My first laser cutting machine from China seemed like a great deal high power, low price, fast shipping. But within weeks, I regretted it. Imprecise cuts. Software crashes. No real customer support.

Over the years, I’ve tested different machines, visited factories, and spoken with industry experts. I’ve seen which brands deliver and which ones fail.

In this guide, I’ll share the top 10 laser cutting machines in China, compared for precision, power, price, durability, and after-sales support so you can invest wisely.

By the end, you’ll know exactly which machine fits your needs without the trial-and-error frustration.

So let’s begin!

Quick Comparison Chart

Here’s a quick look at all 10 laser cutting machines side by side. This gives you a fast snapshot before diving into each one in detail.

| Machine Name | Laser Type | Power Range | Cutting Area | Best For | Key Feature |

| Blue Elephant LECNC 1390 | CO₂ | 60W–150W | 1300×900mm | Furniture, signage, creative makers | Trusted performance, easy to use, built to last |

| Bodor 1kW–12kW | Fiber | 1kW–12kW | 1500×3000mm | Exporters, mid-size shops | Auto-focus lens + clean design |

| HSG 1.5kW–20kW | Fiber | 1.5kW–20kW+ | 1500×3000mm+ | Large metal workshops, dealers | Fast cutting + automation |

| Han’s Laser HF·6025G | Fiber | 3kW–20kW | 2500×6000mm | Aerospace, defense, heavy industry | Handles large sheets + smart features |

| GWEIKE LF3015GA | Fiber | 1kW–6kW | 1500×3000mm | Small factories, budget metal shops | Dual-exchange table + enclosed build |

| HGTECH TP6535 | Fiber | 3kW–12kW | Custom (tube & sheet) | OEMs cutting both tubes and plates | Multi-format + thermal stability |

| Golden Laser JMC Series | CO₂ | 150W–300W | Up to 2500mm width | Textile, shoes, furniture fabrics | Conveyor system + non-stop roll feed |

| SENFENG SF3015H | Fiber | 1kW–12kW | 1500×3000mm | Rentals, mid-size workshops | Enclosed design + remote monitoring |

| PENTA LASER Speedy One | Fiber | 6kW–20kW | 1500×3000mm+ | Shipbuilding, heavy machinery | High-speed platform + European motion |

| DNE LC3 | Fiber | 1kW–12kW | 1500×3000mm+ | Exporters, high-end fab shops | Swiss precision + value pricing |

Now that you have a clear overview, let’s explore each manufacturer in more detail to help you find the best fit for your business.

1. Blue Elephant LECNC 1390 CO₂ Laser Cutting Machine

The first time I powered up the LECNC 1390, I could hear the smooth hum of the fans and smell the light scent of freshly cut wood. The laser moved gracefully across the surface, carving out clean, sharp lines like it had done this a thousand times before. It felt more like drawing than cutting—controlled, precise, and quiet.

If you work with signs, crafts, or furniture panels, this machine delivers both creativity and consistency. It’s simple to run, even on detailed projects, and the results speak for themselves—sharp edges, smooth curves, and professional finishes.

Specifications

- Laser Type: Sealed CO₂ glass laser tube

- Power Range: 60W–150W

- Cutting Area: 1300×900mm

- Supported Materials:

- Wood (plywood, MDF, hardwood veneer)

- Acrylic

- Leather and fabric

- Plastic sheets and foam board

- Ease of Operation:

- Touchscreen interface with simple controls

- Compatible with LightBurn and RDWorks

- Adjustable bed height for material flexibility

- Spare Parts & Support:

- Reliable global support from Blue Elephant CNC

- Fast spare parts delivery and responsive technical help

How It Works

Start by designing in LightBurn or RDWorks. The software is easy to navigate, even if you’re new. Once the file is ready, you connect via USB or network, set your parameters, and begin cutting.

The motion system is smooth and quiet. The beam stays consistent throughout the cut, and you don’t need to worry about burn marks or rough edges. Whether it’s thick wood or soft leather, you’ll get clean, beautiful results with every pass.

Best For

- Furniture makers creating detailed designs

- Signage shops producing sharp lettering and logos

- Craft makers building personalized products

Final Thought

The Blue Elephant LECNC 1390 is compact, powerful, and built with creative professionals in mind. It’s a machine that helps you work faster, finish cleaner, and bring your ideas to life—every single time.

2. Bodor 1kW–12kW Fiber Laser Cutting Machines

If you’re someone who cares about both function and design, Bodor might catch your eye right away. I remember visiting a mid-size workshop where the operator showed me a Bodor cutting metal signs with sharp corners and smooth curves—without any extra cleanup.

You don’t need to be a CNC expert to run one of these. Bodor’s touchscreen control makes things easy, and the auto-focus lens saves time. If you’re working with standard sheet metal and want a machine that feels polished, this one’s worth a closer look.

Specifications

- Laser Type: Fiber

- Cutting Area & Power: 1500×3000mm; 1kW–12kW

- Supported Materials: All standard metal sheets (steel, aluminum, etc.)

- Ease of Operation: Touchscreen UI with auto-focus lens

- Software Support: Works with DXF, PLT, AI, G-code

- Spare Parts & Support: Fast-response team and offices worldwide

How It Works

You load your design file—whether it’s a DXF, AI, or G-code—and set it up using the machine’s built-in touchscreen. The interface is simple, even for new users. Once cutting starts, the auto-focus head adjusts itself, keeping your lines sharp without manual tweaks.

It’s smooth, accurate, and surprisingly quiet. I’ve seen it cut decorative panels with tiny patterns that cheaper machines would mess up. Setup time is short, and support is available fast if you hit a snag.

Best For

- Exporters and mid-size fabrication shops

- Dealers who serve clients focused on product appearance

Final Thought

Bodor isn’t the cheapest option—however, it’s a solid choice if you want both reliability and looks. With a presence in over 180 countries, it’s one of the few brands that balances design and performance well.

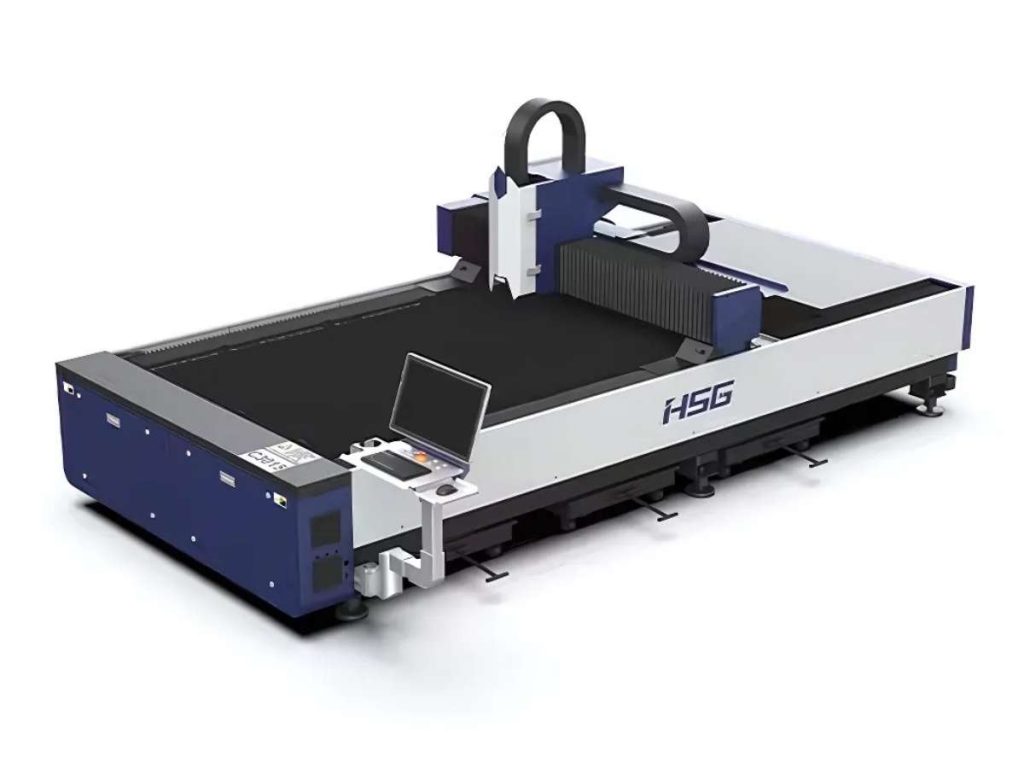

3. HSG 1.5kW–20kW Fiber Laser Cutting Machines

The first time I saw an HSG laser cutter in action, I was inside a metal shop that barely slowed down. The machine ran all day, cutting thick steel like it was nothing. No errors, no breakdowns—just clean, fast cuts.

That’s when I realized HSG wasn’t built for hobbyists. It was made for serious, high-volume work. If you’re running a busy shop, this kind of machine can make a big difference.

Specifications

- Laser Type: Fiber

- Cutting Area & Power: 1500×3000mm; 1.5kW–20kW+

- Supported Materials: Stainless steel, carbon steel, aluminum, copper

- Ease of Operation: Touchscreen control; good automation options

- Software Support: Compatible with major CAD/CAM software

- Spare Parts & Support: Good global support and warranty network

How It Works

Once your design is ready in CAD/CAM software, you upload the file to the machine’s interface—usually through a USB or network connection. The touchscreen makes it easy to set cutting parameters like speed, thickness, and material type.

Many HSG machines come with auto-loading systems and real-time monitoring. That means less hands-on work during production. You can run long batches with fewer interruptions. The fiber laser’s precision also reduces rework and material waste.

Best For

- Large-scale metal workshops

- Dealers offering industrial machine solutions

Final Thought

HSG may cost more than some entry-level options—however, it’s trusted for long production runs, used in global automation lines, and built to perform under pressure.

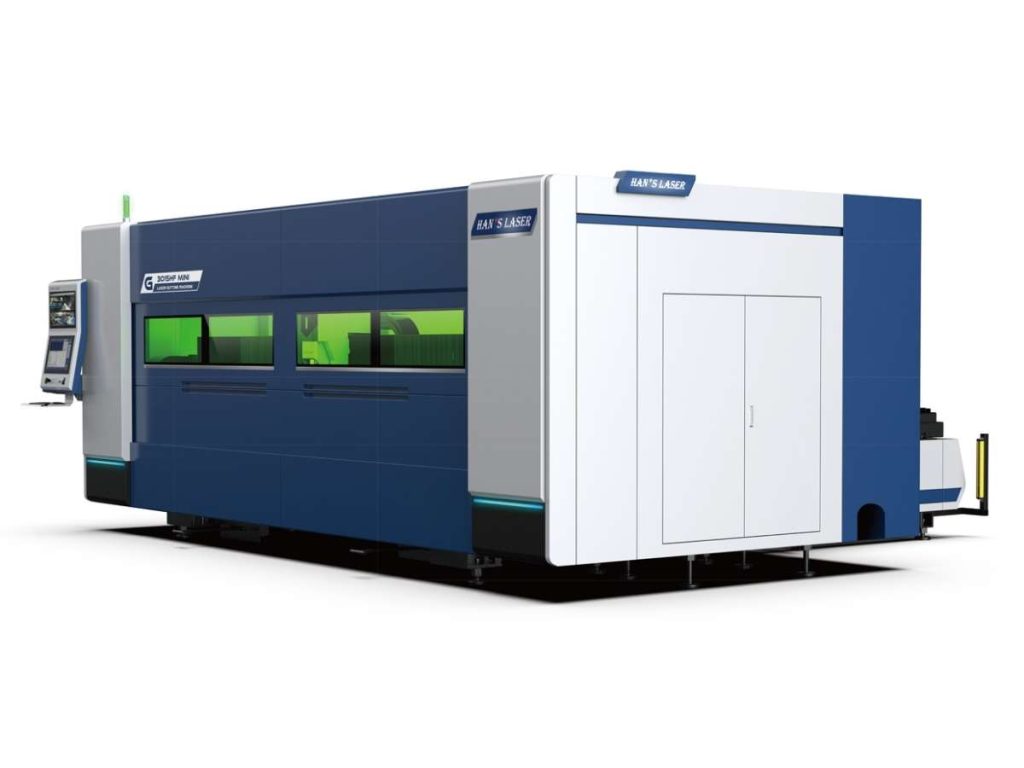

4. Han’s Laser HF·6025G Fiber Laser Cutting Machine

If you work with large metal sheets, you know how demanding those jobs can get. I remember walking into a facility where they were cutting 6-meter-long steel panels like they were paper. The machine doing the work? Han’s Laser HF·6025G—and it didn’t miss a beat.

This machine is made for big jobs. Think aerospace, shipbuilding, or custom metal parts at industrial scale. If you’re managing complex cuts across thick or wide material, this machine is built to handle it with ease.

Specifications

- Laser Type: Fiber

- Cutting Area & Power: 2500×6000mm; 3kW–20kW

- Supported Materials: Steel, copper, aluminum alloys

- Ease of Operation: Touchscreen control with smart automation options

- Software Support: Compatible with advanced CAD/CAM systems and factory networks

- Spare Parts & Support: Global support team with fast-response service hubs

How It Works

You upload your file from your design software, connect through the touchscreen panel, and fine-tune your settings. The high-speed servo motors deliver smooth, accurate movement—even across long sheet runs.

I’ve seen it work through thick aluminum and still maintain sharp edge quality. You can also integrate it with smart factory features—auto loading, part sorting, even maintenance alerts. It’s fast, controlled, and built to scale.

Best For

- Aerospace and defense companies

- High-volume metal fabricators

- Businesses handling large or thick materials regularly

Final Thought

The Han’s Laser HF·6025G offers serious cutting power, speed, and automation—however, its size and complexity may be more than smaller shops or first-time users need.

5. GWEIKE LF3015GA Fiber Laser Cutting Machine

If you’re upgrading from a CO₂ or plasma cutter, this is one machine you’ll want to check out. I remember helping a small factory replace their old system with the LF3015GA. The difference in cut quality—and the drop in noise and fumes—was noticeable right away.

You don’t need a massive budget to get a solid fiber laser. This model gives you industrial features without pushing your shop over budget. It’s a smart step up for growing metal businesses.

Specifications

- Laser Type: Fiber

- Cutting Area & Power: 1500×3000mm; 1kW–6kW

- Supported Materials: Stainless steel, carbon steel, aluminum

- Ease of Operation: Touchscreen interface; stable motion system

- Software Support: Compatible with DXF, AI, G-code, and most major CAM platforms

- Spare Parts & Support: Available through GWEIKE’s global service network

How It Works

You start by uploading your design file, setting material type and thickness, then letting the system guide you through setup. The interface is simple, even if you’re new to fiber lasers.

One thing I liked is the dual-exchange platform. While one sheet is being cut, the next one gets loaded automatically. That saves time and keeps production flowing. The enclosed building also keeps dust and sparks contained, which is great for a clean shop environment.

Edge quality is solid across all three main metals. And even on thicker stainless steel, the machine keeps a steady pace without stalling or overheating.

Best For

- Small factories moving up from CO₂ or plasma

- Metal shops looking for a balanced, cost-effective fiber system

Final Thought

The GWEIKE LF3015GA delivers solid performance and industrial features—however, it’s not designed for heavy-duty manufacturing or nonstop production shifts. For small to mid-size operations, it hits the mark. For large factories, you may need something bigger.

6. HGTECH TP6535 Tube & Sheet Fiber Laser Cutter

If you cut both pipes and flat sheets, you know how frustrating it is to switch between machines. I visited a shop where they were fabricating stair railings and flat steel panels for custom builds. They used the HGTECH TP6535—and didn’t need to stop once to change machines.

This model is built for flexibility. Whether you’re cutting square tubes, round pipes, or sheet metal, it handles everything in one setup. If you’re tired of delays and want a cleaner workflow, this combo machine can help.

Specifications

- Laser Type: Fiber

- Cutting Area & Power: Customizable layout; 3kW–12kW

- Supported Materials: Stainless steel, carbon steel, galvanized steel

- Ease of Operation: Integrated interface for both tube and sheet cutting

- Software Support: Supports major CAD/CAM formats and automation links

- Spare Parts & Support: Backed by HGTECH’s international service network

How It Works

You load your tube or sheet into the machine using the appropriate fixture. The system identifies the material type and cutting position, then starts processing. The touchscreen controls both formats from one interface, which saves space and time.

I was impressed by the thermal stability—it stayed cool even during long cutting runs. That matters when you’re cutting thick material or working in a hot environment. You can also automate feeding and unloading to keep things moving.

Best For

- OEMs working with both tubing and sheet metal

- Heavy industry shops that need a multi-purpose solution

Final Thought

The HGTECH TP6535 is powerful and versatile—however, its size and multi-function design may be too much for shops that only process one type of material.

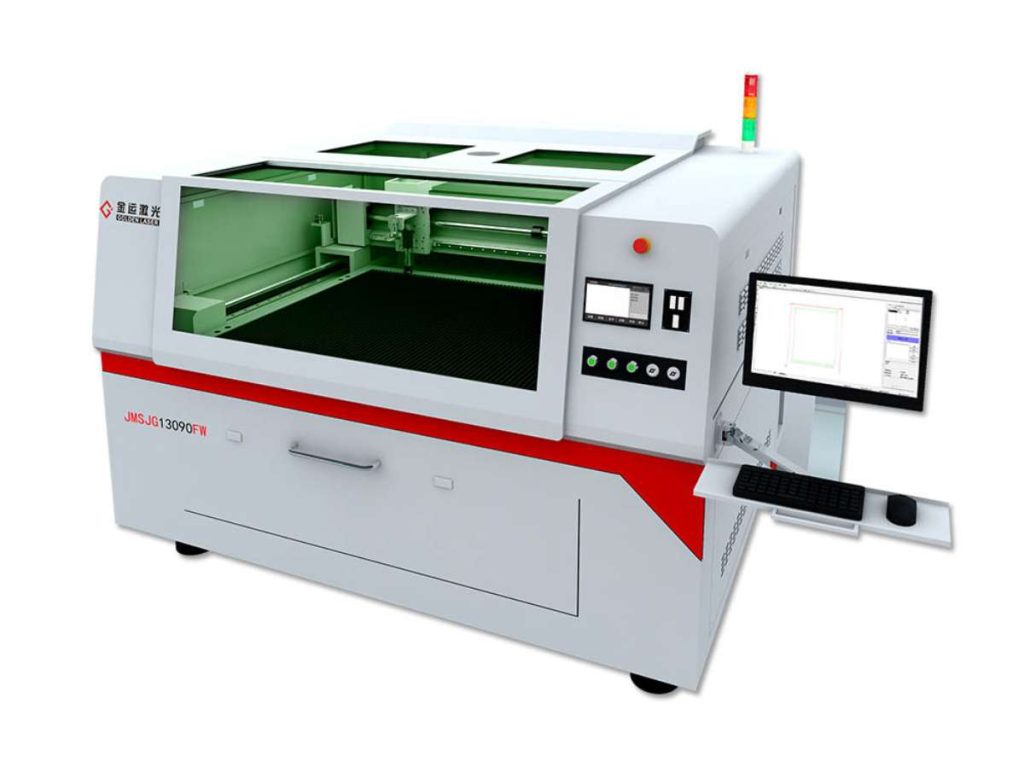

7. Golden Laser JMC Series CO₂ Laser Cutter

“This can’t be right,” I thought, watching fabric feed through the machine without pausing. But there it was—cutting with speed, no burns, no snags. The operator smiled and said, “We just let it run. It doesn’t stop unless we tell it to.”

That was my first time seeing the Golden Laser JMC Series in action. If you work with fabric, leather, or soft signage, this machine changes everything. It’s built to keep moving—and that makes a real difference when you’re cutting full rolls of material.

Specifications

- Laser Type: CO₂

- Power Range: 150W–300W

- Cutting Area: Up to 2500mm in width

- Supported Materials: Fabrics, leather, denim, felt, and other textiles

- Ease of Operation: Conveyor-based material feeding with user-friendly interface

- Software Support: Works with industry design formats like PLT, DXF, AI

- Spare Parts & Support: Backed by Golden Laser’s textile-focused service team

How It Works

You load a roll of fabric onto the conveyor, align your design file, and hit start. The laser follows your pattern while the conveyor feeds material nonstop. This is key for mass production—no manual sheet loading, no downtime.

I was especially impressed by the minimal heat impact. Even on delicate fabric, there was no discoloration or warping. That’s something older machines always struggled with. It cuts fast, clean, and cool. And with smart nesting software, you can reduce waste and speed up layout planning.

Best For

- Clothing and apparel manufacturers

- Footwear and leather goods

- Soft signage and home textile businesses

Final Thought

The Golden Laser JMC Series delivers fast, clean textile processing for high-volume production—however, it’s best suited for operations focused on roll-fed materials, not rigid sheets or mixed-use tasks.

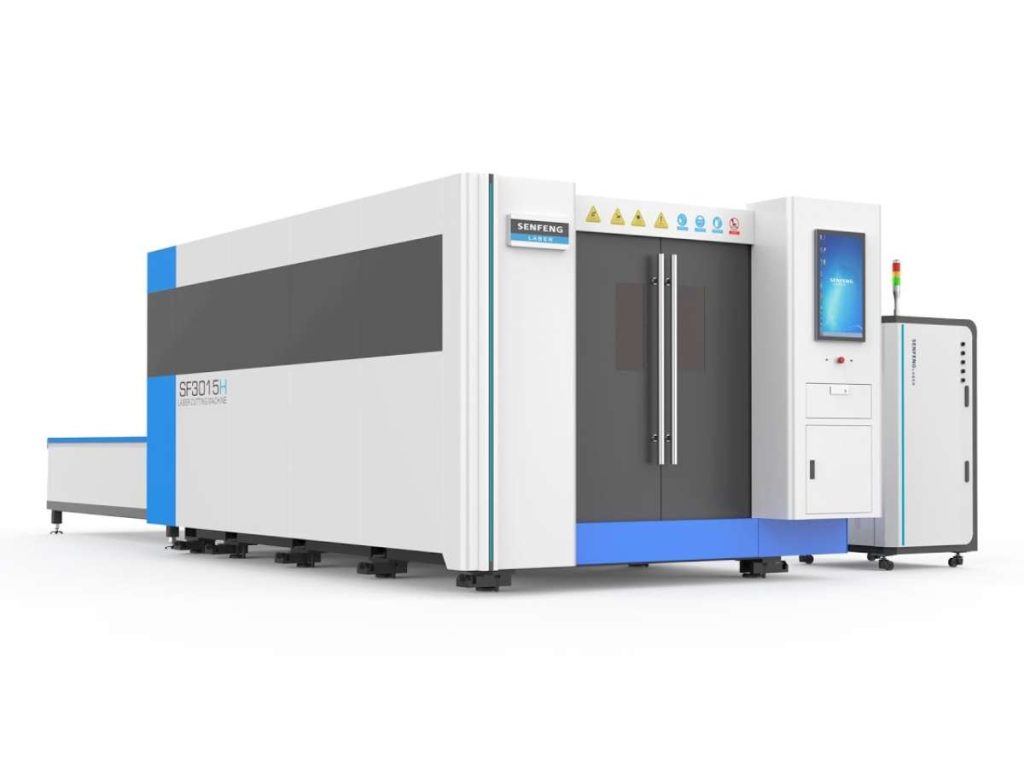

8. SENFENG SF3015H Fiber Laser Cutting Machine

I remember visiting a rental company that had just added the SENFENG SF3015H to their lineup. The owner pointed to it and said, “This one doesn’t give us trouble. It just works.” I watched it cut through stainless steel cleanly—no sparks flying, no loud noise—just smooth motion inside a fully enclosed frame.

That stuck with me. For a medium-size operation or a business that rents out machines, you want something dependable. The SF3015H offers that kind of peace of mind without overcomplicating things.

Specifications

- Laser Type: Fiber

- Cutting Area & Power: 1500×3000mm; 1kW–12kW

- Supported Materials: Steel, stainless steel, aluminum

- Ease of Operation: Touchscreen interface with clear menu structure

- Software Support: Compatible with G-code, DXF, AI formats

- Spare Parts & Support: Supported by SENFENG’s global service team with remote help

How It Works

You start by loading your metal sheet and uploading your file to the system. The interface is easy to follow, and the enclosed design keeps everything safe while cutting.

One thing I appreciate is the remote monitoring feature. You can track cutting progress or check machine status without standing next to it. That’s useful if you’re managing multiple jobs or overseeing other machines.

The cuts are sharp, especially stainless and aluminum. It holds up well even during long shifts, and the enclosed build keeps dust and sparks inside—making it cleaner and safer for shared workspaces.

Best For

- Machine rental companies

- Medium-sized fabrication shops

- Businesses needing solid tech at a fair price

Final Thought

The SENFENG SF3015H gives you speed, safety, and solid results—however, it may not have the customization depth or add-ons that larger industrial operations require.

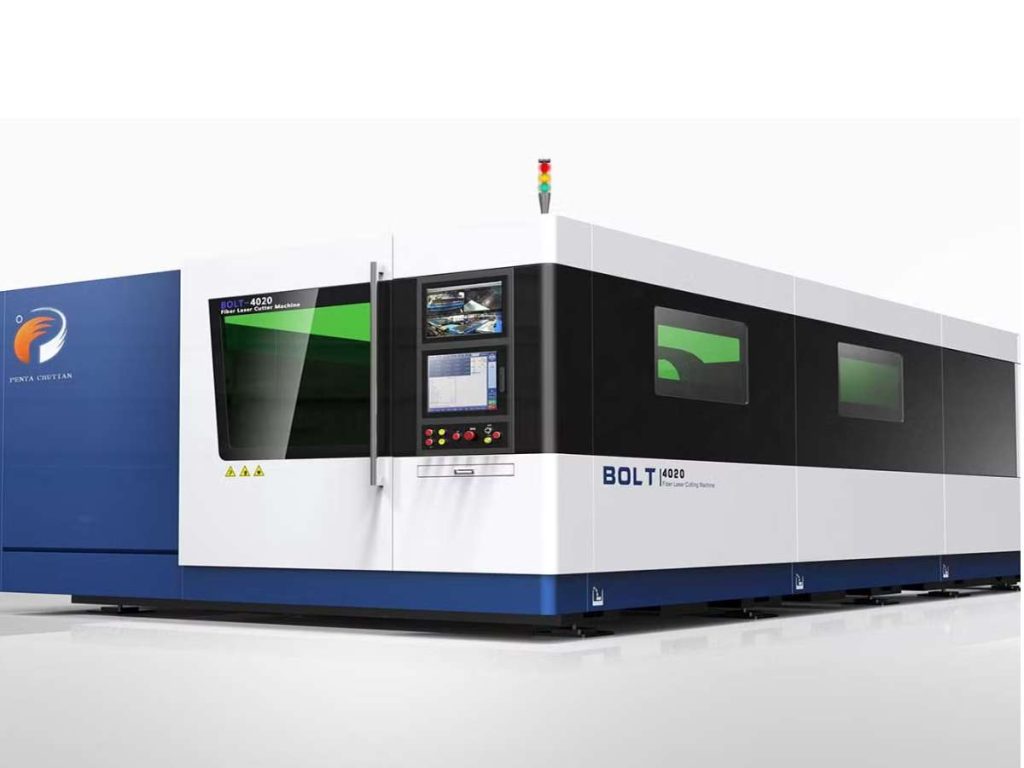

9. PENTA LASER Speedy One Fiber Laser Cutting Machine

I visited a machinery workshop where they were rebuilding an old press system. One technician pointed to a thick stainless part and said, “We used to outsource this—it took three days. Now we cut it in under an hour with the Speedy One.”

That shift—bringing tough jobs in-house—is a big deal. If you’re working with thick metals and tight schedules, you need a machine that can handle both without slowing you down.

Specifications

- Laser Type: Fiber

- Cutting Area & Power: 1500×3000mm and larger; 6kW–20kW

- Supported Materials: Thick carbon steel, stainless steel

- Ease of Operation: Stable drive platform; intuitive control panel

- Software Support: Compatible with major CAD/CAM formats; runs on European controller

- Spare Parts & Support: Global support network through PENTA LASER

How It Works

You load your material, set up your file, and let the system take over. The high-speed motion platform allows for smooth cutting, even when handling large or heavy sheets.

What stands out is its thermal control. The machine stays steady during deep cuts, which keeps edge quality high. That also helps reduce the need for secondary processing.

The European controller and drive systems give it a refined feel—movements are clean, and reactions are quick. It’s not just powerful; it’s smart and steady.

Best For

- Shipbuilders

- Heavy machinery and parts manufacturers

- Industrial plants that work with thick steel regularly

Final Thought

The PENTA LASER Speedy One is made for serious jobs with tight deadlines—however, its size, power, and cost may be more than necessary for shops focused on light-duty cutting.

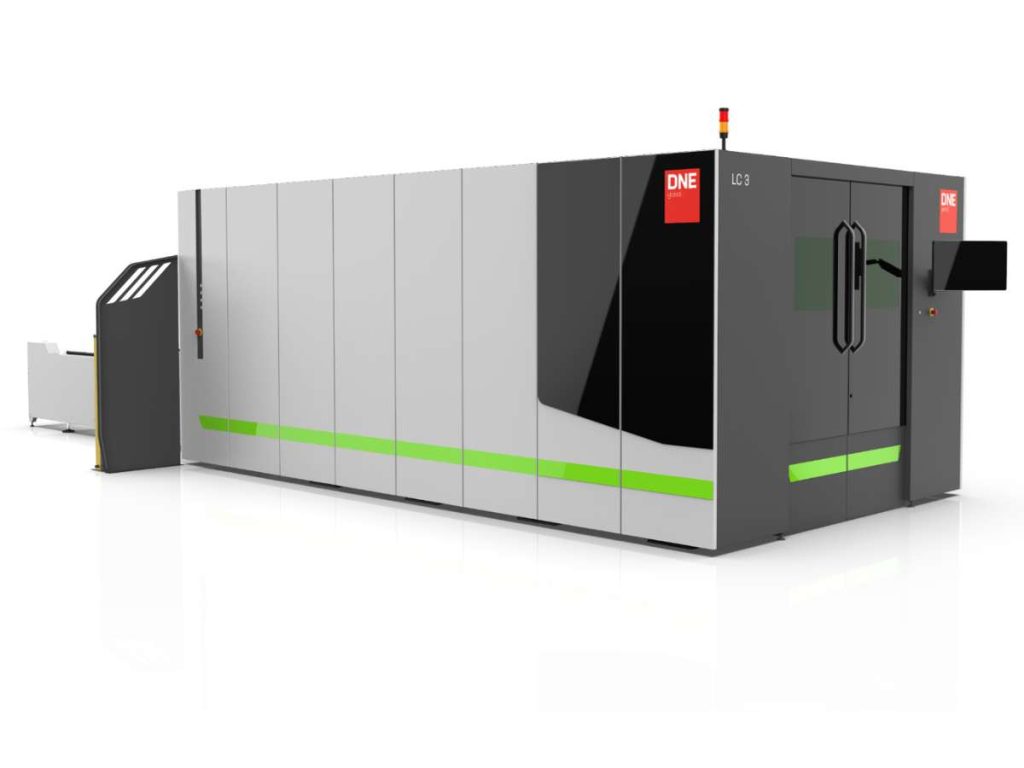

10. DNE LC3 Fiber Laser Cutting Machine

“This feels smoother than it should,” I thought, watching the LC3 glide through a stainless sheet. The operator leaned in and said, “It’s Swiss control, but made practical.” The cuts were sharp, fast, and quiet—no hesitation, no rough edges.

If you run a high-end fabrication shop or ship precision parts overseas, this machine fits right in. It’s made for shops that care about detail but still need to move fast.

Specifications

- Laser Type: Fiber

- Cutting Area & Power: 1500×3000mm and up; 1kW–12kW

- Supported Materials: All common sheet metals (mild steel, stainless, aluminum)

- Ease of Operation: Bystronic-grade touchscreen controller

- Software Support: Compatible with DXF, G-code, and major CAD platforms

- Spare Parts & Support: Backed by DNE’s international service and parts network

How It Works

You upload your file, adjust your speed and material settings, and let the system handle the rest. The machine pierces fast and switches between paths quickly. That keeps production flowing, even on detailed or layered jobs.

What stood out was the motion stability. Even on thin cuts or curves, the LC3 stayed accurate. You don’t get vibration or second-guessing. Just steady movement and crisp results. And with its solid frame and tight controls, you can keep tolerances consistent across long shifts.

Best For

- Exporters shipping precision-cut parts

- High-end metal fabrication shops

- Businesses that prioritize both speed and detail

Final Thought

The DNE LC3 delivers excellent performance with tight control—however, its advanced features may be more than you need if your jobs are basic or low volume.

Conclusion

Looking for a laser cutting machine in China?

This article showed you which brands deliver precision, power, and support without the guesswork. Whether you’re cutting metal, fabric, or wood, there’s a fit for your shop.

I’ve seen bad machines slow down good businesses. Don’t let that be your story.

You have the info. You’ve seen the proof.

Now it’s time to take the next step.

Contact us today and let’s find the perfect laser cutting solution together.