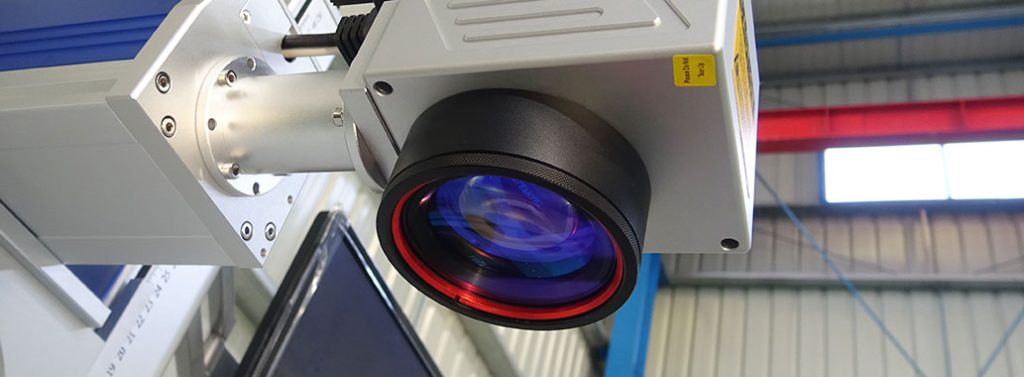

Fiber laser marking machine is one of the most advanced and commonly used laser marking system in the world today. It has features of strong adaptability, low maintenance, and no consumables in the marking process. So the fiber laser marker has wide applications, especially in the metal and plastic processing industries for precise and efficient marking. The fiber laser marking machine is designed to meet your requirements for making marks or other information on hard and high-density materials. What do you need to know about the fiber laser marking system?

This article offers a complete guide for potential customers of fiber laser marking machines. It lists ten matters you need to know before buying a fiber laser marker, including definition, advantages, applications, parameters, price, etc.

What is fiber laser marking machine

Fiber laser marking machine is a type of laser marker machine used to mark characters, figures and patterns on certain materials. The fiber laser marking machine is also known as fiber laser marker and is also a kind of fiber laser engraver or fiber laser engraving machine.

Laser marking refers to the use of laser beams to make permanent marks on the surface of various materials. The principle of laser marking is to expose the deep material through the evaporation of the surface material, or to engrave traces through the chemical and physical changes of the surface material caused by light energy, or to burn off part of the material through light energy to show the required marks. Fiber laser marking machines are mainly used in the occasions requiring finer and higher precision.

Fiber laser marking VS CO2 laser marking

As two most commonly used laser marking machines, there are plenty of differences between the fiber laser markers and CO2 laser markers.

Different lasers

The fiber laser engraver adopts a fiber laser while the Co2 laser marker adopts a Co2 laser. Working wavelength of a fiber laser marker is 1.064um, 10 times shorter than that of a CO2 laser marking machine. Due to this much smaller focal distance, the intensity of a fiber laser marking system is almost 100 times higher than a CO2 system with a similar power output.

Different laser transmission method

Fiber laser marking machines rely on fiber cables to transmit the laser, while CO2 laser markers uses optical system to transmit the laser. As a result, it’s necessary to adjust the optical path of a CO2 laser marker, but there is no need for a fiber laser marker.

Different applications

Fiber laser engraving machine is applicable for marking and engraving most metals and partial non-metal materials. For example, steel, aluminum, copper, gold, engineering plastics, ceramics, epoxy resin, painting materials, electroplating material, etc.

CO2 laser engraving machine is good at engraving and marking most of non-metal materials. For instance, bamboo products, wood, acrylic, leather, glass, rubber and so forth.

Other differences

In terms of marking precision, fiber marking belongs to a nanoscale machining method, so its precision is higher than CO2 laser marking.

The maximum service life of a fiber laser engraving machine can reach 100,000 hours, because it doesn’t need much maintenance and consumables. However, the CO2 laser marker requires regular maintenance and replacement of vulnerable parts, so its maximum life could be 30,000 hours.

With the same laser power, the laser marker price of the two also varies. The fiber laser marking machine price may be higher than that of the CO2 laser marking machine.

What can fiber laser marking machine do

From the view of functions, the fiber laser engraving machine can achieve:

Marking on metal materials and certain plastics;

Black marking on the alumina. This is achieved by a fiber laser marking machine with adjustable pulse width, which differs somewhat from an ordinary fiber laser marker;

Color marking on metal. This requires some adjustments and attempts on the parameters according to the material, and various colors can be marked on the stainless steel;

On-line flying marking. This means to combine the fiber laser engraver with the assembly line, marking while feeding. It can greatly improve work efficiency, and suitable for marking items that need to be marked on the assembly line.

In terms of materials, the fiber laser engraver has significant advantages for marking materials of high hardness, high melting point and brittleness. In other words, most metal materials, as well as certain non-metallic materials such as plastics, can be marked by fiber laser marking machines. For example, common metals and alloys (iron, copper, aluminum, magnesium, zinc, etc.), rare metals (gold, silver, titanium), metal oxides, special surface treatment (phosphating, aluminum anodization, electroplating surface), ABS, Epoxy resin, etc.

Applicable industries

The fiber laser marking machine has applications in a wide range of industries.

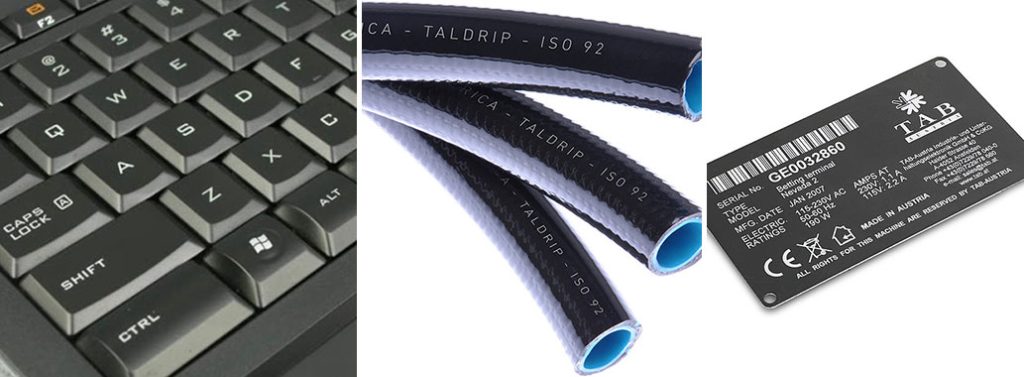

Automotive and mechanical industry: bearings, steel jackets, piston rings, engine labels, buttons on auto panel, machine tool accessories, etc.

Electronic communication industry: mobile phone keys, keyboards, electronic components, home appliance panels, optical cables, cables, etc.

Hardware tool industry: tools, measuring tools, cutters, sanitary ware, tableware, locks, knives and scissors, medical equipment, fitness equipment, etc.

Jewelry industry: buttons, luggage buckles, belt buckles, gold and silver jewelry, leather bags, belts signs, badges, attendance cards, business cards, etc.

Craft and advertising industry: welcome signs, calendars, photo frames, pens and pencil cases, certificates, trophies, medals, certificates, collectors, artworks, stamps, plaques, etc.

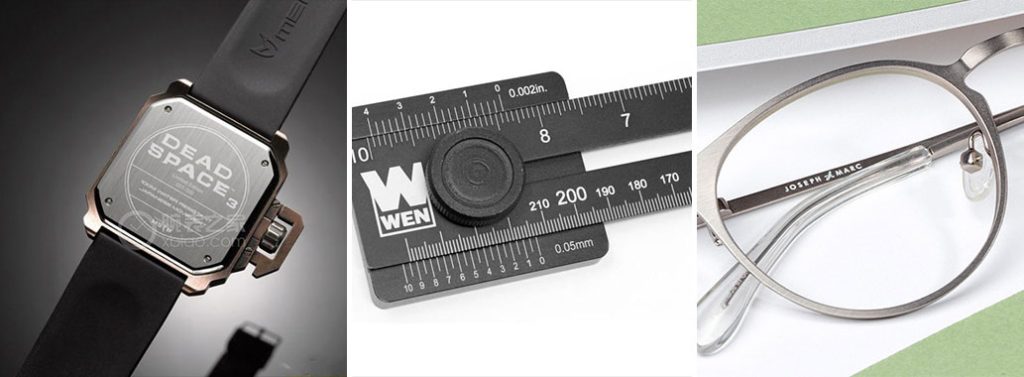

Instrument industry: metal watch cases, glasses frames, instrument and equipment panels, guages, etc.

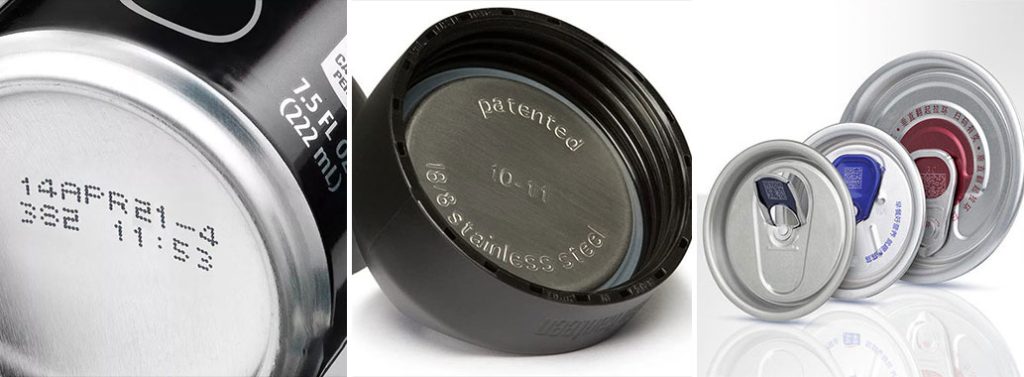

Packaging industry: internal and external packages of food, drugs and cosmetics, cans, metal bottle caps, etc.

Advantages of fiber laser marking machine

Since the metal laser marker adopts fiber laser technology, it has all the advantages of the fiber laser. In addition, the fiber laser engraver also has the following advantages.

Permanent effect

The marks made by a fiber laser marker will not fade due to any changes in time, environment and other elements. And the marking effect is difficult to imitate and change, and has a strong anti-counterfeiting function. Therefore, the fiber laser marker machine has prominent advantages in the automotive and other industries where traceability requirements are very strict.

Delicate marking effect

The minimum spot diameter of the fiber laser marking machine after focusing can reach 0.04mm or less, so the marking effect is quite delicate.

Low operation cost

Although the purchase investment is larger than that of a traditional marking equipment, the metal laser marker has faster marking speed and smaller energy consumption. And the fiber laser engraving machine is easy to operate and does not require many consumables. As long as the laser can work normally, the laser marker machine can achieve long-term continuous marking. Comprehensively, it has great advantages compared with traditional marking methods in terms of use cost and overall technical benefits.

Non-contact processing

The energy carrier of fiber laser marking is a beam of uniform wavelength. The beam does not produce any mechanical stress when irradiating the surface of the material. Therefore, it will not affect the mechanical properties of the material, and also eliminate the chemical and noise pollution. The marks are clean and tidy.

Strong adaptability

Fiber laser cutting machine can mark most metals and some non-metal materials. Because of the use of computer intelligent control, the fiber laser engraving machine can quickly adjust the marking content through software, including bar codes, QR codes, etc. It is also compatible with multiple file formats, like DXF, BMP, JPG, CAD, CDR, DWG, etc. This provides great convenience for flexible processing.

Environmentally friendly

Fiber laser marking has no pollution source and is a clean and environmentally friendly processing method.

Major parameters of fiber laser marking machine

Major parameters of the fiber laser marking machine are as shown in table below.

| Brand | Blue Elephant |

| Laser source | Fiber laser |

| Laser power | 20W, 30W, 50W, 100W |

| Laser wavelength | 1064nm |

| Working voltage | AC110V/220V 50/60Hz |

| Laser source lifetime | 100,000h |

| Marking area | 110mm*110mm (customizable) |

| Laser repetition rate | 5-20kHz |

| Marking depth | ≤1.2mm |

| Marking speed | ≤7,000mm/s |

| Min. line width | 0.01mm, depending on material |

| Min. character | 0.2mm, depending on material |

| Repeated positioning accuracy | ±0.01mm |

| Cooling mode | Air cooling |

| Operating temperature | 10℃-40℃ |

| Operating humidity | 5%-95% |

| Supportive graphic format | PLT, DST, AI, DXF, BMP, JPG, CAD, CDR, DWG |

| Package | Standard export wooden case |

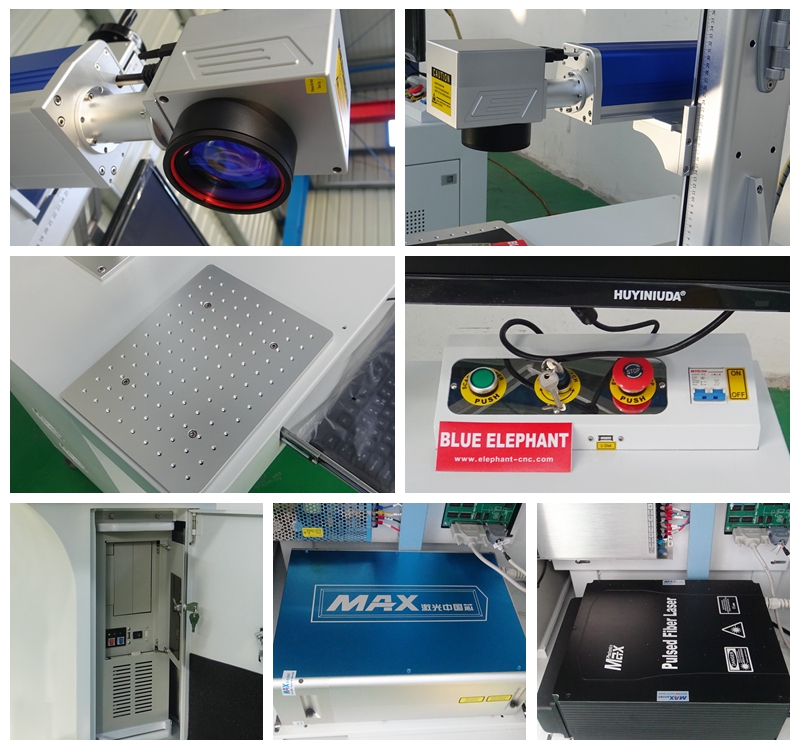

Core components of fiber laser marking machine

The fiber laser engraver mainly adopts the principle of laser thermal effect. It uses the high heat generated by the laser to burn the surface of the workpiece to form a mark. Its core components include:

Fiber laser

Undoubtedly, the fiber laser is the core and most valuable accessory of a fiber laser engraver. And its quality directly determines the use effect and the service life of the fiber laser engraver.

Fiber laser marking machines adopt imported pulsed fiber laser, which has a good output laser mode and long service life. It is designed to be installed in the casing of the fiber laser marker.

Galvo scanning system

Galvo scanning system is an importance component of a fiber laser marking machine. It consists of three parts: a scanning motor, reflection lenses and a controller.

Because the galvanometer is a fast and precise component, it is required to change from one working state to another at a fast speed. In this way, the idle time of the laser marking machine will be much less. Therefore, the quality of the galvanometer could affect the processing speed and accuracy of the laser marker machine.

Focusing system

Function of the focusing system is to focus the parallel laser beams at one point. This is realized by a f-θ lens. The focal length of different f-θ lenses is different, so the marking effect and range are different.

Fiber laser marking machines usually use a high-performance focusing system with focal length f=160mm. The common scanning range is Φ110mm. Customers can choose a lens according to their needs.

Computer controlling system

Computer controlling system is the control and commanding center of the whole fiber laser engraving machine. It is also the carrier of the marking software. The computer controlling system controls and coordinates the laser system and galvanometer system to complete the marking process.

Fiber laser marking machine price

Fiber laser marking machines adopt the integrated design with compact size, low power consumption, long life and high efficiency. It requires little maintenance but has high-quality laser beam and fine spot. The fiber laser marking machine price ranges from $4,000 to $10,000.

Factors that affect the laser marker price

As mentioned above, the fiber laser marking machine price varies greatly. What are the factors that affect the laser marker price?

Brand and power of fiber laser

As one of the core accessories, the choice of fiber laser is definitely one important factor affecting the fiber laser marking machine price. Different brands have different prices for fiber lasers. The fiber lasers of big brands have guaranteed quality, stable operation and long life, so the price will be high. As a result, the fiber laser marking machine price will also be high.

In addition, the power of the fiber laser also impacts the laser marker price. The greater the power, the higher the fiber laser marking machine price.

Selection of other parts

The cost of other parts of the fiber laser engraving machine will also affect the overall fiber laser marking machine price. Imported spare parts or big brand, high-quality spare parts will cause extra cost to the laser marker price.

For example, the choice of lens will affect the marking area. The focal length of the general lens is 160mm, and the marking area is 110*110mm. However, if you choose a lens with a larger focal length, it will result in a larger effective focus range and a larger marking area. Correspondingly, the fiber laser marking machine price will be high.

After-sales service

In general, the more comprehensive the after-sales service, the higher the fiber laser marking machine price. The quality of after-sales service relates to the customer satisfaction, and good after-sales service makes customers more assured.

Fiber laser marker recommendation

Blue Elephant fiber laser marking system allows users to mark or engrave a wide range of materials, including metals, plastics and ceramics. Such marks include but not limited to numbers, letters, words, bar codes, QR codes, graphics and other patterns.

This portable laser marker machine is small and does not take up much space, which can meet basic marking needs. Its characteristics include fast marking speed, non-contact marking, long working life, flexible installation and maintenance-free. The high beam quality and the small spot make it suitable for batch marking applications of small parts.

Please watch the video below to see our 30W and 50W fiber laser marking machines marking numbers, letters and QR codes on different materials.

Why choose Blue Elephant fiber laser marker

Blue Elephant offers many types of high quality series of laser marking machine for metal and non-metal materials. The principal features of our machines include little maintenance, few consumables, stability, and long working life (100,000 hours). Here’s why you should choose us:

Blue Elephant CNC has been committed to the CNC machinery industry for over 10 years. Its products are sold to over 130 countries and regions. All kinds of mechanical products have been well received by consumers around the world.

Blue Elephant provides laser marking machines, both CO2 and fiber model. You can get more machine customization options than our competitors provide.

Our factory occupies an area over 40,000 square meters and both the production equipment and assembly skill meet the European standards. The production ability and delivery capacity are guaranteed.

We have a R&D team of over 100 people and have obtained more than 50 domestic and foreign patents.

Advanced assembly technology and 160 strict testing procedures ensure the high quality of Blue Elephant CNC machines.

Our prices are more affordable than other suppliers.

Our laser systems support laser head integrated solutions, so you can set up your production line for automatic marking and engraving.

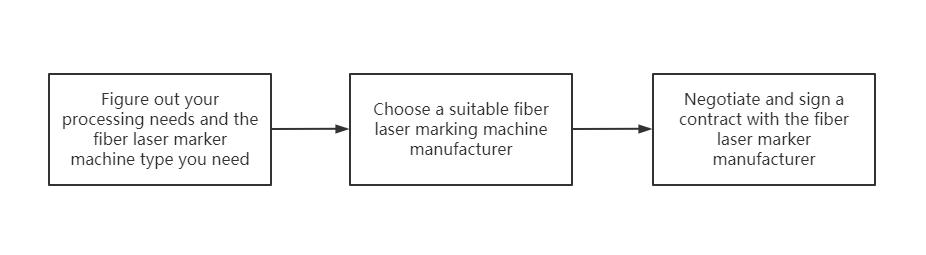

How to choose a suitable fiber laser marker

Figure out your processing needs and the fiber laser engraver machine type you need.

Firstly, you need to determine the type of laser marking machine you need according to your specific processing needs.

This step requires you to figure out your processing requirements, like the type and size of materials, marking depth, main purpose, etc. It can help you determine the type, laser power and other specification of the laser marking machine you need.

If you are mainly marking on non-metallic materials such as glass, acrylic, fabric, leather, etc. you can choose a CO2 laser marking machine. The fiber laser engraver is mainly a laser marking machine for metal. Its processing materials include various common metals and rare metals.

When you require a deeper (≥1.5mm) engraving on a harder metal, then you may need a fiber laser engraving machine with greater power.

If your factory requires marking operation in production lines, flying fiber laser marker is your ideal choice. It can be combined with other production processes to greatly improve work efficiency.

Choose a suitable fiber laser marking machine manufacturer.

There are currently many laser marking system manufacturers on the market. Product quality is uneven. Therefore, it is necessary to do some investigations before choosing a fiber laser marking machine manufacturer. For example, the manufacturer’s professionalism, production capacity, delivery capacity, available products and services, customer satisfaction, etc. If possible, it is best to go to the factory of the metal laser marker manufacturer to see the real production condition.

Sign a contract with the fiber laser marker manufacturer.

After choosing a suitable metal laser marker manufacturer, you can communicate your processing needs with it. If you have specific requirements for the machine configuration, you can also tell the manufacturer. Many laser marking machine manufacturers can customize their machines according to customer requirements.

Please note that the price shall not be the only criterion for your purchase of the machine. Don’t be tempted by low prices. You should consider all factors before choosing an acceptable price. In addition, remember to sign a contract with the manufacturer in order to protect the rights and interests of both parties.

Factors affecting fiber laser marking quality

Sometimes, the marks made by the fiber laser marking machine are inferior, such as fuzzy, whitish or dull. At this point, you should stop laser marking and look for the reasons for these poor results. After solving the problem, you can continue the marking process. So what can affect the laser marking quality?

Energy and mode of the laser beam

This is a prior factor in all types of laser machining work. Choosing a suitable laser energy and laser beam mode is the premise of laser marking.

Focusing performance of the laser beam

The laser energy is highly concentrated because the focus of the laser beam is tiny. Without good focusing performance, you can’t have an ideal laser spot. As a result, the fiber laser marker machine can’t achieve good laser marking effect.

Mechanical precision of worktable

The worktable is the mechanical part that drives the movement of the laser beam. And its accuracy directly affects the accuracy of laser marking.

Optical system

The optical system plays an important function in laser beam transmission. Good work of this system ensures smooth, stable and excellent laser beam transmission.

Moving speed of the laser beam

Moving speed of the laser beam matters during the interaction between the laser and the substance. It affects the speed of the laser marking.

Characteristics of materials

Different materials react differently with the laser beam. When using a fiber laser marking machine, you should choose suitable parameters based on the material type.

Working condition of auxiliary equipment

Good auxiliary equipment can not only extend the service life of the hardware but also improve the effect of laser marking.

How to maintain fiber laser marking machine

Although the fiber laser marking machine adopts advanced technology and is free of frequent maintenance, it still needs daily clean and care.

Keep the room and the surface of the fiber laser engraver clean and tidy.

When the fiber laser marking machine is not working, cut off the power supply and turn off the computer. Cover the field lens cover to prevent dust from contaminating the optical lens.

The circuit is in a high-voltage state when the fiber laser engraving machine is working. So do not overhaul the machine when it is working to avoid electric shock.

Cut off the power immediately in case of any emergency or failure.

Dust in the air will be absorbed on the lower surface of the focusing lens in the long-term use of the machine. It will affect the marking effect. So it is necessary to remove and clean the focusing lens carefully on a regular basis.

In case of cleaning the lens, you can use the mixed liquid of absolute ethyl alcohol and diethyl ether in the proportion of 3:1. Dip the cotton swab or lens paper into the mixed liquid and clean the lower surface of the focusing lens gently.

Do not move the fiber laser marker machine when it is running, for fear of affecting the marking accuracy.

Do not cover or put other irrelevant items on the fiber laser engraver, so as not to affect the heat dissipation of the machine.

Regularly check the environment temperature and relative humidity of the laser marking machine for metal.

Frequently check if the fiber laser engraving machine has any abnormal vibration or noise.

Conclusion

This article gives a detailed introduction of the fiber laser marking machine, including definition, application, advantages, purchase and maintenance method, etc.

Laser marking machine has been a mature CNC laser machine after decades of years of development. The mainstream laser marking machines on the market include CO2 laser marking machine, fiber laser marking machine and UV laser marking machine.

CO2 laser marking machines have a wide range of applications, such as food, medicine, leather, tobacco, wood products, electronics and other non-metal industries. While fiber laser marking machines have higher photoelectric conversion efficiency, which is suitable for marking all kinds of metal materials. For example, electronic separation components, auto parts, integrated circuits, hardware, knives, kitchenware, tools, accessories, precision instruments, glasses, clocks, PVC pipes, etc. Especially for marking the sophisticated products like IC chips, computer accessories etc, a fiber laser engraver is the best choice. For example, date of manufacturing, QR code, tracing code, etc.

Fiber laser marking machines, particularly the portable laser marker, are quite popular with metalworking workshops. The compact size and highly automated design make it very simple to operate. Blue Elephant fiber laser marking machines have features of good quality, long service life and high precision and can serve as your excellent assistant for metal marking.