What are metal cutting machine?

Metal cutting machines are tools or equipment designed to shape or cut metal workpieces into desired shapes or sizes. These machines utilize various methods and technologies to achieve precise cuts in metal materials. Some common types of metal cutting machines include:

Milling Machines

Milling machines use rotary cutters to remove material from a workpiece. They can perform a wide range of operations such as face milling, end milling, slotting, and keyway cutting.

Cutting Bandsaws

Bandsaws use a continuous band of metal with teeth to cut through metal workpieces. They are often used for cutting irregular shapes or curves.

Plasma Cutting Machines

Plasma cutting machines utilize a high-velocity jet of ionized gas (plasma) to cut through electrically conductive materials such as metal.

Waterjet Cutting Machines

Waterjet cutting machines use a high-pressure stream of water mixed with abrasive particles to cut through metal and other materials.

Laser Cutting Machines

Laser cutting machines use a focused laser beam to melt, burn, or vaporize material, resulting in precise cuts. They are commonly used for high-precision cutting of various metals.

Electrical Discharge Machining (EDM)

EDM machines use electrical discharges to remove material from a workpiece. They are particularly useful for machining hard metals and complex shapes.

Can I make money with metal cutting machine?

Of course you can make money with metal cutting machines. Metal cutting machines are used in various industries such as manufacturing, construction, automotive, aerospace, and more. Here are some ways you can generate income with a metal cutting machine.

How to make money with metal cutting machine?

Making money with a metal cutting machine can be lucrative if you approach it strategically. Here are some steps to consider:

Identify Your Niche: Determine the specific market or niche you want to target with your metal cutting services. This could include industries like automotive, aerospace, construction, or custom fabrication.

Invest in Quality Equipment: Purchase a high-quality metal cutting machine that suits your intended applications. Make sure it’s capable of handling various types of metals and cutting techniques to cater to a wide range of customer needs.

Offer a Variety of Services: Don’t limit yourself to just one type of cutting service. Offer a variety of services such as plasma cutting, laser cutting, waterjet cutting, or traditional machining. This allows you to cater to different customer requirements and expand your client base.

Market Your Services: Develop a marketing strategy to promote your metal cutting services. This could include creating a professional website, attending trade shows, networking with industry professionals, and utilizing social media platforms to showcase your work and attract potential customers.

Provide Excellent Customer Service: Focus on delivering high-quality work and excellent customer service to build a strong reputation in the industry. Satisfied customers are more likely to return for repeat business and refer others to your services.

Explore Value-Added Services: Consider offering value-added services such as design assistance, material sourcing, or additional machining and finishing options. This can help differentiate your business from competitors and attract customers looking for comprehensive solutions.

Manage Costs Effectively: Keep a close eye on your operating costs and pricing to ensure profitability. Efficiently managing expenses such as materials, labor, and overhead will help maximize your margins and overall profitability.

Stay Updated with Technology: Continuously invest in upgrading your equipment and staying updated with the latest technological advancements in metal cutting. This ensures you can offer cutting-edge solutions and remain competitive in the market.

Build Relationships with Suppliers: Establish strong relationships with metal suppliers to secure favorable pricing and access to high-quality materials. This can help streamline your operations and improve your bottom line.

Expand Your Reach: As your business grows, consider expanding your reach geographically or diversifying into related services or industries. This can open up new opportunities for revenue growth and business expansion.

10 Profitable metal cutting ideas

Custom Metal Art: Create intricate designs, sculptures, and decorations from metal using cutting techniques such as plasma cutting, water jet cutting, or laser cutting. These custom pieces can be sold online, at craft fairs, or through local art galleries.

Metal Jewelry: Use metal cutting techniques to craft unique jewelry pieces such as earrings, pendants, rings, and bracelets. Precise cutting allows for intricate designs and customization, catering to various tastes and styles.

Industrial Parts Manufacturing: Offer metal cutting services to produce custom industrial parts for machinery, equipment, and tools. This can include cutting precise components from metal sheets or bars according to client specifications.

Metal Signage: Create custom metal signs for businesses, events, or personal use. Metal cutting techniques enable the fabrication of durable and visually appealing signs with intricate designs, logos, and lettering.

Architectural Metalwork: Provide metal cutting services for architectural projects, such as cutting decorative panels, railings, gates, and fences. These custom metal elements add aesthetic appeal and functionality to residential and commercial buildings.

Automotive Fabrication: Specialize in cutting metal components for automotive customization and restoration projects. This can include fabricating custom body panels, brackets, exhaust systems, and suspension parts.

Metal Furniture Manufacturing: Design and manufacture metal furniture pieces such as tables, chairs, shelving units, and bed frames. Metal cutting techniques allow for the creation of modern, industrial-style furniture with clean lines and sleek finishes.

Knife and Blade Making: Utilize metal cutting and shaping techniques to craft custom knives, blades, and cutting tools. These artisanal products can appeal to collectors, outdoor enthusiasts, chefs, and craftsmen.

Metal Recycling: Offer metal cutting services for recycling and repurposing scrap metal materials. By cutting and shaping scrap metal into usable forms, you can contribute to sustainable practices while generating revenue from recycled metal sales.

Where to sell metal cutting ideas?

Online Marketplaces

E-commerce Platforms: Create your own online store using platforms like Shopify, WooCommerce, or Etsy to sell your metal cutting creations directly to customers worldwide.

Marketplace Websites: List your products on popular online marketplaces such as Amazon Handmade, eBay, or Artfire, which attract a large audience of potential buyers.

Local Markets and Craft Fairs

Participate in local craft fairs, art markets, and trade shows to showcase and sell your metal cutting products directly to consumers. Collaborate with local artisanal shops, galleries, and boutiques to display and sell your creations on consignment or through wholesale agreements.

Social Media and Networking

Utilize social media platforms like Instagram, Facebook, and Pinterest to showcase your metal cutting work, engage with followers, and attract potential customers. Join online communities, forums, and groups related to metalworking, crafting, and design to network with fellow artisans, share your work, and promote your products.

How much to start a metal cutting business?

The cost of starting a metal cutting business can vary widely depending on various factors such as the scale of operations, equipment needed, location, and business model.

Best metal cutting machines to make money

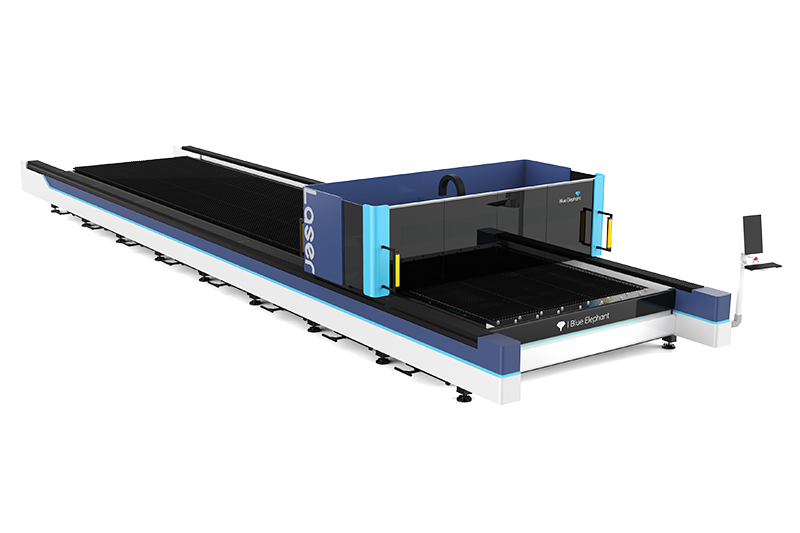

1. High Power 10KW Fiber Laser Metal Cutting Machine

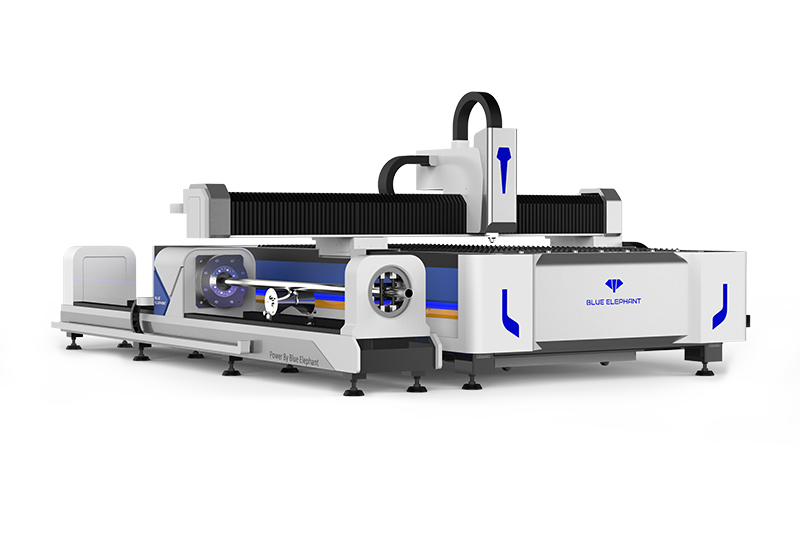

2. Dual-use Sheet and Tube Fiber Laser Metal Cutting Machine

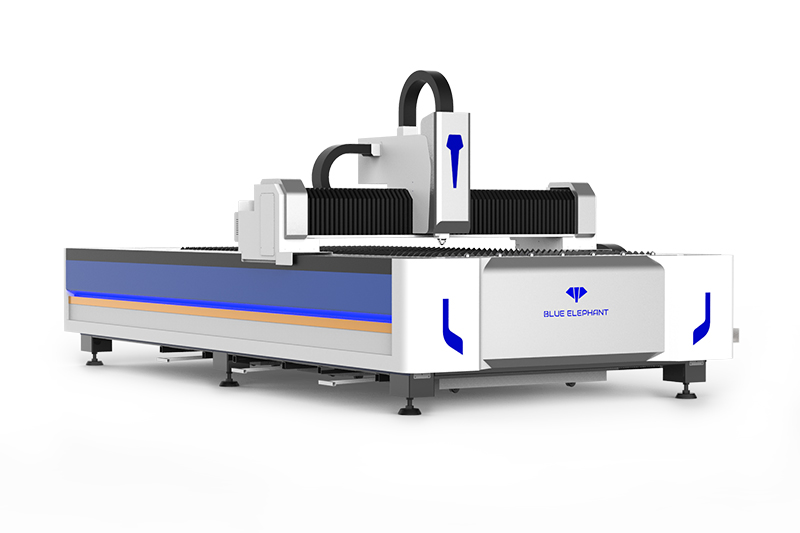

3. Entry-level Fiber Laser Metal Cutting Machine

Conclusion

So to sum up, there are many machines that can process metal, including metal cutting machines, metal engraving machines, metal polishing machines, etc. Among them, the main ones that can make money are metal cutting machines, and the last popular cutting machine is the fiber laser cutting machine. This article also provides you with the ten best metal cutting projects that can make money with metal cutting machiens. If you still want to know more making money ideas, please click the following button.