Someone asked if fiber laser cutting machines can make money? The answer is of course yes! According to overseas market research institutions, the global laser cutting machine market will grow at an annual compound growth rate of about 7%-8% in the next few years, and the market value is expected to reach US$2.35 billion in 2024. The demand for fiber laser cutting machines in North America and Europe is also growing, which has promoted the market’s research and development of newer technologies. Judging from the current market share of fiber laser machines, it still has a solid position in functionality and universality in the next 5-10 years. Various machine parts, various decorations and souvenirs in daily life cannot be separated from the processing of laser cutting machines. Therefore, the demand for laser cutting is very large, and the advantages of fiber laser cutting machines are also revealed. The answer to the question of whether it can make money is obviously affirmative. Therefore, in this article, let us learn more about Fiber laser cutting machine and learn how to make money with them.

What Is a Fiber Laser Cutting Machine and How Does It Work?

Fiber laser cutting machine is a CNC mechanical equipment that utilizes the ability of fiber laser to cut metal, combines fiber laser with CNC machine tools, and makes metal cutting more convenient and faster through the operation and control of systems, motors and other equipment. Compared with bulky gas lasers and solid lasers, it has obvious advantages and has gradually developed into an important candidate in the fields of high-precision laser processing, laser radar systems, space technology, laser medicine, etc.

The working principle of the fiber laser cutting machine is to use a laser beam to perform thermal processing on the workpiece. The laser emits a high-energy-density laser beam. The laser beam is focused into a high-density, high-energy light spot through the lens and lens. The high-energy light spot is shone on the part to be processed, causing its surface to vaporize or melt due to high-temperature heat, thereby achieving cutting and engraving. The fiber cutting machine controls the processing effect by controlling the position and power of the laser beam, thereby processing different patterns and determining the cutting thickness, thereby achieving high-precision and high-efficiency processing.

What Materials Can Fiber Laser Cutting Machines Cut?

Fiber laser cutting machines have a wide range of applications. Combined with higher levels of intelligent, automated, and digital technologies, fiber laser cutting machines are widely used in new infrastructure, rail transit, shipbuilding, aerospace, medical equipment, kitchen and bathroom hardware, lighting industry, sheet metal processing, and other fields.

Fiber laser cutting machines are mainly used to cut metal materials and cannot be used to cut non-metallic materials such as stone, cloth, leather, density board, and other materials.

The following materials are common processing materials for fiber laser machines:

1.Carbon steel. Fiber laser cutting machines can use oxygen as processing gas, but the cutting edge will be slightly oxidized. For plates up to 4mm thick, nitrogen can be used as processing gas for high-pressure cutting. In this case, the cutting edge will not be oxidized.

2.Copper and brass. Brass with a thickness of less than 1mm can be cut with nitrogen; copper with a thickness of less than 2mm can be cut, and oxygen must be used as the processing gas.

3. Stainless steel. When cutting stainless steel, the fiber laser cutting machine uses nitrogen to obtain an oxidation-free and burr-free edge. Applying an oil film on the surface of the plate will achieve a better perforation effect without reducing the processing quality.

4. Aluminum. Aluminum with a thickness of less than 6mm can be cut, depending on the alloy type and laser capacity. When cutting with oxygen, the cut surface is rough and hard. When using nitrogen, the cut surface is smooth. Pure aluminum is very difficult to cut because of its high purity. Aluminum can only be cut when a “reflection absorption” device is installed on the fiber laser cutting machine system. Otherwise, the reflection will destroy the optical components.

5. Titanium. Titanium plates are cut with argon and nitrogen as processing gases.

Fiber laser cutting machines can process most metals, but the conditions for cutting are also different. The cutting conditions of the cutting machine should be determined according to the actual metal material and metal thickness.

What Are the Advantages of a Fiber Laser Cutter?

Fiber laser cutting machines can be transmitted through optical fibers, with few fault points, high efficiency, easy maintenance, and great advantages in cutting thin plates within 4mm. The photoelectric conversion rate of fiber laser is as high as 25% or more, and the advantages of fiber laser in terms of electricity consumption and supporting cooling systems are quite obvious.

Let’s take a closer look at the advantages of fiber laser cutting machines.

1. Low cost of use. The primary advantage of fiber laser cutting machines is low cost of use and low maintenance cost. The steel plate cost of fiber laser cutting machines is low, and they can be replaced at any time after melting, so more time can be spent on products, which is conducive to product updates and upgrades and the development of enterprises.

2. Easy to operate. Equipped with computer numerical control operation, the cutting drawing file can be directly imported, and the machine can be operated by itself with one-button start. The cutting machine can also be equipped with an automatic loading and unloading platform. No manual loading and unloading is required, which greatly saves labor costs.

3. High efficiency and high cutting accuracy. In the existing cutting field, fiber laser cutting has a higher photoelectric conversion rate of about 30%, which is 3 times that of carbon dioxide cutting machines, with low power consumption, energy saving and environmental protection. At the same time, it can cut carbon steel plates and stainless steel plates within 12 mm, and the cutting speed is twice that of the CO2 laser machine with the same power. In addition, the fiber laser cutting machine cuts the workpiece with high precision, up to a precision of less than three threads, eliminating the process of secondary grinding and saving labor costs.

4.Fast cutting speed. The fiber laser cutting machine can reach a speed of 100 meters per minute, and the average workpiece efficiency is a few seconds, which is several times more efficient than traditional plasma cutting or wire cutting.

What Can I Do with A Fiber Laser Cutting Machine to Make Money?

1. Automobile manufacturing. Fiber laser cutting machines are required for the production of many precision parts in automobile manufacturing, such as automobile brake pads. Since the safety of automobiles must be guaranteed, the processing requirements for parts are very high, and traditional manual precision is difficult to achieve. Fiber laser cutting machines have high processing precision and high efficiency, so they are widely used in the automobile manufacturing industry.

2. Sheet metal processing and manufacturing. Metal sheets have a very wide range of applications and are widely used in construction, furniture manufacturing, and shipbuilding. Therefore, the scope of application of fiber laser cutting machines is also correspondingly wide. Fiber laser cutting machines have high cutting precision and fast cutting efficiency, replacing traditional cutting tools. The wide application of fiber laser cutting machines in the metal processing industry is the future trend.

3. Shipbuilding industry. Fiber laser cutting of ship steel plates can be well vertically cut, with a smooth and flat surface, without secondary processing, which can ensure the high requirements of ship processing.

4. Agricultural equipment production. China is a big agricultural country, and agriculture is the primary industry. The production demand for agricultural equipment can be said to be very large. With the development of agricultural technology, agricultural equipment has also tended to be flexible, diversified and precise, and the processing requirements of agricultural equipment have also increased accordingly. The advanced high-precision and high-efficiency cutting characteristics of the fiber laser cutting machine meet the processing requirements of agricultural equipment and reduce the manufacturing costs of agricultural production.

5. Sports and fitness equipment manufacturing industry. Currently, fitness for all is advocated. From young people to middle-aged and elderly people, many people choose to exercise in the gym, and many people also have fitness equipment at home. Therefore, the demand for sports and fitness equipment is very large. Fiber laser cutting equipment is highly flexible and supports customization of different pipes and plates. The finished products are smooth and burr-free, which not only ensures fitness safety, but also saves labor costs, and greatly improves product quality and production efficiency.

6. Kitchen equipment manufacturing industry. Fiber laser cutting machines can cut metal products such as stainless steel and carbon steel. In the kitchen field, stainless steel basins, stainless steel sinks, range hoods, etc., will use fiber laser cutting machines for cutting, and can meet the production of personalized customization and differentiated products, and can meet many requirements for kitchen equipment production.

From the above analysis, the market prospects of automobile manufacturing, shipbuilding, sheet metal processing, agricultural equipment production, sports and fitness equipment, kitchen equipment manufacturing, etc. are very broad, and the corresponding application range of fiber laser cutting is also very wide. In addition, fiber laser cutting machines can also be used for rental services. It can be seen that using fiber laser cutting machines to make money is certain, and it is also a very good way to make money. Investing in fiber laser cutting machines to make money is a very good choice.

What Do I Need to Start A Fiber Laser Cutting Machine Project?

First of all, you need a fiber laser cutting machine with good quality. You need to find a reliable brand, a reliable laser cutting machine manufacturer, consider the laser power of the machine that suits your processing needs, and investigate the technical support and after-sales service of the machine. After comprehensive consideration, Blue Elephant, which has more than ten years of experience in laser production, is the most ideal choice.

Below are some good fiber laser cutting machines for you to choose from.

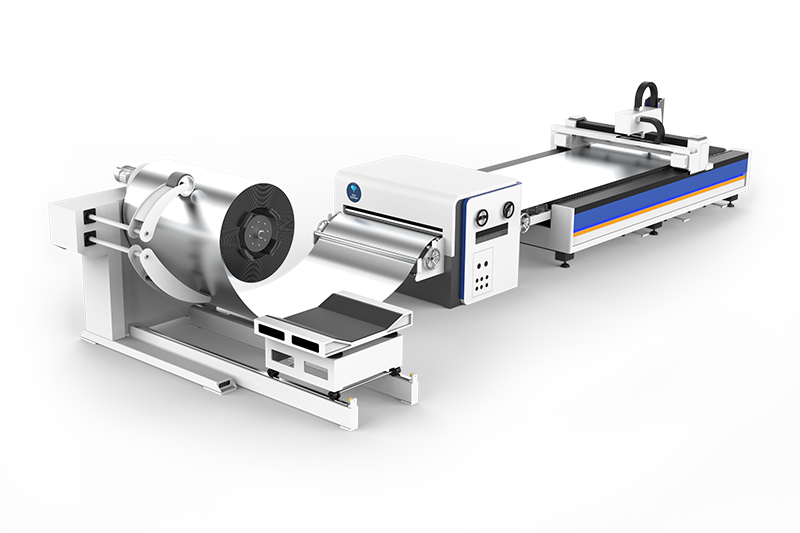

Top Ranked Automatic Coil Fed Laser Sheet Cutting Machine for Fiber Laser Metal Cutting

It realizes the loading, uncoiling, leveling and cutting processes automatically, which saves labor and improves working efficiency.

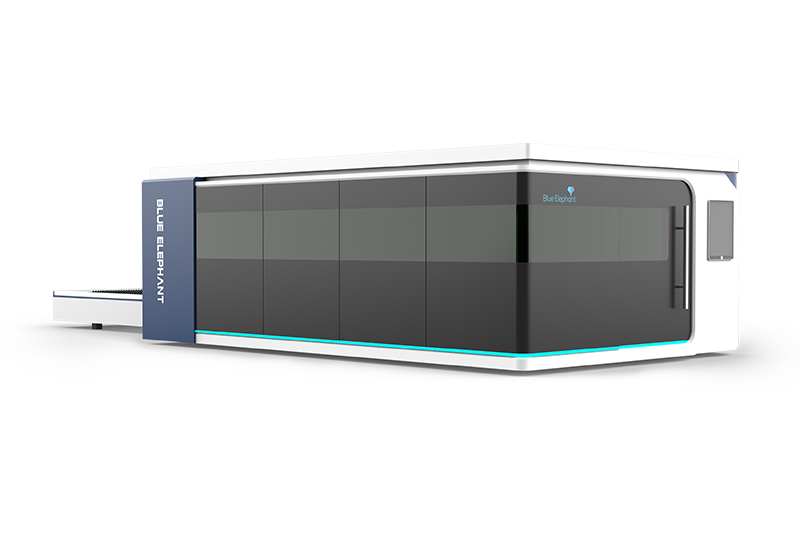

Fully Enclosure 3000W Sheet Metal Laser Cutting Machine with Exchange Table

The price is between US$25,000 and US$60,000. It uses a fully enclosed laser protection cover and operates stably, safely and efficiently.

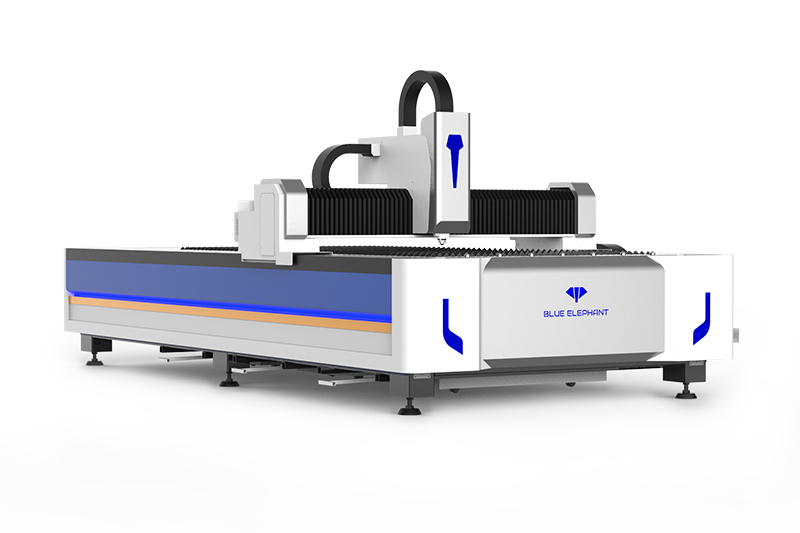

Entry Level Fiber Laser Metal Cutting Machine for Sheet Metal Laser Cutter At Affordable Price

This laser cutting machine is an ideal entry-level laser cutting machine with simple operation and convenient maintenance, which can meet the user’s needs for high cutting efficiency and strong cutting capacity.

Now that you have the machine, what you need to do is to determine the direction of the processing project. We have introduced many investment directions before. You can choose from them, or open up another niche track. After determining the investment direction, what you need to do is to work hard to attract consumers and introduce them to the products you can provide, and do a good job of advertising and marketing. You can use social media platforms such as FB, Twitter, Linked, etc. for promotion. You can learn from how your peers promote and add your own characteristics. Investing to make money is a long-term job. You don’t have to be impatient. Make a good plan, pay attention to details, and deliver high-quality products in time, then you are not far from making money successfully.

Conclusion

Investing in a fiber laser cutting machine is a major decision. Once you have made the decision, you don’t have to hesitate. Just stick to it confidently. It is a pleasure to make money through a fiber laser cutting machine. Committed to product quality and gaining customer trust, I believe you will soon have a large customer base. Welcome to cooperate with Blue Elephant. I believe you can use the fiber laser cutting machine to gain wealth in life.