A few years ago, I made a mistake. I rushed into a deal with a CNC machine manufacturer in India without digging deep. The price was good. The promises sounded right.

But the machine? It broke down within months. The support? Nonexistent.

That mistake cost me time and money. But it also taught me a lesson—choosing the right manufacturer is everything.

Over the years, I’ve worked closely with machine dealers, repair experts, and suppliers to understand which manufacturers truly deliver.

If you’re looking for a trusted CNC milling machine manufacturer in India, I’ve done the hard work for you. This article lists seven companies that consistently meet industry standards. By the end you’ll get insights that will help you source machines under your own business.

Let’s dive in!

Comparison Table

Before we explore each manufacturer in depth, let’s take a quick look at how they compare. This table gives you a side-by-side comparison of India’s top CNC milling machine manufacturers—helping you see their strengths at a glance.

| Manufacturer | Year Established | Location | Product Range | Certifications | Best For | Drawbacks |

| Bharat Fritz Werner Ltd. (BFW) | 1961 | Bangalore, Karnataka | VMCs, HMCs, Five-Axis Machines, Horizontal Turning Centers | ISO 9001, ISO 14001 | Large-scale manufacturers needing advanced precision and reliability | Higher price point, longer lead times |

| Jyoti CNC Automation Ltd. | 1989 | Rajkot, Gujarat | CNC Turning Centers, VMCs, HMCs, Five-Axis Machines | ISO 9001, ISO 14001, OHSAS 18001 | Companies needing a balance of price, innovation, and performance | Some machines may require longer setup times |

| HMT Machine Tools Limited | 1953 | Bangalore, Karnataka | CNC Lathes, Machining Centers, Grinding Machines | National Quality Standards | Industries needing durable, long-lasting machines | Some technology is outdated compared to competitors |

| Ace Micromatic Group | 1979 | Bangalore, Karnataka | CNC Turning Centers, Machining Centers, Automation Solutions | Industry Recognized, ISO Standards | Businesses looking for automation-driven solutions | Some machines may require specialized training |

| Lakshmi Machine Works Limited (LMW) | 1962 | Coimbatore, Tamil Nadu | Turning Centers, Machining Centers, Special Purpose Machines | Industry Recognized, ISO Standards | Companies needing a mix of standard and customized CNC solutions | Machines may have a steeper learning curve |

| Makino India Private Limited | 2001 (India) | Bangalore, Karnataka | HMCs, VMCs, Graphite Milling Machines, EDMs | ISO 9001 | High-precision industries like aerospace and automotive | Premium pricing may not suit budget-conscious buyers |

| DMG MORI India Private Limited | Global since 1948, India presence active | Pune, Maharashtra | Turning Machines, Milling Machines, Advanced Automation | Global Standards, ISO Certified | Large enterprises requiring cutting-edge CNC solutions | Higher costs compared to domestic competitors |

Now that you’ve seen the side-by-side comparison, let’s dive deeper into each manufacturer. In the next sections, we’ll explore their strengths, specialties, and what makes them stand out.

1. Bharat Fritz Werner Ltd. (BFW)

BFW isn’t just a machine builder—it’s a pillar of Indian manufacturing.

Started in 1961 as a technical collaboration with Fritz Werner of Germany, BFW has grown to become a name deeply respected by Indian machinists, toolroom managers, and plant heads alike.

I’ve seen BFW machines working flawlessly on shop floors where conditions are far from ideal—heat, dust, and unpredictable power. Yet, they run reliably. That’s no accident. These machines are built for Indian realities but match global expectations.

Product Range

BFW offers a variety of machine tools, including:

- Vertical Machining Centers (VMCs): Machines where the spindle axis is vertically oriented, suitable for tasks like drilling and milling.

- Horizontal Machining Centers (HMCs): Machines with a horizontally oriented spindle, ideal for heavy-duty cutting.

- Five-Axis Machines: Advanced machines that move a part or tool along five different axes simultaneously, allowing for complex shapes and precision.

- Horizontal Turning Centers: Machines designed for precise turning operations, often used for creating cylindrical parts.

These products cater to industries such as automotive, aerospace, and general engineering.

Manufacturing Capabilities

BFW’s manufacturing capabilities include:

- State-of-the-Art Facilities: BFW operates two advanced manufacturing plants equipped with modern machinery and technology.

- Global Expansion: In 2023, BFW inaugurated a new facility in Hosur, Tamil Nadu, significantly increasing its production capacity.

- Research and Development: The company has invested in R&D, launching the Dr. Kalam Center for Innovation in 2016 to develop next-generation manufacturing technologies.

Reputation and Certifications

BFW’s reputation and certifications include:

- Industry Recognition: BFW was recognized as one of the top 25 most innovative companies in India by the Confederation of Indian Industry (CII).

- Quality Certifications: The company holds ISO 9001:2000 and ISO 14001:2004 certifications, reflecting its commitment to quality management and environmental standards.

- Customer Relationships: BFW has well-established relationships with reputed clients, contributing to repeat orders and a diversified customer base.

Key Takeaways

Bharat Fritz Werner Ltd. (BFW) is a trusted choice for high-precision CNC milling machines, serving industries like automotive and aerospace. With decades of experience and a strong reputation for quality, they offer advanced machining solutions.

However, their machines can be costly for small businesses, and lead times may be longer due to high demand.

2. Jyoti CNC Automation Ltd.

When I first learned about Jyoti CNC, I was surprised to find such a world-class capability built entirely in India. What started as a small workshop in Rajkot in 1991 and has grown into one of the country’s top CNC exporters, now operating globally in over 30 countries.

Jyoti CNC stands out because it’s not just trying to “keep up”—it’s pushing the limits. Their acquisition of Huron Graffenstaden, a prestigious French machine tool builder, gave them access to world-leading 5-axis and high-speed machining technology. That move put them on the global map.

Product Range

Jyoti offers a diverse array of CNC machines:

- CNC Turning Centers: Machines designed for precise turning operations, suitable for producing cylindrical parts.

- Vertical Machining Centers (VMCs): Machines with a vertically oriented spindle, ideal for milling and drilling tasks.

- Horizontal Machining Centers (HMCs): Machines with a horizontal spindle orientation, facilitating heavy-duty cutting and complex machining.

Manufacturing Capabilities

Jyoti’s manufacturing strengths include:

- Advanced Facilities: Equipped with modern machinery and technology to ensure high-quality production.

- Research and Development: A dedicated R&D team focuses on innovation and technological advancements.

Reputation and Certifications

Jyoti’s reputation is built on:

- ISO 9001:1994 (2000)

- ISO 9001:2000 (2003)

- ISO 9001:2008 (2010)

- ISO 14001:2005 and BS OHSAS 18001:2007 (2016)

- Recognized for innovation and quality in CNC machinery.

- Strong presence in both domestic and international markets.

Key Takeaways

Jyoti CNC Automation Ltd. is known for its commitment to quality and innovation. Their machines are reliable and cater to various industries. However, their lead times might be longer due to high demand. I recall visiting their facility and being impressed by their state-of-the-art machinery and dedication to precision engineering.

3. HMT Machine Tools Limited

Founded in 1953, HMT Machine Tools Limited is a government-owned company based in Bangalore, Karnataka. Initially established to manufacture machine tools, HMT has diversified into various sectors over the decades.

Over the years, the company has evolved to offer both traditional machines and CNC solutions. They may not be at the cutting-edge other brands, but what they do offer is solid, affordable, and reliable Indian-built machines, especially suited for government units, defense shops, and vocational training centers.

Product Range

HMT’s offerings include:

- CNC Lathes: Machines designed for precise turning operations.

- Machining Centers: Versatile machines capable of performing multiple machining operations.

- Grinding Machines: Machines used for precision grinding of components.

Manufacturing Capabilities

HMT’s manufacturing capabilities encompass:

- Extensive Facilities: Multiple manufacturing units across India equipped with diverse machinery.

- Skilled Workforce: Experienced professionals ensuring quality production.

Reputation and Certifications

HMT’s standing includes:

- Legacy: Decades-long presence in the machine tool industry.

- Quality Standards: Compliance with national and international quality norms.

Key Takeaways

HMT Machine Tools Limited has a rich history in India’s industrial landscape. Their machines are durable and have served various sectors effectively.

However, some of their technology may be considered outdated compared to newer manufacturers. I remember my grandfather’s workshop housing an HMT lathe that, despite its age, functioned reliably—a testament to their machine’s longevity.

4. Ace Micromatic Group

Ace Micromatic Group is one of those rare machine tool companies that truly understands how Indian manufacturing works—from small workshops to high-volume Tier 1 suppliers.

Founded in 1973, the group combines several specialized brands like Ace Designers, Ace Manufacturing Systems, Micromatic Grinding, and Pragati Automation. Each one brings something different to the table, but together, they offer a complete machining ecosystem.

Product Range

Ace Micromatic offers a diverse array of CNC machines:

- CNC Turning Centers: Designed for precise turning operations, these machines are ideal for producing cylindrical parts.

- Vertical Machining Centers (VMCs): With vertically oriented spindles, VMCs are suitable for milling and drilling tasks.

- Horizontal Machining Centers (HMCs): Featuring horizontal spindles, HMCs facilitate heavy-duty cutting and complex machining.

- Automation Solutions: The group provides integrated automation systems to enhance manufacturing efficiency.

Manufacturing Capabilities

Ace Micromatic’s manufacturing strengths include:

- Integrated Facilities: Multiple plants with specialized production lines ensure efficient manufacturing processes.

- Technological Innovation: A strong emphasis on R&D leads to continuous development of advanced manufacturing solutions.

- Global Presence: The group’s products cater to industries worldwide, including automotive, aerospace, and general engineering sectors.

Reputation and Certifications

Ace Micromatic’s reputation is built on:

- Industry Leadership: Recognized as a leader in the Indian machine tool industry, the group has received numerous accolades for its contributions.

- Quality Assurance: Adherence to international quality standards ensures reliable and durable products.

- Customer-Centric Approach: The group maintains strong relationships with clients, focusing on customized solutions and after-sales support.

Key Takeaways

Ace Micromatic Group exemplifies innovation and quality in the Indian machine tool sector. Their extensive range caters to various industries, providing reliable and advanced machining solutions.

However, the complexity of their machines might require specialized training for operators.

5. Lakshmi Machine Works Limited

Established in 1962, Lakshmi Machine Works Limited (LMW) is based in Coimbatore, Tamil Nadu. Initially focused on textile machinery, LMW has diversified into CNC machine tools and other sectors, showcasing adaptability and growth over the decades.

Product Range

LMW’s CNC offerings include:

- Turning Centers: Machines designed for precise turning operations, suitable for producing cylindrical components.

- Machining Centers: Versatile machines capable of performing multiple machining operations, including milling and drilling.

- Special Purpose Machines: Customized machines tailored to specific manufacturing requirements.

Manufacturing Capabilities

LMW’s manufacturing strengths are:

- Modern Facilities: Equipped with advanced machinery and technology, ensuring high-quality production.

- Diversified Manufacturing: Experience across multiple sectors enhances their adaptability and expertise.

- Research and Development: A dedicated R&D team focuses on continuous innovation and technological advancements.

Reputation and Certifications

LMW’s reputation is built on:

- Industry Recognition: Awards for excellence in manufacturing and contributions to various sectors.

- Quality Assurance: Certifications reflecting commitment to international quality standards.

- Customer Trust: A strong customer base with long-standing relationships, reflecting reliability and trustworthiness.

Key Takeaways

Lakshmi Machine Works Limited’s transition from textile machinery to CNC tools showcases adaptability and commitment to innovation. Their machines are reliable and cater to various industries. However, their focus on advanced technology may come at a higher price point, which could be a consideration for smaller businesses.

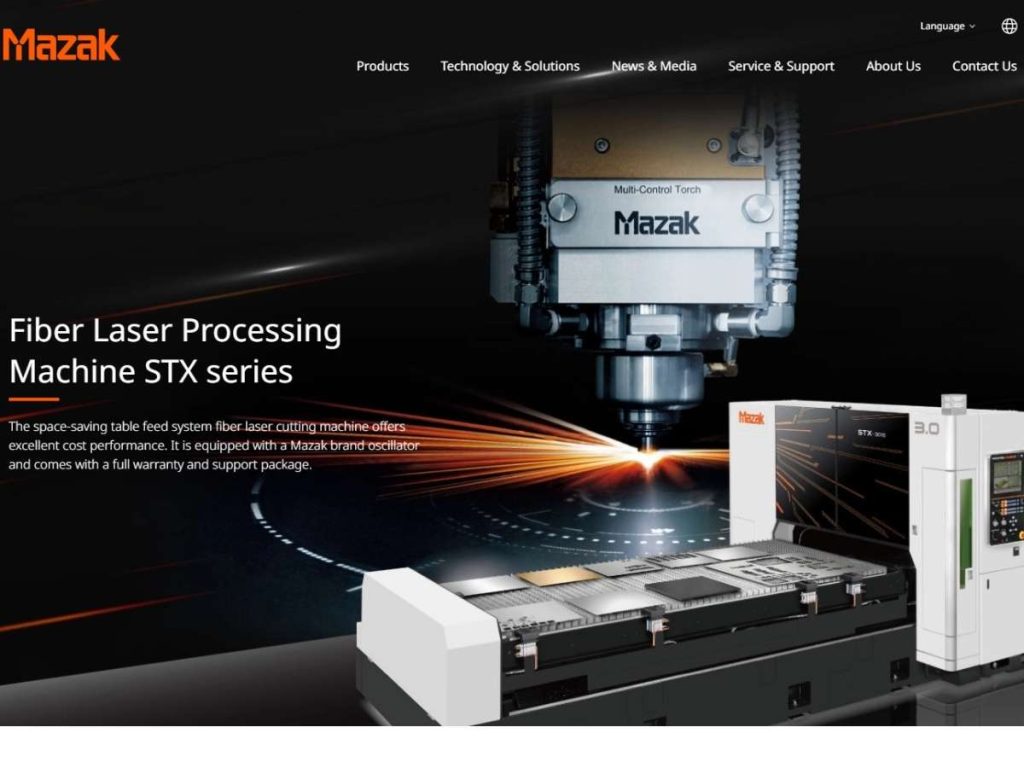

6. Yamazaki Mazak India Private Limited

Mazak entered India in 1998 and set up a full-scale manufacturing facility in Pune to serve Indian and South Asian markets. This wasn’t just a marketing move—it showed a long-term commitment to Indian industry.

What really stands out about Mazak is their blend of global engineering precision with local relevance. I’ve seen their India-made machines hold tolerances to micron levels while being more cost-effective than their imported counterparts.

Product Range

Mazak India’s offerings include:

- Multi-Tasking Machines: Machines capable of performing multiple operations, such as milling and turning, in a single setup.

- 5-Axis Machining Centers: Advanced machines that move a part or tool along five different axes simultaneously, allowing for complex shapes and precision.

- Laser Processing Machines: Machines that use laser technology for cutting and processing materials with high precision.

- CNC Turning Centers: Designed for precise turning operations, suitable for producing cylindrical components.

Manufacturing Capabilities

Mazak India’s strengths include:

- Advanced Technology: Integration of the latest CNC and automation technologies to enhance productivity.

- Customer Support: Comprehensive support services, including training and maintenance, ensuring optimal machine performance.

- Global Standards: Adherence to international manufacturing standards, ensuring high-quality products.

Reputation and Certifications

Mazak India’s reputation encompasses:

- Global Leadership: As part of the Yamazaki Mazak Corporation, a global leader in machine tools, the Indian subsidiary benefits from a rich legacy of innovation.

- Quality Certifications: Compliance with ISO standards, reflecting a commitment to quality management systems.

- Industry Recognition: Awards and accolades for excellence in manufacturing and technological advancements.

Key Takeaways

Makino India Private Limited stands as a testament to precision and innovation in the CNC machining industry. Their advanced machinery caters to various sectors, providing reliable and efficient solutions.

However, the high precision and advanced technology of their machines may come at a higher price point, which could be a consideration for smaller businesses.

7. DMG MORI India Private Limited

DMG MORI isn’t just a machine supplier—it’s what many precision manufacturers turn to when failure simply isn’t an option.

What I find most impressive is how they bridge cutting-edge engineering with real-world support. For many Indian aerospace, medical, and die-mold shops, DMG MORI machines are the go-to when a part has to be 100% right, every single time.

Product Range

DMG MORI India’s offerings include:

- Turning Machines: Machines designed for precise turning operations, suitable for producing cylindrical components.

- Milling Machines: Machines capable of performing various milling operations with high precision.

- Advanced Technologies: Incorporates automation and digitization solutions to enhance manufacturing efficiency.

Manufacturing Capabilities

DMG MORI India’s strengths include:

- Global Integration: Access to DMG MORI’s worldwide resources and expertise ensures cutting-edge technology.

- Customer Support: Comprehensive support services, including training and maintenance, ensuring optimal machine performance.

- Innovation Focus: Continuous development of advanced manufacturing solutions to meet evolving industry needs.

Reputation and Certifications

DMG MORI India’s reputation encompasses:

- Global Leadership: As part of the DMG MORI group, recognized for high-precision machine tools worldwide.

- Quality Assurance: Adherence to international quality standards ensures reliable and durable products.

- Industry Recognition: Awards and accolades for excellence in manufacturing and technological advancements.

Key Takeaways

DMG MORI India Private Limited exemplifies global excellence in CNC machining solutions. Their advanced machinery caters to various sectors, providing reliable and efficient solutions.

However, the high precision and advanced technology of their machines may come at a higher price point, which could be a consideration for smaller businesses.

Looking for a Manufacturer Outside India?

I remember going through supplier lists across India hoping to find a CNC manufacturer that matched my needs. But the specs weren’t right, prices didn’t add up, and the delivery timelines just didn’t work for my projects.

So, like many others, I looked to the China and found Blue Elephant. Honestly, it was a game-changer. Here’s why:

- Wide Machine Selection: Offers 3-axis, 4-axis, and 5-axis CNC routers, ATC systems, laser cutters, and full furniture production lines.

- Strong Customization Capabilities: Machines can be tailored to your specific industry needs—size, function, tools, software, and more.

- Excellent After-Sales Support: Includes video training, remote setup help, and 24/7 online assistance—no ghosting after purchase.

Since then, I’ve continued working with them and even recommended them to others who were stuck in the same spot I was.

If you’re still searching and feeling stuck, maybe it’s time to widen the search. Reach out if you want to hear more about our offerings!

Conclusion

You now have the facts of seven of India’s best CNC milling machine manufacturers You know their strengths, their challenges, and what makes them unique.

So, what’s stopping you? Can’t find the right one in India? Partner with Blue Elephant for your CNC milling machine needs.

We provide affordable spare parts and lifetime online support for ongoing assistance. Plus, our user-friendly machines come with pre-configured software.

Let’s discuss—contact us today!