Fabric materials of all kinds are everywhere in our life. The clothes you wear, the sheets you sleep on, and the toys in your child’s hands are all fabric. And all these fabric products are cut by the fabric cutting machine.

You must have also used scissors to cut a piece of fabric for some reason in your life. The most simple and practical fabric cutting tool for family use is the scissors. However, for factories that produce clothes, beddings, and other fabrics, fabric cutting machines that increase productivity are the best choice. If you want to work in the garment or other textile industry and are hesitating to buy a fabric cutting equipment, please read this article.

The traditional textile industry generally uses scissors and other manual tools to cut fabric. With the development of technology, the electric fabric cutting tool has greatly improved efficiency. However, with the innovation of CNC technology, high-tech automatic fabric cutting machine brings more efficient and safer fabric cutting solutions to various manufacturing companies.

Electric fabric cutting device

The emergence of handheld electric fabric cutting tools has indeed reduced the amount of labor and improved efficiency. It is an indispensable fabric cutting tool for some small shops or fabric product lovers. But such fabric cutter also has great limitations. Since it is hand-held, deviations in accuracy are inevitable. In addition, the efficiency and accuracy of electric fabric cutters are far from enough for mass production of precise fabric products.

Therefore, the electric fabric cutter cannot meet the requirements for starting a fabric factory.

However, the advent of CNC technology and laser technology has ushered a new era in fabric cutting. Here, I would like to introduce you to two kinds of CNC fabric cutting machines. Their common features are high efficiency and good precision. They can fully meet the needs of mass production.

Digital fabric cutting machine

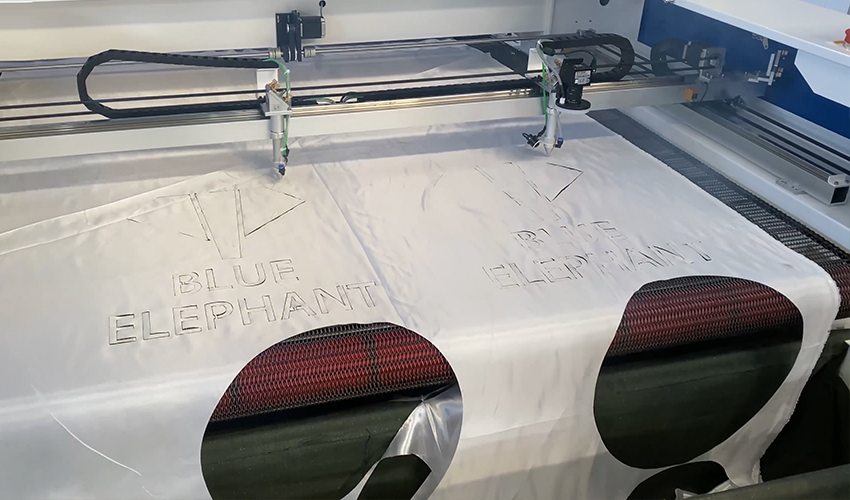

As an automatic fabric cutting machine, the digital cutting machine has wide applications in the cutting of flexible materials. It uses the up and down high-frequency vibration of the blade to cut the fabric. The digital cutting machine has such features as high precision, fast speed, no limitation to the cutting patterns, etc. So the digital fabric cutting machine has gradually improved or replaced the traditional flexible cutting equipment.

Digital cutting machines with different configurations can cut a variety of non-metal and flexible materials. For instance, fabric, foam, sponge, plastic, composite, PVC, KT board, rubber, carton board, leather, etc.

Characteristics of digital fabric cutting machine for sale

- The body of the oscillating knife cutting machine is welded by an integrated structure, which makes the machine less deformable and more stable in the operation.

- In terms of the cutter seat, the digital cutting machine can choose different cutters to cut different materials.

- Its aluminum honeycomb worktable is sturdy and durable. The vacuum adsorption function of the machine can absorb fabric materials firmly on the table during cutting.

- Equipped with a smart cutting system, the digital fabric cutting machine can realize cutting, semi-cutting, routering, drilling, and other processes.

- Automatic fabric cutting machine has an automatic loading and unloading device. It is possible to customize different rolling devices for different fabrics without worrying about mismatch problems. Besides, it can ensure that the conveying process is smooth and supple when cutting fabric.

- The digital cutting machine for sale has the automatic nesting function, which can make a layout quickly. This frees the nesting workers from the original boring manual work and greatly reduces the workload and time.

- With good cutting accuracy, the digital fabric cutting machine can realize the nesting and cutting of large-sized fabric materials.

Digital CNC fabric cutting machine recommendation

There are many models of fully automatic fabric cutting machines with a digital cutter on the market today. Some specialized oscillating knife cutting machines have multiple knives or an automatic feeding device. This can greatly improve the feeding and cutting speed of fabric. While some are combined with CNC router machines to form a CNC router digital cutting machine.

The specific digital fabric cutter machine is computer controlled and easy to operate. Computerized automatic nesting method not only reduces the time waste on manual layout, but also makes a more reasonable layout. This also helps reduce the labor force and avoids the waste of materials.

The industrial fabric cutting machine with a digital cutter supports multiple data formats. And it is compatible with common garment design and layout software. Its cutting edge is neat, smooth and without burrs.

Watch the following video to show the cutting process of a digital cutting machine.

The oscillating knife cutting machine is suitable for assembly line workshops and fabric production with higher product standardization.

Below I’d like to introduce a new type of CNC fabric cutting machine combined with a woodworking tool.

CNC router with digital cutter for non-metal materials

This CNC machine is a combination of a woodworking tool and a digital cutter. The digital cutter is for cutting various flexible materials. While the CNC router tool is to cut wood, acrylic, PVC, and other hard materials. Therefore, the CNC router machine with a digital cutter is more versatile and has a wider range of applications. It is quite popular with the customers in the advertising industry.

With the CCD automatic edge detecting system, this digital cutting machine is very suitable for cutting irregular shapes with patterns. For instance, UV boards, KT boards, and advertising signs. Without manual locating, it can automatically make cutting paths and cut fabric with strong recognition ability and accurate positioning. This greatly reduces positioning time and human error.

In addition, the ATC spindle of this oscillating knife cutting machine can cut various wood, acrylic, PVC, and other materials. The automatic tool change function greatly reduces downtime and human workload.

Therefore, if your business involves the processing of flexible materials and wood, this CNC digital cutter is the best choice.

Let’s watch the video together to understand the processing of this digital fabric cutting machine.

Fabric laser cutting machine

With the maturity of laser technology, laser fabric cutting machine is increasingly used in the textile industry. The garment pattern cutting, tie design, leather engraving, and denim fading can all be done by laser fabric cutter.

The fabric laser cutting machine is the laser cutting machine that uses CO2 as the laser source. A CO2 laser cutting machine uses the instantaneous high temperature generated by the laser to melt the material. With the movement of the laser head, it cut various patterns out from the fabric.

Laser fabric cutter machines are widely used by the clothing industry due to their reduced cost, flexibility, and anti-counterfeiting properties.

Features of laser fabric cutting machine

- Cutting fabric materials with a CO2 laser cutter has a good cutting result and no fabric sticking issues.

- The laser fabric cutter is quite cost-effective and has low consumption.

- With no mechanical pressure on the fabric, the cutting effect, accuracy, and speed of the cut-out products are very good.

- Smooth running, fine and clean cut, safe operation, and simple maintenance. The textile laser cutting machine can work continuously for 24 hours.

- Designed graphics with computer software, the CO2 laser cutter can cut any complex shape with high efficiency and accuracy.

- With precise calculations by nesting software, the fabric laser cutting machine can optimize the nesting. It can cut the entire piece of fabric into the desired shapes without any dies. This saves time and increases material utilization.

- The non-contact processing method has no harm to the fabric material. And the cut surface is flat and smooth, saving processing time.

- A laser fabric cutter can cut any shapes, including curved lines, quickly according to the program.

- The fabric laser cutting machine has a user-friendly human-machine interface. It allows users to select files directly on the machine without connecting to the computer.

- It has consistent laser power output at all locations on the worktable, and no limitation to cutting patterns.

- Compared with manual fabric cutters, the laser fabric cutter is safer. Especially in batch processing, the CO2 laser cutter will not fatigue and maintain good precision and consistency in mass production.

Fabric laser cutting machine recommendation

Due to the above advantages, the application of the fabric laser cutting machine in the textile industry is gradually increasing. Speed, flexibility, and precision are some of the irreplaceable advantages of laser cutting machines for fabric.

I’d like to introduce to you an entry-level CO2 laser cutting machine with a working size of 1300x900mm.

For laser cut fabric, we recommend the 130W laser power and honeycomb work surface. With vacuum adsorption function, the fabric can be firmly adsorbed on the table to prevent sliding during operation. Since it is thermal cutting, the fabric laser cutter requires a water chiller for cooling when in use.

You can also choose an automatic loading system and automatic feeding table for this CO2 laser cutting machine. This is for continuous cutting of coiled fabric. The video below shows the cutting process of our auto loading textile laser cutting machine. The working size of this CO2 laser fabric cutter is 1600x1000mm.

How much does a fabric cutting machine cost?

The fabric cutting machine price varies based on different machine types and specifications. For instance, the manual electric fabric cutter is much cheaper than the CNC automatic fabric cutting machine for sale.

An electric fabric cutting tool for sale may only cost you $100 to $300 on average. However, the CNC fabric cutting machine price could range from $2,000 to $10,000 on average. Besides, even the same machine type, the fabric cutting machine price can also have big differences.

The price range above is only for reference only. And the specific price is subject to the detailed specifications of each machine. So you need to negotiate with the machine supplier and decide the specifications in person.

How to choose a CNC industrial fabric cutting machine?

The CNC fabric cutting machine is an advanced fabric cutting solution in technology compared with traditional cutting machines. The computerized fabric cutting machine runs automatically and offers consistent quality and precision. Because the consistency of products in the same batch is essential for mass production. The CNC cutting machine can perfectly ensure the consistency of the products.

But how to choose a suitable automatic fabric cutting machine model?

The finished product cut by the digital cutting fabric machine is clean and smooth at the edges. And the cut pieces are precise in size, odorless, and environmentally friendly. In addition to fabric, the digital cutter can also cut leather, felt, wool, and other textile materials. Moreover, the digital cutting machine price is cost-effective. This makes it the first choice for many garment and leather industries.

If, besides the flexible materials, you also cut wood and acrylic sheets, please consider our digital cutter CNC router. This type of woodworking machine is very popular in the advertising industry. It has wide applications in cutting wooden plaques, acrylic characters, light signs, KT boards, PVC boards, UV boards, etc.

The fabric laser cutting machine is specifically for the garment, leather products, plush toys, beddings, and other fabric products. It can cut any patterns precisely from a variety of fabric materials. For some coil fabric materials, it can realize continuous cutting with an automatic feeding device. The laser fabric cutter can meet the processing needs of small enterprises and the mass production of large enterprises.

Customers can choose the fabric cutting machine according to your processing needs. If you still have any doubts, contact us immediately. We will recommend the most suitable fabric cutting machine for you.