Laser rust removal is a method of removing rust from metal surfaces using laser technology. We often refer it to as laser cleaning or laser ablation. Laser rust removal is widely used in the manufacture, refurbishment, and repair of metal parts or equipment. Because laser cleaning is a fast, repeatable, and pollution-free rust removal process that increases efficiency and reduces costs.

Laser cleaning can not only clean organic pollutants but also inorganic substances, including metal rust, metal particles, dust, etc. It can magically make various materials look new, and can be called a “beautician” in the manufacturing industry.

Continue to read this article if you are wondering what is laser rust removal and laser cleaning. This guide will introduce you to some basic information about laser rust removal. It will help you buy a laser cleaning machine.

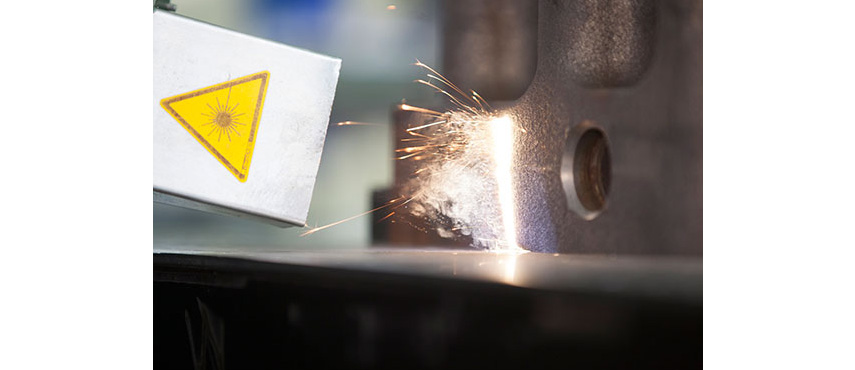

Laser rust removal principle

Laser rust removal is a new environmentally friendly cleaning method. The machine used to clean rust is a laser cleaning machine. Besides, it is a cleaning solution that uses a high-frequency short-pulse laser as the working medium.

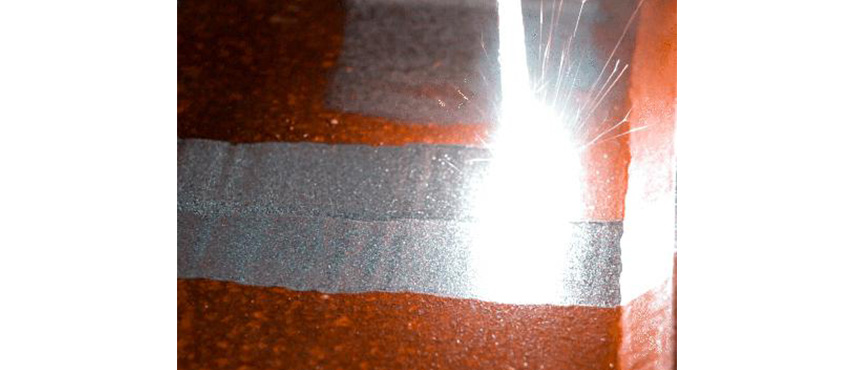

The rust, paint, and pollution layer absorb the laser beam of a specific wavelength, forming a rapidly expanding plasma. At the same time, a shock wave is generated, which causes the contaminants to become fragments and be removed. The substrate does not absorb energy. So laser rust cleaning does not damage the surface of the object or reduce its surface finish.

Why choose laser rust removal?

Non-contact cleaning

Laser rust removal technology has no contact with the surface of the material and has wide applicability. It can clean components of various shapes. Besides, laser rust removal also solves the curve surface cleaning problem that mechanical cleaning is difficult to deal with.

No damage to the substrate

There is no damage to the substrate or product after laser cleaning. It can solve the problem that mechanical grinding is easy to cause damage to the surface of the workpiece.

Efficient and environmentally friendly

Laser rust removal technology is efficient, energy-saving and environmentally friendly. Compared with other cleaning methods, it solves the problems of damaged substrates, limited component size, long time, and low efficiency. Besides, It has no chemical reagent that is harmful to the human body and the environment.

Laser rust or laser paint removal reduces the amount of toxic waste and can meet strict environmental protection regulations. At the same time, it also reduces the operation cost and human cost.

Precise and controllable

Laser rust removal is a high-throughput process that consistently cleans rust. The flexible laser cleaning system can remove coatings, contaminants or rust from surfaces without contaminating or degrading material surfaces. You can customize laser parameters for specific applications, realizing fast rust removal and cleaning.

If we have to say some cons of laser rust removal, most of its applications are in the mid-market. For example, cleaning molds, equipment, parts, etc. However, it has less usage in the high-end cleaning market, such as rust and paint removal of ships. But technology iteration is rapid. We believe that in the near future, laser cleaning will surely replace the traditional cleaning industry. And it will become a disruptor in the field of industrial cleaning!

Comparison of laser rust removal and other rust removal methods

There are many industrial rust cleaning methods, such as manual rust removal, sandblasting rust removal, chemical rust removal, etc. In addition to rust removal, there are also industrial cleaning methods such as dry ice cleaning and ultrasonic cleaning. A simple comparison of the industrial rust cleaning methods is shown in the table below.

| Manual grinding | Mechanical grinding (sandblasting, shot blasting, etc) | Chemical cleaning | Laser rust removal | |

| Cleaning method | Grinding disc, abrasive paper, etc., contacting | Mechanical contact with blast abrasive grains | Chemical cleaning agent, contacting | Laser, non-contacting |

| Workpiece damage | Yes | Yes | Yes | No |

| Rust removal efficiency | Lowest | Low | Low | High |

| Removal result | Uneven | Uneven | Uneven | Excellent |

| Cleaning accuracy | Uncontrollable, lowest | Uncontrollable, low | Uncontrollable, low | Controllable, high |

| Safety/pollution | Environmental pollution | Environmental pollution | Chemical pollution | Non |

| Human operation | Great physical strength, safety protection required | Great physical strength, safety protection required | High requirements on operators, safety protection required | Easy operation, handheld or automated |

| Consumables | Grinding disc, abrasive paper, etc. | Grinding disc, abrasive paper, etc. | Cleaning agent | Electricity |

| Investment | Low first invest, high labor cost, consumables | High first invest, Labor cost, consumables | High consumable cost | High first invest, no consumables, maintenance free |

Sandblasting rust removal can damage the substrate and produce a lot of dust pollution, especially in open spaces. Chemical cleaning will have residual cleaning agents, and the cleaning efficiency is not high enough. Besides, it will affect the acid-base property and the hydrophilicity of the surface, and cause environmental pollution.

In conclusion, these cleaning processes have various inconveniences. Some of them cannot meet the environmental protection requirements or efficiency of the manufacturing industry.

The advantage of laser rust removal is that it is non-contact, more accurate and clean, and can be remotely controlled. It helps to realize semi-automated or fully automatic unmanned workshops. Laser rust cleaning can maximize the retention of the original surface hardness, roughness, and hydrophilicity of the material.

What’s more, unit cost, energy consumption, and efficiency of the rust cleaning laser method are better than other cleaning methods. It can achieve industrial-level zero pollution to the environment.

Laser rust removal machine for sale

The laser rust cleaning machine uses a fiber laser source, whose wavelength is more easily to be absorbed by metals. So we also call it the laser cleaning machine, or fiber laser cleaning machine. In addition to rust removal, the rust cleaning laser machine can also clean tires, stone, glass, rubber, and other materials.

According to the rust cleaning laser power, laser cleaning machines have low-power, medium-power, and high-power cleaning machines. The low-power laser rust removal machine has laser power less than 100w, such as 20W, 50W, etc. Medium power includes 100W, 200W, 500W, etc.

Now many companies have also developed high-power laser cleaning machines, such as 1000W, 1500W, or even 4000W, 6000W, etc. The cleaning efficiency of the high-power laser cleaning machines is more than 5 times that of ordinary laser cleaning machines. They also have strong removal capacity and high cleaning efficiency. They are especially suitable for cleaning large-scale machinery and equipment or large-scale projects such as aircraft and ships.

Laser cleaning machines can also be divided into handheld cleaning machine and automatic laser cleaning machine. A handheld laser cleaner has a laser rust removal gun. Operators can hold this laser rust removal gun and remove the rust wherever required. Portable laser rust remover is also a type of handheld laser cleaner. Some portable laser rust remover machines are only the size of a suitcase. It is very convenient and flexible to use.

Automatic laser cleaning integrates the laser cleaning system with manipulators, robots, AGV, and other equipment for precise and efficient cleaning.

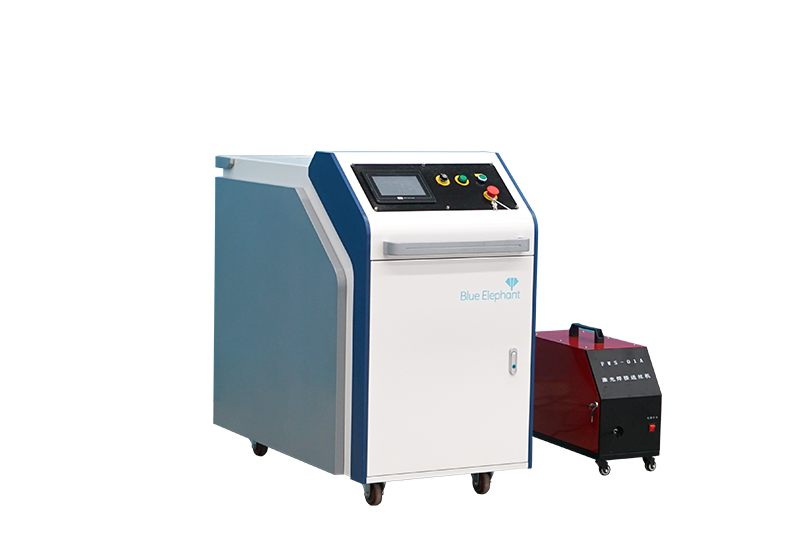

Blue Elephant laser rust removal machine for sale

At present, Blue Elephant mainly provides handheld laser cleaner machines of two types. One is a simple model of handheld laser cleaner and the other is a three-in-one fiber laser cleaning machine. Both of them are handheld structures with a laser rust removal gun. The rust cleaning laser power is optional from 100W to 1000W.

The handheld laser cleaner or portable laser rust remover has many advantages. And the biggest one is the ease of use. The machine is small in size. Besides, the universal wheels on the bottom make it convenient to use anywhere in the factory. With lightweight, it is also convenient for high-altitude laser cleaning operations.

The video shows the process of cleaning metal surfaces with our handheld laser rust removal machine.

This handheld laser cleaning machine is more suitable for users having not only laser cleaning demands but also cutting and welding. It can clean the verdigris on copper alloy surface, oxide on steel, and also rust on iron or other metals. You can choose 1kW, 1.5kW, 2kW, and 3kW laser power for this machine to complete different jobs.

The following video shows the three working modes of this three-in-one fiber laser machine.

Fiber laser cleaning applications

The laser rust cleaning is used for metal substrate cleaning and product cleaning in many industrial productions. It can also clean other different materials, especially suitable for the irregular, uneven surface that cannot be cleaned by traditional cleaning.

In addition to removing rust from metal, laser cleaning is also widely used in many other cleaning fields. For example, laser paint removal, laser oil/grease removal, etc.

- Molds, such as tire molds and food molds, require regular and rapid cleaning to maintain accurate production and reduce downtime. Laser cleaning technology can clean industrial molds effectively without hurting the precision.

- The laser cleaning system can quickly remove rust and contaminants from weapons and equipment. The waste removed by the laser is pollution-free to the environment and human health.

- Laser paint removal is widely used in fields such as mechanical equipment refurbishment or aircraft repainting.

- Laser cleaning system is also used to clean the exterior walls of buildings. Fiber laser machines can effectively remove pollutants from various metals, stones, glass, etc. In addition, the use of laser cleaning has a very good effect on protecting ancient buildings and restoring their appearance.

- Electronic component pins must be thoroughly de-oxidized to ensure optimal electrical contact. Besides, the decontamination process cannot damage the pins. Laser cleaning can meet the requirements of electronic component cleaning and is very efficient. One pin only needs to be irradiated with a laser once.

Laser rust removal machine price

The first thing you need to know is that the laser cleaning machine price varies greatly due to various specifications. This is just similar to other custom CNC machines. A fiber laser machine can also have customized specifications according to customers’ demands.

For the same air-cooled 200W handheld laser cleaner, some users use it to remove rust and paint from tire molds. While some users use it to de-coat PCB boards. The former may ask to install PIC because they want faster and more efficient. However, the latter wants a PLC to monitor relevant data in real-time. What’s more, you can also choose pulse or continuous laser, QCS or QBH, or other specifications according to specific needs. So the laser rust removal machine price varies even for the same 200W handheld laser cleaner.

Therefore, the laser cleaning machine price is closely related to machine specifications. Generally, the low- and medium-power laser cleaning machine price is about 8,000 to 30,000 US dollars. Such laser rust removers can basically meet the processing needs of small and medium-sized enterprises. For large factories or large-scale rust removal projects, the price of high-power laser cleaning machines may be over $300,000.

Conclusion

Laser cleaning is quite practical and has broad market prospects in contamination, rust, paint, rubber, and plastic cleaning fields. Laser rust removal, as one of the most common applications, has developed rapidly in the past 10 years. It has gradually replaced the traditional cleaning process in many fields with its irreplaceable advantages. For example, non-contacting, no grinding, no chemical residue, no pollution, and no thermal effect.

Whether handheld laser cleaner or integrated laser cleaning system provides green and safe laser rust cleaning solutions. It has broad prospects in microelectronics, construction, nuclear power plants, automobile manufacturing, medical care, cultural relics protection and other fields.

We provide custom portable laser rust remover and handheld laser cleaning machines for users all over the world. Feel free to contact us to learn more details about laser rust removal.