A few years ago, I made a costly mistake—I bought the wrong machine. I thought a 3D printer would be perfect for my custom parts business, but the materials weren’t strong enough, and the print time was too slow. I had to start over with a CNC machine.

Since then, I’ve worked with both, testing their limits and learning what really matters.

In this guide, I’ll break down the key differences—materials, precision, speed, cost, and more—so you don’t waste time or money on the wrong choice.

By the end, you’ll know exactly which machine fits your needs.

So let’s get down to it!

Quick Comparison Chart

Selecting the right machine comes down to production efficiency, material requirements, and scalability. Whether you prioritize precision machining or flexible prototyping, understanding the differences will help you align your choice with your business objectives.

| Factor | CNC Machine | 3D Printer |

| Manufacturing Method | Subtractive – removes material by cutting or drilling. | Additive – builds objects layer by layer. |

| Material Compatibility | Works with metals, wood, plastics, and composites. | Uses plastics, resins, powders, and some metals. |

| Precision & Tolerance | High accuracy (±0.001 mm), ideal for tight tolerances. | Moderate accuracy (±0.05 mm or more), depends on the printer type. |

| Surface Finish | Smooth finish with minimal post-processing. | Layered texture, often requires sanding or curing. |

| Production Speed | Fast for large-scale manufacturing, once programmed. | Slower, especially for larger parts. |

| Cost (Initial Investment) | Expensive upfront, often requiring multiple tools and setup. | More affordable entry-level models, but industrial printers can be costly. |

| Ongoing Costs | Tool wear, material waste, power consumption, maintenance. | Filament/resin costs, printer maintenance, post-processing. |

| Best Use Cases | Ideal for industrial manufacturing, precision parts, and high-strength components. | Best for prototyping, custom designs, and complex geometries. |

| Scalability | Suitable for mass production, repeatability is high. | Limited to small-batch production due to speed constraints. |

| Learning Curve | Requires knowledge of CAD, CAM, G-code, and machine setup. | Easier to learn, but requires CAD modeling and slicing software skills. |

| Post-Processing Needs | Minimal for most materials, polishing for aesthetics. | Often necessary—sanding, curing, and chemical smoothing may be required. |

| Durability of Parts | Produces strong, long-lasting components. | Strength varies based on material and print method. |

| Environmental Impact | Produces material waste from cutting. | Minimal waste, but some resins and filaments are not recyclable. |

At the end of the day, the best choice depends on what you’re making and how often you need to produce it. The right investment will improve workflow, optimize costs, and support long-term growth.

1. How CNC Machines and 3D Printers Work

I once assumed 3D printing could handle everything. I designed a part, printed it, and expected it to work just like a machined component. But when I picked it up, the surface was rough, the fit wasn’t precise, and the material felt weak. That’s when I realized not every project is suited for 3D printing. Some require precision and durability that only a CNC machine can deliver.

If you’re deciding between a CNC machine and a 3D printer, understanding how they work will help you avoid costly mistakes.

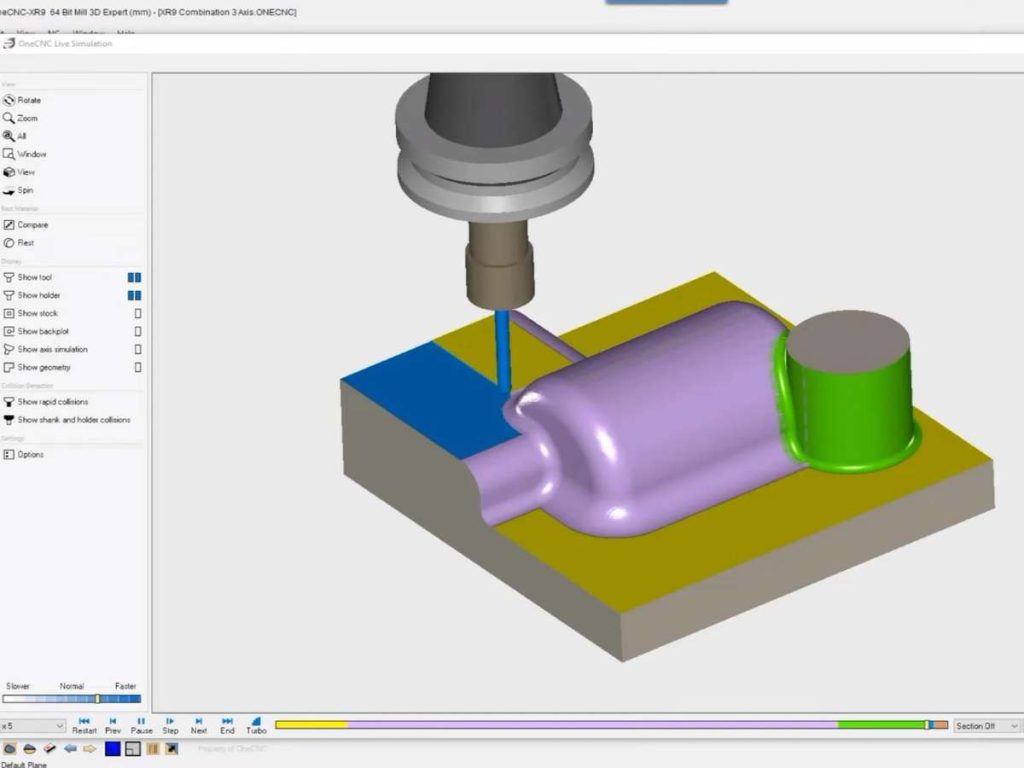

How CNC Machines Work

A CNC (Computer Numerical Control) machine cuts, drills, or engraves a solid block of material to create a finished part. Instead of manually shaping the material, CNC machines follow G-code, a programmed set of instructions that controls every movement. This automation allows for extreme accuracy and repeatability.

There are several types of CNC machines, each designed for specific tasks:

- Milling Machines: Great for detailed cuts, holes, and contours

- Lathes: Best for cylindrical parts (think screws or pipes)

- Laser Cutters: Use a laser to slice through thin materials like acrylic or metal sheets

- Plasma Cutters: Cut thick metal using a high-temperature plasma arc

- CNC Routers: Similar to milling machines but mostly used for wood, foam, and plastics

CNC machining is fast, strong, and repeatable—which is why industries like aerospace, automotive, and manufacturing rely on it. At Blue Elephant, our machines deliver precision and efficiency, making them a trusted choice for businesses that need high-performance manufacturing solutions.

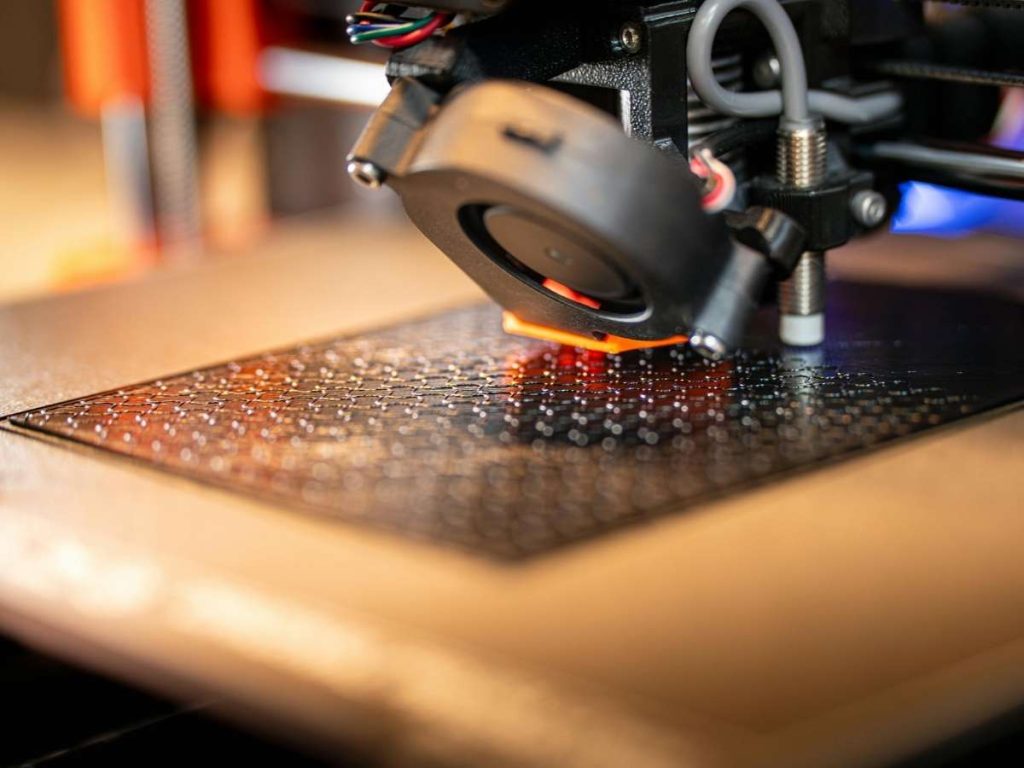

How 3D Printers Work

A 3D printer creates objects by adding material layer by layer based on a digital model. Unlike CNC machines, which remove material, 3D printers build the part from the ground up, allowing for intricate designs and minimal waste. They rely on slicing software, which converts a 3D model into printable layers.

Different types of 3D printers serve different applications:

- FDM (Fused Deposition Modeling): Melts plastic filament and extrudes it in layers to create a solid shape.

- SLA (Stereolithography): Uses UV light to harden liquid resin, producing smooth, high-detail parts.

- SLS (Selective Laser Sintering): Fuses powdered materials with a laser to create complex, durable structures.

- Metal 3D Printing: Uses metal powder and extreme heat to produce functional metal parts.

3D printing is widely used for prototyping, custom designs, and low-volume production. While it offers flexibility and design freedom, printed parts often require post-processing, such as sanding or sealing, to improve strength and surface quality.

2. Material Compatibility: Which Machine Can Handle What?

Before investing in a CNC machine or a 3D printer, it’s critical to consider the materials you’ll be using. I learned this the hard way when I attempted to produce a custom bracket for a heavy-duty application. I started with a 3D-printed version, expecting it to hold up under pressure. It didn’t. The material was too weak, and the part failed almost instantly. I switched to a CNC-cut aluminum bracket, and it performed flawlessly.

Some projects require strength and durability, while others benefit from flexibility and intricate design. Choosing the wrong machine for your material can result in wasted time, resources, and money.

CNC Machine Materials

CNC machines cut through tough materials with ease, making them perfect for strong, long-lasting parts.

Common CNC materials include:

- Metals: Aluminum, brass, steel, titanium

- Wood: Hardwoods, softwoods, plywood, MDF

- Plastics: ABS, acrylic, nylon, polycarbonate

- Composites: Carbon fiber, fiberglass

3D Printer Materials

3D printing works differently. Instead of cutting, it builds parts layer by layer, making it great for complex shapes and lightweight designs.

Popular 3D printing materials include:

- Plastics: PLA, ABS, PETG, nylon

- Resins: Liquid resin hardened with UV light

- Metals (limited): Stainless steel, titanium (in industrial 3D printers)

- Ceramics: Used for art, medical, and engineering applications

If you’re designing prototypes, models, or intricate custom parts, 3D printing is a great choice. But if you need high-strength, load-bearing components, CNC machining is usually better.

3. Precision & Surface Finish: Which One Delivers Better Results?

Have you ever tried assembling a part, only to find that it doesn’t fit quite right? Maybe the edges weren’t sharp enough, or the surface was rougher than expected. If you’ve been there, you know how frustrating it can be. Precision and surface finish matter, especially in machining and manufacturing.

When choosing between a CNC machine and a 3D printer, you need to ask: How exact do your parts need to be? Will surface imperfections affect performance?

CNC Machine Precision

If you need high precision, CNC machining is your best option. These machines cut with an accuracy of ±0.001mm, which makes them ideal for tight-fitting mechanical parts and detailed engravings.

Here’s what CNC machining delivers:

- Sharp edges and clean details: No layers, just smooth, precise cuts.

- Consistent accuracy: Every movement follows G-code, so you get the exact same result every time.

- Professional surface finishes: Polishing, anodizing, or coating can make the final product even smoother.

At Blue Elephant, we provide CNC machines built for accuracy and long-term performance. Our CNC machining delivers production-ready results with minimal post-processing for metal, plastic, and wood parts that require strength and precision, making it a reliable choice across various industries.

3D Printer Precision

With 3D printing, layer thickness affects precision. Even high-end printers leave visible layer lines, which means extra finishing work.

Here’s what you can expect:

- FDM printers: Good for general-use plastic parts but may have rough surfaces.

- SLA and SLS printers: Better detail, but still require sanding or polishing.

- Post-processing is necessary: Smoothing techniques like chemical baths or grinding can improve surface quality.

If you’re working on prototypes or custom shapes, 3D printing is great. But if you need flawless, tight tolerances, be prepared for extra finishing.

4. Production Speed & Efficiency: Which One is Faster?

Time is money. Whether you’re making a single prototype or producing parts in bulk, speed and efficiency matter. The right machine can help you meet deadlines and reduce costs. But which one is faster—a CNC machine or a 3D printer?

The answer depends on what you’re making and how many you need for your business. Let’s compare below:

CNC Machining

If you need fast, repeatable production, CNC machining is the better choice. Once a part is programmed, the machine can cut through material quickly and efficiently.

Here’s why CNC is ideal for speed:

- Works fast once set up: A single part may take minutes.

- Handles large production runs: Can produce hundreds or thousands of identical parts efficiently.

- Minimal downtime – Machines can run continuously with little manual intervention.

However, the setup time can be long. You’ll need to program the machine, choose the right tools, and secure the material. But once that’s done, CNC machining is much faster per unit than 3D printing.

3D Printing

3D printing is great for custom, one-off parts, but it’s not the fastest option for large-scale production.

Here’s what you need to know:

- Perfect for rapid prototyping: No setup time, just load the file and print.

- Slower per part: Printing even small objects can take hours.

- Not ideal for mass production: Printing in batches is slow and expensive.

If you’re testing a new design, 3D printing saves time on setup. But if you need hundreds of parts, CNC machining will get the job done faster.

5. Cost Comparison: Which One is More Affordable?

Budget matters. Whether you’re running a business or working on a personal project, knowing the costs upfront can save you from expensive mistakes. CNC machines and 3D printers both come with costs beyond the purchase price—but which one is the better investment for you?

Initial Investment: CNC vs. 3D Printing

If you’re buying a CNC machine, be prepared for a high upfront cost. Entry-level machines start at a few thousand dollars, while industrial models can cost tens or even hundreds of thousands.

Why? Because CNC machines need:

- Specialized cutting tools

- A rigid frame and powerful motors

- Advanced software for programming

A 3D printer, on the other hand, is much cheaper to get started with. Basic desktop models cost a few hundred dollars, while high-end industrial 3D printers can reach $100,000 or more.

If you’re on a tight budget, 3D printing is the more affordable way to start. But don’t forget—there’s more to cost than just the machine.

Maintenance & Operating Costs

Owning a machine isn’t just about the initial purchase. Ongoing costs add up over time.

For CNC machines, expect to pay for:

- Tool wear and replacements: Drill bits and cutting tools wear out.

- High power consumption: CNC machines require a lot of energy.

- Material waste: Since parts are cut from solid blocks, leftover material is often unusable.

For 3D printers, the main costs are:

- Material expenses: Filament, resin, or metal powder can be pricey.

- Machine upkeep: Nozzles clog, resin tanks degrade, and parts need cleaning.

- Post-processing: Some prints require sanding, curing, or chemical smoothing.

6. Industry-Specific Applications: Which Machine is Best for Your Business?

Every industry has different needs. A furniture maker and an automotive engineer won’t use the same machine for their work. So, which one is best for your business?

CNC machines and 3D printers both have specialized applications. Choosing the right one saves time, money, and resources. Let’s look at where each machine performs best and efficiency in CNC machining.

CNC Applications

CNC machines are built for precision and durability. They excel in industries that need strong, long-lasting parts.

Here’s where CNC machining shines:

- Furniture Manufacturing: Cutting wood panels, carving designs, and shaping custom furniture pieces.

- Metal Fabrication: Making brackets, frames, and components for construction and machinery.

- Automotive & Aerospace: Producing engine parts, gears, and structural components that must handle stress.

- Precision Machining: Creating tools, molds, and detailed mechanical parts with tight tolerances.

If you’re working with wood, metal, or heavy-duty plastics, a CNC machine is the way to go. It’s reliable, repeatable, and scalable for mass production.

3D Printer Applications

3D printing is more flexible than CNC machining. It’s best for industries that need custom, low-volume, or intricate designs.

Ideal uses for 3D printing include:

- Prototyping & R&D: Quickly testing new product designs before full production.

- Custom Craft & Decoration: Making unique, artistic, or decorative pieces with complex geometries.

- Mold Design & Small-Scale Production: Producing short-run molds or specialized parts without expensive tooling.

If you need lightweight, complex, or one-off parts, 3D printing offers unmatched creative freedom.

7. What Skills Are Required to Operate a CNC Machine or a 3D Printer?

Buying a machine is one thing—learning how to use it effectively is another. Whether you’re considering a CNC machine or a 3D printer, there’s a learning curve involved. The question is, how much time and effort are you willing to invest?

CNC machines and 3D printers both require technical knowledge, but they demand different skill sets.

Skills Needed for CNC Machining

CNC machining isn’t plug-and-play. It requires training and hands-on experience to operate correctly.

Here’s what you need to learn:

- CAD/CAM Software – You’ll need to design parts in CAD (Computer-Aided Design) software and convert them into tool paths using CAM (Computer-Aided Manufacturing) software.

- G-code Programming – CNC machines follow G-code, a language that tells the machine where to cut, how fast to move, and what depth to carve.

- Physical Machine Setup – You must secure materials, select the right cutting tools, and adjust machine settings before running a job.

If you’re new to CNC machining, expect a steep learning curve. But once you master it, CNC machines offer high precision and repeatability—valuable for any business.

Skills Needed for 3D Printing

3D printing is generally easier to learn, but it still requires technical know-how.

Here’s what you’ll need to understand:

- CAD Modeling & Slicing Software – You design parts in CAD and use slicing software to prepare files for printing.

- Printer Calibration & Material Settings – You’ll need to adjust temperatures, print speeds, and layer heights for different materials.

- Post-Processing Techniques – Sanding, curing, or chemical smoothing may be required to get a high-quality finish.

Compared to CNC machining, 3D printing is more beginner-friendly. However, fine-tuning print settings and troubleshooting failures can still take time to master.

8. Which One Should You Choose? CNC vs. 3D Printer

Choosing between a CNC machine and a 3D printer depends on your goals, budget, and skill level. The right machine can save you time and money, while the wrong choice can lead to frustration. Here’s how they compare across key factors:

Business Goals

Start by identifying your primary need. If you require mass production with consistent quality, a CNC machine is the better fit. It processes materials quickly and produces strong, durable parts. For projects that focus on prototyping or custom, low-volume production, a 3D printer offers greater flexibility. When durability is the top concern, CNC machining is the way to go. If intricate, complex shapes are a priority, 3D printing allows for more creative freedom.

Budget & Skill Level

Consider your budget and experience. A 3D printer is cheaper and easier to learn, making it great for beginners. CNC machines cost more and require machining skills but offer long-term value for precision work. If you need quick results with minimal training, 3D printing is the better option.

Making the Right Decision

Match the machine to your priorities. CNC is best for strength and production, while 3D printing is ideal for design flexibility. Choose based on whether speed, durability, or customization is most important to your business.

Conclusion

Every business has different needs. Some require speed and scale—that’s CNC machining. Others need creativity and adaptability—that’s 3D printing. Now you have the knowledge to choose wisely.

The right machine can increase efficiency, reduce waste, and improve production quality. It all comes down to what you need and how you plan to grow.

Which solution fits your business best?

Contact us today and let’s find the right tool for your needs.