As the name supplies, a metal cutting machine is the machine or tool dedicated to cutting metal materials. The metal cutting machine falls into manual, semi-auto, or auto types based on its driven mode. Many metal cutting tools, such as band saws, chop saws, are cheap, flexible, and simple to operate. They are more suitable for metal cutting workshops with small productivity. And sometimes, the manual metal cutting tools provide poor cutting quality with great errors.

For heavy-duty and long-term metal cutting work, the CNC metal cutting machine is the best choice. More and more metalworking companies choose CNC metal cutting machines due to their high automation, excellent precision, and high efficiency.

This article introduces the four most common CNC metal cutting machines, namely laser cutting, plasma cutting, water-jet cutting, and flame cutting. Each machine has its respective advantages, disadvantages, and applicable uses. Among them, the fiber laser and plasma metal cutting machines are the most popular ones. In addition, this article also briefly explains how to choose a CNC metal cutting machine.

What is CNC metal cutting?

Computer numerical controlled metal cutting methods mainly include laser, flame, plasma, and water-jet cutting methods. They can realize automatic, high-efficiency, and high-quality cutting according to the optimized cutting program provided by the CNC nesting software. CNC metal cutting represents a modern high-tech production method. The metal cutting CNC machine is a product of the combination of advanced computer numerical control technology and cutting machinery.

Compared with traditional manual cutting, the metal cutting CNC machine effectively controls and improves the cutting quality and cutting efficiency.

CNC metal cutting machine — Fiber laser cutting machine

Although high-power CO2 laser machines can also cut stainless steel, it has low efficiency and consumes much energy. Besides, the most common use of a CO2 laser machine is to process organic materials, like wood, acrylic, leather, fabric, and stone. Currently, most sheet metal cutting applications—especially below 6 mm—are mainly done by fiber cutting systems.

The fiber laser cutter is a kind of metal cutting CNC machine. It irradiates a high-density laser beam to the metal surface, and the energy released by the laser melts the metal. The laser head moves above the metal sheet along a certain route given by the computer to form a slit. Then certain shapes are cut off from the sheet.

The fiber steel metal laser cutting machine adopts a non-contact-based cutting method. This method has a small heat-affected area and leaves no damage to the workpieces. The metal products cut by a fiber laser cutter have tiny heat deformation, excellent precision, and smooth surfaces. There’s no need for further processing.

The fiber laser beam provides a metal-friendly wavelength, and metal material can absorb the laser energy effectively. The small spot size and excellent beam profile make it ideal for cutting most metals.

The photoelectric conversion rate of the fiber laser sheet metal cutting machine can reach 30%. This can greatly save power consumption and the use cost is low.

The laser beam has good quality and stable performance. The laser adopts optical fiber transmission mode instead of easily worn-out reflective lenses. So it basically does not need maintenance.

CNC metal cutting machine — Plasma cutting machine

The CNC plasma cutting machine is accurate and reliable. However, its precision is a little inferior to that provided by a fiber laser metal cutting machine.

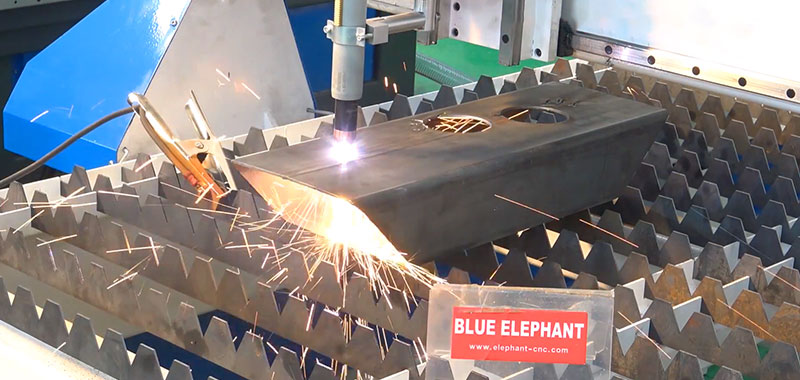

The plasma cutter table uses the heat of a high-temperature plasma arc to partially melt (evaporate) the metal. And it uses the power of the high-speed plasma airflow to remove the molten metal to form the incision. When the metal sheet exceeds 20mm thick, the plasma cutting machine is more advantageous than the steel metal laser cutting machine.

A CNC plasma table can cut many materials that are difficult to cut by traditional methods. In terms of cutting speed, the CNC plasma cutter is several times faster than the traditional oxygen cutting when cutting thin carbon steel sheets. At the same time, the cutting surface remains smooth and the thermal deformation is small.

The plasma CNC cutting machine has many advantages such as simple operation, high accuracy, high efficiency, and low labor intensity. It is widely used in automobiles, locomotives, pressure vessels, chemical machinery, nuclear industry, general machinery, engineering machinery, steel structures, etc.

CNC metal cutting machine — Flaming cutting machine

Flame cutting is also known as gas cutting or oxygen-fuel cutting. The CNC flame cutting machine uses the thermal energy of the gas flame to pre-heat the workpieces to a certain temperature. Then it ejects high-speed cutting airflow to melt the metal and release heat to achieve the purpose of cutting.

The commonly used flame cutting gases include acetylene, propane, liquefied gas, coke oven gas, natural gas, etc. From the comprehensive consideration of pollution, energy consumption, and cost ratio, natural gas is currently the most suitable gas. But natural gas also has its limitations. For instance, the natural gas flame temperature is not high, which causes the cutting efficiency to be inferior to acetylene.

The CNC flame metal cutting machine can cut large-thickness metal plates. It can cut metal plates with thicknesses ranging from 1mm to 1.2m. Meanwhile, the cutting costs are low. However, its heat-affected area is relatively larger, and the material is more prone to thermal deformation. Therefore, the cutting accuracy of the flame metal cutting machine is relatively inferior to other cutting methods.

CNC metal cutting machine — Water-jet cutting machine

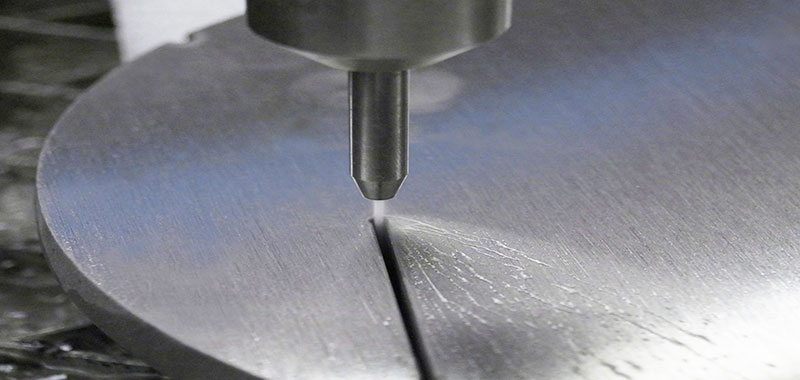

The CNC water-jet cutting machine is a machine that uses high-pressure water to cut. With the continuous improvement of technology, garnet sand, emery, and other abrasives are mixed in high-pressure water to assist cutting. This greatly improves the cutting speed and cutting thickness of the CNC water-jet metal cutting machine.

Only the water-jet cutting belongs to the cold cutting mode compared with laser cutting, plasma cutting, and flame cutting. It directly uses the kinetic energy of the abrasive water jet to cut the metals. The heat generated during cutting is immediately taken away by the high-speed water jet. And the cutting process produces no harmful substances and no thermal effect on the metals.

It has advantages of no influence on the physical and chemical properties of the cutting material. And also no thermal deformation, narrow slitting, high precision, smooth cut surface, clean and pollution-free. It can process materials that cannot be processed or are difficult to process with traditional processing methods. For example, glass, ceramics, composite materials, reflective materials, chemical fibers, heat-sensitive materials, etc.

Comparison of metal cutting machine

| Metal cutting method | Cutting thickness (approx.) | Characteristics | Price range (approx.) |

| Laser cutting | 0.1-20mm | Highest precision Excellent cutting quality | $10,000-$100,000 |

| Plasma cutting | 0.5-100mm | High precision Fast cutting speed | $2,000-$9,000 |

| Flame cutting | 4-150mm | Maximum cutting thickness Less precision | $2,000-$5,000 |

| Water-jet cutting | <100mm | No heat effect Cut organic materials | $9,000-$40,000 |

Laser metal cutting machines are mainly for cutting metals that are not easily oxidized. For example, stainless steel, titanium, aluminum, and their alloys. It can give full play to its greatest advantages when cutting thin metal plates and tubes. The steel laser cutting machine has a faster cutting speed and the highest precision among the four metal cutting methods. Its positioning accuracy can reach 0.03mm, and the repeat positioning accuracy can reach 0.02mm. In addition to cutting, it can also engrave thin metal without affecting the material.

A plasma metal cutting machine with different working gas can cut all kinds of metals that are difficult to cut by oxygen. Especially for non-ferrous metals (stainless steel, carbon steel, aluminum, copper, titanium, nickel), the cutting effect is better. Plasma cutting has a certain thermal effect and its accuracy is lower than that of laser cutting machines. It is not easy to perform secondary processing on the cut surface. The CNC plasma table can cut thicker metal plates than the fiber laser cutter.

The advantage of the CNC flame metal cutting is that it can cut very thick metals, like the steel several inches thick. However, it can only cut fewer types of metal materials, including carbon steel, low alloy steel, and cast iron. Most other types of materials will not be cut cleanly by flame cutting. Flame cutting is also generally slower than plasma cutting and water-jet cutting. The accuracy of flame cutting is generally not very high.

Water-jet cutting can cut many different types of materials, not just metals. Water-jet cutting is also much cleaner than plasma or flame cutting because it does not emit dangerous fumes. It is not suitable for thick cuts on hard metals. A water-jet metal cutting machine is expensive and may require considerable maintenance.

How to select a metal cutting machine

There are many factors to consider when choosing a metal cutting CNC machine. Here are some suggestions. When purchasing, you have to make specific choices based on your actual processing needs, budget, conditions of use, etc.

If you have strict requirements on cutting accuracy and quality, and your metal material is between 0.2-20mm thick, the fiber laser machine is the best choice. The steel laser cutting machine can cut a large number of metal parts with high quality and fast speed. These parts can be used directly without further processing. But, you may prepare for high initial investment.

A plasma cutter table is good at cutting most conductive metals. If you mainly cut 3-4 inch sheet metals, you can consider a plasma metal cutting machine. Plasma cutters produce a very hot and very localized “cone” to cut with. So they are extremely useful for cutting sheet metal in curved or angled shapes.

The CNC flame cutting machine has a small production investment and a large processing thickness. It is suitable for rough metal processing industries with low precision requirements. If you are in the metal material recycling industry, the flame metal cutting machine could be a good choice. For instance, cut large scrap steel plates, steel castings, scrap boilers, and steel structural frames.

In addition to metal, water-jet cutting is also good at cutting ceramics, stone, glass, foam, rubber, leather, and composite materials. If you need to cut metals up to 6 inches thick and most other materials up to 18 inches, you can consider the water-jet cutting.

Metal cutting machine recommendation

Through the above comparison, we know that if you want high-precision, fast and high-quality cutting, laser and plasma machines are the best choices. The following introduces a laser cutting machine and plasma metal cutting machine.

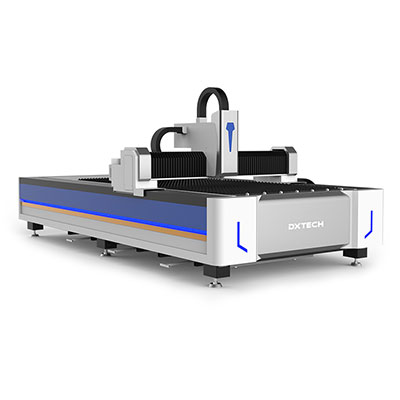

Fiber laser metal cutting machine

This laser sheet metal cutting machine is available in many laser power options, from 1000W to 12000W. Its effective working size is also optional of 1530, 1540, 1560, 2040, 2560, etc. The laser metal cutting machine price varies greatly for the different powers and sizes. Commonly, the larger the power and size, the higher the laser metal cutting machine price.

The metal cutting process with a fiber laser requires the assistance of certain gases. Different metal sheets may require different types of auxiliary gases. For example, it usually adopts oxygen (O2) as the auxiliary gas when cutting carbon steel plates. While it uses nitrogen (N2) for stainless steel and brass sheets. The following videos show the fiber metal laser cutter cutting carbon steel and brass sheets of different thicknesses.

Video 1: Fiber laser sheet metal cutting machine cutting carbon steel sheets of 3mm, 6mm, 16mm, and 20mm thick.

Video 2: Metal laser cutting machine cutting brass sheets of 2mm, 3mm, and 5mm thick.

Among all the above metal cutting CNC machines, the fiber metal cutting machine price is the highest. The fiber metal cutting machine price ranges from $10,000 to $30,000 and is affected by many factors. For instance, laser power, machine size, domestic or imported parts, etc.

CNC plasma cutter for sale

The worktable size is 1500x3000mm, which is also available in 1300x2500mmm, 2000x4000mm, or bigger. Except for cutting metal sheets, it can also simply cut square tubes. If customers have demands of cutting round metal items, we can also add a rotary device to this plasma table.

In theory, the CNC plasma cutting machine can cut any shapes that can be drawn with the AutoCAD. With a user-friendly operating system and interface, the metal cutting process is easy to learn and simple to operate.

Although its cutting precision is inferior to the metal laser cutter, it still has a wide range of applications. The CNC plasma metal cutting machine is widely used in chemical machinery, automotive, equipment manufacturing, and other engineering machinery industries.

Here’s a video showing our 1530 plasma cutter table cutting irregular shapes from a big square tube.

Conclusion

This article briefly introduces 4 metal cutting CNC machines, namely laser cutting, plasma cutting, flame, and water-jet cutting. Since all these machines adopt CNC control, they all have flexibility and efficiency features. But they have some differences in working principle, cutting precision, machine price, and applications. So it is important to figure out your processing needs and required precision before selecting a metal cutting machine.

The metal laser cutter and CNC plasma metal cutting machine are the most popular among the four. Precision instruments, automotive, aerospace and other industries requiring higher precision can choose the fiber laser cutting machine. The CNC plasma table also has extensive use in automotive, chemical machinery, engineering, and other metalworking industries.

Blue Elephant provides multiple models of high-precision laser machines and plasma cutting machines. Apart from the two above, there are many other models of metal cutting machines with different functions. To know more information, contact me now!