Ever had a CNC supplier that seemed helpful—right up until you needed support?

I have. Before the sale, they promised top-tier quality and fast service. After? Silence. No response. No help. Just frustration.

I don’t want you to go through that.

Taiwan has some of the best CNC machine manufacturers, but not all deliver on their promises. Some are reliable partners. Others disappear the moment you need them.

In this guide, I’ll break down seven trusted manufacturers based on product quality, pricing, reliability, and after-sales support—so you can make the right choice from the start.

By the end, you’ll know how to evaluate a manufacturer before spending a dime.

Let’s get started!

1. Quick Comparison Chart

Choosing the right CNC manufacturer takes careful research, but sometimes, a quick side-by-side comparison helps to see the bigger picture. Below, you’ll find a detailed comparison of the top CNC manufacturers from Taiwan, giving you a glimpse of their strengths, specialties, and key offerings.

| Manufacturer | Year Established | Specialties | Certifications | Global Support | Notable Features |

| Victor Taichung | 1954 | CNC Lathes, Machining Centers, Plastic Injection Molding Machines | ISO 9001, ISO 14001, TÜV Rheinland | Worldwide service centers | Strong after-sales support, in-house manufacturing |

| Goodway Machine Corp. | 1975 | CNC Turning Centers, Swiss-Type Lathes, Multi-Axis Turning Machines | ISO 9001, ISO 14001 | Global distribution & service network | Focus on high-speed, high-precision turning |

| YCM (Yeong Chin Machinery) | 1954 | Vertical & Horizontal Machining Centers, CNC Lathes, 5-Axis Machines | ISO 9001, ISO 14001, CE Certification | Over 30 service centers worldwide | Rigid machine structures, Smart automation |

| Hartford (She Hong) | 1965 | Large-Scale Vertical & Horizontal Machining Centers, 5-Axis Machines, Gantry Mills | ISO 9001, ISO 14001, CE Certification | Over 20 global service locations | AI-driven diagnostics, automation integration |

| SYIL Machine Tools | 2001 | Small to Medium-Sized CNC Mills, Lathes, Drill Tap Centers | ISO 9001, ISO 14001, CE, CSA | Global presence with service centers in 15+ countries | Affordable yet precise CNC machines for small businesses |

| Chien Wei Precise Technology | 1981 | CNC Grinding Machines, CNC Milling Machines, EDM Machines, 5-Axis Machining Centers | ISO 9001, ISO 14001, CE Certification | International support network | Specializes in high-precision grinding & EDM machining |

With this quick overview, you have a solid starting point. Now, let’s break things down further and explore each manufacturer in more depth.

2. Victor Taichung Machinery Works Co., Ltd.

I’ve seen plenty of CNC manufacturers come and go, but Victor Taichung has been around since 1954—and there’s a reason for that. Based in Taichung City, Taiwan, they started as a small machine tool company and have grown into one of the country’s largest CNC manufacturers.

They focus on innovation and long-term durability. If you’ve been burned by machines that break down too soon or lack support, you’ll appreciate how Victor Taichung builds its equipment. Their goal isn’t just to sell machines—they aim to provide reliable, long-term solutions for businesses worldwide.

Products & Specialties

Victor Taichung makes a range of CNC machines, including:

- CNC Lathes: Used for precise metal cutting and shaping.

- Machining Centers: Vertical and horizontal machines designed for milling, drilling, and tapping.

- Plastic Injection Molding Machines: Used to produce plastic parts in various industries.

What stands out is their in-house manufacturing. Many companies source parts from different suppliers, but Victor Taichung handles casting, machining, and assembly themselves. This means tighter quality control and fewer surprises when the machine arrives at your shop.

Certifications & Compliance

If you care about quality standards (and you should), Victor Taichung holds:

- ISO 9001: A global standard for quality management.

- ISO 14001: Focused on environmental responsibility.

- TÜV Rheinland Certificatio: A third-party endorsement of their product quality.

- Green Building Label (Bronze Level): Recognized for energy efficiency and sustainability.

These certifications tell you that their machines are built to last—and that they aren’t cutting corners on quality.

Customer Support & Services

I’ve learned the hard way that a machine is only as good as the support behind it. That’s where Victor Taichung does well. They don’t just sell you a machine and disappear.

Here’s what they offer:

- Global Support Centers: They have eight service centers across the United States, Europe, and Asia, so you’re not left waiting for help.

- After-Sales Service: If your machine needs maintenance or troubleshooting, they have technicians who respond promptly.

- Warranties: While they don’t list specifics, their warranty covers essential components, and they actually follow through on claims.

- Operator Training: If you’re new to CNC machines, they offer hands-on training to help your team use their equipment properly.

One of my biggest frustrations with CNC manufacturers is the lack of spare parts when things break down. Victor Taichung stocks parts globally, so you don’t have to wait months for replacements.

Final Verdict

Victor Taichung is a solid choice if you want a CNC manufacturer that stands behind its machines. They’ve been in the business for over six decades, and their commitment to quality, service, and durability makes them one of Taiwan’s best.

That said, their machines aren’t the cheapest. If you’re shopping purely on price, you might find more budget-friendly options elsewhere. But if you value precision, long-term reliability, and good support, they’re worth considering.

Would I recommend them? Yes—but only if you prioritize quality over upfront cost.

3. Goodway Machine Corp.

I first came across Goodway Machine Corp. when a manufacturer told me, “If you want a lathe that holds up under pressure, get a Goodway.” At the time, I wasn’t sure what made them different. But after seeing their machines in action, I understood—they’re built for precision and endurance.

Founded in 1975 in Taichung, Taiwan, Goodway has grown into one of the largest CNC lathe manufacturers in Taiwan. Their focus is simple: make CNC machines that run smoothly, require less maintenance, and deliver consistent accuracy.

Products & Specialties

Goodway specializes in:

- Horizontal Lathes: Ideal for high-speed turning and precision metal cutting.

- Vertical Lathes: Built for heavy-duty machining, especially for large-diameter parts.

- Swiss-Type Lathes: If you need tiny, intricate components with ultra-tight tolerances, these are a solid choice.

- Multi-Axis Turning Centers: These combine milling and turning into one setup, reducing the need for multiple machines.

One thing that stands out? Their focus on automation. Many of their machines integrate robotic loading and advanced control systems, making them a smart choice for high-production environments.

Certifications & Compliance

Goodway follows strict manufacturing standards and holds:

- ISO 9001:2015: Ensures their quality control processes are up to global standards.

- ISO 14000: Reflects their commitment to environmentally friendly manufacturing.

These certifications mean you’re not just buying a CNC machine—you’re investing in a product that meets international quality and sustainability requirements.

Customer Support & Services

Support can make or break a CNC investment. Goodway provides:

- After-Sales Support: They offer on-site troubleshooting, remote diagnostics, and spare parts availability. Their service teams respond quickly, which is crucial when downtime means lost revenue.

- Training Programs: They provide hands-on operator training for companies and CNC education programs for technical schools. This helps businesses get the most out of their machines.

- Global Service Network: With support centers in the U.S., Europe, and Asia, customers can access assistance without long wait times.

Final Verdict

Goodway makes machines that last, but they aren’t the cheapest option on the market. Their lathes are built for long-term reliability, making them a great fit for businesses focused on precision and high-volume production.

The downside? Some of their high-end models come at a premium, and if you need fully customized machines, your options may be limited. However, if you want a CNC lathe that delivers accuracy, speed, and strong support, Goodway is a solid choice.

4. YCM (Yeong Chin Machinery Co., Ltd.)

Finding the right CNC machining center can be frustrating. Some machines promise high precision but wear out too soon. Others boast automation features but require endless adjustments. I learned this the hard way after dealing with machines that couldn’t hold accuracy over time.

That’s when I heard about YCM (Yeong Chin Machinery Co., Ltd.). A manufacturer I trusted said, “If you want a CNC that stays precise year after year, YCM is built for that.”

Founded in 1954 in Taichung, Taiwan, YCM has spent decades perfecting vertical and horizontal machining centers, turning centers, and 5-axis machines. Their goal is clear: build machines that last, maintain accuracy, and integrate automation without unnecessary complexity.

Products & Specialties

YCM produces a range of CNC machines, including:

- Vertical Machining Centers: Best for milling, drilling, and tapping operations.

- Horizontal Machining Centers: Designed for high-efficiency metal cutting with multi-sided machining capability.

- CNC Turning Centers: Used for precision turning and lathe operations.

- 5-Axis Machining Centers – Ideal for complex, multi-surface machining required in aerospace and medical industries.

One thing I appreciate is their focus on high-rigidity machine structures. They design their machines to minimize vibration and maximize accuracy, which means better surface finishes and longer tool life.

Certifications & Compliance

YCM follows strict quality control standards and holds:

- ISO 9001: Ensures that their manufacturing process meets global quality standards.

- ISO 14001: Shows their commitment to environmentally responsible production.

- CE Certification: Required for machines sold in Europe, proving compliance with safety and environmental regulations.

These certifications mean you’re getting machines that meet international standards for reliability and performance.

Customer Support & Services

A great machine is useless without good support. Here’s what YCM offers:

- After-Sales Service: They provide on-site machine diagnosis, spare parts replacement, and technical troubleshooting.

- Smart Machine Monitoring: Some models include real-time performance tracking, so you can prevent breakdowns before they happen.

- Training Programs: They offer operator and maintenance training, covering everything from basic controls to advanced programming.

- Global Support Network: YCM has service centers in over 30 countries, ensuring you get local support when needed.

What I really like is their investment in digital solutions. Their smart monitoring systems help you track machine efficiency, detect issues early, and reduce downtime.

Final Verdict

If you need high-speed, high-precision CNC machines with a focus on automation and durability, YCM is a strong choice. Their rigid machine designs and smart technology features make them ideal for high-precision industries.

The downside? Their advanced automation features may require a learning curve if you’re used to simpler systems. However, if you’re serious about precision and long-term reliability, YCM is worth considering.

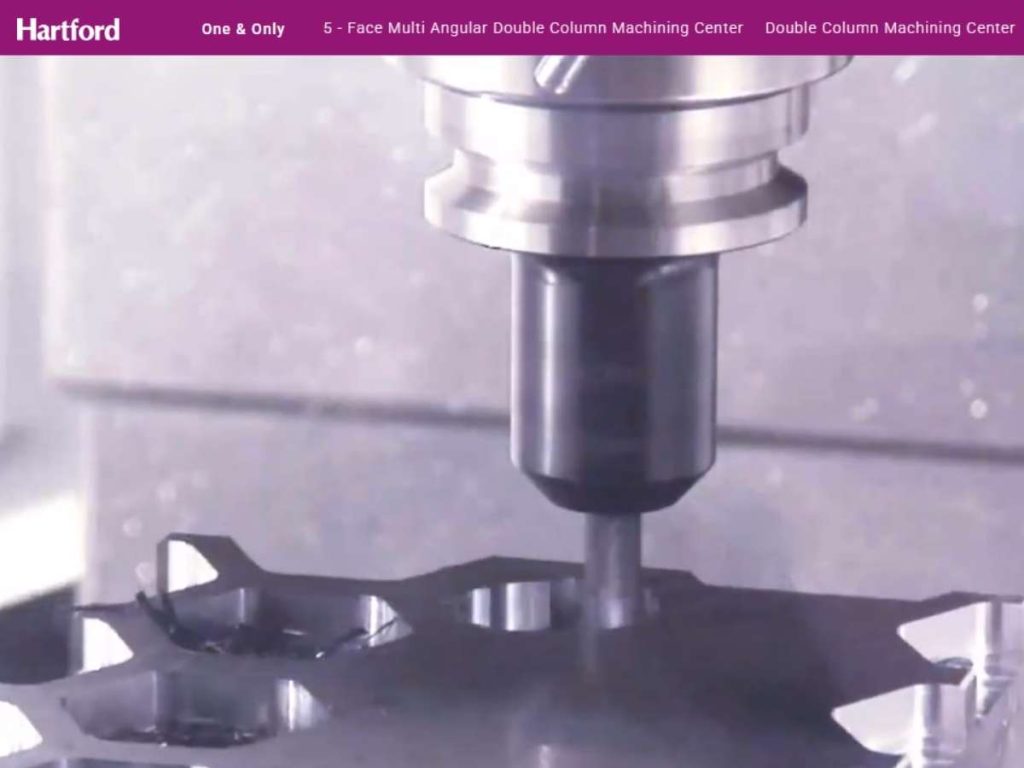

5. Hartford (She Hong Industrial Co., Ltd.)

When it comes to large-scale CNC machining, Hartford is a name that keeps coming up. I once asked a factory owner, “What do you use for machining heavy parts?” Without hesitation, they said, “Hartford. It’s built for real production work.” That stuck with me.

Founded in 1965 in Taichung, Taiwan, She Hong Industrial Co., Ltd., better known as Hartford, has built a strong reputation for manufacturing high-performance CNC machining centers. Their machines are known for handling large, complex workpieces with precision.

Products & Specialties

Hartford specializes in:

- Vertical Machining Centers: Designed for high-speed milling, drilling, and cutting.

- Horizontal Machining Centers: Built for multi-sided machining with efficiency.

- 5-Axis Machining Centers: Ideal for complex, multi-surface machining used in aerospace and medical industries.

- Gantry-Type Machining Centers: Best for heavy-duty, large-scale parts such as aircraft components.

One thing Hartford does well is integrating automation into their machines. Many of their models come with AI-driven diagnostics and real-time monitoring, which can reduce downtime and improve accuracy.

Certifications & Compliance

Hartford follows international quality standards and holds:

- ISO 9001: Ensures consistent quality control in manufacturing.

- ISO 14001: Focuses on environmentally responsible production.

- CE Certification: Required for machines sold in Europe, proving compliance with safety and performance regulations.

These certifications mean their machines are built to meet strict global standards.

Customer Support & Services

CNC breakdowns can cost you time and money, so strong support matters. Hartford offers:

- After-Sales Support: They provide on-site maintenance, remote troubleshooting, and replacement parts.

- Smart Diagnostic Systems: Some machines include AI-powered self-diagnosis, reducing unexpected failures.

- Training Programs: They offer operator training for new buyers and advanced programming courses for experienced users.

- Global Service Centers: Hartford has support teams in over 20 countries, ensuring help is available when needed.

I’ve heard from machine operators who say Hartford’s customer service is responsive, which is a huge plus if you need urgent repairs.

Final Verdict

Hartford is a great choice if you need a heavy-duty, high-precision CNC machining center. Their large-format machines, smart technology, and automation features make them ideal for industries that require precision on big parts.

The drawback? These machines take up a lot of space and may require specialized setup and training. But if you’re working with complex, large-scale machining, Hartford is a solid investment.

6. SYIL Machine Tools Co., Ltd.

I remember when I first started looking for a CNC machine that wouldn’t break the bank but still offered solid performance. That’s when I stumbled upon SYIL, a family-owned business established in 2001.

Based in Ningbo, China, SYIL has supplied over 12,000 machines worldwide, focusing on making precision CNC machines accessible to small businesses and hobbyists. Their mission is clear: provide affordable yet high-quality CNC solutions.

Products & Specialties

SYIL offers a range of CNC machines:

- Vertical Mills: Ideal for milling tasks, these machines are compact yet powerful. Models like the X5, X7, X9, and X11 cater to various needs.

- Lathes: Their L2, L3, and L4 lathes are designed for precision turning operations.

- Drill Tap Centers: The T5 and T7 models are perfect for high-speed drilling and tapping tasks.

What impressed me was their focus on making these machines both affordable and reliable, a combination that’s hard to find.

Certifications & Compliance

SYIL is committed to quality and environmental responsibility. They hold:

- ISO 9001:2015: Ensures their manufacturing processes meet international quality standards.

- ISO 14001:2015: Demonstrates their commitment to environmentally sustainable practices.

- CE and CSA Compliance: Their machines meet European and Canadian safety standards, making them suitable for international markets.

Customer Support & Services

SYIL understands that support is crucial, especially for small businesses. They offer:

- After-Sales Support: A “zero obsolescence” policy ensures they provide parts for every machine they’ve ever made, with a service parts fill rate greater than 95%.

- Warranty: In the UK, they offer warranties of up to 5 years, fully supporting your investment.

- Training Programs: While specific training programs aren’t detailed, their responsive customer care suggests they provide guidance to help you get the most out of your machine.

- Global Support: With operations in over 15 countries, SYIL ensures that help is available wherever you are.

Final Verdict

If you’re a small business owner or hobbyist looking for an affordable yet reliable CNC machine, SYIL is worth considering. Their machines are designed to be cost-effective without compromising on quality.

However, their focus on affordability means they might not offer the advanced features found in higher-end models. But if you’re starting out or need a dependable machine for everyday tasks, SYIL provides a solid balance between cost and performance.

7. Chien Wei Precise Technology Co., Ltd.

Precision machining isn’t just about cutting metal—it’s about accuracy, repeatability, and durability. When I asked a toolmaker which brand they trusted for grinding and milling, they said, “Chien Wei. They know how to build precision machines.”

Founded in 1981 in Taichung, Taiwan, Chien Wei Precise Technology Co., Ltd. specializes in high-precision CNC grinding, milling, and EDM (Electrical Discharge Machining) solutions. Their mission is to create machines that deliver high accuracy with minimal operator effort, making them a popular choice in industries like mold making, aerospace, and automotive manufacturing.

Products & Specialties

Chien Wei specializes in:

- CNC Profile Grinding Machines: Used for high-precision mold and die manufacturing.

- CNC Vertical Grinding Machines: Designed for fine surface finishes and ultra-precise machining.

- CNC Milling Machines: Built for high-speed cutting and complex part production.

- Automation Solutions: Many of their machines come with integrated robotic systems for increased efficiency.

Unlike some manufacturers that offer general-purpose CNC machines, Chien Wei focuses on high-precision solutions. If accuracy and fine surface finishes are a top priority, their machines are built for the job.

Certifications & Compliance

Chien Wei maintains strict quality control and holds:

- ISO 9001: Ensures their manufacturing process meets international quality standards.

- ISO 14001: Reflects their commitment to environmentally friendly production methods.

- CE Certification: Meets European safety and quality regulations, making their machines suitable for global markets.

Customer Support & Services

Precision machines require strong technical support. Chien Wei offers:

- After-Sales Service: They provide on-site troubleshooting, remote diagnostics, and spare parts availability.

- Training Programs: Operator training for new users and advanced programming courses for experienced machinists.

- Automation Assistance: If you integrate their machines with robotic systems, they offer setup guidance and optimization support.

- Global Support Network: With service centers across Asia, Europe, and North America, help is accessible when needed.

One thing that stands out? Their focus on precision-driven industries means they offer specialized support tailored to mold-making and grinding applications.

Final Verdict

If your business requires extreme precision, Chien Wei is a strong choice. Their grinding and milling machines deliver accuracy that general-purpose CNCs can’t match.

The downside? These machines aren’t for everyone. If you don’t need high-precision mold or die manufacturing, their offerings might be overkill. But for manufacturers who prioritize accuracy, Chien Wei’s machines are built to meet demanding standards.

Looking for a Manufacturer Outside in Taiwan?

Finding the right CNC manufacturer isn’t always straightforward. I’ve been there—comparing specs, weighing costs, and wondering if I was making the right investment.

Maybe you’re in the same boat. You’ve looked at Taiwan’s CNC brands, but something isn’t quite right. Maybe the machines look good on paper, but do they fit your workflow?

If that sounds familiar, China is another option worth exploring. It’s home to some of the biggest CNC manufacturers in the world, offering precision machines at competitive prices with global shipping and after-sales service.

One company that stands out is Blue Elephant CNC. Here’s why:

- Advanced 3-axis to 5-axis CNC machines for woodworking, stone, and metal processing

- Custom-built solutions designed to match your production needs

- Reliable after-sales support so you’re never left figuring things out alone

I know how frustrating it can be to feel like you’re settling. You don’t have to. If Taiwan’s manufacturers aren’t quite the right fit, Blue Elephant CNC could be the alternative you’ve been looking for. Contact us today to discuss your specific requirements.

Conclusion

I’ve been in your shoes—comparing specs, weighing costs, and wondering if I was making the right decision.

Finding the right CNC manufacturer takes time. But settling for the wrong one costs more.

Taiwan has some of the best in the business, but if you haven’t found the right fit, don’t stop looking. China is another CNC manufacturing powerhouse, offering top-tier machines at competitive prices.

What’s holding you back from making the next move? Are you ready to take your production to the next level?

Contact us now and let’s make it happen.