

Price & Value

This machine falls within the $250 to $350 price range, making it one of the most affordable tabletop CNC machines available.

- Additional costs may include better router bits, an upgraded spindle, and a laser module for engraving.

- For beginners, it’s a great value since it teaches CNC fundamentals without a big financial risk.

- For business use, it’s not ideal for large production but works well for prototypes and custom engraving.

If you’re looking for an inexpensive way to start CNC machining, this is a fantastic entry-level option.

Who It’s Best For

The Genmitsu 3018-PRO is best for hobbyists, students, and beginners looking to learn CNC basics without spending a lot of money. It’s ideal for engraving, light cutting, and DIY electronics projects.

However, it’s not suited for heavy-duty milling or professional manufacturing. The small work area and limited spindle power mean it won’t replace a high-end machine. If you need high-speed cutting on thick materials, you’ll need a stronger CNC.

5. Axiom Iconic-4 (24” x 24”)

When I first heard about the Axiom Iconic-4, I was skeptical. I had tried compact CNC machines before, and many of them lacked the power and precision needed for serious projects. But after using the Iconic-4, I realized that not all small machines are built the same.

This one felt solid, reliable, and most importantly, accurate.

If you need a desktop CNC that delivers professional results, the Iconic-4 is worth a look. It’s designed for woodworkers, sign makers, and small business owners who need precision without the bulk of an industrial machine.

Specifications

| Feature | Details |

| Spindle Power | 1HP (800W) Electro-Spindle |

| Work Area | 24” x 24” x 4” |

| Supported Materials | Wood, plastics, acrylic, aluminum |

| Accuracy & Speed | High precision, smooth linear guideways |

| Software Compatibility | VCarve Desktop (included), works with Fusion 360, Aspire |

Performance

The Axiom Iconic-4 stands out for its rigid frame and precise motion system. This CNC doesn’t feel like a hobby machine, it’s closer to an industrial setup in a tabletop size.

- The electro-spindle runs quietly and delivers consistent cutting power.

- Aluminum frame construction eliminates vibration and improves accuracy.

- Speed vs. accuracy is well-balanced, fast enough for production but refined enough for detailed carvings.

This CNC is perfect for woodworking projects like furniture components, cabinetry, and decorative engravings, and it even handles soft aluminum well when used at the right speeds.

Maintenance & Longevity

A machine of this quality doesn’t need much daily maintenance, but regular cleaning and lubrication will extend its life.

- Dust collection is recommended to prevent buildup inside the system.

- The spindle is air-cooled, meaning no complicated water systems to manage.

- Linear bearings should be lubricated periodically to maintain smooth movement.

With proper care, the Axiom Iconic-4 can last 7-10 years, making it a long-term investment for serious CNC users.

Price & Value

The Axiom Iconic-4 is priced in the $3,000 to $4,500 range, depending on accessories and upgrades. It’s not the cheapest option, but you’re paying for a high-end build with professional features.

- Hidden costs may include additional software, router bits, and clamps.

- Compared to entry-level CNCs, this machine offers better precision and a more rigid structure.

- For small businesses and advanced users, the investment is justified by the machine’s performance and longevity.

If you need a CNC that delivers industrial-grade precision without taking up an entire workshop, this one is worth considering.

Who It’s Best For

The Axiom Iconic-4 is ideal for:

- Woodworkers, sign makers, and small business owners who need a compact but highly precise CNC machine.

- Users working with detailed engraving, cabinetry, or aluminum parts that require consistent accuracy.

- Professionals looking for a long-term investment rather than an entry-level machine.

It’s not the best choice for:

- Beginners on a budget, as the learning curve is steeper than basic models.

- Users who need high-speed production, since this machine prioritizes accuracy over cutting speed.

- Heavy-duty metalworkers, as it’s not designed for thick steel or industrial-scale projects.

6. Sherline 12″ Deluxe Tabletop Mill

I remember the first time I needed a CNC milling machine that could handle small metal parts with precision. Most tabletop models were either too weak or too large for my space. That’s when I came across the Sherline 12” Deluxe Tabletop Mill, a compact but powerful machine designed for precision milling in small workshops.

If you need a CNC mill for fine-detail work, this one stands out. It’s small, reliable, and built to last, making it an excellent choice for metalworkers, model makers, and precision machining.

Specifications

| Feature | Details |

| Spindle Power | 90V DC motor with electronic speed control |

| Work Area | 13.0” x 2.75” x 5.38” |

| Supported Materials | Aluminum, brass, wood, plastic, steel (light cuts) |

| Accuracy & Speed | 0.001” accuracy, variable speed (70–2800 RPM) |

| Software Compatibility | Compatible with Mach3, LinuxCNC, and Fusion 360 |

Performance

The Sherline 12” Deluxe Tabletop Mill delivers exceptional precision for small-scale metalworking and engraving. Unlike larger CNC routers, this machine focuses on fine detail rather than speed.

- Perfect for aluminum, brass, and other soft metals, but can also handle light steel cuts.

- Frame is made from high-quality aluminum, which keeps it lightweight yet rigid.

- It’s not built for rapid production, but it’s excellent for precision machining.

If you need a machine for detailed milling, jewelry work, or small prototype parts, this CNC mill is a great choice.

Maintenance & Longevity

Keeping the Sherline 12” Mill running smoothly doesn’t require much effort.

- Lubrication is key, especially for the lead screws and bearings.

- Cleaning after each use prevents dust buildup and extends motor life.

- Replacement parts are easy to find, and Sherline offers solid customer support.

With proper care, this machine can last 10+ years, making it a long-term investment for serious users.

Price & Overall Value

The Sherline 12” Deluxe Tabletop Mill falls into the $2,000 to $3,000 price range, depending on upgrades and accessories.

- Hidden costs include tooling, software, and additional clamps for certain projects.

- For hobbyists, it’s expensive but worth it if you need metalworking precision.

- For professionals, it’s a great value for small-batch production and prototyping.

If you need detailed, high-precision milling, this CNC mill is worth every dollar.

Who It’s Best For

The Sherline 12” Deluxe Tabletop Mill is ideal for:

- Model makers and machinists who need tight tolerances and fine control.

- Jewelry designers and precision metalworkers working with brass, aluminum, and steel.

- Hobbyists and professionals who want a small but powerful CNC mill.

But it’s not the best fit for:

- Woodworkers who need a large cutting area, this machine is built for metal, not big wood projects.

- Users looking for a high-speed CNC because this mill prioritizes precision over speed.

- Beginners with no CNC experience, it requires some learning and setup.

7. Bantam Tools Desktop CNC Milling Machine

When I first ventured into CNC milling, I was overwhelmed by the complexity and size of industrial machines. The Bantam Tools Desktop CNC Milling Machine felt like a breath of fresh air.

A compact, user-friendly device that didn’t compromise on capability. Designed for prototyping in aluminum, other soft metals, plastics, and more, it brings precision machining to your desktop.

Specifications

Before we get into performance, let’s look at the numbers. This will give you an idea of what the Bantam Tools machine is capable of.

| Feature | Details |

| Spindle Power | 28,000 RPM spindle |

| Work Area | 7” x 9” x 3.3” |

| Supported Materials | Aluminum, brass, wood, plastic, and other soft metals |

| Accuracy & Speed | Repeatability of ±0.001”; variable speed up to 250 inches per minute |

| Software Compatibility | Bantam Tools Milling Machine Software; supports EAGLE BRD, Gerber RS-274X, G-code, SVG |

If you’re working on precision prototypes, small mechanical parts, or circuit boards, this machine is built for that level of detail.

Performance

Once you start using this machine, one thing becomes clear: it’s made for precision work. Unlike larger CNC mills, this one is compact but still powerful enough to handle soft metals and detailed milling tasks.

- The high-speed 28,000 RPM spindle makes cutting aluminum and brass feel effortless.

- The rigid frame reduces vibration, which helps maintain accuracy over long runs.

- It’s not the fastest machine, but it trades speed for exceptional precision.

If you need clean, sharp cuts without excessive post-processing, this CNC does the job well.

Maintenance & Longevity

Like any high-precision machine, regular maintenance is important to keep it performing well.

- Clean the machine after every use to prevent material buildup, especially when working with metal.

- Lubricate moving parts periodically to keep the motion smooth and precise.

- Replacement parts and support are readily available from Bantam Tools, so keeping it in good shape for years is easy.

With proper care, you can expect this machine to last 7+ years, making it a strong long-term investment.

Price & Overall Value

At $6,999, the Bantam Tools Desktop CNC Milling Machine is not a budget option. But if you’re looking for professional-grade accuracy in a small footprint, it’s well worth considering.

- Hidden costs include tooling, work-holding accessories, and software upgrades, depending on your workflow.

- For hobbyists, the price is steep, but for professionals needing precise metal milling, it’s a solid investment.

- If you compare it to larger industrial mills, this machine delivers similar accuracy without taking up as much space.

If precision, build quality, and software integration matter to you, this machine delivers.

Who It’s Best For

The Bantam Tools Desktop CNC Milling Machine is ideal for:

- Engineers and product designers working with aluminum and prototype parts.

- Educators and makerspaces that need a compact, professional CNC mill.

- Small businesses and hobbyists looking for a high-accuracy desktop milling solution.

It’s not the best fit for:

- Woodworkers or large-scale users, as the work area is relatively small.

- Those needing high-speed production, since it prioritizes precision over cutting speed.

- Beginners looking for an entry-level CNC, as the price and setup might be overwhelming.

Conclusion

Finding the right tabletop CNC machine isn’t just about specs. It’s about choosing the right tool for your work, your goals, and your space.

We’ve explored seven of the best options, from budget-friendly starter models to professional-grade machines that handle precision milling. Each one has its strengths, but the best one for you depends on what you need to create.

Now, it’s time to take action.

Let’s find the machine that works for you. Contact us today to get started!