The CNC acrylic cutting machine has gradually replaced the traditional electronic cutting tools for acrylic engraving and cutting. As a cheap, beautiful, and durable material, acrylic products can be seen everywhere in life. For cutting a small acrylic board, you can use a hook knife or other manual tools. Although it is convenient, the cutting accuracy is poor and the speed is slow. However, in case of batch processing or complex patterns engraving, the best choice is to use a CNC acrylic cutting machine.

Today, we gonna talk about what CNC machines can be used to cut acrylic and how to use and choose them.

Acrylic material

Speaking of acrylic, or PMMA, or organic glass, people may be quite familiar with it. It is deeply favored by the advertising industry because of its good transparency and workability. For example, acrylic advertising signs, boards, letters, logos, nameplates, etc. Besides, acrylic also has wide applications in craft, building, decoration, and other fields.

Characteristics of acrylic include high transparency, high-temperature resistance, corrosion resistance, long service life, high workability, etc.

In terms of the production process, the acrylic falls into cast acrylic and extruded acrylic.

Cast acrylic has outstanding rigidity, strength, and chemical resistance. So it is suitable to make large-sized signs and boards. Besides, cast acrylic has incomparable flexibility in terms of color and surface texture effect.

Extruded acrylic has weaker mechanical properties and higher flexibility than cast acrylic. However, this makes it convenient for bending and thermal forming processing with less softening time.

What machines can be used to cut acrylic?

The average thickness of acrylic boards is around 3-20mm. The traditional cutting method has a long production cycle, complex processes, and low precision. And the cutting results are barely satisfactory.

However, the appearance of the CNC cutting machine solves all the above questions perfectly. Currently, the most common acrylic CNC cutting machines include the CNC router and the acrylic laser cutter.

For processing approaches, both machines can cut and engrave acrylic boards.

Engraving: Generally, the acrylic engraving is conducted on the back of the acrylic board. Of course, you can also engrave the top surface. Remember to mirror the patterns before carrying out the back-side acrylic engraving. Besides, the acrylic engraving process requires fast speed but low power. Because a high power may cause uneven stripes on the product surface. You may need to do some tests before getting the best acrylic engraving results.

Cutting: Cutting acrylic is more simple than acrylic engraving. CNC router acrylic cutting machine requires dedicated CNC bits for acrylic cutting and engraving. The cutting edges are smooth and clean without blurs. Besides, the acrylic laser cutting machine uses air blowing device to improve the cutting quality.

Let’s take a look at the laser machine and CNC router machine for acrylic respectively.

Laser acrylic cutting machine

The acrylic laser cutting machine uses the high temperature of a laser beam irradiated to the surface to melt the acrylic. Laser cut acrylic workpieces have smooth and clean cutting edges. And laser engraving acrylic products also have clear and durable lines and letters. Besides, laser cutting and laser engraving acrylic are easy to learn and operate.

The extruded acrylic is still transparent after the laser engraving process, and will not show too much contrast. However, the melting point of extruded acrylic is relatively low, so the acrylic CNC cutting effect will be much better. Meanwhile, the cutting edges are also relatively smooth and transparent. However, the frosting effect of the cast acrylic after being engraved is in sharp contrast with the texture of the original transparent acrylic.

Therefore, the laser cut acrylic projects mainly adopt extruded acrylic boards. While the cast acrylic is more suitable for laser engraving acrylic projects.

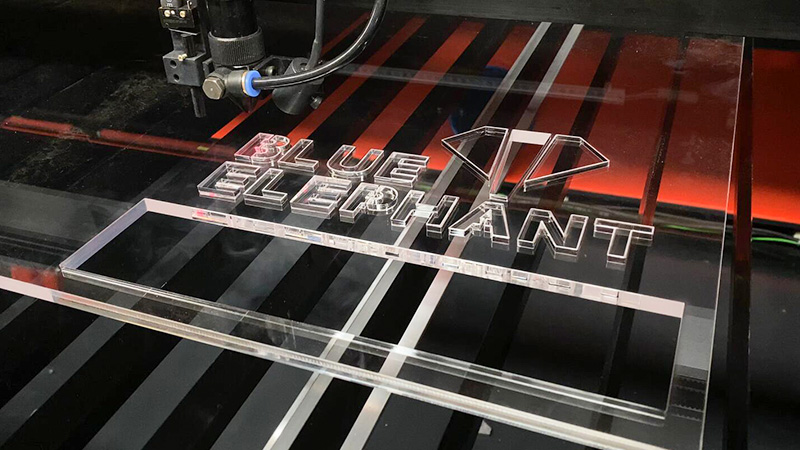

Laser acrylic cutting machine demonstration

The acrylic laser cutting machine belongs to the CO2 laser cutter adopting a CO2 laser source. Generally, the laser power of the acrylic laser cutter is less than 200W. Because the CO2 laser cutter is mainly for cutting non-metallic materials. And the power of 200W is sufficient for cutting most non-metals.

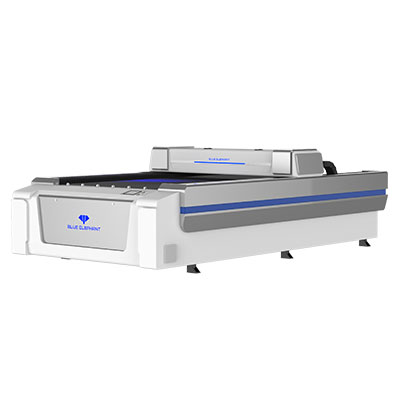

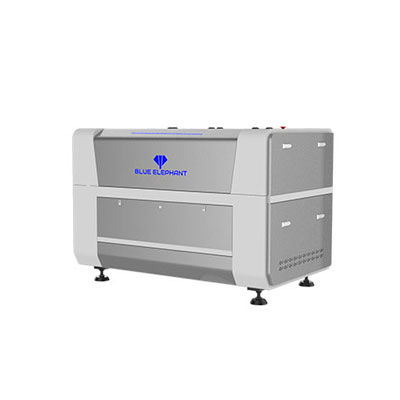

A CO2 laser cutting machine can cut acrylic boards with a thickness of 0-25mm. Blue Elephant now can offer two standard models of laser acrylic cutters, namely 1325 and 1390. You can click to know more details.

In addition to acrylic, a CO2 laser cutting machine can cut other non-metal materials. For instance, wood, fabric, leather, plastic, etc. With different laser power, the laser cut acrylic thickness also varies.

The following video shows a cutting test of a 1325 acrylic laser cutter with RECI W6 CO2 laser source before packing. We will organize special personnel to debug and test every acrylic laser cutter before delivery. You can also provide files and we will run the laser cut acrylic tests according to your files.

How to set laser acrylic cutting machine parameters

Acrylic laser cutter parameters vary for cutting acrylic sheets of different thicknesses. Therefore, be sure to carefully read the relevant instructions or consult a professional before starting to cut. Or, you can conduct several cutting tests with different parameters to find the most suitable laser cutting or laser engraving acrylic parameters.

| Acrylic board thickness | Focal length of focusing lens | Beam intensity |

| <5mm | 50mm | 45%-65% |

| 5-10mm | 63.5mm | 50%-75% |

| 10-20mm | 75mm | 60%-70% |

| 25mm | 100mm | 70%-80% |

The above table gives the focal length of beam intensity recommended when laser cutting acrylic of 0-25mm thick. For example, we recommend using a focusing lens with a focal length of 50mm for laser cutting acrylic less than 5mm thick. And the beam intensity can be 45%-65% and the cutting speed is about 0.3-0.8m/min.

Slight vibration may occur when an acrylic engraving machine is used to cut a large-sized acrylic sheet. This will reduce the accuracy of the acrylic CNC cutting. So try not to laser cut acrylic sheets with very a large area.

Pay attention to the resolution setting when laser engraving acrylic. For instance, the resolution should generally be above 600dpi when outputting BMP patterns. At this point, the engraving speed is 8-18 m/min, and the beam intensity is 20%-30%.

Certainly, the above values are for reference only. Plenty of factors could impact the specific acrylic CNC cutting process. So, it is necessary to set your laser acrylic cutting machine parameters based on your specific working conditions.

CNC router acrylic cutting machine

In addition to the acrylic laser cutter, CNC router machines can also be used for acrylic CNC cutting and acrylic engraving. The CNC router acrylic cutting machine uses CNC bits to cut acrylic boards physically under computer control. Although the CNC router machine is quite good at woodworking, it can also cut acrylic effectively and accurately with appropriate CNC bits for acrylic.

CNC bits for acrylic

One of the most important decisions when cutting acrylic with a CNC router is to choose the right bits. This step relies on what do you want to do.

You may not get satisfactory results if you use common wood CNC bits to cut acrylic boards. Because removing the cuttings is also very important. So, we recommend using dedicated CNC bits for acrylic cutting.

For instance, we usually use O -flute end mill bits for CNC acrylic cutting. Because it has an up-score. It can pull out the chips during the cutting process. And it also prevents the chips from accumulating inside the curve of the cut. You can use all types of CNC bits for acrylic, but we still recommend using the bigger ones. Because bigger bits may increase the depth, stability, and removal of chips.

Besides, a 60° engraving bit can realize perfect V carving for acrylic engraving with a CNC router. Because it has a flat-edge tip which can leave a better edge quality.

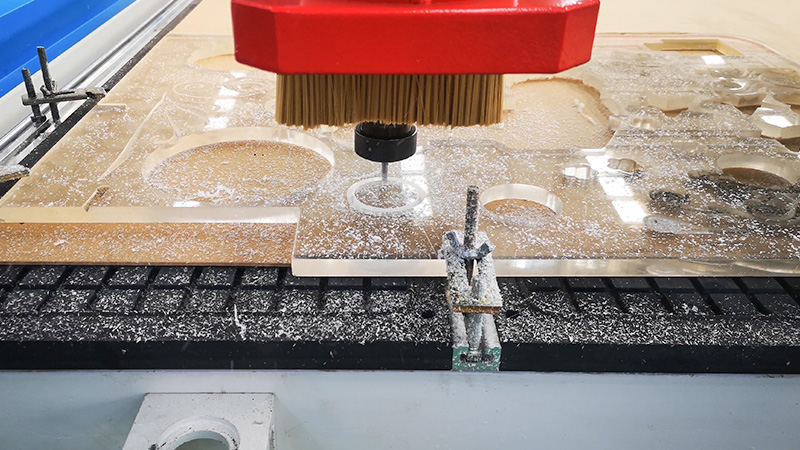

CNC router acrylic cutting machine demonstration

Many of our customers in the woodworking industry also involve in the production of acrylic products. So they will also use our CNC router machine to process acrylic sheets. The following video is the feedback sent by a Portuguese customer using our 2030 CNC router to cut acrylic.

How to cut acrylic with a CNC router?

Step #1: Securely fix the acrylic sheet on the table of the CNC acrylic cutting machine.

If not, the sheet may vibrate or bend, causing damages to the cutting and surfaces. The vacuum worktable has a strong and constant absorption force and can absorb the acrylic sheet firmly. Alternatively, you can use fixtures to secure the sheet.

Step #2: Choose the right CNC bits for acrylic.

As we mentioned before, larger CNC bits may have better cutting and engraving results in acrylic engraving and cutting. Because the selection of CNC bits has a great influence on the cutting accuracy and quality of acrylic.

Step #3: Set appropriate rotating speed.

Our CNC router machines adopt spindles with a rotating speed of at least 18000rpm. This is also the minimum rotating speed we recommend. In this case, the CNC acrylic cutting machine can cut through the acrylic sheet without melting it.

Step #4: Set the feed speed according to the CNC bits for acrylic. The recommended feed speed of the acrylic cutting machine is 75-300ipm. In addition, larger bits require a faster feed speed.

Step #5: Decide the cutting depth. Acrylic cutting and acrylic engraving reflect different cutting depths. So you need to set the required depth according to your needs. It’s better be less than the 1/2 diameter of the bit, avoiding breaking of the bit.

Step #6: Make sure the CNC router machine starts cutting with a ramp instead of plunging in vertically. It helps avoid distortion of the acrylic.

Step #7: Start your CNC router and enjoy the cutting process.

Acrylic cutting machine price

The CNC acrylic cutting machine price varies greatly depending on the machine models. The CNC router acrylic cutting machine price is about USD2,000 to USD20,000. While the price of an acrylic laser cutter may range from USD5,000 to USD15,000.

Plenty of factors can affect the acrylic cutting machine price. For example, internal factors such as machine specifications, dimensions, parts, laser power, etc. In addition, there are also additional costs including freight, shipping fees, customs clearance fees, software fees, training fees, etc.

Specifications of an acrylic cutter include machine size, selection of parts and components, optional upgraded parts, etc. Generally speaking, the larger the machine size, the higher the acrylic cutting price. Besides, the cost of imported parts is slightly higher than domestic ones. Hence the machine price is also more expensive. To know the specific acrylic cutting machine price, please leave your contact information. I’ll find a professional salesperson for you.

How to choose an acrylic cutting machine

The application of laser cutting technology has ushered in new developments in acrylic material processing. The laser cutting machine adopts non-contact processing, which can minimize the deformation of acrylic. Due to the high precision of laser processing, there are no cracks in the cutting seam, and generally, no post-processing is required. In addition, laser processing can also produce patterns and shapes that traditional methods cannot produce. Therefore, laser cutting has gradually become the most common processing method for acrylic CNC cutting.

However, the CNC router acrylic cutting machine still plays an important role in acrylic CNC cutting. Because it can not only process acrylic sheets but also cut wooden boards in a large amount. So a lot of wood and acrylic manufacturers would choose the CNC router machine.

Hence, the answers to how to choose an acrylic CNC machine are not complicated. It mainly depends on your processing demands. A CO2 laser cutter melts the acrylic by non-contacting method, while a CNC router machine cuts through acrylic with a CNC bit.

If your business is to cut and engrave various acrylic products, an acrylic laser cutter can be a good choice. The laser acrylic cutting machine occupies a small area and produces high-quality and high-precision laser cut acrylic products.

But, in the event that you cut wooden boards a lot besides acrylic boards, please consider a CNC router machine. The CNC router is professional in cutting and engraving wooden boards for various furniture, like doors, cabinets, wardrobes, etc.

Acrylic cutting machine VS acrylic cutting service

This is a frequently asked question. It also depends on your processing requirements just like the above question.

When you have an acrylic cutting machine, you can start your acrylic cutting projects at any time. Our acrylic CNC machines are easy to learn and operate, and the cutting process is done automatically. There is no error even for the mass production of acrylic products. Besides, the whole cutting process is under your control and you can make adjustments in time in case of errors.

Acrylic cutting service refers to the method that you pay someone to process acrylic products for you as you wish. You only need to provide ideas and pay production costs instead of manufacturing by yourself. The cutting process is under the acrylic cutter service provider’s control. So there are risks that the products may not meet your requirements. Hence, you need to pay attention to choosing a suitable acrylic cutting service provider.

In conclusion, if you produce and sell acrylic production, buying an acrylic processing machine is the best choice. However, if you just need some acrylic products occasionally, selecting the acrylic cutting service is more suitable. Even if you buy an acrylic cutting machine, the utilization rate is slow, causing wastes of resources.

To know more details about whether the acrylic laser cutter or the CNC router acrylic cutting machine, don’t hesitate to contact me.