Buying a furniture making machine can be a significant investment, so it’s important to consider several factors before making a decision. Here’s a buyer’s guide to help you navigate the process in 2023.

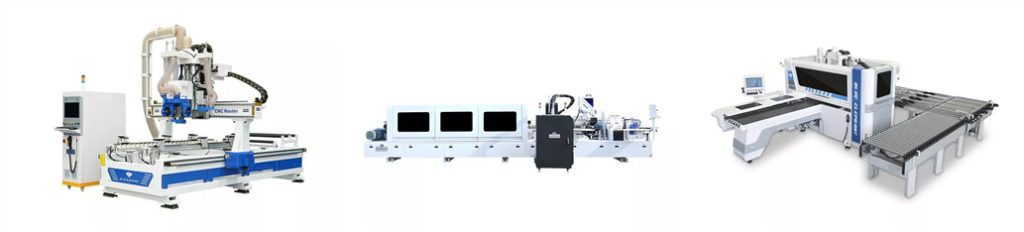

Furniture making machine list

| Nesting CNC Machine | Ball Screw-driven Nesting CNC Machine; Linear ATC Nesting CNC Machine; 4 Processes Nesting CNC Machine; Auto Feeding Nesting CNC Machine; Intelligent Labeling Nesting CNC Machine… |

| Edge Banding Machine | Manual Edge Banding Machine; Semi-automatic Edge Banding Machine; Fully Automatic Edge Banding Machine; Double Gluepots Edge Banding Machine… |

| Pane Saw | Sliding Table Saw; Computer Beam Saw; Front Loading Computer Beam Saw; Rear Feeding Computer Beam Saw… |

| Drilling Machine | Horizontal CNC Drilling Machine; Multi-head CNC Drilling Machine; Six-sided CNC Drilling Machine; Double Head Six Side Drilling Machine… |

| Door Lock Hole Machine | Horizontal Door Lock Machine; Vertical Door Lock Hole Machine |

| Subsidiary Equipment | Automatic Vacuum Press Machine; Hinge Drilling Machine; Polishing Machine; Trimming Machine… |

5 advantages of furniture making machine

1. Increased Efficiency and Productivity

Furniture making machines automate various processes involved in furniture production, resulting in significantly increased efficiency and productivity. These machines can perform tasks such as cutting, shaping, drilling, and sanding with speed and precision, reducing the time required to manufacture furniture pieces.

2. Consistent Quality and Precision

Furniture making machines are designed to perform tasks with high precision and accuracy, ensuring consistent quality in each piece produced. These machines eliminate human errors and inconsistencies, resulting in furniture products that meet exact specifications and design requirements.

3. Cost Savings

While the initial investment in furniture making machines may be significant, they can lead to long-term cost savings. These machines streamline production processes, reduce material waste, and optimize resource utilization, resulting in lower production costs over time. Additionally, the increased efficiency and productivity achieved with machines can lead to higher output and revenue generation.

4. Customization and Flexibility

Furniture making machines can be programmed to produce a wide range of furniture designs and styles, allowing for customization and flexibility in manufacturing. Manufacturers can easily adjust settings and specifications to accommodate different customer preferences, sizes, and variations, providing a diverse range of furniture options to meet market demands.

5. Improved Safety and Worker Well-being

Furniture making machines are equipped with advanced safety features and protective measures, reducing the risk of accidents and injuries in the workplace. By automating potentially hazardous tasks, machines minimize the physical strain on workers, contributing to a safer and healthier working environment.

How much does the furniture making machine cost?

The cost of a furniture making machine can vary significantly depending on various factors such as the type of machine, its specifications, features, brand, and market conditions. Different types of machines, such as nesting CNC routers, panel saws, edge banding machines, and CNC drilling machines, have different price ranges.

For example, the small-scale nesting CNC machines will have the price range from around $10,000 to $30,000. While the industrial-grade nesting CNC machine cost will around $80,000 and go up to several hundred thousand dollars, depending on the size and specifications. The entry-level edge banding machine price can start from $2,000 to $5,000. Mid-range edge banding machine price can range in price from approximately $5,000 to $15,000. And the high-end edge banding machine price can go up to tens of thousands of dollars. While the price for panel saws will range from $1,000 to $15,000. Besides, the price of a CNC drilling machine is usually from $5,000 to $50,000 or even higher.

Generally, smaller and more basic machines can start from a few thousand dollars, while larger and more advanced machines can cost tens or even hundreds of thousands of dollars. High-end and industrial-grade machines with advanced automation, precision, and customizability tend to have higher price tags.

What machine do you need to make furniture?

First of all, you should clearly know your specific processing needs. To make doors, cabinets, drawers, or other furniture? Because making different furniture may need different machine combination. Next, I will take two of them for examples.

CNC machine for cabinet making

Usually, cabinet making manufacturers or businesses tend to purchase a nesting CNC machine or panel saw machine, edge banding machine, and CNC drilling machine. Some of them who pursue higher precision will also buy a polishing machine.

CNC machine for door making

Door making manufacturers would like to use a nesting CNC machine, door lock hole machine, and edge banding machine. Besides, if you want to make more perfect product, you can also order a vacuum press machine.

How to Make Money with Furniture Making Machines?

Furniture making is an art that combines craftsmanship with innovation. With the advent of advanced furniture making machines, the potential for turning this craft into a profitable business has never been higher. Whether you’re a seasoned carpenter or a novice woodworker, leveraging modern machinery can significantly boost your productivity and profitability. Here’s a comprehensive guide on how to make money with furniture making machines.

1. Invest in the Right Machinery

The first step to making money in furniture making is investing in the right equipment. Here are a few essential machines that can elevate your production:

CNC Router: Ideal for intricate designs and mass production, CNC routers offer precision and efficiency.

Table Saw: Essential for straight cuts and larger pieces, a high-quality table saw is a staple in any workshop.

Edge Banding Machine: Perfect for finishing edges, this machine ensures a polished look for your furniture.

Laser Cutting Machine: For detailed work and fine cuts, a laser cutter is indispensable.

2. Master the Technology

Understanding how to operate your machinery to its fullest potential is crucial. Invest time in learning through online tutorials, manufacturer workshops, and hands-on practice. Mastery of your equipment will lead to higher quality products and more efficient production processes.

3. Develop a Unique Product Line

To stand out in the market, create a unique product line that showcases your craftsmanship and the capabilities of your machinery. Focus on niche markets or offer customizable options to attract a diverse clientele. Unique designs and high-quality finishes can command higher prices and build a loyal customer base.

4. Optimize Production Processes

Efficiency is key to profitability. Streamline your production process by:

Automating repetitive tasks: Use machinery to handle repetitive and labor-intensive tasks, freeing up time for creative work.

Maintaining your equipment: Regular maintenance ensures your machines run smoothly and prevents costly downtime.

Managing inventory effectively: Keep track of materials and supplies to avoid overstocking or shortages.

5. Market Your Business Effectively

A well-executed marketing strategy can significantly increase your sales. Consider the following:

Build an Online Presence: Create a professional website showcasing your products, process, and company story. Utilize social media platforms to reach a broader audience.

Leverage SEO: Optimize your website for search engines to attract organic traffic. Use relevant keywords related to furniture making and your specific products.

Participate in Trade Shows: Attend furniture and woodworking trade shows to network with potential clients and showcase your work.

6. Offer Exceptional Customer Service

Providing excellent customer service can set you apart from competitors. Ensure timely communication, offer warranties, and handle any issues promptly and professionally. Happy customers are likely to return and refer your business to others.

7. Diversify Your Income Streams

Maximize your revenue by diversifying your offerings. In addition to selling finished furniture, consider:

Offering Custom Work: Cater to clients looking for bespoke furniture tailored to their specifications.

Teaching Workshops: Share your expertise by offering woodworking classes and workshops.

Selling Plans and Kits: Provide DIY furniture plans or kits for hobbyists and amateur woodworkers.

8. Keep Up with Trends and Innovation

The furniture industry is ever-evolving. Stay updated with the latest trends and technological advancements. Incorporate new materials, design styles, and techniques to keep your product line fresh and appealing.