CNC router bits are the most critical tools for CNC routers realizing cutting, engraving, pocketing and other processes. They determine the kind of processing you can do and the quality of your finished designs. Without them, CNC routers can do nothing. The CNC router tools fall into many types, and different process requires different tools. If your projects involve not only cutting work, but also 2D and 3D engraving, pocketing, etc., what kind of CNC router cutters should you choose? What should you consider when buy and use such CNC bits? This complete buyer guide will give you a complete introduction to the CNC router bits, including definition, classification, purposes and precautions for choosing or using them.

What are CNC router bits

CNC router bits are the tools installed on CNC routers to cut and engrave workpieces, and also called CNC router tools, CNC router cutters, router machine bits, CNC engraving bits etc. CNC router bits of different types can achieve different processes.

Types

Based on the processing method, the CNC router cutters fall into two categories, i.e. CNC drill bits and CNC milling bits.

CNC drill bits are usually used for pre-drilling holes for screws. These CNC bits drive into materials. They don’t have side edges, so they can’t mill horizontally.

CNC milling bits, also known as CNC carving bits, CNC end mills or engraving router bits, can cut or move across the surface of the workpieces. They are designed to carve or engrave the materials to realize 2D patterns or 3D designs.

Features

The CNC router bits are subjected to high pressure, high temperature, strong impact and vibration when cutting or engraving materials. So the CNC router cutter shall have certain characteristics to endure the high temperature, high speed and high cutting force situation. Such features include:

Great hardness and abrasion resistance.

High strength and toughness.

High temperature resistance.

Classification of CNC router bits

On the basis of the tip shapes, the CNC router bits can be divided into many types and each type has specific functions. The following will give a general introduction of the types of the most commonly used CNC router tools.

Flat bottom bits

Such bits are also called cylindrical router bits. They can engrave mainly relying on the side edge and the bottom edge is mainly for surface milling. The cylindrical CNC router cutters generally have two types based on the shapes of side edge. The left picture shows the spiral edge flat bottom CNC router bits, which are mostly used for engraving metal and plastic material. The right picture shows the straight edge flat bottom router machine bits, and these CNC router bits are mainly for cutting wood materials.

Ball nose bits

Sometime they are also called round nose bits, and they have many types according to the shapes of such CNC engraving bits. The cutting edge of ball nose CNC end mills is in arc shape, which could form a hemisphere during engraving process. So the ball nose bits are subject to uniform force when cutting and can cut smoothly. The ball nose bits, therefore, are especially suitable for semi-finish and engraving curved surfaces but not for milling planes. They are perfect for routing channels in cutting boards and counter tops and to produce flutes in solid wood.

Tapered ball nose bits

Also called tapered ball nose CNC end mills. They are the mixer of tapered router bits and ball nose bits. So they have the characters of both the tapered router machine bits having small tips, and the ball nose CNC end mills. The tapered ball nose CNC router bits are often used for relief carving, projection carving and so forth.

Corn teeth end mills

This type of CNC end mills has teeth on the side edges, looking like a corn. Such end mills are perfect for cutting hard or super-hard materials, such as printed circuit board, HDF, hard wood, carbon fiber, fiber glass, HDF composite boards, etc.

Drill bits

This type of CNC router bits are mainly used for drilling holes on workpieces for screws. The drill bits have only bottom edges without side edges, so they can’t achieve milling work in horizontal direction except for drilling holes. These bits are able to drill holes with different diameter and depth, making it convenient for the following process.

Three-dimensional irregular router bits

They are actually a kind of tapered router end mills with a big taper angle at the cutter tip. Different from common CNC router bits that the cutter head is directly machined from the shank, these CNC router tools have cutter heads welded additionally on the shank. So we often call them big head router bits. They are capable for engraving work of various special forms on many materials. The head of such CNC end mills could be in any shape, so you need to choose this type of router machine bits according to your project designs.

Major cut types of spiral CNC router bits

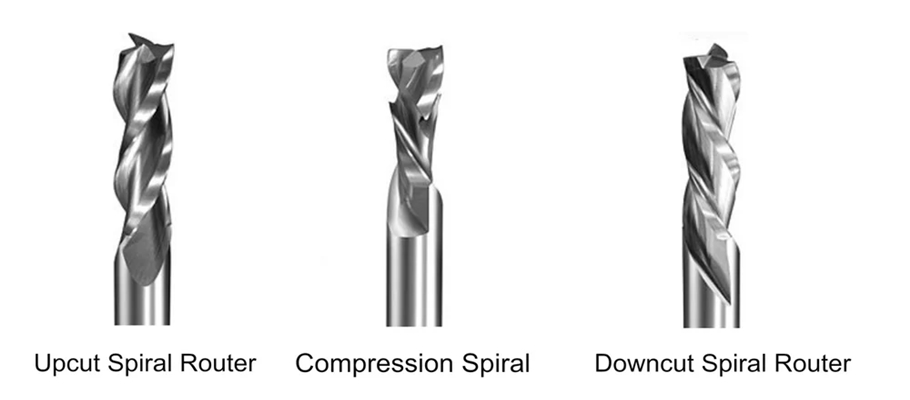

Spiral CNC end mills are among the most commonly-used router machine bits. They are suitable for a wide range of applications. But the cut type mainly includes three kinds, up-cut, down-cut and compression cut.

Up cut

The up-cut CNC router tools clear the chips away from the material during processing. Such up-cut CNC milling bits can be used for grooving or slotting, for upward chip evacuation and best finish on the bottom side of the part. These CNC end mills are ideal for cutting relatively thick materials, but not recommended for thinner or softer materials. During processing, the upward force can pull the chips up, causing a ragged finish on the top surface, or even worse, eject the part from the table. So your material will need to be securely held down. This type of CNC router bits is used whenever the best finish is needed on the bottom side of a workpiece.

Down cut

On the contrary to The down-cut type CNC router bits press the chips and the material back into the cut. They are suitable for cutting thin, flexible materials but not for drilling holes. Down-cut CNC router tools are predominantly used when a high quality cut finish is required on the top surface of a workpiece. However, it may wear the bottom surface.

Compression cut

Compression CNC router bits are the combination of both up-cut and down-cut CNC bits. So they have features of both these two types of CNC router tools. The bottom of the material is pulled upwards while the top of the material is pushed downwards thus eliminating the risk of damaging the laminated surfaces during processing. Therefore, when cutting materials like plywood, you may get a sharp and clean edge on both sides of the workpieces.

Choose different CNC router bits for your specific projects

It is often said that: To do a good job, an artisan needs the best tools. Choosing the right CNC router tools will help you obtain high quality products, avoid reworking and reduce abrasion of the CNC bits as well. The following text may give you a hint for choosing a right tool for a specific material.

For cutting acrylic, the single flute spiral milling cutter is recommended. This kind of CNC router bits can cut acrylic material with fast speed and high efficiency, without smoke and smell and not sticking any chips. The fine grain (or even no grain) on this CNC end mills ensures a smooth cutting surface.

For processing the acrylic surface to achieve dull polishing effect, we recommend to use double flutes or three flutes spiral milling cutters.

The double flute chip-breaker spiral mill cutter is suitable for cutting MDF, because it has two large grooves to remove chips. Besides, it can keep good balance state and will not blacken or emit smoke during cutting process.

For cutting aluminum plates, we recommend to use CNC bits for aluminum, such as single flute milling cutter. The cutting process is non-stick, fast and efficient. While for engraving small aluminum relief, the round bottom engraving router bits could be a good choice.

If you are making large size deep relief with soft wood, MDF, natural wood, PVC or acrylic, you’ll need some single flute spiral ball nose milling router bits.

For processing high density fiberboard (HDF) or hard wood, you can choose corn teeth CNC end mills.

In case of rough processing of particle boards, melamine boards etc., you can get yourself multiple tool grain milling router bits.

When making large 3D carvings, you’ll want ball nose bits that are appropriately sized for the level of detail in your model.

If you want to create lettering and or sign making, you’ll need to get a v-groove router bit. This is the only way to get a sharp grooves on your workpiece.

How to choose CNC router bits

How to choose suitable CNC router bits? There are plenty of variables to take into account when choosing the right CNC router cutter, but the type of material and project are two major factors that you must always take into consideration.

Material compatibility

What are you cutting or engraving? Is it wood or soft metal? Is it stainless steel, fiberglass, acrylic or soft wood?

The materials you cut or engrave determine the choice of the CNC router cutters to some extent. You can find different grades of carbides used for different materials. Wrong or unsuitable use of CNC end mills could be detrimental to the bits or even the CNC router. Hard materials, like steel or stone, require CNC router tools with bigger hardness and greater toughness, such as diamond router end mills. While soft materials, like soft wood or foam, may require engraving router bits with common hardness and toughness, such as carbide CNC carving bits.

Project suitability

What project are you undertaking? Different projects require different types of bits as well.

For example, if you are making smooth contouring and fine detail passes or complex shapes like 3D carvings, then the ball nose spiral end mills may be your best choice. The rounded ends of these CNC router bits produce smooth curves that would be impossible to achieve with flat end bits. However, when making signage with lettering and other shallow detail on a flat surface, V groove engraving router bits could be a good assistant. You can also choose different V groove angles for producing grooves with different depth.

Materials of CNC router bits

The material of CNC router bits is also an important factor when choose a bit for your projects. For example, if you are carrying out stone carving work, you may need a harder CNC end mill. Generally speaking, the materials of the CNC router bits mainly include the following four categories.

| Material | Description | Applications |

| Ultra-hard material |

| Rough and finish machining of:

Processing of:

|

| Solid carbide (SC) |

| 2D and 3D cutting, engraving, milling of:

|

| Coated CNC router tools |

| Suitable for cutting:

For high production nesting operations |

| high-speed steel (HSS) |

| Excellent for cutting:

|

Brand and functions

Except for the foregoing, you may also have to consider the brands and functions of the CNC router bits. Try to choose the CNC router cutters from formal manufacturers, because they can guarantee the quality of the router machine bits. If you buy the CNC milling bits from some small workshops, you may end up with a knock-off. In addition, in case you’re new to CNC engraving and looking for a multi-function bit, you can choose two-flute spiral bits since they cut a wide range of materials. Such as plastic, aluminum, wood and foam.

Precautions when using CNC router bits

As a kind of consumables, the CNC router bits have a certain service life. Proper use could prolong their service life and save cost, but using the CNC router tools incorrectly or with improper manner will shorten their service life and also cause waste of materials, time and cost. So please check the following precautions when using CNC router bits to help you use them for a longer time.

Thickness of the processing material shall not exceed the maximum thickness that the router machine bits can cut. Otherwise, it will end up with broken bits or unsatisfied engraving results.

The shank of the bits shall match with the collet and can be firmly inserted into the collect. If the collect has deformation due to long-term use, it may cause vibration of the shank and unsatisfied results, so please replace with new ones timely.

Be sure to check the toughness and sharpness of the CNC router bits frequently. Replace with new ones in case of any damage or blunt.

Please use dedicated cleaning agent to clean the CNC router tools.

Select suitable CNC end mills and reasonable working speed for cutting and engraving different materials. Try to use consistent working speed during processing.

Do not polish or change the flute of the CNC milling bits personally.

Pay attention to personal safety when the milling router bits is rotating at high speed. Especially that try not to wear too large overalls and the female should tie up their long hair to avoid accidents.

In case that the CNC router tools are not used for the moment, please apply butter on the bits to avoid rusting.

When to change CNC router bits

I have mentioned in the above that the CNC router bits belong to consumables, and they wear gradually during using. Worn CNC router cutters have a great impact on not only the processing results but also the service life of spindle motor. So it is very important to change CNC router bits in a timely manner. Then how can we know that it’s time to change the router machine bits?

The processing sound becomes obviously louder.

The vibration of materials during processing is greater than usual.

The machined bottom surface grain is clearly circle-shaped.

Please note that in actual processing work, you shall not replace the CNC router tools when they reach their wear limit, but shall replace in advance. Because if you continue to use the worn tools, the cutting force will increase greatly. As the force is directly related to the spindle motor service life, it will influence the spindle motor life significantly. So you’d better change the CNC router bits before they reach the wear limit.

How to reduce tool wear

Since you have known when to change the worn CNC router tools, then what you can do in daily work to reduce the tool wear?

Ensure that the collect is clean and free of foreign objects to make sure the CNC router cutters are installed correctly.

Use the CNC router bits with good rigidity (large diameter).

In case of starting to use a tool, perform a breaking-in for 10 minutes at a low speed of 50% of the normal speed.

Try to adopt climb milling in case of rough processing.

Select proper spindle speed and cutting parameters.

In case of increased vibration, stop the CNC router to lower the rotating speed and feeding speed.

Timely clean the chips in the cutting area to avoid cutting them for the second time.

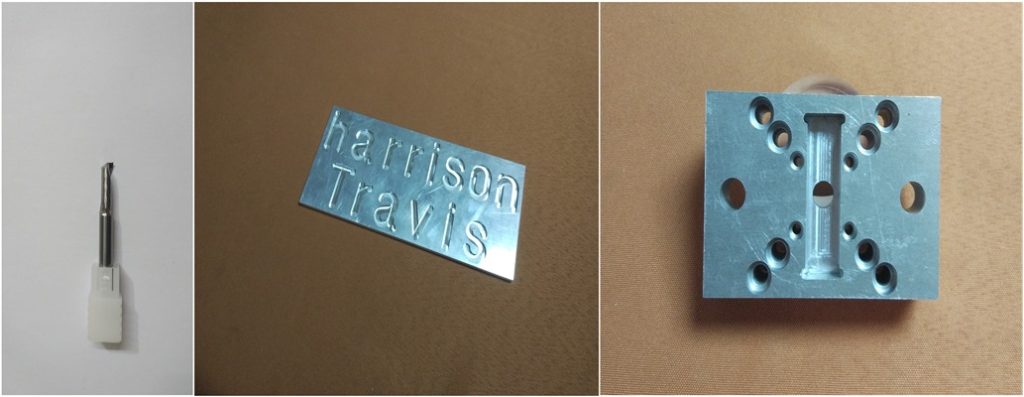

Frequently-used CNC router bits and product samples

The following part lists several types of CNC router bits that are frequently used by our CNC routers to cut or engrave different materials, and also shows the samples made by these milling router bits.

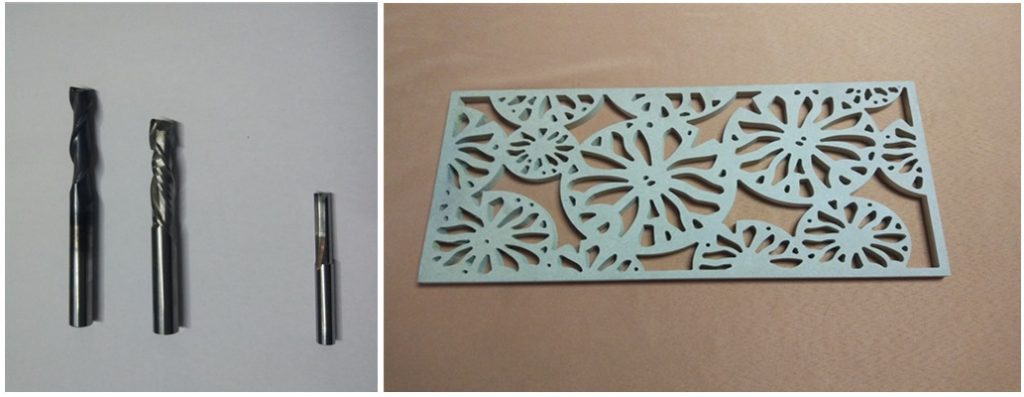

Single flute spiral end mills

The diameter can be 6mm or 8mm and the flute length can be 22mm, 50mm and 60mm. They are mainly used to cut or mill grooves, and suitable for processing wood, MDF, PVC, etc. Such CNC end mills are available in up-cut and down-cut type.

Double flutes spiral end mills

The diameter can be 6mm, 8mm or 10mm, and the flute length can be 22mm, 50mm, 60mm and 80mm. It is also available in up-cut and down-cut types. The functions that such CNC end mills can achieve are similar with the single flute spiral end mills.

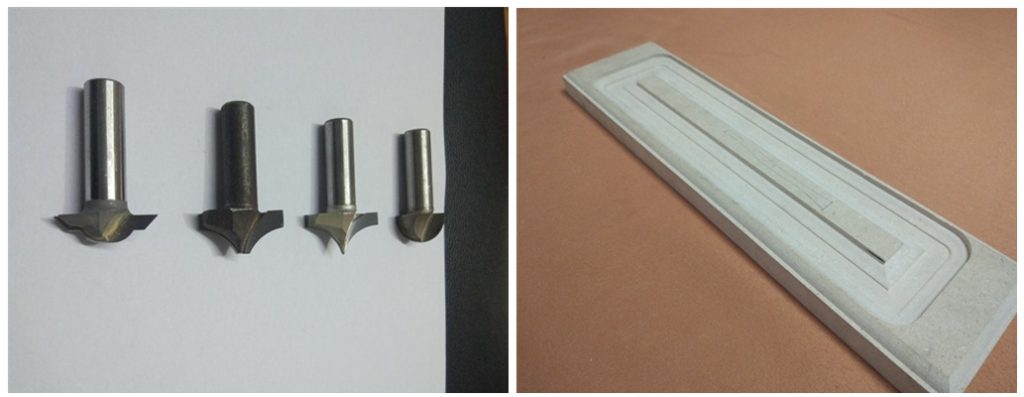

V groove router bits

The V groove angel varies, such as 60°, 90° and 120°, and determines how deep you can plunge for a given groove width. A narrower angle produces a deeper groove while a wider angle produces a shallower groove. The maximum width of flute is 32mm. Such CNC engraving bits are suitable for creating projects with an engraved design on a flat wood, MDF or aluminum composite panels.

Surface milling bits

They are mainly used for milling the material surface quickly. The diameter of shank can be 6mm or 12mm and the flute diameter can be 20mm or 32mm. Such CNC milling bits are suitable for milling wood, MDF, PVC.

Double straight flutes engraving bits

These CNC engraving bits are generally used for engraving complex relief. They are able to engrave materials with large depth. The diameter of shank can be 6mm and 8 mm and the flute length can be 50mm, 60mm and 70mm.

Double flutes ball nose bits

Such carving bits are general applied to engrave large or simple relief and suitable for materials, like wood, MDF, PVC, etc. These bits are also excellent for routing fluted columns and channels in cutting boards and countertop edges. The diameter of shank includes 4mm, 6mm, 8mm and 10mm, and the flute length can be 22mm, 50mm and 60mm.

Irregular router bits

The bit head has a variety of shapes, and can achieve different engraving results. Choose according to your specific processing requirements.

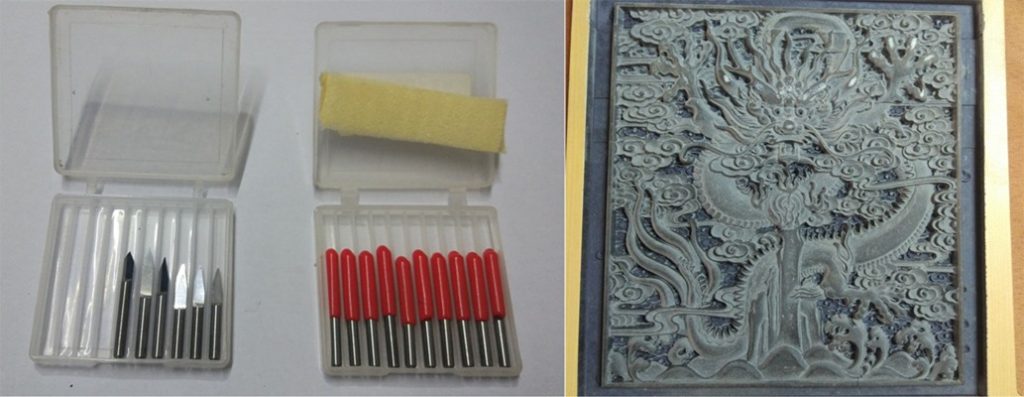

Small engraving bits

Diameter of such CNC bits is only 3mm and the flute length ranges from 5 to 20mm. They are mainly for engraving complex 3D designs and patterns, usually with shallow depth.

CNC bits for aluminum

Such bits are excellent for cutting and engraving aluminum, aluminum composite panels and also acrylic. The flute length is 22mm. The bits are similar with single flute CNC router bits but made of different material.

Conclusion

In conclusion, the CNC router bits are available in a variety of types, and different type has own special processing results. So the choice of the CNC router bits plays an important role in different processing requirements. Selecting the right tools can not only achieve excellent product results, but also reduce the abrasion of the tools themselves and prolong their service life. What’s more, there are also plenty of considerations with respect to using and storing the CNC router cutters. To summarize, the CNC router bits matter a lot and you may carefully select the bits that suitable for your projects.