Automatic bridge saws for granite and marble are indispensable in the building decoration industry. However, for many companies, it is not easy to purchase an automatic bridge saw that suits their needs. This article aims to introduce you to this machine and discuss the key factors that influence the price of the machine. Blue Elephant sincerely hopes to provide useful assistance for your production and investment.

What Is an Automatic Bridge Saw for Granite and Marble?

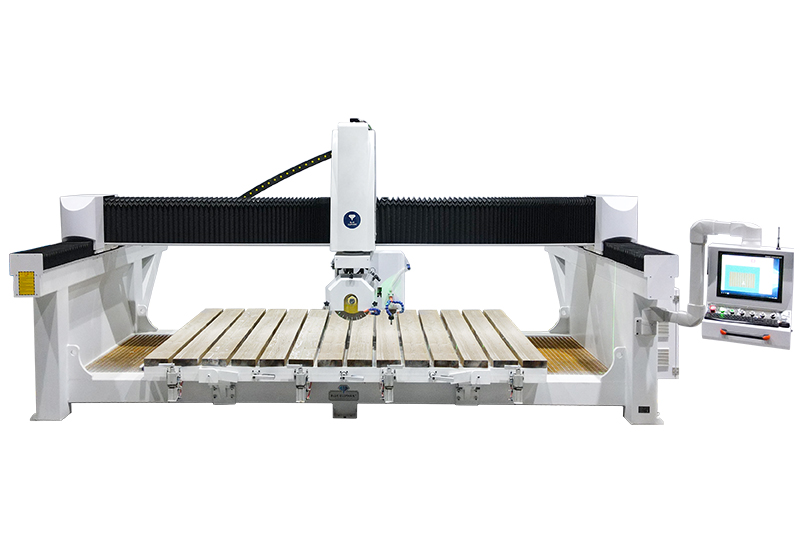

An automatic bridge saw for granite and marble is a piece of equipment specially used for cutting hard stones such as granite, marble, and other building materials. It can automatically complete complex cutting tasks and improve production efficiency and product quality. Its basic structure mainly includes the following parts:

1)Bridge structure: The bridge structure is one of the core components of the equipment and looks like a bridge. It sits across the workbench and carries the cutting head and other key components.

2)Cutting head: The operator can adjust the height and angle of the diamond saw blade as needed to adapt to different cutting operations.

3)Control system: Automatic bridge saws are usually integrated with CNC (computer numerical control) technology. The operator controls the cutting path, speed, and other parameters by inputting commands.

4)Guide rail system: The guide rail system allows the bridge to move smoothly in the predetermined direction, ensuring straightness and accuracy of cutting.

5)Cooling system: It is used to prevent high-temperature damage to the saw blade due to friction during high-speed cutting, and also helps to extend the life of the saw blade.

Safety devices: Safety devices include emergency stop buttons, protective covers, etc. to ensure the safety of operators.

How Does the Automatic Bridge Saw for Granite and Marble Work?

The cutting begins when the secured stone slab is positioned on the machine’s table. The bridge saw’s gantry system, which includes rails for smooth movement, positions the blade precisely over the slab according to the programmed instructions. The saw then operates automatically, making straight or curved cuts as required.

These machines also incorporate safety measures such as protective guards and emergency shut-off switches. With the ability to perform complex cuts and improve workplace safety and cleanliness through dust extraction systems, automatic bridge saws are indispensable tools in modern stone fabrication workshops.

Common Types and Prices of Automatic Bridge Saws for Granite and Marble

Here are 5 common types of automatic bridge saws used for cutting granite and marble. And their typical price ranges are as follows::

| Name | Description | Features | Price Range |

| CNC Bridge Saw (3-Axis) | Basic automatic saws designed for straight-line cuts. They are widely used for simple slab cutting. | Automatic head movement, simple programming, manual or semi-automatic slab positioning. | $10,000 to $30,000 |

| CNC Bridge Saw (4-Axis) | A 4-axis CNC-controlled saw adds rotational movement, enhancing versatility in stone cutting. | CNC control, programmable for straight and vertical cuts, high precision. | $40,000 to $100,000 |

| CNC Bridge Saw (5-Axis) | A more advanced CNC bridge saw with 5-axis control, allowing for intricate, multi-dimensional cuts and designs. | Full CNC automation, 5-axis control for complex angles, curves, and shapes. | $60,000 to $150,000+ |

| Tilting Table Bridge Saw | A saw with a tilting table for easier handling of large and heavy slabs. It helps to reduce manual labor during loading/unloading. | Tilting table for easy slab manipulation, automatic blade control. | $20,000 to $50,000 |

| Water-Jet Assisted Bridge Saw | Combines traditional bridge saw cutting with water-jet technology for enhanced precision, used for intricate or delicate cuts. | Water-jet integration, precision cutting, reduced material stress. | $80,000 to $200,000+ |

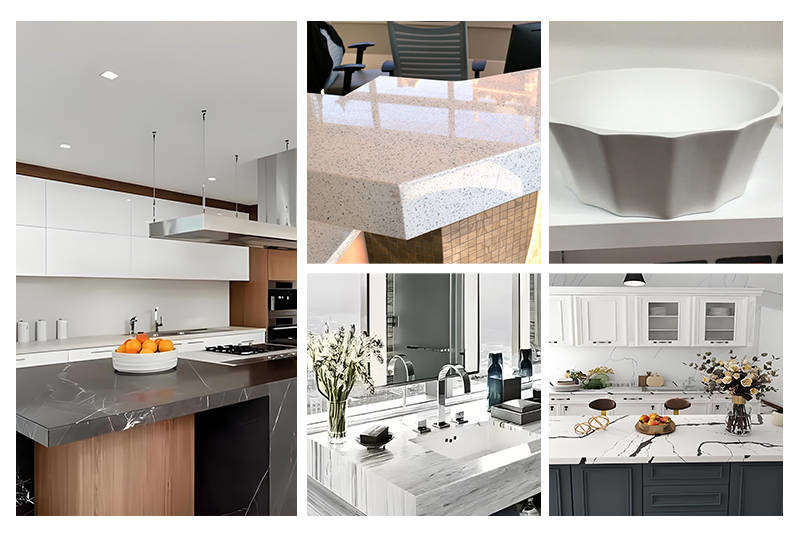

Each of these bridge saw types offers different levels of automation, precision, and functionality. These machines can cater for a variety of applications from basic slab cutting to complex custom stone designs.

Where to Buy a High-Performance Automatic Bridge Saw for Granite and Marble?

There are many different suppliers of automatic bridge saw for granite and marble on the market, but it is very important to choose a reliable brand.

1. Brand and Reputation of Automatic Bridge Saw Manufactures

Before purchasing any large industrial equipment, it is very important to understand the history and market evaluation of the brand. As a well-known brand, Blue Elephant has a good reputation in the stone processing industry. Its automatic bridge saw is known for its high precision and stability.

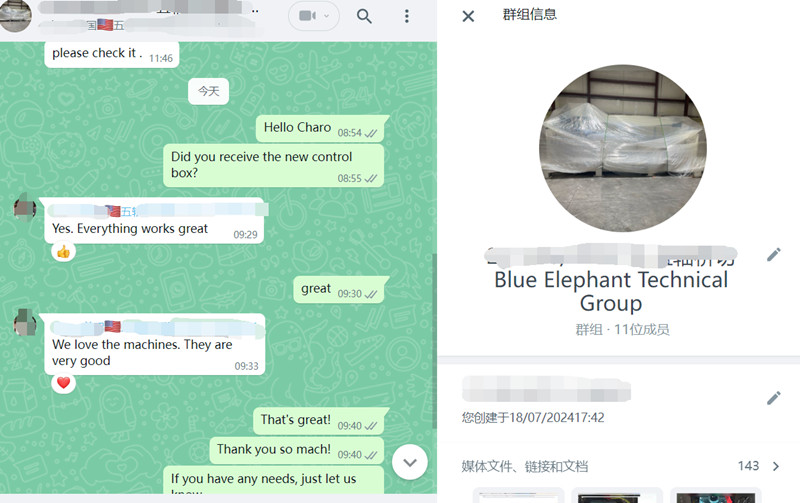

We have received high praise from American customers for our five-axis automatic bridge saw. They said the equipment not only significantly improved production efficiency, but also greatly reduced human error. In the future, we will continue to work hard to improve product quality and services to bring better products to customers.

2. Technical Parameters of Automatic Bridge Saws

When choosing automatic bridge saw for granite and marble, you need to pay attention to whether the technical parameters of the equipment meet your production needs. Spindle power, processing size, moving speed, etc. are all key factors that affect the quality of the final product. The automatic bridge saw provided by Blue Elephant usually has high-speed operation capabilities and high-precision positioning systems to ensure production efficiency.

3. Services of Automatic Bridge Saws

No matter how advanced the automatic bridge saw is, good after-sales service and support are essential. Blue Elephant provides one-stop service from pre-sales consultation to after-sales technical support. This can help you solve technical problems you may encounter during use.

This American customers are very satisfied with Gary’s service. At present, the machine is running well, and we expect our machine to bring greater value to the customers in the future.

Our after-sales engineer Gary visited America to train the customers:

4. On-site Visits of Automatic Bridge Saws Factories

If conditions permit, it is recommended that you go to the factory or showroom in person to inspect the actual operation of automatic bridge saw for granite and marble. Through on-site experience, you can more intuitively understand the equipment’s operating procedures, working environment requirements, and actual processing effects.

Welcome Indian Customer to Visit Factory to Learn 5 Axis CNC Bridge Saw Machine:

Purchase Channels:

You can purchase Blue Elephant or other brands of high-performance automatic bridge saw for granite and marble in the following ways:

1)Official website: Visit the brand’s official website directly. There are usually detailed product introductions and contact information on the website.

2)Authorized dealer: Find an officially certified dealer for consultation and purchase.

3)Industrial exhibitions: Participating in relevant industrial exhibitions is also a good choice. You can experience and compare products from different brands on the spot.

4)Online platforms: Don’t forget to use online purchasing platforms such as Alibaba to find suppliers and get more choices.

Best Automatic Bridge Saws for Granite and Marble Recommendation

6 factors affecting the automatic bridge saw for granite and marble price

1. Brand and Reputation of the Bridge Saw

The brand of the bridge saw for granite and marble plays a crucial role in determining its price. Established manufacturers with a strong reputation for quality, durability, and customer support often command higher prices.

Brands like Blue Elephant, GMM, and Park Industries are well-known for their reliability and performance. Higher-priced machines from reputable brands typically come with better warranties, support services, and proven technology. In contrast, lesser-known brands may offer more competitive prices but could lack the same level of quality or support, which may lead to increased costs in the long run due to repairs or replacements.

2. Level of Automation of the Bridge Saw

The level of automation in a bridge saw for granite and marble significantly impacts its cost. Basic models may have limited automation, such as manual slab positioning and simple programmable functions, making them more affordable. However, more advanced models with full CNC capabilities offer intricate programming, automatic blade height adjustments, and even features like automatic slab handling.

These sophisticated machines allow for higher precision and efficiency but come at a premium price. Buyers must weigh the benefits of automation against their production needs and budget constraints.

3. Cutting Capacity and Size of the Bridge Saw

The cutting capacity of the saw, including the maximum slab size it can handle and the diameter of the blade, also affects the price.

Larger machines designed for cutting thicker or oversized slabs generally cost more due to the additional materials and engineering required. The blade size can influence both performance and cost; larger blades often enable faster cutting but may require more powerful motors and more expensive replacement blades.

Buyers should assess the types of projects they will be working on to determine the necessary cutting capacity, balancing it against their budget.

4. Technological Features of the Bridge Saw

Modern bridge saws often come equipped with various technological features that enhance performance, safety, and ease of use. For instance, features like laser alignment systems, water-cooling systems, and programmable touchscreens improve cutting accuracy and efficiency. Advanced CNC software that allows for complex designs and automation of the cutting process can also add to the cost.

While these technological advancements may increase the initial investment, they can lead to significant time savings and improved product quality, ultimately providing a better return on investment.

5. Material and Build Quality of the Bridge Saw

The materials used in the construction of the bridge saw for granite and marble directly influence its durability and performance. Machines made from high-quality steel and robust components tend to have longer lifespans and require less maintenance, which can justify a higher initial price. On the other hand, lower-cost machines may use cheaper materials that could wear out faster, leading to more frequent repairs or replacements.

Buyers should consider the long-term costs associated with maintenance and downtime when evaluating the price of a machine based on its build quality.

6. Geographic Location and Shipping Costs of the Bridge Saw

The geographic location of the buyer and the origin of the bridge saw for granite and marble can affect the price due to shipping costs and regional market dynamics. Importing a machine from overseas may incur additional shipping fees, tariffs, and customs duties, increasing the overall cost.

Additionally, local demand and competition can influence pricing; regions with a higher concentration of stone fabrication businesses may see more competitive pricing than areas with fewer suppliers. Buyers should factor in these logistics when budgeting for a new bridge saw for granite and marble.

Conclusion

In conclusion, the cost of an Automatic bridge saws for granite and marble varies widely. Different types of machines have different price ranges. Factors such as brand reputation, level of automation, cutting capacity, technological features, material quality, and geographic location all play significant roles in determining the final price. Businesses must carefully find the right balance between cost and functionality.

Don’t worry if you encounter difficulties, the power of the team is endless! We sincerely welcome friends from all over the world to communicate with us!