Laser cutter is well known for its wide range of applications in industrial processing. With the continuous advancement of technology, the brands and types of laser cutters on the market are becoming increasingly abundant. Currently, this technology plays an indispensable role in modern manufacturing due to its efficiency, precision, and flexibility. This article will introduce some well-known brands and their popular models on the market, hoping to provide some useful help for your choice.

What is a Laser Cutter?

Laser projects a high-intensity laser beam onto the material surface. The laser beam then rapidly heats the material to the point of evaporation and cuts it into the designed shape. It is usually produced by a carbon dioxide laser, a fiber laser, or a YAG laser. Sometimes, the operator also needs to add auxiliary gas to blow away the slag and keep the incision clean. Common auxiliary gases include air, argon, and nitrogen.

Types of Laser Cutters

CO2 Laser Cutter

This type of laser cutter generates laser light by exciting CO2 molecules. Because of its high output power and good beam quality, it can be used for cutting and engraving non-metallic materials (such as wood, plastic, fabric, etc.).

Fiber Laser Cutter

Fiber laser cutter uses optical fiber as the laser transmission medium. Its high-energy beam is particularly suitable for precision cutting of thin sheet metal. Such machines play an important role in automobile manufacturing, aerospace, electronics industries, and other fields.

Solid Laser Cutter (such as YAG laser)

Use a solid material such as yttrium aluminum garnet as the gain medium. This type of laser cutter is often used in precision processing fields, such as jewelry making, mold repair, etc.

Top 5 Laser Cutter Manufacturers

As an industry professional, I have witnessed significant advancements in laser cutting technology over the past few years. Therefore, there are a large number of companies on the market that specialize in manufacturing state-of-the-art laser engraving machines. To help buyers choose the trustworthy one among the complex brands on the market, I introduced some of the top laser cutter manufacturers. These manufacturers have various advantages in terms of machine quality, precision, and reputation for customer satisfaction.

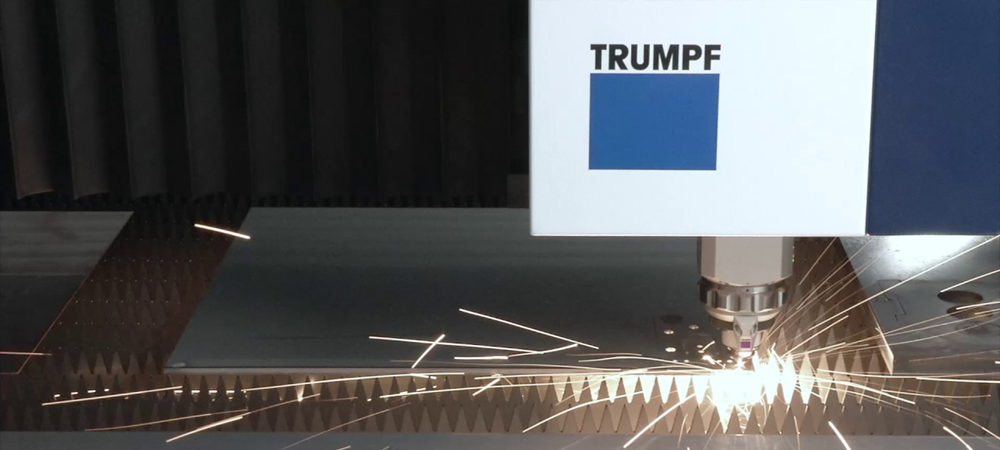

TRUMPF Laser (Germany)

TRUMPF Laser is a world-leading high-tech enterprise. Founded in Germany in 1923, it focuses on laser technology and machine manufacturing. The company offers a variety of high-end equipment, including the laser engraving machine. Its products are known for their high precision and performance.

TRUMPF’s laser engraving machine includes fiber laser and carbon dioxide laser. It adopts advanced technology and can meet the processing needs of different industries, especially in the field of metal processing. Its products are not only suitable for traditional sheet metal cutting but also meet complex material handling challenges, with excellent flexibility and reliability.

Bystronic (Switzerland)

Bystronic is an internationally renowned high-tech enterprise specializing in the development and manufacturing of laser cutters. The company is headquartered in Switzerland. Currently, it is famous all over the world for its high-quality products.

Bystronic offers a range of laser cutting solutions, including fiber optic laser cutters and CO2 laser cutters. It is committed to technological innovation and continuously launches products and services that adapt to new market needs. And it meets customers’ needs for efficient, flexible and intelligent processing. Its machines are particularly suitable for processing parts with complex shapes and high precision requirements.

Epilog Laser (USA)

Epilog Laser was founded in 1988 in Colorado, USA. It is a well-known manufacturer of laser cutting and engraving systems. The company is known for its high-quality laser equipment and is committed to providing customers with machines that are innovative, reliable and easy to use.

The brand’s products are characterized by their compactness and portability. Many customers working in small studios and home workshops love this brand. Epilog Laser’s laser cutting

and engraving machines are suitable for a variety of materials such as wood, plastic, leather, paper, and more. Therefore, this type of equipment is particularly suitable for personalization, art creation, and small commercial projects. Whether you are an amateur or a professional designer, you can find a solution to meet your needs from Epilog Laser products.

Mazak (Japan)

Mazak is a world-renowned manufacturer of metal processing machine tools. The brand was founded in 1919 and is headquartered in Japan. The company specializes in the production of high-precision, high-performance machine tool equipment. These machines combine advanced laser technology with precision mechanics. Different series and models can meet the needs of different customers.

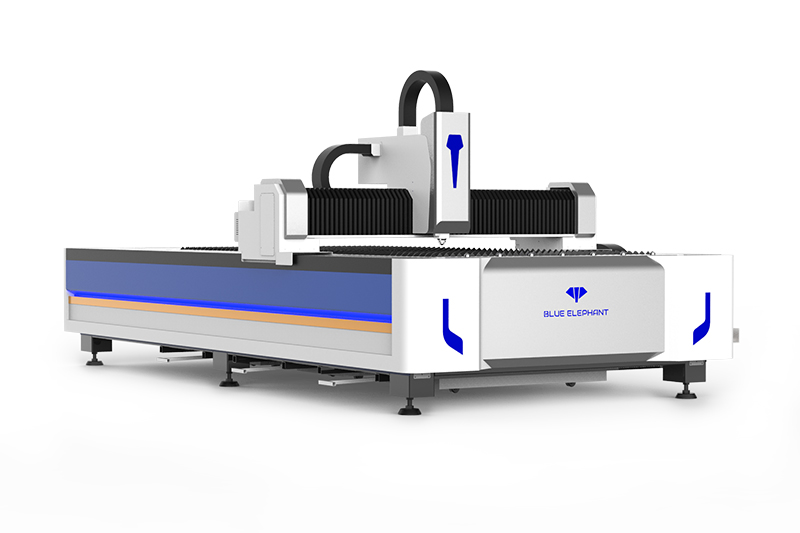

Blue Elephant (China)

Blue Elephant is an enterprise specializing in the R&D and manufacturing of CNC machines and laser processing equipment. This company has won a good reputation in the industry with its advanced technology and high-quality services. The CNC laser cutting machine provided by Blue Elephant covers a variety of types, including fiber optic laser cutter and CO2 laser cutter, which are widely used in metal processing, advertising production, furniture manufacturing, and other fields.

Its products are characterized by a high level of automation, excellent cutting accuracy and stable working performance. Blue Elephant’s CNC laser cutting machines are not only easy to operate but also have low maintenance costs. In addition, the company also provides customized solutions to meet the specific needs of customers, ensuring that every user can get the most suitable processing solution.

Blue Elephant’s Services

1. Pre-sales consultation: To help customers choose the most suitable equipment, the professional sales team provides detailed product introduction and technical consultation.

2. Customized solutions: According to the specific needs of customers, the factory can provide product customization and process optimization suggestions.

3. Lifetime maintenance: For purchased products, our professional after-sales team will provide long-term technical support and accessories supply. We always make sure our equipment is in top working order.

4. Professional training: The professional after-sales team regularly shares machine operation and maintenance skills to enhance customers’ experience.

5. Quick response: With a complete service network, we can ensure our quick response and we can solve problems with no need to wait.

6. Continuous upgrading: Blue Elephant continues to track industry development trends and upgrade product functions in time. We make sure our customers always have the latest technology.

How to choose the highest quality laser machine manufacturer?

When choosing the highest quality CNC laser cutting machine manufacturer, you need to consider multiple aspects to ensure you get the products and services that best meet your needs. I introduce the following key points for you as a reference.

Technical strength and R&D capabilities

Excellent manufacturers should have a strong technical R&D team and continuous R&D investment. These investments can ensure technological innovation and stable performance of products. Blue Elephant excels in this regard. Its technical R&D team has many years of experience and enjoys a high reputation in the industry.

Product quality and certification

Product quality is one of the important criteria for measuring manufacturers. The high-quality laser cutter not only has high cutting accuracy but also has a long service life. Blue Elephant’s products have passed a number of international quality certifications, such as ISO9001, CE, etc. This fully proves the reliability of its products.

After-sales service and support

A complete after-sales service system is crucial to buyers. Good after-sales service can effectively solve any problems during the use of the equipment. Blue Elephant provides 24-hour online technical support and promises to respond quickly to customer needs to ensure that customers’ production activities are not affected.

Market reputation and case sharing

Knowing what other users are saying can help you make a more informed choice. Now, you can see Blue Elephant machines all over the world. Many customers will recommend their friends to choose Blue Elephant. This is due to its good market reputation and many successful cases.

Industry experience and professionalism

Rich industry experience and professional knowledge are also an important aspect when considering manufacturers. Blue Elephant has been deeply involved in the laser cutting field for many years and has accumulated rich practical experience. We can provide customers with professional solutions for different application scenarios.

Cost performance

Products with high-cost performance are more likely to win the favor of the market. By optimizing the cost structure, Blue Elephant can provide customers with competitive prices while maintaining high performance.

Q&As

Is laser cutting safe?

CNC laser cutting machine itself is safe, but it requires proper use and maintenance. ModernCNC laser cutting machines usually have a closed design to prevent laser leakage. Some machines are also equipped with a transparent protective cover to protect the operator and facilitate observation of the cutting process. In addition, the emergency stop button is one of the necessary safety devices. It can shut down the machine quickly in emergency situations.

Operators need to undergo special training to understand the correct operating procedures. For safety, equipment may also be equipped with anti-collision protection and smoke extraction systems. Therefore, as long as you follow the correct operating instructions and perform regular equipment maintenance inspections, the laser cutter can operate safely and reliably.

What software does a laser cutter need?

CNC laser cutting machine usually requires specific control software to operate. And laser cutter software can be roughly divided into the following categories:

Graphic design software: Graphic design software can design graphics and text, such as Adobe Illustrator, CorelDRAW, etc.

CAD/CAM software: This type of software is not only used for design (CAD), but also for converting designs into manufacturing instructions (CAM). Common softwares include AutoCAD, SolidWorks, etc.

Laser cutting control software: Software specifically used to control laser cutter includes LaserCut, LightBurn, etc. This type of software usually has functions such as importing graphics files, setting cutting parameters, and previewing cutting paths.

When choosing software, you first need to consider the brand and model of your laser cutting machine. Because different machines may support different software. Additionally, it’s important to consider your specific needs. For example, whether you need plane cutting or three-dimensional engraving, and whether you need special functional support, etc.

How should I choose the laser power?

Choosing the power of a laser cutting machine mainly depends on the following aspects:

1. Application requirements: First of all, you must clarify your processing needs, such as whether you need high-speed cutting or fine processing.

2. Material Properties: The type and thickness of material is critical. Thicker or harder materials require a higher power laser to cut effectively.

3. Cut Quality: Additionally, you should also consider cut quality requirements such as edge smoothness and cutting accuracy. This will also have an impact on the choice of laser power.

4. Cost-effectiveness: Although high-power laser cutting machines can improve production efficiency, the initial investment and operating costs are relatively high.

Therefore, when choosing the power of a machine, you need to take these factors into consideration. In order to make a more appropriate choice, you can consult professional suppliers for advice.

Conclusion

The above is a basic introduction to the well-known brands of laser cutter and its popular types. Different CNC laser cutting machines are suitable for different application scenarios, and it is very important to choose the appropriate model. When choosing a machine manufacturer, we need to comprehensively consider multiple factors such as technical strength, product quality, and after-sales service. Blue Elephant has won high praise in the industry for its high-quality products and services.

If you are looking for a reliable laser cutter supplier, Blue Elephant is undoubtedly a trustworthy choice. You can leave a message with your specific needs or the machine model you want to know about, and I will try my best to provide you with more information.