When I first started working with CNC machines, I made a costly mistake—I. I ordered the wrong part. I thought I knew what I needed, but I used the wrong name when talking to the supplier.

It delayed production, wasted money, and made me realize how little I actually understood about CNC components.

I don’t want you to go through that.

Knowing the names and functions of CNC parts isn’t just useful—it’s essential for your business. It helps you diagnose problems faster, communicate with suppliers more clearly, and avoid expensive errors.

In this guide, I’ll break down the key components of a CNC machine. You’ll learn their names, what they do, and how they work together.

By the end, you’ll have the knowledge you need to work more efficiently and avoid the mistakes I once made.

Let’s dive in!

Quick Chart

Before we dive deep into each CNC part, here’s a quick snapshot to help you get familiar with the essentials. This table gives you a clear, high-level view of what each component does and why it matters.

| Part Name | Purpose | Quick Notes |

| 1. CNC Controller | Directs machine operations | Acts as the brain; interprets G-code and controls motion |

| 2. Spindle | Rotates the cutting tool | Core cutting power; speed and torque matter |

| 3. Tool Turret | Holds and changes tools | Boosts speed by switching tools automatically |

| 4. Tool Holder | Connects cutting tool to spindle | Key to accuracy and vibration control |

| 5. Ball Screw | Converts motor rotation into linear motion | Crucial for precision movement |

| 6. Servo Motor | Moves machine axes with feedback | Accurate, responsive, ideal for high-end machines |

| 7. Stepper Motor | Moves axes in fixed steps | Affordable; works well for entry-level systems |

| 8. Guideways (Linear Rails) | Guides linear motion along axes | Affects alignment, vibration, and surface finish |

| 9. Worktable | Holds the workpiece during machining | Stability is key for clean and accurate cuts |

| 10. Chuck | Clamps the workpiece (mainly in lathes) | Must grip securely to avoid slipping or shifting |

| 11. Headstock | Houses the spindle and drive system | Controls spindle rotation and torque |

| 12. Tailstock | Supports long workpieces from the end | Prevents bending and vibration during turning |

| 13. Coolant System | Cools tool and flushes away chips | Prevents overheating and improves tool life |

| 14. Automatic Tool Changer (ATC) | Automatically changes tools | Boosts speed and consistency in high-volume jobs |

Now that you’ve seen the big picture, let’s break down each part in detail so you can use this knowledge in real-world business decisions.

1. CNC Controller

The CNC controller is the brain of a CNC machine. Without it, nothing moves, cuts, or functions. It processes instructions and tells every part what to do.

I remember struggling with a faulty controller once. The machine wouldn’t respond, and production came to a halt. Hours of troubleshooting later, I realized the issue: a wiring fault inside the controller. That’s when I truly understood how important this component is.

What Does a CNC Controller Do?

The CNC controller takes commands from a computer program and translates them into movements. Think of it like a conductor leading an orchestra. Every part follows its signals precisely.

Here’s what it controls:

- Movement: Directs motors to move the cutting tool or workpiece.

- Speed: Adjusts feed rates to match cutting requirements.

- Tool Changes: Switches tools automatically during machining.

- Error Detection: Identifies and corrects issues like tool misalignment.

Types of CNC Controllers

There are three main types:

- PC-Based Controllers: Use a regular computer with CNC software. Common in small shops.

- Microcontroller-Based Controllers: Compact and efficient. Found in simpler machines.

- Industrial CNC Controllers: Powerful and built for high-volume production.

A CNC machine is only as good as its controller. If you want precision, reliability, and efficiency, choose the right controller matters. At Blue Elephant, we guarantee controller solutions that match your production goals—whether you’re scaling up, improving accuracy, or solving downtime issues.

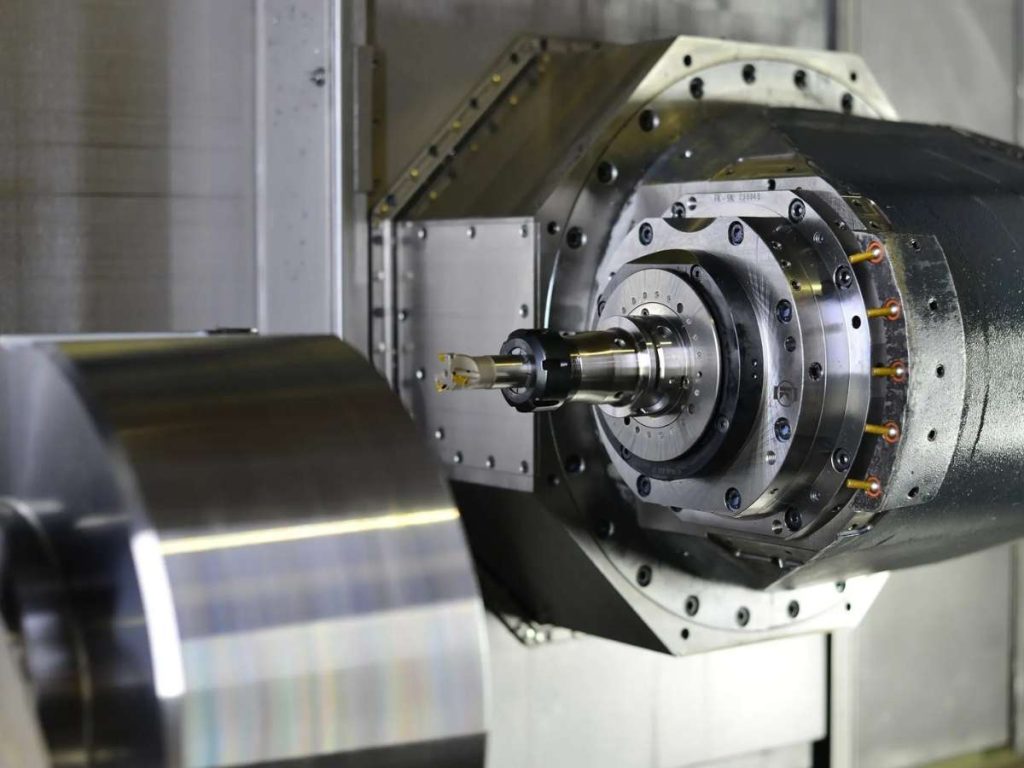

2. Spindle

If the CNC controller is the brain, the spindle is the heart. It holds the cutting tool, spins at high speeds, and does the actual cutting. Without it, nothing gets machined.

I learned this the hard way when a spindle suddenly failed on me. The machine screeched, the tool stopped mid-cut, and I knew I had a problem. Replacing it cost time and money—something no shop wants to waste. That’s when I realized, if you don’t understand your spindle, you’ll run into trouble sooner or later.

Types of CNC Spindles

Not all spindles work the same way. Choosing the right one depends on your production needs.

- Belt-Driven Spindles: These use a belt and pulley to transfer power. They’re affordable and easy to repair, but belts wear out and slip over time.

- Direct-Drive Spindles: The motor connects directly to the spindle. No belts, no slipping. They offer better accuracy and speed control but come with higher maintenance costs.

- Motorized Spindles: These have an integrated motor inside the spindle itself. They’re compact, powerful, and built for high-speed precision. If you need efficiency, this is the way to go.

What Affects Spindle Performance?

A spindle isn’t just about spinning—it’s about spinning right. Several factors impact its performance.

- Speed and Torque: High speeds work well for soft materials, but harder metals need more torque. If spindle isn’t matched to thematerial, tools wear out fast.

- Cooling System: Heat is the enemy. Spindles get hot, and without proper cooling (air or liquid), they break down faster. A friend once ignored cooling on his spindle—he regretted it when the bearings burned out.

- Tool Balancing: An unbalanced tool creates vibration, leading to poor cuts and potential spindle damage. If machine is vibrating more than usual, check tool balance.

Taking care of spindle isn’t just about maintenance—it’s about protecting your business in bottom line.

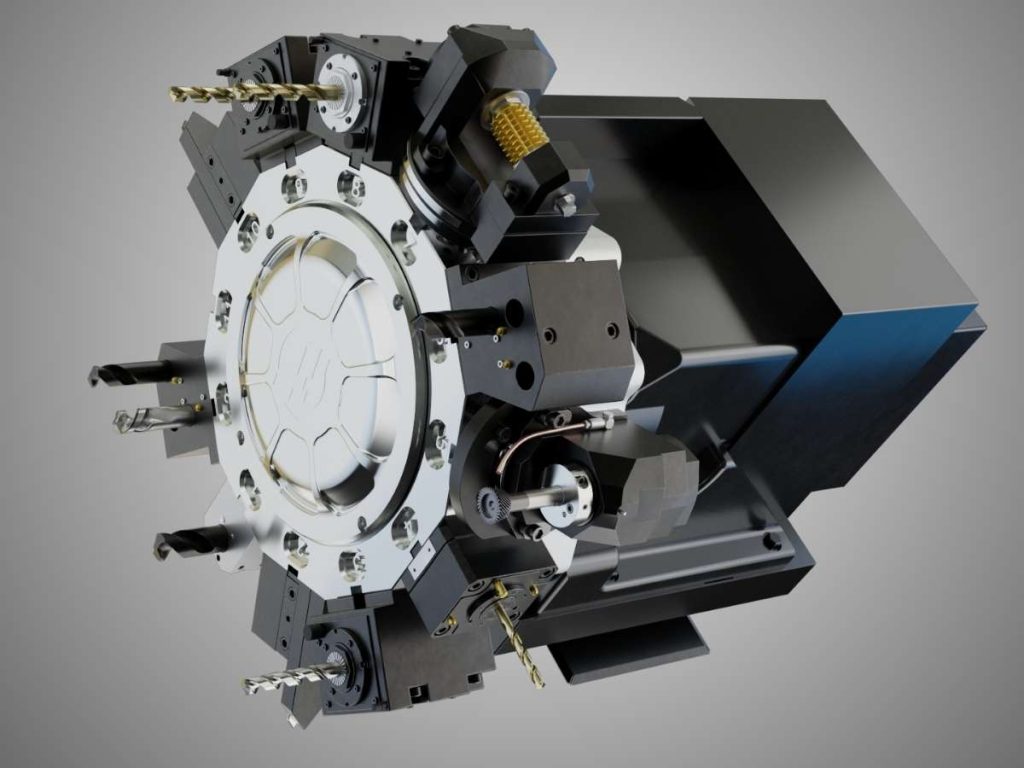

3. Tool Turret

A CNC machine without a tool turret is like a mechanic with only one wrench. It slows everything down. The tool turret holds multiple cutting tools and quickly switches between them during machining. This saves time and makes production more efficient.

Types of Tool Turrets

Not all tool turrets are the same. The right choice depends on your business machining needs.

- Disc-Type Turret: Holds tools in a circular pattern. It’s compact, simple, and great for light to medium-duty machining.

- Drum-Type Turret: A more rigid design that allows for heavier cutting loads. Found in high-production environments.

- Servo-Driven Turret: Uses a servo motor for fast and precise tool changes. If speed matters, this is a great option.

I’ve used all three. For high-volume jobs, the servo-driven turret is a game changer. What type do you use?

How Tool Turrets Improve Efficiency

A tool turret makes machining faster and more accurate. Here’s how:

- Reduces Downtime: No need to stop and manually change tools.

- Improves Precision: Tools stay in a fixed, pre-programmed position.

- Handles Complex Jobs: Multiple tools in one setup allow for continuous machining.

If you want better cycle times and higher output, upgrading your turret is a smart move.

4. Tool Holder

A tool holder might seem like a small part, but it plays a big role. It holds the cutting tool in place and connects it to the spindle. Without a good tool holder, you get poor accuracy, vibration, and tool failure.

Types of Tool Holders

Different jobs need different tool holders. Choosing the right one can improve accuracy and extend tool life.

- Collet Tool Holder: Uses a collet (a small sleeve) to grip the tool tightly. Best for high-speed machining and smaller tools.

- End Mill Holder: Holds end mills with a set screw. Strong and rigid, making it ideal for heavy cutting.

- Shell Mill Holder: Designed for large cutting tools like face mills. Used for milling wide surfaces.

I’ve used all of these. For precision work, collet holders are my go-to. For roughing, end mill holders perform better. What works best in your shop?

How to Choose the Right Tool Holder

A few key factors matter when selecting a tool holder:

- Material and Coating: Hardened steel or carbide-coated holders last longer.

- Balance and Runout: A well-balanced holder reduces vibration and improves accuracy.

- Tool Compatibility: Match the holder to the tool size and machine type.

Ignoring these factors can lead to tool wear, poor finishes, and even spindle damage.

5. Ball Screw

Every CNC operator knows that precision is everything. If machine isn’t hitting exact positions, the parts won’t fit, and quality takes a hit. That’s where the ball screw comes in. It takes the motor’s rotation and turns it into smooth, controlled movement. Without a reliable ball screw, machine won’t perform at its best.

I learned this firsthand when a machine at my shop started producing out-of-spec parts. At first, I blamed the programming. Then, I checked the tooling. Nothing seemed wrong. Finally, I inspected the ball screw. The backlash was terrible. We replaced it, and just like that, accuracy was restored.

Types of Ball Screws

Not all ball screws work the same way. The right choice depends on machining needs.

- Ground Ball Screws: Precision-machined for high accuracy. They cost more but deliver the best performance.

- Rolled Ball Screws: More affordable with slightly lower accuracy. Good for general machining.

- Precision Ball Screws: A middle-ground option, balancing cost and accuracy.

How Ball Screws Improve Accuracy and Efficiency

A high-quality ball screw does more than just move parts. It makes a real difference in machining performance.

- Reduces Backlash: Less play means better precision.

- Increases Efficiency: Lower friction helps the machine run smoother.

- Extends Machine Life: Less wear means fewer breakdowns.

6. Servo Motor

Without a servo motor, a CNC machine wouldn’t move with accuracy. This motor controls the movement of the machine’s axes, adjusting speed and position in real time. It responds to commands from the CNC controller, keeping every cut precise.

Types of Servo Motors

Not all servo motors are the same. The right one depends on the machine’s power and precision needs.

- AC Servo Motors: Powerful, efficient, and commonly used in high-speed CNC machines.

- DC Servo Motors: Simpler and used in smaller or older CNC machines.

- Stepper Motors: Not true servos but often used in budget CNC systems. Less precise but cost-effective.

I’ve worked with all three. For serious production work, AC servo motors are the best.

How Servo Motors Improve Accuracy and Efficiency

A strong, reliable servo motor makes all the difference in machining.

- Real-Time Adjustments: Keeps the machine on the correct path.

- High Torque at Low Speeds: Ideal for cutting tough materials.

- Long-Term Stability: Holds position without drift or error.

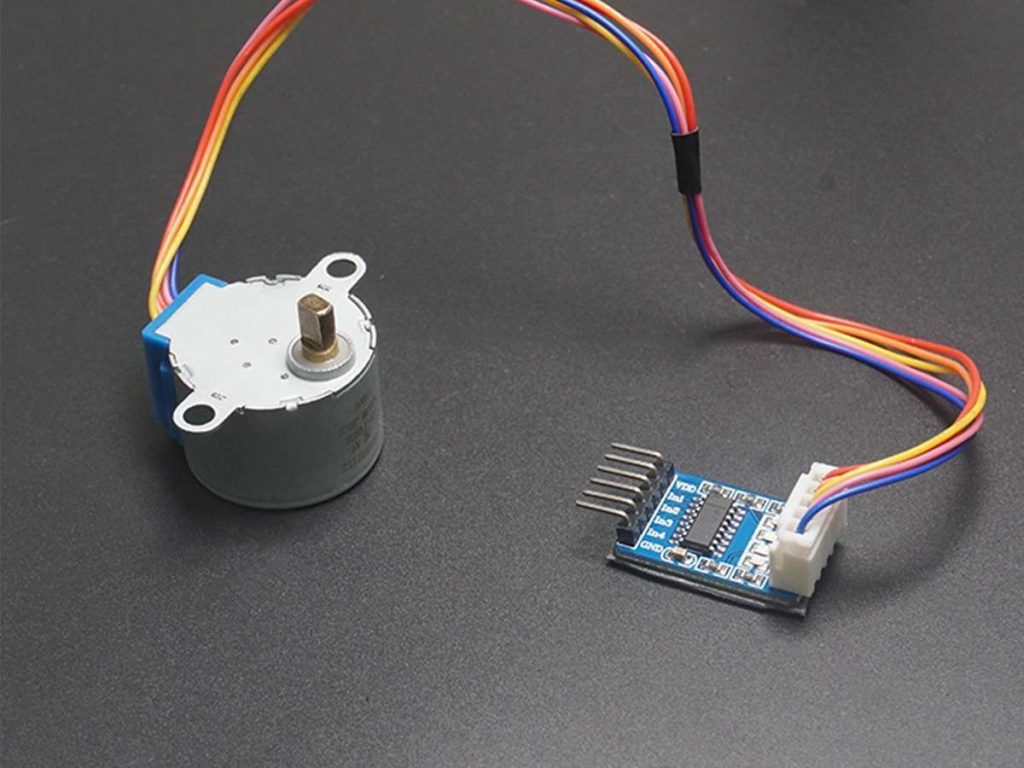

7. Stepper Motor

A CNC machine needs precise movement. That’s where the stepper motor comes in. It moves the machine’s axes in small, controlled steps. Unlike a servo motor, it doesn’t need feedback—it moves exactly as instructed.

Advantages of Stepper Motors in CNC Machines

Stepper motors work well in many CNC applications. They’re simple, cost-effective, and easy to maintain.

- No Feedback System Needed: Unlike servos, they don’t require encoders to track movement.

- Precise Positioning: Each step moves at a fixed angle, making repeatability easy.

- Lower Cost: A budget-friendly option for light-duty CNC machines.

For small-scale machining, stepper motors get the job done. But they struggle with high-speed, high-torque applications.

Key Features of High-Performance Stepper Motors

Not all stepper motors are the same. A good one will have:

- High Torque Output: Helps prevent missed steps under load.

- Microstepping Control: Increases accuracy and reduces vibration.

- Strong Holding Force: Keeps the tool in place when not moving.

I remember working on an entry-level CNC router that used stepper motors. The movements were smooth, but when we pushed the machine too fast, it lost steps. The result? Misaligned cuts. That’s the tradeoff with stepper motors—they’re reliable, but they have limits.

8. Guideways

A CNC machine needs smooth, controlled movement. That’s where guideways, also called linear rails, come in. They support and guide the moving parts along the machine’s axes. Without them, cuts won’t be precise, and machine won’t run smoothly.

Types of Linear Rails

Guideways come in two main types. Each has its own strengths.

- Profiled Guideways: Use rolling elements like ball bearings for low friction and high speed. Best for precision machining.

- Box Guideways: Heavier and more rigid. Absorbs vibration well, making it ideal for cutting tough materials.

How Guideways Affect CNC Precision

Guideways do more than just provide movement. They impact machining quality.

- Reduce Vibration: Prevents chatter and improves surface finish.

- Maintain Alignment: Keeps the tool on track for accurate cuts.

- Increase Machine Lifespan: Less wear on components means fewer breakdowns.

If machine isn’t cutting as precisely as it should, check guideways. They might be the problem.

9. Worktable

The worktable is where everything happens. It holds the material in place during machining. If it’s not stable, accurate, and durable, your final product won’t be either.

Materials Used for CNC Worktables

Different worktables are made for different jobs. The material affects durability, stability, and even machine performance.

- Aluminum: Lightweight, corrosion-resistant, and common in smaller CNC machines.

- Cast Iron: Heavy, rigid, and absorbs vibrations. Ideal for precision machining.

- Steel: Strong and durable but prone to rust without coating.

- Vacuum Tables: Use suction to hold down materials, great for thin or delicate workpieces.

I’ve used aluminum tables on light-duty machines, but for heavy machining, cast iron is unbeatable. What type do you use?

Why Worktable Stability Matters

A solid worktable improves machining quality. Here’s why:

- Prevents Material Movement: Keeps the workpiece steady for precise cuts.

- Reduces Vibration: Helps maintain accuracy and tool life.

- Supports Heavy Loads: Essential for machining metal and large workpieces.

If the parts aren’t coming out as expected, check worktable. Even a small shift can throw off an entire job.

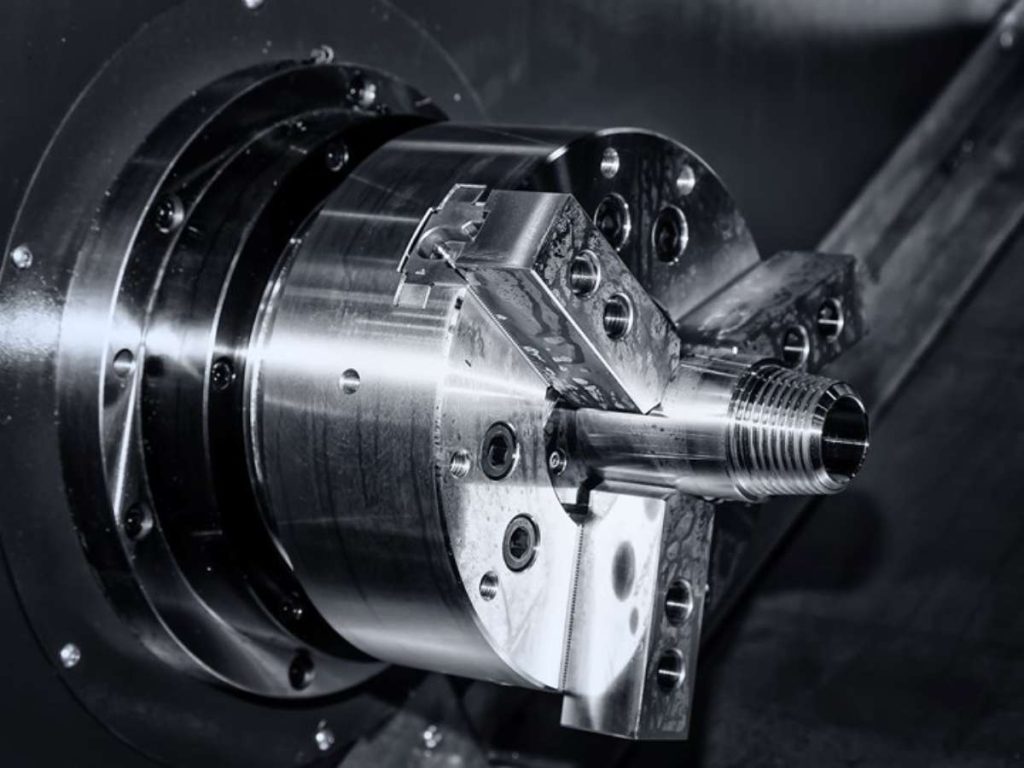

10. Chuck

The chuck is one of the most important parts of a CNC lathe. It holds the workpiece firmly in place while it spins and gets machined. Without a secure grip, the part can slip, shift, or even fly off, leading to costly mistakes and safety risks.

Types of CNC Chucks

Not all chucks work the same way. Choosing the right type depends on the material, shape, and machining needs.

- Three-Jaw Chucks: Self-centering and great for round workpieces. Common in general machining.

- Four-Jaw Chucks: Each jaw moves independently. Ideal for holding irregular shapes.

- Collet Chucks: Use collets for small, precise parts. Best for high-speed machining.

- Hydraulic Chucks: Provide strong, even clamping. Used in high-precision applications.

I’ve worked with all of them. For fast, repeatable work, three-jaw chucks are a solid choice. For odd-shaped parts, four-jaw chucks give more flexibility.

Why a Good Chuck Matters

A strong, well-maintained chuck improves machining accuracy and efficiency. Here’s why:

- Prevents Workpiece Slippage: Holds the part securely in place.

- Reduces Vibration: Leads to cleaner, more precise cuts.

- Speeds Up Production: Quick clamping means less downtime between setups.

If the chuck is worn or misaligned, machining quality will suffer.

11. Headstock

The headstock is where the real action happens in a CNC lathe. It holds and powers the spindle, which rotates the workpiece during machining. Without a strong, well-designed headstock, precision goes out the window.

Key Components Inside the Headstock

The headstock isn’t just a metal casing—it’s a system of critical components working together.

- Spindle: Rotates the workpiece at high speeds. A high-quality spindle improves accuracy.

- Bearings: Support the spindle and reduce friction. Worn-out bearings cause vibrations.

- Gearbox or Belt Drive: Controls spindle speed and torque. Direct-drive systems provide more precision.

- Cooling and Lubrication System: Prevents overheating and extends machine life.

Every part plays a role. If one fails, machining quality suffers.

Headstock Design for Precision Machining

A well-built headstock leads to better performance. Look for:

- Rigid Construction: Reduces vibration and increases accuracy.

- Precision Bearings: Help maintain spindle stability at high speeds.

- Proper Alignment: Ensures smooth, consistent cutting.

If machine isn’t cutting as accurately as it should, the headstock might be the issue.

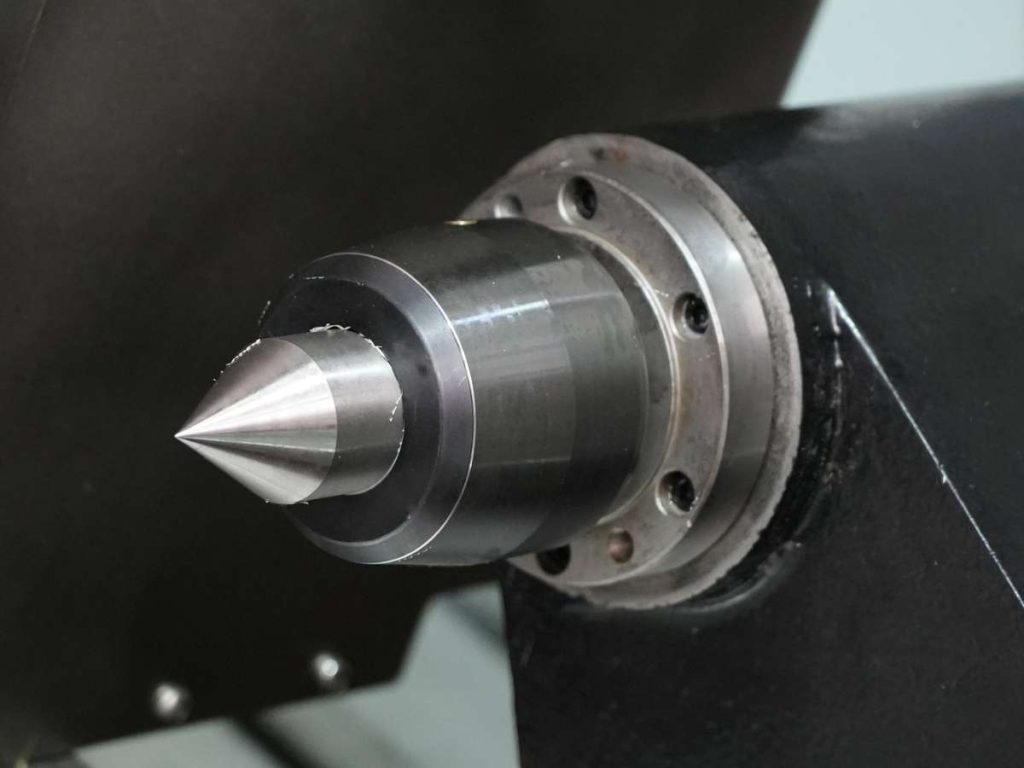

12. Tailstock

Ever had a workpiece vibrate or bend during machining? That’s where the tailstock comes in. It provides extra support for long or thin parts, preventing deflection and keeping everything stable. Without it, accuracy suffers, and tool life shortens.

Long shafts and delicate workpieces are a challenge without proper support. A machinist I worked with ignored the tailstock on a long aluminum rod. At first, everything seemed fine. But as the cut deepened, the rod flexed, and the dimensions were off. Adding the tailstock locked everything in place, and the final result was flawless.

Uses of a Tailstock in CNC Turning

The tailstock isn’t always needed, but when it is, it makes a huge difference. It:

- Prevents Deflection: Stops the workpiece from bending under cutting pressure.

- Reduces Vibration: Leads to a smoother surface finish and better tool life.

- Improves Accuracy: Keeps parts concentric, especially in deep cuts.

Skipping the tailstock on long workpieces can cost you time and material.

How to Adjust a CNC Tailstock Properly

A poorly adjusted tailstock can cause as many issues as not using one at all. Here’s what to check:

- Headstock Alignment: Misalignment causes tapering and inaccuracies.

- Clamp Tightness: Loose tailstocks move during machining, ruining precision.

- Pressure Setting: Too much force damages the workpiece, too little won’t provide enough support.

A quick check before running the machine can prevent costly mistakes.

13. Coolant System

Heat is a CNC machine’s worst enemy. Without proper cooling, tools wear out faster, workpieces warp, and precision suffers. That’s why the coolant system is so important. It keeps temperatures under control, removes chips, and improves cutting performance.

A shop I visited once had a machine struggling with poor surface finishes. The cause? A clogged coolant line. Chips weren’t being cleared properly, and heat was building up. After flushing the system and refilling it with fresh coolant, the difference was obvious—smoother cuts, longer tool life, and a happier machinist.

Types of CNC Coolant Systems

Different jobs require different cooling methods. Here are the main types:

- Flood Coolant: A high-volume stream of liquid that cools and clears chips efficiently. Great for heavy machining.

- Mist Coolant: A fine spray that provides cooling with minimal fluid use. Works well for light-duty operations.

- Through-Spindle Coolant: Delivers coolant directly through the tool, reaching deep cuts and improving chip evacuation. Best for high-speed or deep-hole machining.

Choosing the right system depends on your material, tooling, and machine setup.

Best Practices for CNC Coolant Maintenance

A dirty or neglected coolant system can cause major problems. Keep it in top shape by:

- Checking Coolant Levels Daily: Running dry can damage tools and workpieces.

- Filtering Out Contaminants: Chips, dirt, and bacteria can build up over time.

- Replacing Old Coolant: Overused coolant loses effectiveness and can cause odors or rust.

Neglecting coolant maintenance leads to overheating, poor finishes, and machine downtime.

14. Automatic Tool Changer (ATC)

Stopping a CNC machine to change tools wastes time. That’s why an automatic tool changer (ATC) is a game changer. It swaps tools automatically, keeping production moving without delays.

How an Automatic Tool Changer Works

An ATC stores multiple tools and changes them when needed. Here’s how it works:

- The CNC program signals a tool change.

- The machine moves to the tool change position.

- The ATC swaps the current tool for the new one.

- Machining resumes without operator input.

This process happens in seconds, keeping production efficient.

Common ATC Mechanisms

Different ATCs use different designs:

- Carousel ATC: Stores tools in a rotating drum. Fast and compact.

- Chain ATC: Uses a chain system to hold more tools. Good for machines needing large tool capacity.

- Arm-Type ATC: Uses a robotic arm to swap tools quickly. Best for high-speed machining.

Choosing the right ATC depends on production needs and machine size.

Why ATCs Matter in High-Speed Production

An ATC boosts efficiency in several ways:

- Reduces Downtime: No manual tool changes mean more machine uptime.

- Improves Precision: Tools are changed consistently, reducing human error.

- Handles Complex Jobs: Multiple tools can be used in one setup without stopping.

Without an ATC, high-speed production becomes slow and inefficient.

Conclusion

I messed up because I didn’t know the right CNC part name. That mistake cost me time, money, and trust.

You don’t have to go through that.

Now you’ve got a clear breakdown of every major CNC machine part—what it does, how it works, and why it matters.

Want smoother production? Fewer breakdowns? Better supplier talks?

Start by learning the names. Master the functions. Take what you learned today and apply it to your shopping floor.

Ready to avoid costly errors?

Contact Blue Elephant today to upgrade your CNC knowledge and equipment!