A CNC machine can transform your production process, but how much should you actually spend on one? I asked myself the same question when I first considered buying one. The price differences were staggering.

That’s because there’s more to the cost than just the machine itself. Features, capabilities, and even operational expenses all play a role.

I’ve spent years analyzing CNC pricing and helping businesses invest wisely. This guide cuts through the noise and gives you real, practical insights.

By the time you finish reading, you’ll know exactly what impacts CNC machine prices, from entry-level models to high-performance systems. No more guesswork.

Ready to make an informed decision?

Let’s start!

1. Types of CNC Machines and Their Price Ranges

The CNC machine landscape is diverse, with each type designed to meet specific manufacturing needs. Understanding these variations is crucial to aligning your investment with your operational requirements.

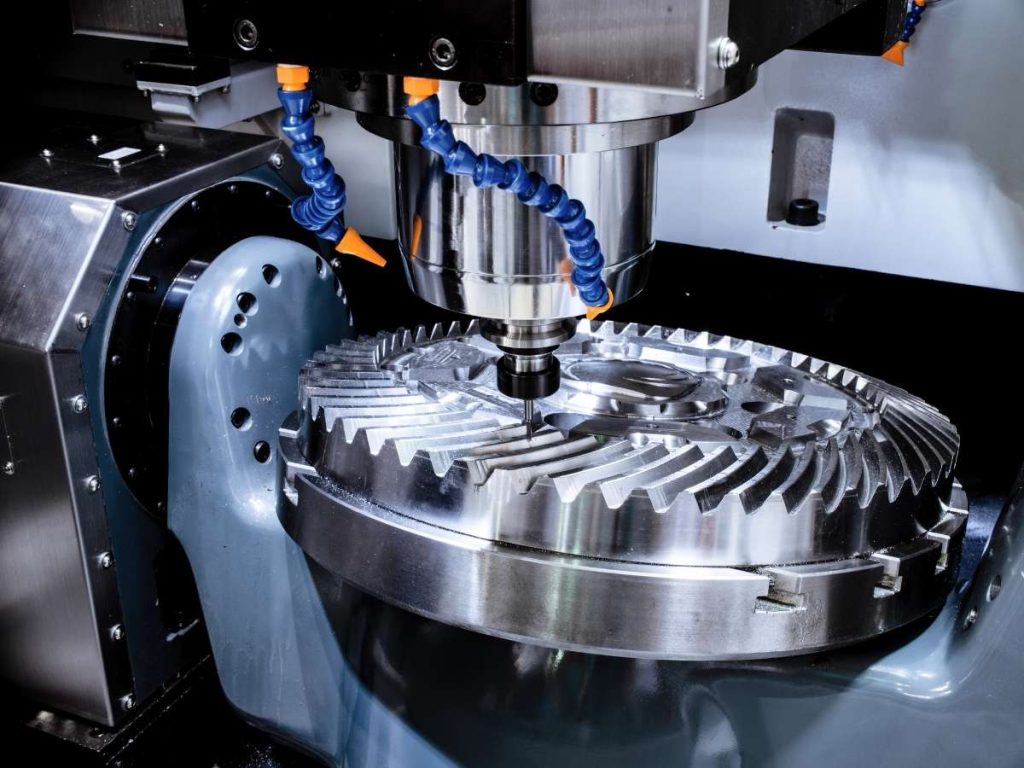

- CNC Milling Machines: These machines are adept at cutting and drilling materials with precision. Entry-level models suitable for small workshops start around $30,000, while advanced industrial versions can exceed $200,000.

- CNC Lathes: Ideal for producing symmetrical objects like shafts and cylinders, basic CNC lathes begin at approximately $25,000. High-precision models with enhanced features can surpass $100,000.

- CNC Routers: Commonly used for woodworking, plastics, and softer materials, desktop CNC routers start at about $5,000. Industrial-grade routers, capable of handling larger projects, can reach up to $150,000.

- CNC Plasma Cutters: Utilized for cutting conductive metals, these machines range from $15,000 for entry-level models to over $300,000 for high-definition systems.

- CNC Laser Cutters: Known for precision in cutting and engraving, laser cutters start around $10,000, with industrial models exceeding $500,000, depending on power and capabilities.

- CNC Grinders: Specialized for surface finishing and high-precision grinding, these machines can range from $50,000 to over $500,000, influenced by accuracy and complexity.

2. CNC Machine Fee: Initial Purchase Cost

When investing in a CNC machine, the initial cost goes beyond just the sticker price. While some businesses may be tempted to focus solely on the base price, overlooking additional factors can lead to unexpected expenses or even purchasing the wrong machine for your needs.

Machine Size and Capacity

Larger machines capable of handling bigger workpieces generally come with higher price tags. If you’re working with large metal sheets, industrial components, or high-volume production, a compact machine simply won’t cut it. You’ll need a machine with a bigger work envelope, which often means a higher price.

I learned this firsthand when I initially considered a smaller model to save money, only to realize it couldn’t handle the size of our typical jobs. Upgrading later ended up costing more than if I had just bought the right size from the start.

Complexity and Features

Machines equipped with advanced functionalities such as multi-axis capabilities, automatic tool changers, and enhanced precision systems tend to be more expensive. If you’re producing complex parts with intricate details, you’ll need more than just a basic three-axis machine. A machine with an automatic tool changer saved us hours of downtime every week, proving that the upfront cost was well worth it.

Brand and Build Quality

Reputable brands known for durability and reliability may command higher prices but often offer better long-term value. I once tried to cut costs by looking at lesser-known brands, thinking I was getting a bargain. Eventually, we switched to a trusted brand, and despite the higher upfront investment, the reliability and service support paid off in the long run.

If uptime and precision matter, spending a little extra for a well-known brand can save you major headaches.

3. CNC Machine Cost per Hour: Operational Expenses

Beyond the purchase price, operational costs significantly impact the total cost of ownership. Key considerations include:

- Machine Depreciation: The purchase price of a CNC machine, divided over its expected operational lifespan, contributes to the hourly operating cost. For example, a $100,000 machine with a 10-year lifespan operating 2,000 hours per year adds $5 per hour to costs.

- Labor Costs: Skilled operators are essential for efficient CNC machine operation. Operator wages typically range from $20 to $50 per hour, depending on experience and region.

- Material Costs: The type, weight, and volume of materials used directly affect costs. For instance, materials like titanium are more expensive than aluminum or steel.

- Tooling Expenses: Cutting tools and consumables require regular replacement. High-quality tools may have higher upfront costs but can lead to long-term savings through increased durability and performance.

- Energy Consumption: Machines with higher power requirements will increase electricity expenses. Investing in energy-efficient models can mitigate these costs.

- Maintenance and Repairs: Regular maintenance is essential to prevent costly downtime. Annual maintenance costs can range from $1,000 to $5,000, depending on the machine’s complexity and usage.

4. Hidden Costs and Long-Term Expenses

When budgeting for a CNC machine, it’s essential to account for hidden costs that may not be immediately apparent:

- Software Licenses: Operating a CNC machine requires specialized software, which may involve significant licensing fees.

- Installation and Setup: Proper installation and calibration are crucial for optimal performance. These services can add to the initial expenditure.

- Facility Modifications: Accommodating a new CNC machine may necessitate electrical upgrades, ventilation improvements, or structural changes to you.

- Depreciation and Resale Value: Over time, machines depreciate. Understanding the potential resale value can aid in long-term financial planning.

5. Considerations When Selecting a CNC Machine

Choosing the right CNC machine requires a thorough assessment of your business’s specific needs. A rushed decision can lead to costly inefficiencies, while a well-planned investment can streamline operations and boost profitability. Here’s what you need to consider:

Material Compatibility

Make sure the machine can handle the materials you work with, whether metals, plastics, or composites. Not all CNC machines are built to cut every material, and using the wrong one can lead to excessive wear and tear or even machine failure. I once saw a shop invest in a machine that wasn’t rated for hardened steel, and within months, they faced serious spindle issues.

Production Volume

Align the machine’s capabilities with your expected production levels to avoid underutilization or overextension. If you’re only making a few parts per week, investing in a high-speed, high-capacity machine might be overkill. On the flip side, if you’re running large batches, a lower-end machine could become a bottleneck, slowing down your entire operation.

Precision Requirements

Machines vary in accuracy. Select one that meets the tolerance levels required for your products. If you’re producing aerospace or medical components, even the smallest deviation can be unacceptable. I once worked with a company that tried to save money by choosing a machine with lower precision, only to lose a contract because their parts didn’t meet the client’s strict tolerance requirements.

Space and Infrastructure

Consider the physical space available and any necessary facility modifications to accommodate the machine. Some CNC machines require reinforced floors, dedicated electrical circuits, or additional ventilation, all of which add to setup costs. I once heard about a business that purchased a large CNC machine without measuring their facility doorways, only to realize they had to remove part of a wall to get it inside!

6. Cost Comparison: Buying vs. Leasing vs. Outsourcing

Choosing how to acquire CNC machining capabilities is a crucial decision for any business. The 3 main options, buying, leasing, and outsourcing, all have distinct financial and operational impacts. Below is a side-by-side comparison to help you determine the best fit for your needs.

| Factor | Buying | Leasing | Outsourcing |

| Initial Investment | High upfront cost, ranging from $30,000 to $500,000+ depending on the machine type. | Lower upfront cost, typically requiring a deposit and first payment. | No upfront investment in machinery; costs are per project or production run. |

| Monthly Costs | No monthly leasing fees, but loan payments may apply if financed. | Fixed monthly lease payments, which may be higher than ownership costs over time. | Variable costs based on usage; no fixed monthly expenses unless under contract. |

| Long-Term Cost | Lower cost in the long run if the machine is used extensively. | Can be more expensive over time due to continuous payments. | Costs can add up if production volumes are high over time. |

| Flexibility | Limited flexibility, once purchased, it’s a long-term commitment. | More flexible, leases can be short-term or long-term based on needs. | Highly flexible, businesses only pay for what they need when they need it. |

| Maintenance Responsibility | Owner is responsible for all repairs, maintenance, and downtime. | Maintenance may be included in the lease agreement, reducing operational burden. | Supplier is responsible for maintenance, ensuring machines stay in top condition. |

| Technology Upgrades | Limited to the technology purchased; upgrades require a new investment. | Often allows for upgrades to newer models at the end of the lease term. | Access to the latest technology without any additional investment. |

| Scalability | Can be limiting if demand fluctuates; expansion requires additional purchases. | More scalable, businesses can upgrade or change machines as production needs evolve. | Easily scalable, can ramp production up or down without capital investment. |

| Best for Businesses That… | Need full control over production and plan to use the machine extensively. | Want access to newer machines without long-term commitment or high upfront costs. | Have fluctuating demand or lack the expertise to operate CNC machinery in-house. |

Conclusion

Buying a CNC machine isn’t just a purchase, it’s a serious investment. I learned that the hard way when I underestimated the extras.

We’ve gone over the full cost picture:

- Purchase fees

- Operating costs

- What to watch out for

- Whether buying, leasing, or outsourcing fits you best

Blue Elephant offers CNC machines with dependable pricing and good support.

Now the question is, are you ready to take the next step? Contact us now to get started!