A few years ago, I met a business owner who regretted his CNC machine purchase. The supplier promised quality but failed to deliver, leading to costly production delays. His mistake? Not researching his options thoroughly.

If you’re looking for a CNC machine supplier in the Philippines, you can’t afford to take chances. A wrong choice can slow down your operations, waste resources, and impact your bottom line.

We’ve done the legwork for you. This review is based on thorough research, industry insights, and supplier credibility, so you can make an informed decision without the guesswork.

Inside this article, you’ll find the top 7 CNC machine suppliers in the Philippines, their strengths, and why they stand out. By the end, you’ll know exactly which supplier fits your needs best.

Now, let’s dive in!

Quick Comparison Chart

Choosing the right CNC machine supplier depends on factors like manufacturing capabilities, pricing, quality standards, and industry specialization. Below is a detailed comparison of the top CNC manufacturers in the Philippines to help businesses find the best fit.

| Manufacturer | Year Established | Location | Specialty | Certifications | MOQ (Minimum Order Quantity) | Best For | Downside |

| Famous Secret Precision Machining Inc. (FSPMI) | 1994 | Silang, Cavite | Aerospace, automotive, motorcycle, industrial parts | AS9100, ISO 9001:2015 | High | Large-scale precision manufacturing | High pricing, not ideal for small businesses |

| Primateknica Corporation | 2010 | Taguig, Metro Manila | Custom jigs, fixtures, engineering plastics, CNC milling | Not specified | Low | Small to mid-sized businesses needing customization | Not suited for high-volume mass production |

| Northeast Precision, Inc. | 2003 | Ciudad de Calamba, Laguna | Automotive, electronics, industrial machining | Serves international markets but certifications not specified | Medium to high | Businesses needing export-quality parts | Not cost-effective for small-batch production |

| MESCO, Inc. | 1956 | Pasig City, Metro Manila | CNC machine supply, precision machining, training | ISO 9001:2015 | Flexible | Companies looking to buy CNC machines and receive technical support | Focuses more on machine sales than contract manufacturing |

| Primark Tooling Industries | 2008 | Philippines | CNC routers, laser cutting, plasma cutting, custom CNC machines | Not specified | Low | Small businesses needing affordable, custom CNC solutions | Limited capacity for high-volume manufacturing |

| Rockwell Machine Shop Ltd. | 1988 | Sta. Ana, Manila | Custom fabrication and printing machine part repair | Not specified | Flexible | Businesses needing repair and small-batch fabrication | Not suited for mass production |

| SYIL CNC Philippines | 2001 | Philippines (global presence) | Compact, affordable CNC machines for workshops and small factories | ISO, CE, CSA | Varies (machines sold, not parts manufactured) | Small workshops needing cost-effective CNC machines | 4-5 month lead times, customer support concerns |

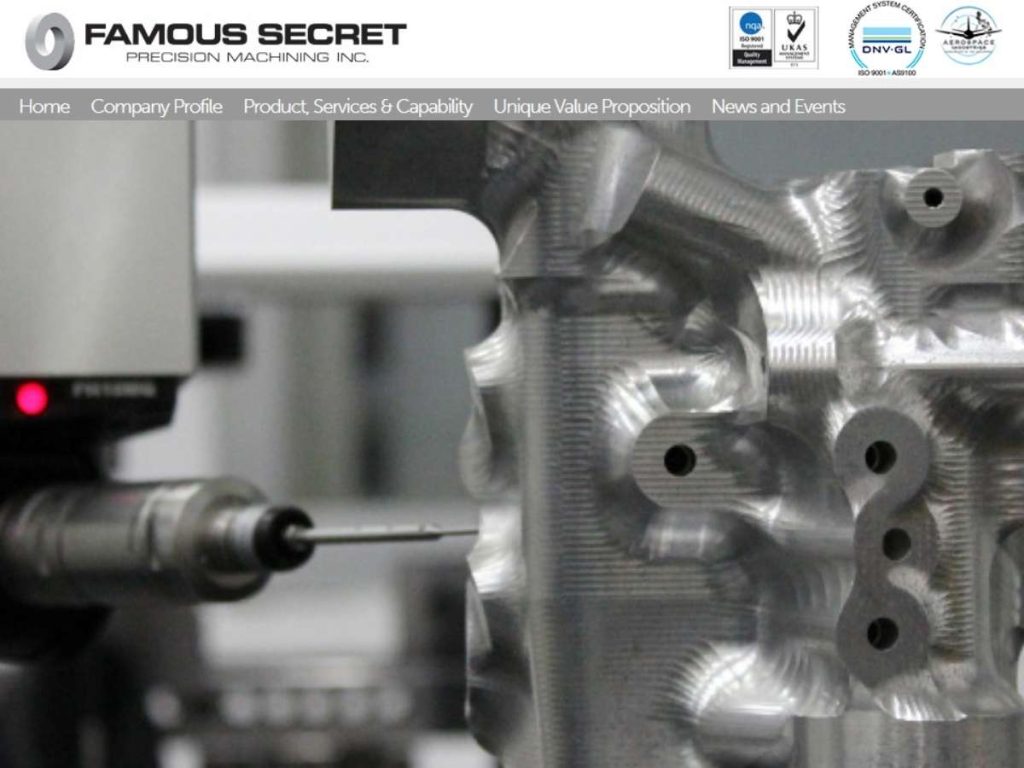

1. Famous Secret Precision Machining Inc.

Finding a reliable CNC machining supplier can be overwhelming. I’ve seen businesses struggle with late deliveries, poor-quality parts, and unresponsive suppliers. That’s why choosing the right manufacturer is crucial.

Famous Secret Precision Machining Inc. (FSPMI) has been in the CNC machining business since 1994. They operate a large manufacturing facility in Silang, Cavite, equipped with over 250 CNC machines. They specialize in aerospace, automotive, motorcycle, and industrial parts, industries that demand high precision and quality control.

Manufacturing Capabilities

FSPMI can handle large-scale production, making them ideal for businesses needing bulk orders.

What They Manufacture:

- Aerospace components (aircraft parts, defense equipment)

- Automotive & motorcycle parts (engine, chassis, suspension parts)

- Industrial equipment parts (machinery components, heavy-duty tools)

They offer OEM (Original Equipment Manufacturer) and private label services, so you can have products made under your brand.

One thing that stands out? Their use of advanced automation to ensure precision. Unlike suppliers that still rely on manual processes, FSPMI’s CNC machines reduce human error, improving efficiency.

Quality Assurance & Compliance

FSPMI is serious about quality control. If you need high-precision parts, they might be a good fit.

- They source raw materials from trusted suppliers and track their quality.

- Every product goes through strict testing, using CMMs (Coordinate Measuring Machines) to check for defects.

- Their AS9100 and ISO 9001 certifications ensure they meet international manufacturing standards.

Pricing, Lead Times & Supply Chain

FSPMI’s pricing reflects their focus on quality rather than affordability.

- MOQ (Minimum Order Quantity): High, best for businesses ordering in bulk.

- Lead Times: Fast for their industry, but depends on the complexity of your order.

- Shipping & Logistics: They handle both domestic and international distribution.

Final Recommendation

FSPMI is an excellent choice if you need high-precision CNC parts in large quantities. Their certifications and automated processes ensure top-notch quality, making them a trusted supplier for aerospace and industrial sectors. They also have a strong reputation for delivering on time.

However, if you’re looking for low-cost production or small-batch orders, this may not be the right fit. Their high MOQs and premium pricing could be a challenge for smaller businesses.

2. Primateknica Corporation

When I first started looking into CNC machining suppliers, I realized something, many companies offer similar services, but not all deliver on their promises. Some are slow, unreliable, or lack proper support. That’s why researching a supplier before committing is so important.

Primateknica Corporation, founded in 2010, is a precision machining company based in Taguig, Metro Manila. They specialize in CNC milling, lathe machining, and grinding, catering to industries like electronics, automotive, and industrial manufacturing.

Manufacturing Capabilities

Primateknica isn’t a mass production factory. Instead, they focus on custom, high-precision machining.

What They Manufacture:

- CNC milled and lathed components (used in industrial and electronic equipment)

- Custom jigs and fixtures (for specialized manufacturing processes)Anti-static & high-temperature plastics (

- in electronics manufacturing)

They offer OEM and private label services, meaning they can produce parts under your brand. Unlike larger manufacturers, they are highly flexible with custom orders.

One thing I like? Their ability to work with unique materials like anti-static plastics, which aren’t common in many CNC shops.

Quality Assurance & Compliance

Primateknica follows strict quality control processes to ensure consistency and accuracy in their parts.

- They use high-precision CNC machines to ensure tight tolerances.

- Raw materials are sourced from verified suppliers to maintain quality.

- Every product undergoes thorough inspection before delivery.

Pricing, Lead Times & Supply Chain

Primateknica balances quality and affordability, making them an attractive option for businesses that need custom, high-precision parts.

- MOQ (Minimum Order Quantity): Low, making them ideal for smaller custom orders.

- Lead Times: Generally fast, but depends on order complexity.

- Shipping & Logistics: They cater to local and Southeast Asian markets.

Final Recommendation

Primateknica Corporation is a great option if you need customized CNC machining with a focus on precision. They are flexible, responsive, and experienced in handling specialized materials. Their low MOQs and ability to create custom parts make them perfect for small and mid-sized businesses.

However, if you need high-volume, mass production, they may lack the capacity to handle extremely large orders efficiently.

3. Northeast Precision, Inc.

Finding the right CNC supplier isn’t just about price. I’ve heard stories from business owners who saved money upfront but lost thousands due to inconsistent quality and late deliveries. That’s why reliability matters just as much as cost.

Northeast Precision, Inc. was founded in 2003 and operates in Ciudad de Calamba, Laguna. They specialize in high-precision machining for industries like automotive, electronics, and telecommunications. Their focus is on export-grade CNC parts, supplying both local and international markets in the US and Europe.

Manufacturing Capabilities

Northeast Precision, Inc. focuses on precision-engineered components, particularly for electronics and automotive applications.

What They Manufacture:

- CNC milled and turned parts

- Precision components for automotive and telecom industries

- High-accuracy industrial parts

They work with OEM clients, meaning they manufacture parts that businesses rebrand and sell as their own. Their automated machining processes allow them to maintain tight tolerances, reducing errors in mass production.

Unlike smaller shops, they focus on mid-to-high production volumes, making them a strong choice for businesses needing consistent large-batch orders.

Quality Assurance & Compliance

Northeast Precision takes quality control seriously, especially since they supply export markets with strict regulations.

- Raw materials come from verified, high-quality sources.

- Each component undergoes precision testing before leaving the facility.

- Their production meets international quality standards required by global clients.

Pricing, Lead Times & Supply Chain

Northeast Precision offers competitive pricing while maintaining high-quality standards.

- MOQ (Minimum Order Quantity): Medium to high, best for businesses with regular production needs.

- Lead Times: Consistent, but bulk orders may require extended production times.

- Shipping & Logistics: Handles both local and international distribution, primarily exporting to the US and Europe.

Final Recommendation

Northeast Precision is a solid choice if you need export-quality CNC parts with a focus on automotive, telecom, or industrial applications. They are reliable, consistent, and equipped to handle high-precision machining at scale.

However, if you require low-cost prototyping or small-batch production, their higher MOQs and focus on mass production could be a limitation.

4. MESCO, Inc.

One of the biggest mistakes businesses make when choosing a CNC supplier is focusing only on price. I’ve seen companies go for the cheapest option, only to deal with machine breakdowns, delays, and poor after-sales support. That’s why experience and reliability matter.

MESCO, Inc. is one of the oldest machine tool suppliers in the Philippines, founded in 1956. Based in Pasig City, they provide CNC machines, machining services, and engineering support to manufacturers, industrial businesses, and research institutions.

Manufacturing Capabilities

MESCO focuses on precision machining and CNC equipment supply rather than mass production.

What They Offer:

- CNC milling and turning services

- 5-axis CNC machines for high-precision work

- Lathes, grinding systems, and drilling machines

- In-house tooling analysis and customization

Unlike suppliers that only provide CNC services, MESCO sells CNC machines and trains businesses on how to use them. This makes them a great option for companies looking to develop in-house manufacturing capabilities.

Quality Assurance & Compliance

MESCO is ISO 9001:2015 certified, ensuring their processes meet global manufacturing standards.

- They source high-quality CNC machines from trusted brands.

- Their machining services go through strict quality checks to ensure accuracy.

- They provide training and technical support, helping businesses optimize their machining processes.

Pricing, Lead Times & Supply Chain

MESCO follows a mid-to-premium pricing strategy, focusing on quality and long-term value.

- MOQ (Minimum Order Quantity): Flexible, since they offer both machining services and equipment sales.

- Lead Times: Vary depending on machine availability and order complexity.

- Shipping & Logistics: Nationwide coverage with reliable after-sales service.

Final Recommendation

MESCO is a strong choice if you need CNC machines, precision machining, and technical training. Their engineering support and after-sales services set them apart from basic CNC service providers.

However, if you’re looking for a high-volume, low-cost CNC manufacturer, their focus on machine sales rather than mass production may not align with your needs.

5. Primark Tooling Industries

I’ve spoken with business owners who struggled to find a CNC supplier that offers both affordability and quality. Some manufacturers are great at customization but too expensive. Others are budget-friendly but unreliable. That’s where a mid-sized, specialized manufacturer like Primark Tooling Industries comes in.

Primark Tooling Industries was founded in 2008 and is based in the Philippines. They focus on CNC routers, laser cutting machines, and plasma cutting systems, catering to businesses that need customized, high-precision cutting solutions.

Manufacturing Capabilities

Primark is not a mass production CNC service provider. Instead, they design and manufacture cutting and engraving machines.

What They Offer:

- CNC routers for wood, acrylic, and aluminum cutting

- Laser cutting and engraving machines

- Plasma cutting systems for industrial use

- Custom-built CNC solutions for businesses

They offer OEM and private label services, meaning they can build machines under your brand name. Their focus on customization and flexibility makes them stand out from generic CNC machine sellers.

Quality Assurance & Compliance

Primark follows strict quality control to ensure their CNC machines meet industry standards.

- Their engineering team tests all machines before delivery.

- They use high-grade components to ensure durability.

- They provide technical support and after-sales service, ensuring clients get the most out of their machines.

Pricing, Lead Times & Supply Chain

Primark offers mid-range pricing, balancing quality and affordability.

- MOQ (Minimum Order Quantity): Low, making them ideal for small to medium businesses.

- Lead Times: Vary depending on customization requirements.

- Shipping & Logistics: They handle domestic distribution and work with local suppliers.

Final Recommendation

Primark Tooling Industries is a solid choice for businesses looking for custom CNC cutting and engraving machines. Their flexibility, customization options, and local industry focus make them a strong option for small to mid-sized businesses.

However, if you need large-scale CNC manufacturing or highly specialized machining, their focus on machine design rather than mass production could be a limitation.

6. Rockwell Machine Shop Co., Ltd.

Choosing the right machine shop can be challenging. I recall a colleague who faced delays because their supplier couldn’t handle specific repairs. That’s why it’s essential to know a shop’s capabilities.

Established in 1988, Rockwell Machine Shop Co., Ltd. is located in Sta. Ana, Manila. They specialize in fabricating and repairing printing machinery parts, such as shafting and gears. Starting with just two workers and a single lathe machine, they’ve grown steadily over the years.

Manufacturing Capabilities

Rockwell focuses on custom fabrication and repair rather than mass production.

What They Offer:

- Printing machinery parts fabrication: Creating components like shafts and

- Repair services: Fixing and restoring printing equipment.

- General machine shop works: Handling various machining tasks.

They cater to businesses needing specialized parts or equipment repairs, especially in the printing industry.

Quality Assurance & Compliance

While specific certifications aren’t mentioned, Rockwell emphasizes quality workmanship. Their growth from a small operation to a company with 30+ employees suggests a commitment to quality and customer satisfaction.

Pricing, Lead Times & Supply Chain

Rockwell offers competitive pricing for custom fabrication and repair services.

- MOQ (Minimum Order Quantity): Flexible, suitable for both small and large projects.

- Lead Times: Depend on project complexity; repairs might be quicker than new fabrications.

- Shipping & Logistics: Primarily serves the local Manila area, with potential for broader services upon inquiry.

Final Recommendation

Rockwell Machine Shop Co., Ltd. is a dependable choice for custom fabrication and repair needs, especially within the printing industry. Their decades-long experience and specialization position them well to handle unique machining challenges.

However, if your business requires mass production capabilities or services outside their primary focus areas, they might not fully meet your needs.

7. SYIL CNC Philippines

When I first ventured into CNC machining, I quickly learned the importance of balancing quality with affordability. Established in 2001, SYIL is a family-owned enterprise specializing in the development and manufacturing of precision CNC machine tools. Over the years, they’ve supplied over 12,000 machines worldwide, catering to both individual enthusiasts and large enterprises.

SYIL’s Philippine division focuses on providing affordable yet high-quality CNC machines suitable for various applications, from hobbyist projects to industrial manufacturing. They aim to make CNC technology accessible to businesses of all sizes, offering machines that balance performance, cost, and space efficiency.

Manufacturing Capabilities

SYIL offers a range of CNC machines designed to meet diverse machining needs.

What They Offer:

- Vertical Mills: Compact machines suitable for precision milling tasks.

- Lathes: Designed for efficient turning operations.

- Drill Tap Centers: Ideal for high-speed drilling and tapping processes.

Their machines are known for their compact design, making them suitable for workshops with limited space. Despite their size, models like the SYIL X7 deliver impressive power and speed, capable of handling materials ranging from aluminum to titanium.

Quality Assurance & Compliance

SYIL emphasizes quality and compliance in their manufacturing processes.

- Certifications: All SYIL CNC machines meet ISO, CE, and CSA standards, ensuring adherence to international quality benchmarks.

- Customer Feedback: Users have praised the SYIL X7 for its balanced performance, compact design, and advanced features, making it suitable for both beginners and experienced machinists.

Pricing, Lead Times & Supply Chain

SYIL positions itself as a provider of affordable CNC solutions without compromising on quality.

- Pricing: Competitive pricing, making CNC technology accessible to a broader audience.

- Lead Times: Estimated delivery time for their machines to any location worldwide is between 4 and 5 months.

- Shipping & Logistics: Handles global distribution, with machines assembled in their state-of-the-art factory in China.

Final Recommendation

SYIL CNC Philippines offers a range of affordable and compact CNC machines suitable for various applications. Their commitment to quality is evident through international certifications and positive user feedback.

However, potential buyers should be aware of reported concerns regarding machine reliability and customer support. Additionally, the lead time of 4 to 5 months may not align with urgent project timelines. It’s advisable to assess specific needs and timelines before making a decision.

Can’t Find the Right Philippine CNC Machine Supplier?

Still searching for the perfect CNC supplier? It’s frustrating when none of the options fit your exact needs. Maybe the minimum order quantities (MOQs) are too high, or their capabilities don’t match your production demands.

You might be wondering: Should I look beyond the Philippines? Many businesses do. Expanding your search can open up more competitive pricing, advanced technology, and better customization.

China is a global leader in CNC manufacturing. That’s where Blue Elephant CNC comes in. We specialize in high-precision CNC machines, offering:

- Custom-built solutions for different industries

- Low MOQs, making it easier for small businesses

- Advanced automation to boost efficiency

If you’re open to exploring global alternatives, we’d love to help. Contact us today and see if we’re the right fit for your business.

Conclusion

You now have a list of the top CNC machine suppliers in the Philippines, each with its strengths and specialties. But what’s next? Here’s how to move forward:

- Define Your Needs: Do you need mass production, custom machining, or budget-friendly solutions

- Compare Your Options: Revisit the list and find the supplier that fits your business.

- Reach Out: Request quotes, ask questions, and assess their responsiveness.

Will you stay stuck in research mode or take action? Your next supplier is waiting.

Need a global alternative? Contact Blue Elephant today and explore CNC solutions outside the Philippines.