Introduction of Laser Rust Removal

Laser rust removal is also known as the laser cleaning and laser derusting. It is a new technology based on the interaction effect between laser and matter. Unlike traditional mechanical cleaning methods, chemical cleaning methods, and ultrasonic cleaning methods, laser cleaning technology does not require any CFC organic solvents that destroys the ozone layer. Moreover, it has the advantages no pollution, no noise, no harm to human body, high efficiency, fast speed, no pollution to the environment, and wide adaptability. It is a “green” cleaning technology that is very suitable for large-scale and large-volume rust removal. And because of its excellent rust removal effect, it has received more and more extensive market and attention. At the same time, laser cleaning technology is strongly supported by the state and has been included in the 2025 industry catalogue.

Why Choose Laser Rust Removal Instead of Other Cleaning Methods?

As we all know, metal plays an essential role in people’s daily life and in major manufacturing industries. But when iron reacts with oxygen and moisture, some metal surfaces will get rust. Therefore, metal rust removal has become a major problem that people face. In order to continue metal reuse plans, the rust must first be removed. However, depending on the amount, area, as well as application of the metal, the rust removal method used is also different. How should we remove rust from metals without damaging the metal itself? Below I will take you on an exploration.

Manual rust removal

Manually removing rust off metal refers to grinding with wire brushes, sandpaper, files, and scrapers to remove the rust on the metal surface. This method is the most primitive and most commonly used method to remove metal rust. This method is simple, easy to implement, and with low cost. But the work efficiency is extremely low and the labor intensity is high.

Chemical rust removal

Chemical rust removal is more common in home rust removal, such as by using white vinegar, soda, acid, lemon juice cream, potatoes, etc. to remove rust. The principle is to dissolve the metal rust in the acid- use the acid to react with the rust (oxide) on the metal surface. The advantage of this method is that it is safe and non-corrosive. It does not produce harmful substance, and can be easily operated even at home. And it is great for rust removal of knives, shovels, small workpieces, metal parts, and other small rusty items.

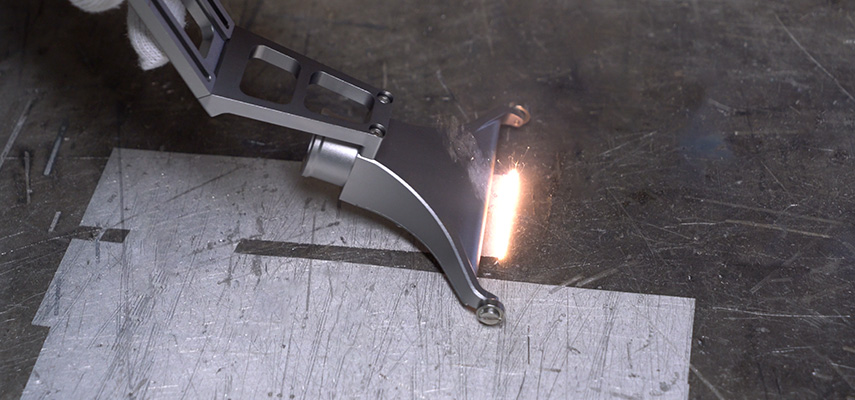

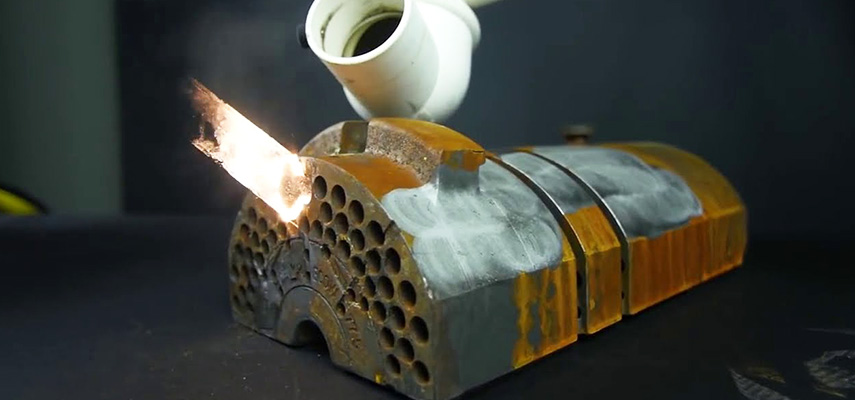

Flame rust removal

Flame rust removal is mainly to shovel off the rust layer on the surface of the substrate. Then bake or heat it with flames, and use a power wire brush to clean it. It is suitable for derusting the steel surface or castings with a certain thickness. However, this method cannot completely remove rust. More often, it removes old oxide skin and generates new oxide skin. Therefore, you should clean immediately for the second time with other rust removal tools. Besides, it has the pros of low production efficiency and high energy consumption.

Shot blasting

Shot blasting is the most suitable derusting method for most kinds of coating materials. This method is mainly composed of particle jet erosion to achieve surface cleaning and suitable roughness. On the one hand, the shot blasting derusting method has high efficiency and good derusting quality. But on the other hand, its waste is not recyclable and it is troublesome to clean up. Thus resulting in the serious environmental pollution. So it has been gradually restricted in use recently.

Laser rust removal (☆)

Laser rust removal also known as laser cleaning. It refers to the use of high-frequency and high-energy laser pulses to irradiate the surface of the workpiece. In order to effectively remove surface attachments or surface coatings at a high speed without additional chemicals. Moreover, the power of the laser beam also determines the thickness and range of rust removal. The higher the laser power, the more obvious the rust removal effect of the machine. Laser cleaning can remove various types of pollutants on the surface of various materials, and achieve a derusting effect that cannot be achieved by conventional derusting methods. Moreover, it can also selectively remove the pollutants on the surface of the rust material without damaging the surface of the material.

From the above five metal rust removal methods, we can see that laser metal rust removal is currently the most thorough and fastest solution. It is not only safe and pollution-free, but also has wider applications. So it gradually replaces other traditional rust removal methods and becomes the most important metal rust removal method. This is why people are increasingly favoring and choosing laser rust removal.

4 Ways of Laser Rust Removal

Above we briefly introduced the principle of laser rust removal. Next, I will take you to further understand other aspects of laser rust removing. First of all, according to different materials, it includes the following four types:

1. Laser dry cleaning

That is to use pulsed laser direct radiation decontamination. Lasers are divided into continuous lasers and pulsed lasers. Under the same power, pulsed lasers can achieve higher energy output. However, the price of pulsed laser is much higher than that of continuous laser. Therefore, now the domestic mainstream laser rust removal machine ( laser descaling machine) almost use continuous laser with the laser power of 1000w to 2000w.

2. Laser + liquid film

Deposit a layer of liquid film on the surface of the rusty object. When the laser is irradiated on the liquid film, the liquid film is heated rapidly to produce explosive vaporization. Then the explosive shock wave loosens the dirt on the surface of the substrate.

3. Laser + inert gas (☆)

While the laser is irradiating, the dirt is blown away from the surface with an inert gas to avoid re-contamination and oxidation. The inert gas mainly uses nitrogen, which not only blows away dust, but also cools the temperature of the laser head. Thus it effectively protects the laser lens and prolongs the life of the lens. In addition to nitrogen, argon is also acceptable. If there is no inert gas, it is also possible to use an air pump with oil-water filter in the short term. But in a word, you’d better develop a good habit of using gas.

4. Laser + chemical rust removal

Firstly, using laser to loose the dirt. Then adopting non-corrosive chemical reagent to remove off rust.

Among the above 4 common ways, “laser + inert gas” is currently the most main laser cleaning solution. Especially the combination of handheld laser rust remover with inert gas.

Top 2 Laser Metal Rust Removal Machine for Sale

Blue Elephant Laser Cleaning Machine

From the above video, you can clearly see that our handheld laser cleaning machine can remove dust and rust of both metal sheets and tubes. Moreover, during the whole working process, no pollutants and polluting gases are found. It is very safe and green.

1KW Laser Cleaner for Cutting, Welding & Cleaning

This is the newest laser cleaning machine in 2023. In addition to the laser cleaning function, it can also realize laser welding and laser cutting. Three main laser technology are combined in only one small machine. That means, if you buy this three-in-on laser machine, you can make almost all laser processing come true. You can manually change three different laser heads to switch between different laser processing modes. Furthermore, the laser power is much higher than the common desktop laser rust remover- 10 to 20 times. It will not only save you space but also improve work efficiency.

The following video will show you how the 1000w laser cleaning machine work on stainless steel, carbon steel, and aluminum. I think you will be amazed by such a wonderful machine.

The handheld laser cleaning system can be widely used in a variety of irregular paint removal, rust removal, stain removal, scale removal, etc. It is flexible and convenient to operate. However, you should pay high labor intensity because it needs to operate manually.

Uses of the Laser Rust Removing Machine

Laser descaling machines is a good cleaning idea for a wide range of materials. At the same time, the cleaning equipment consumes so little power during the processing. It can easily handle even years of hard-to-remove stains. In addition, it can also remove rust and will not harm or react with the workpiece. And the reduction in the number of scrapped rusted iron products can reduce economic costs. Besides, laser derusting machines have also been widely used in derusting both on metal or non-metallic materials, which has brought convenience to various industries and also brought huge benefits.

1. Metal coating and paint cleaning

Laser cleaners can quickly remove layers of paint and coatings from metal surfaces. It is easy to operate and set up quickly; no media, no dust, no chemical reagents and no cleaning; multi-functional handheld and humanized design laser head; soft optical fiber cable for beam transmission; compact system, space-saving, can be moved to any place; environment friendly.

2. Mold cleaning

CNC laser cleaning machine can clean tire mold, electronic mold, food mold, and so on. It has the following advantages: need for media consumption; saving abrasive costs; non-mechanical contact; no damage to the mold; no preheating treatment; both hot and cold molds can be cleaned; environmental protection; no secondary pollutants; low cleaning cost; no noise.

3. Grease and oxides cleaning

It can quickly remove grease, resin, glue, dust, stains, residues, and various oxides. By the way, the removal speed is fast- up to 80cm² / s. And the laser will not damage the coating, creating an oxide-free metal surface. It is also effective for pollutants that do not absorb laser light, such as oil stains, grease, wax release agents, etc.

4. Aviation components cleaning

In cooperation with the aerospace industry, lasers are able to efficiently clean nickel, stainless steel, aluminum, high-strength steel molds, and parts without damaging the substrate.

5. Weapons and equipment cleaning

Laser cleaning technology is widely used in weapon maintenance. The laser cleaning system can remove rust and pollutants efficiently and quickly. Furthermore, it can select the cleaning part to realize cleaning automation. Using laser cleaning, people will get high cleanliness. By setting different parameters, a dense oxide protective film or metal melting layer can be formed to improve the surface strength and corrosion resistance. And the waste material does not pollute the environment. Besides, it can also be operated remotely, which effectively reduces the health damage to the operators.

6. Historical artifact cleaning

In addition to metal derusting, laser cleaning technology is also used in the cleaning of stone, bronze, oil paintings, ceramics, ivory cultural relics, textiles, and other cultural relics. For example, it can be applied to remove ink, stone deposits, stone grease and deposits, etc. Among them, laser clean stone cultural relics is the most advanced and mature.

Laser cleaning technology is a relatively mild cleaning technology. It has a good cleaning effect, little side effects, and is very friendly to the environment. However, if the laser energy is large or the parameter setting and operation is wrong, it may also cause damage to some fragile cultural relics. Therefore, it is generally not recommended to use this method to clean organic cultural relics.

Buy Laser Rust Remover in Europe, America, Oceania, Asia, Africa

Blue Elephant laser rust remover machines are exported to all over the world. For example, laser cleaning machines in America, laser rust removing machines in Canada, laser cleaner in Australia, laser cleaner machines in India, laser cleaning machines in Chile, etc. No matter you are located in Europe, Oceania, Asia, Africa, North America, or South America, you can become our exclusive laser cleaner agent. We have a professional shopping platform- Alibaba. Our professional sales staff will give you detailed answers, and you can follow the steps to place an order and pick up the goods on it. This platform guarantees the best interests of customers, including cash on delivery.

In addition, the price of our Blue Elephant laser descaling machine is also very economical. Handheld laser cleaning machine price is generally within 20,000 US dollars. The configuration of the machine can also be customized according to your requirements. We will do our best to give customers the best purchasing experience.

Q&A of Laser Rust Removal

1. Does laser rust removal have radiation?

No.

2. Is the laser cleaning machine easy to operate?

It is very easy to use, only takes half an hour of training. And learning for a month, you can learn to adjust parameters.

3. Will laser rust removal cause damage to people?

As long as qualified goggles are worn during the operation, it will not cause any other damage to the human body.

4. Is the price of laser descaling machine very expensive?

The laser cleaning machine price continues to decrease. From 2019 to the present, the laser rust removal machine price has decreased by more than 60%.

5. Is it difficult to maintain the laser descaling machine?

Blue Elephant provides customers with a one-year warranty period. Moreover, we have a professional after-sales support team. If you have any questions about machine operation, installation, repair, and maintenance, you can consult our after-sales personnel. We will patiently answer your questions 24 hours a day, including document guidance and video guidance.

Conclusion

At present, due to the development of my country’s high-end manufacturing industry and the continuous improvement of environmental protection requirements, traditional rust removal technology is far from meeting the demand. The emergence of laser rust removal technology has brought hope to the majority of manufacturing industries. I believe that, with the continuous maturity and development of laser rust removal, it will bring us more benefits.