A business I worked with ordered three CNC lathes from a supplier that looked great on paper—strong specs, fair price, smooth communication. But once the machines were delivered, the support stopped. No service. No parts. No help.

That kind of supplier can cost you more than just money.

Over the years, I’ve helped people choose CNC machines that actually fit their needs. I’ve visited manufacturers, tested machines in person, and followed up long after the sale.

This guide is based on that experience. You’ll find 7 CNC lathe suppliers that have earned their reputation through real results. I’ll explain how they product compare, machine quality, delivery time, and service so you can make a smart, confident choice.

So let’s get down to it!

Quick Comparison Chart

You’re not just comparing brands—you’re weighing real investments. This table gives you a side-by-side look at what each manufacturer truly brings to the table. From global leaders to hands-on partners, here’s how they stack up.

| Manufacturer | Core Strength | Industries Served | Service & Support | Machine Focus | Why Choose Them |

| DMG MORI | Ultra-precise, high-performance builds | Aerospace, medical, defense | Global tech centers, fast parts | Multi-axis, high-tolerance jobs | German-Japanese reliability with cutting precision trusted by global OEMs |

| Haas Automation | User-friendly and budget-conscious | Job shops, education, general machining | Local factory outlets, video support | Entry-level CNC lathes and mills | Easy to use, affordable, and supported by strong local networks |

| Blue Elephant CNC | Flexible, support-driven, and cost-effective | Furniture, signage, decoration, molds | Personalized 1-on-1 help, remote setup | CNC lathes for custom woodturning and light-duty hybrid work | Built for real-world users—customizable, hands-on guidance, and perfect for scaling small shops |

| Okuma | Total system control (hardware + CNC) | Automotive, aerospace, energy | In-house support, global centers | Heavy-duty, multi-operation platforms | Integrated control systems reduce complexity and boost uptime |

| Yamazaki Mazak | Smart factory automation systems | High-volume parts, mixed production | Global network, operator training | Multi-tasking centers and laser hybrids | Great for complex workflows and digital integration |

| DN Solutions | Rigid builds for tough environments | Oil & gas, construction equipment | Field support + strong distributor base | Large-part turning and heavy milling | Built for tough jobs with high chip loads and demanding specs |

| EMAG | Vertical automation + pick-up systems | Automotive, gear and shaft production | Europe-heavy support, remote tools | Gear cutting, shaft turning, automation-first lathes | Ideal for volume production with built-in material handling |

1. DMG MORI

I remember thinking, “This company must be doing something right to be everywhere I look.” You see their machines in factories, trade shows, and online forums. That kind of presence doesn’t happen by accident.

DMG MORI began in 1948 and has grown into one of the most recognized CNC machine manufacturers in the world. With headquarters in both Germany and Japan, they operate in over 40 countries and employ more than 12,000 people.

Product Range

- CNC Lathes: Turning centers and multitasking models

- Machining Centers: Vertical, horizontal, and 5-axis options

- Automation & Software: Tool monitoring, planning, and control systems

Services and Support

- Contact Options: Email, phone, and on-site visits

- Tech Support: Regional teams for fast issue handling

- Training: Operator and engineer programs

- Remote Monitoring: Built-in tools to track machine status

Certifications & Compliance

- ISO 9001: Quality management

- ISO 14001: Environmental practices

- CE-certified: Compliant with European safety standards

- Sustainability: Focused on clean production methods

Key Takeaways

DMG MORI is known for precision, reliability, and strong after-sales support. It’s best suited for larger operations in industries like aerospace and automotive. However, the machines are expensive and may take longer to set up and learn.

2. Haas Automation, Inc.

If you want a machine that’s simple, solid, and gets the job done, Haas could be a good fit. Their machines are built to be easy to use and dependable, without extra complications.

Founded in 1983 in Oxnard, California, Haas is now the largest CNC machine builder in the U.S. Their machines are used worldwide—from home shops to large factories—and every one is made in the USA.

Product Range

- Vertical Machining Centers (VMCs): Let you handle most milling jobs with confidence

- Horizontal Machining Centers (HMCs): Help you improve accuracy and chip control

- CNC Lathes: Give you a solid platform for both simple and complex turning work

- Rotary Tables: Let you expand into 4- or 5-axis machining if you’re ready for more

Services and Support

- You can reach them by phone, email, or through your local Haas Factory Outlet

- You’ll get fast responses, and many service teams offer same-day visits

- You can also access tutorials, manuals, and hands-on training if you need help learning

Certifications & Compliance

- ISO 9001: Shows you the company follows strict quality standards

- CE-compliant: Gives you peace of mind that machines meet EU safety rules

Key Takeaways

Haas is a great fit if you want simple, budget-friendly CNC machines that work hard and are easy to run. However, you may find fewer advanced features compared to higher-end brands.

3. Blue Elephant CNC

A furniture maker once told me, “If this machine doesn’t hold up, I’m out of business.” He chose Blue Elephant and doubled his output in 3 months. When he hit a snag zeroing the machine, their tech jumped on a call and stayed until the first cut was perfect. That kind of support earns trust.

Founded in 2013 in Jinan, China, Blue Elephant CNC builds machines that are practical, powerful, and built for daily use. Today, they serve users in over 80 countries, especially wood, foam, and sign production.

Product Range

- CNC Lathes: Built for smooth, consistent turning on wood and soft materials

- CNC Routers: Covers everything from compact 3-axis to high-performance 5-axis units

- Laser Cutters: CO₂ and fiber systems for precise engraving and clean cuts

- Stone & Foam CNC Machines: Ideal for carving, modeling, and shaping dense material

Services and Support

- Contact options: You can reach them by email, WhatsApp, phone, or chat

- Support style: Clear, patient guidance—before, during, and after setup

- Installation help: Step-by-step walkthroughs via video or remote screen share

- Training: Hands-on instructions, video demos, and follow-up check-ins

Certifications & Compliance

- CE Certified: Meets EU machine safety requirements

- ISO 9001: Confirms standardized quality control

- SGS Audited Supplier: Independently verified for manufacturing quality

Key Takeaways

Blue Elephant CNC gives you reliable performance, responsive support, and machines that are ready for real work. If you’re building furniture, making signs, or crafting custom designs, this brand helps you get serious results—without the guesswork.

4. Okuma Corporation

If you’ve ever run long production jobs, you know how much it matters when a machine holds tight tolerances hour after hour. That’s where Okuma shines. Founded in 1898 in Nagoya, Japan, Okuma has over 120 years of experience building CNC machines.

They design both their hardware and software in-house, so you get full system control without compatibility issues. With global service centers and a reputation for stability, Okuma gives you the confidence to scale your operations without worrying about downtime.

Product Range

- CNC Lathes: High-stability turning for consistent, accurate results

- Multitasking Machines: Let you mill, drill, and turn on the same setup

- Double Column Machining Centers: For large and heavy-duty parts

- OSP Control Systems: Okuma’s proprietary control—easy to use, powerful, and dependable

Services and Support

- How you can reach them: Through local reps, phone, or online service

- Support experience: Technicians are well-trained and quick to respond

- Training: In-person sessions, video guides, and live demos

Certifications & Compliance

- ISO 9001: Ensures standardized quality processes

- ISO 14001: Focus on clean, responsible manufacturing

- CE Certified: Meets European safety standards

Key Takeaways

Okuma is a strong pick if you want stable performance, high precision, and full system control. You’ll get machines that are built to last with smart, integrated software. However, the learning curve for their proprietary control system may take some time—especially if you’re used to standard interfaces.

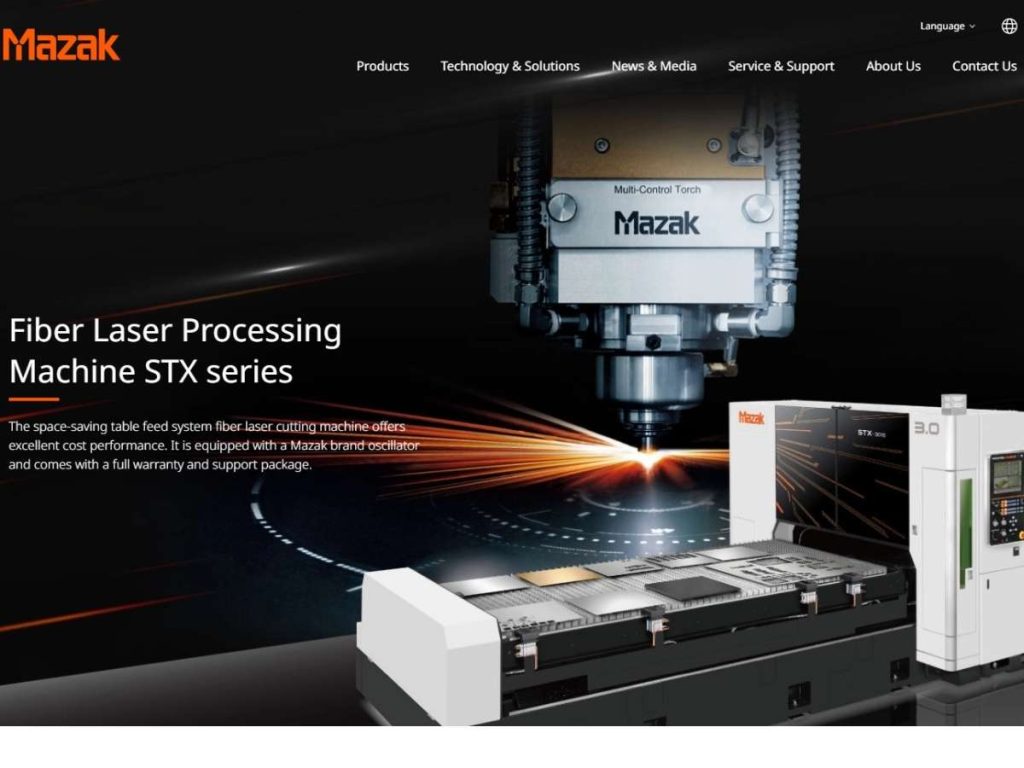

5. Yamazaki Mazak

If you’re looking for a CNC lathe that combines advanced features with easy operation, Mazak is worth considering. They build machines that balance innovation with usability, making them suitable for a wide range of users.

Founded in 1919 in Nagoya, Japan, Yamazaki Mazak has over 100 years of experience. With factories in Japan, the USA, the UK, Singapore, and China, they offer global access and dependable support.

Product Range

- CNC Lathes: High-precision turning centers designed for complex machining tasks.

- Multi-Tasking Machines: Combine milling and turning operations, enhancing efficiency.

- Vertical and Horizontal Machining Centers: Versatile solutions for various milling applications.

- Laser Processing Machines: Advanced systems for precise cutting and engraving.

Services and Support

- Communication Channels: You can reach them via phone, email, or through their extensive network of local offices.

- Responsiveness: Known for prompt and knowledgeable support to minimize downtime.

- Training Programs: Offers comprehensive training to ensure you maximize machine capabilities.

Certifications & Compliance

- ISO 9001: Demonstrates a commitment to consistent quality management practices.

- CE Compliance: Ensures adherence to European safety and environmental standards.

- Environmental Certifications: Showcases dedication to sustainable manufacturing processes.

Key Takeaways

Mazak is a strong choice if you want advanced machines that simplify complex jobs. You’ll benefit from their wide product range and dependable global support. However, some of their systems—especially multi-tasking setups—may come with a steeper learning curve if you’re new to CNC or switching from simpler equipment.

6. DN Solutions.

If you want a CNC lathe that delivers power and stability without overcomplicating things, you should take a serious look at DN Solutions.

Formerly known as Doosan Machine Tools, the company was founded in 1976 in South Korea and has earned a reputation for building high-rigidity machines with dependable performance. Now operating under the DN Solutions brand, they serve customers in over 70 countries, with service centers positioned around the globe to keep support close at hand.

Product Range

- CNC Lathes: Built for heavy cutting and consistent turning

- Horizontal & Vertical Machining Centers: For fast, flexible milling jobs

- Multi-Axis Machines: Combine turning and milling in one setup

- Automation Packages: Robot loaders and pallet systems for hands-free production

Services and Support

- How to reach them: Local reps, phone support, and online service portals

- Response time: Known for fast troubleshooting and parts delivery

- Training options: Hands-on programs, manuals, and remote guidance

Certifications & Compliance

- ISO 9001: Quality system certified

- CE Certified: Meets EU safety and performance standards

- Environmental Certifications: Reflects sustainable manufacturing practices

Key Takeaways

DN Solutions gives you tough, reliable machines that are built to handle demanding workloads. The support is strong, and the product range is wide enough to grow with your business. However, some of their machines can be bulkier and may require more shop space than compact competitors.

7. EMAG GmbH & Co. KG

If you’re machining high volumes of precise, complex parts—especially in automotive—you’ve probably come across EMAG. And if you haven’t yet, you should.

Founded in 1867 in Salach, Germany, EMAG has specialized in turning, grinding, and automation for over 150 years. What makes them different is their focus on vertical pick-up turning technology—a system where the machine automatically loads the workpiece without external automation. It saves you time, labor, and floor space.

Product Range

- CNC Turning Centers: Vertical pick-up lathes ideal for mass production

- Grinding Machines: For ultra-precise surfaces and hardened materials

- Gear Hobbing & Shaping: Designed specifically for automotive transmission components

- Automation Systems: Gantry loaders and modular automation built into the machine

Services and Support

- How you can reach them: Local reps, phone, email, and online portals

- Support network: Strong presence across Europe, North America, and Asia

- Training: On-site, remote, and custom operator programs

Certifications & Compliance

- ISO 9001: For quality management

- CE Certified: For safety and compliance within the EU

- Environmental & Energy Certifications: EMAG promotes resource-efficient machine design

Key Takeaways

EMAG is a smart fit if you’re producing high-volume, high-precision parts and want automation built right into the machine. The vertical design makes your setup cleaner and faster. However, their machines are built with specific applications in mind—so if you’re looking for general-purpose turning, EMAG may not offer the flexibility you need.

Conclusion

We just covered 7 CNC lathe manufacturers each with their own strengths, specialties, and support styles. Some are global leaders. Some are hands-on helpers. All of them offer something valuable.

But only one will truly fit your goals, your space, and your customers.

You go back. You reread. You compare. Then you reach out.

Because moving forward doesn’t start with another Google search. It starts with a decision.

Contact us today and let’s figure it out together.