Laser cut paper and engrave paper has become effective and advanced processing method for paper products. And you can find laser cut paper applications in many industries. Especially in the printing and packaging industry, where design and craftsmanship are very important. Conventional flat printing is difficult to make big differences. However, the development of laser cutting technology has greatly expanded the design of paper packaging. It helps achieve low-cost and high-quality returns.

The popularity of laser cut paper applications relies on the development of laser technology. The most commonly used CNC laser machine is the CO2 laser cutter. It is quite good at cutting non-metallic materials, such as paper, acrylic, fabric, wood, leather, etc. This article also gives a brief introduction to the CO2 laser cutter in the latter part. Come and check this article and find a project that you are interested in to develop your laser cutter paper projects.

Can laser cut paper?

The answer is YES!

Laser cutting is a relatively new post-print processing technology. And laser cut paper is a processing method that uses a high-density laser beam to cut through paper products. It can produce hollow or semi-hollow patterns on various types of paper. By focusing the light into a compact beam, a laser paper cutting machine can precisely control the cutting of paper, including corrugated board and cardstock.

Although the laser machine is expensive, laser cut paper process can realize mass production and keep the production cost at a reasonable level. Combined with the use of computer design software, the CNC paper cutter can achieve complex laser cutting designs. It makes laser cut paper easier and more accurate.

Differing from traditional paper cutting, laser cut paper makes full use of the high energy and density features of the laser. The laser beam irradiates the paper and makes it vaporize, so as to leave certain geometric shapes. Besides, there is no physical contact during the whole laser cutting and laser engraving paper process. So it causes no deformation, damage, or burnt to the paper.

What types of paper can be laser cut?

Paper is probably the finest material for laser applications. Laser cut paper products can be both exquisite and practical. Although paper is thin and flammable, the laser CNC paper cutter can achieve perfect results under correct settings. In addition, the paper materials are easily acquired and have low cost, different colors, smoothness, and thickness. The paper types that can be cut by a CO2 laser cutter include:

Copy paper

As the most used paper, it is cheap and easy to buy. So it is quite suitable for using the copy paper to practice before formal cutting. However, the copy paper is soft and fragile, and the laser cut edges are likely to curl.

Coated paper

It is thicker and more expensive than the copy paper, but less smooth. It is easy to be painted with various colors. So laser cut coated paper has wide applications in advertising, publishing, printing, and packaging industries.

White cardstock

White cardboard is wear-resistant and not easily damaged. And its hardness and stiffness are greater than the coated paper. So the laser cut cardstock is widely used in printing business cards, certificates, desk calendars, etc.

Carton paper

Its thickness ranks between the copy paper and the cardboard. This makes it suitable for making laser cut paper celebration cards and 3D models. Laser cut carton paper products include business cards, invitation cards, postcards, scrapbooks.

Cardboard

Cardboard is very suitable for laser cutting. This kind of paper has a hard texture, is not easy to fold, and has a high ignition point. Laser cut cardboard has flat and smooth cut edges, free of any burrs.

Corrugated cardboard

The corrugated board has a smooth surface, consistent thickness, and high hardness. It is very suitable for use as a packaging box. Besides, there are also many laser cut corrugated cardboard toys and molds.

Laser cut paper approaches

Laser cutting paper

The CO2 laser processes paper materials by vaporizing them quickly into visible smoke. The laser cutting paper can cut through the paper and emit smoke. Meanwhile, the smoke is removed timely to minimize the possibility of burnt or scorch.

Laser engraving paper

The laser engraving paper can obtain different results from cutting. And it is better to use thicker paper for laser engravings, such as cardstock or corrugated board. Unlike cutting, laser engraving paper removes part of the surface material instead of cutting it off.

Laser marking paper

Compared with laser engraving, the processing depth of laser marking is even shallower. It will leave light or dark marks on the paper surface.

Why laser cut paper?

Laser cut paper has the superiority that ordinary die punching machines can’t match. Therefore, more and more paper packaging and craft manufacturers choose the laser cutting method.

- There is no direct contact or impact to the paper during the cutting process. So the paper is free of any mechanical deformation.

- No die or tool wear happens during the laser engraving process. Hence, the laser cut paper has small waste and a low defect rate.

- Laser cut paper offers high flexibility. It adopts computer software to design and layout with excellent accuracy and high efficiency. Furthermore, the CO2 laser machine can cut and engrave complex patterns according to customers’ demands.

- There is no need to use molds to cut paper, nor adjust the machine frequently during the cutting process. This saves plenty of time and production costs.

Laser cut paper projects

Laser cut paper has many uses in the market. For example, three-dimensional greeting cards, wedding invitations, packaging boxes, window paper cuttings, 3D paper sculpture models, paper crafts, three-dimensional notepaper. And also cake borders, cake inserts, hand-painted templates, stickers, etc. Here are a few simple laser cutter paper projects for you. Take a quick look and pick one to start your own.

Laser cut paper packages

Laser cut paper packaging boxes make the products look very high-grade. The hollow patterns on the gift boxes help attract consumers’ attention and purchase desire, thus promoting product sales. Of course, the various hollow elements will undoubtedly increase the cost of manufacturing. So it may cost too much for replacing the molds for the traditional die-cutting machine. However, the CO2 laser machine does not need molds, which saves production costs and improves efficiency.

Laser cut cardstock or corrugated packaging boxes are used to hold gifts, food, handicrafts, stationery, etc. Exquisite packaging can leave a deep impression on the person receiving the gift. In addition, the unique packaging can also make your product stand out and promote sales. Laser-marked packaging can also play a role in anti-counterfeiting.

Laser cut paper cards

Although mobile communication is becoming more common, many people still like to give paper greeting cards on holidays or other occasions. Now, exquisite laser cut paper cards have gradually replaced the traditional flat-printed ones. Because these greeting cards provide more types of and more delicate styles.

The CO2 laser CNC paper cutting machine can not only cut and engrave hollow patterns but also make three-dimensional cards. Imagine how you feel when you open a wedding invitation card with a 3D image of the bride and groom hugging each other standing on the paper. You will definitely feel the happiness and joy of the new couple. And you are also willing to go to the wedding site to bless the couple in person.

Laser cut paper cards include wedding invitation cards, event invitations, holiday cards, birthday cards, and other pop-up cards. The CO2 laser paper cutting machine can cut paper cards with a large number of openings and fine-line cutting contours. Traditional die-cutting machines may find it difficult to produce such designs. But the CO2 laser cutter can complete quickly and efficiently.

Chinese paper cuttings

Paper cutting is one of the traditional folk arts of the Chinese nation. It has a long history and endures for a long time. Traditional paper cutting artworks are made by folding paper and hand-cutting with scissors. But this is unrealistic for companies that have mass production needs.

However, the development of the CO2 laser machine perfectly solves the demand for mass production of paper cuttings. The laser CNC paper cutting machine makes paper cutting more efficient and easier. And the computer design software allows you to design all kinds of interesting and novel graphics. No matter how complicated the pattern is, The laser CNC paper cutter can help you make it come true.

Laser cut paper cuttings have greatly shortened the production time. In addition, the exquisite degree of the laser cuttings is comparable to that of handwork.

Laser cut paper crafts and arts

Laser cutter paper projects have extensive applications in crafts, arts, and 3D paper models areas. It consumes a large quantity of time and energy to cut paper arts and crafts. Besides, a small mistake could make your craft fall short as the paper is fragile. With the help of the laser paper cutting machine, we can make complex and delicate paper crafts and arts quickly without flaws.

You can take the laser cut paper buildings and landmarks back home and give them as travel souvenirs to family members. Also, you can choose some laser cut paper arts to decorate your home or shop during festivals. For instance, Halloween paper lanterns, paper Christmas trees, ornaments, etc. The use of a CO2 laser cutter can realize the rapid batch production of paper arts. You can use this to make a fortune before the holidays.

Laser cut corrugated board projects

Corrugated board is everywhere in your life, such as the express boxes you received every day. Laser cut corrugated board projects are also common in life. Compared with the common paper, the corrugated paper is thick and hard, and unlikely to deform even if made for big-sized projects.

Common laser cutting corrugated paper projects in daily life include lampshades, molds, toys, handicrafts, packaging boxes, etc. In addition to cutting, you can also engrave special patterns or letters on the surface to make your products unique.

Laser cutter paper projects are often exquisite, high-grade, and diverse. The traditional die-cutting equipment is particularly inadequate when cutting and engraving fine and complex patterns. However, the laser paper cutting machine is not limited by the material and process, and one single device can achieve a variety of functions.

How much watt is needed for laser cut paper?

We all know that the thicker the material to be cut, the more important it is to use high power to obtain better cutting quality. So you may need to carry out many tests in order to find the right settings for laser cutting and laser engraving paper. There are many ways to complete this process. Besides, you may repeat the tests due to any change in the paper type. Especially the changes in thickness and weight. Laser cut paper tests may be a boring process, but they can help improve your knowledge and skills. Hence it can save your time in future projects.

Generally speaking, a 40w laser cutter can cut through ordinary paper, corrugated paper, etc. very well. And the 40W laser cutter is also sufficient for laser engraving paper. But if you use special paper, you’d better consult the CO2 laser cutter suppliers and let them recommend the right laser power for you.

Laser cut paper tips

The paper removed during the high-speed laser cutting process will evaporate into smoke. And the smoke takes the heat away from the paper, so the heat load of the paper is small. A laser CNC paper cutting machine can achieve the finest contours with appropriate settings, air supply, and smoke exhaust. So, read the following tips to get better laser cut paper results before starting.

- The power output of different levels will be different even if it is the same CO2 laser engraver model. Therefore, you’d better do some preparation and testing of laser cut paper. This is for determining the most suitable power and other settings for your own project.

- Adjust suitable and correct focal distance. Tiny errors could make big difference in the cutting results. So pay attention to the focal distance and cutting effect.

- Remember to check if the mirrors and lens are clean and intact every time before using a CO2 laser engraver. Clean or replace the mirrors or lens in case of any dust or damage.

- Keep the worktable flat. This is especially important for the CO2 laser paper cutting machine with manual focusing. Otherwise, uneven cutting will occur.

- Fix the paper firmly during the laser cut paper process because the paper is very thin. For example, adopting a vacuum table or honeycomb worktable to help secure the paper.

- Good smoke exhaust prevents the high-temperature smoke from affecting the cutting results. So remember to exhaust the smoke timely.

What laser machine does laser cut paper use?

As we mentioned above, the most commonly used laser CNC paper cutter is the CO2 laser cutting machine. A 40W laser cutter can cut all kinds of paper very well. There are many brands of CO2 laser cutting machines on the market. And some may only cost $500. But the industrial grade paper laser cutting machine price is higher, which can be $2,000 or more. The paper laser cutting machine price varies greatly due to different brands, specifications, configurations, and other factors.

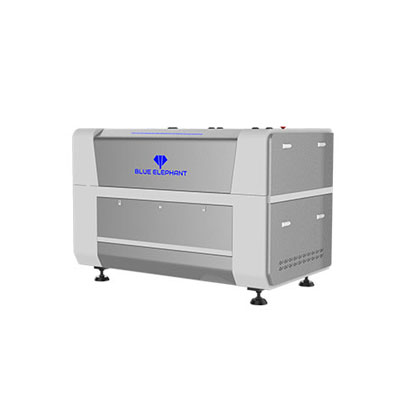

Blue Elephant also offers CO2 laser machines for laser cutter paper projects. Standard models include 1390 and 1350. Both models of the Co2 laser cutter can cut paper and other non-metallic materials effectively. Click the following machine to see more details.

Both two models of laser paper cutting machine are popular with customers in the non-metal material cutting area. The first one is more welcomed by the users from regions with strict environmental protection regulations. There are also other models to choose from.

Basic parameters of the CO2 laser cutter

| Parameters | ELECNC-1390 | ELECNC-1325 |

| Laser source | CO2 laser | CO2 laser |

| Laser power | RECI W series | RECI W series |

| Worktable area | 1300*900mm | 1300*2600mm |

| Voltage | 220V, 50Hz | 220V, 50Hz |

| Worktable | Honeycomb | Blade |

| Cutting speed | 1-1000mm/min | 1-1000mm/min |

| Support file | DST, PLT, BMP, DXG | DST, PLT, BMP, DXG |

| Motor & driver | Stepper | Stepper |

| Applications | Paper, wood, acrylic, leather, fabric cutting Glass engraving | |

| Price range | $3200-$9000 | $3200-$9000 |

CO2 laser cutter videos

The following is a video of a 1390 CO2 laser cutting machine cutting a variety of non-metallic materials. It has a part showing laser cutting corrugated board at 2’12” of the video.

The following is a feedback video of our CO2 laser machine from an Indian customer. He first bought a 6090 ATC CNC router from us and was satisfied with the processing quality of the machine. So he ordered another CO2 laser cutter machine. The video shows the customer’s laser engraving and cutting process on wooden boards.

Paper Laser cutting service

In addition to buying a laser machine, choosing a paper laser cutting service is also a good choice. The paper laser cutting service refers to the service provided by some companies to produce laser cut paper products for customers. You only need to tell them your ideas or give them your design files. And they’ll cut paper products for you. Of course, you need to pay for their services.

Paper laser cutting service has some advantages. For example, you don’t need to buy an expensive CO2 laser cutter, nor operate the machine by yourself. This seems to be more worry-free, but it requires you to communicate fully and effectively with the service provider. So They can fully understand your ideas. Otherwise, the laser cutting paper products do not meet your requirements, wasting the time and cost of both parties. Besides, there are many online paper laser cutting service providers, and you need to identify and screen them carefully.

However, buying a CO2 laser paper cutting machine enables you unlimited processing possibilities. You can cut any laser cutter paper projects at your wish. In addition, you also have countless trial and error opportunities until you find the most suitable setting. Although you get more things to worry about compared with paper laser cutting service, the process can also be rewarding.

Conclusion

Laser cut paper is a process in which a high-energy laser beam is projected on the surface of the paper to cut through or produce a hollow pattern. The processing process is very simple. You use the design software to convert your ideas into files. The CO2 laser cutter can automatically process the file and carry out the cutting process. Of course, you need to set the various parameters correctly. Compared with flat-printed paper products, laser cut paper products have richer geometric designs and more gorgeous 3D effects.

You can also choose the paper laser cutting service in addition to buying a laser machine. But this only applies to the situation that you don’t need laser cut paper frequently. Or you have no idea of how to operate a laser machine. For example, you need to customize unique wedding invitation cards for your wedding or invitation cards for your company anniversary. However, for companies having mass production requirements of laser cutter paper projects, buying a CNC laser cutter is the best choice.

The laser cut paper projects have a broad market. If you also want to participate in this area, you can take a look at our CO2 laser machine. In case of any questions about which laser machine to choose, feel free to contact us.