Laser Welding Machine vs. Traditional Welding Machine

The main traditional welding methods include resistance welding, argon arc welding, plasma arc welding, and electron beam welding.

Resistance welding mainly welds thin metal parts, and the workpiece is easily deformed. And the electrodes used in resistance welding require frequent maintenance. During the processing, the laser welding machine doesn’t touch the thin metal workpiece. At the same time, the laser welding machine can enter areas that are difficult to be welded by conventional welding. And the welding speed is fast.

The welding speed of argon arc welding is slower. And the heat input is much larger than that of a laser welding machine, which is prone to deformation. Plasma arc welding produces a compressed arc, which is faster and deeper than argon arc welding, but inferior to laser welding.

The main disadvantage of electron beam welding (EBW) is that it requires a high vacuum environment to prevent electron scattering. Besides, the equipment is complicated and the size and shape of the weld are limited by the vacuum chamber. Electron beam welding also has magnetic offset and X-ray problems. So it is required to demagnetize the electron beam welding workpiece before welding. X-rays are particularly strong at high pressures. It is necessary to protect the operator’s safety. A laser welding machine does not require a vacuum chamber and demagnetization treatment before welding the workpiece. And laser welding machine can be performed in the atmosphere without an X-ray. So it can be operated in the production line and can also weld magnetic materials.

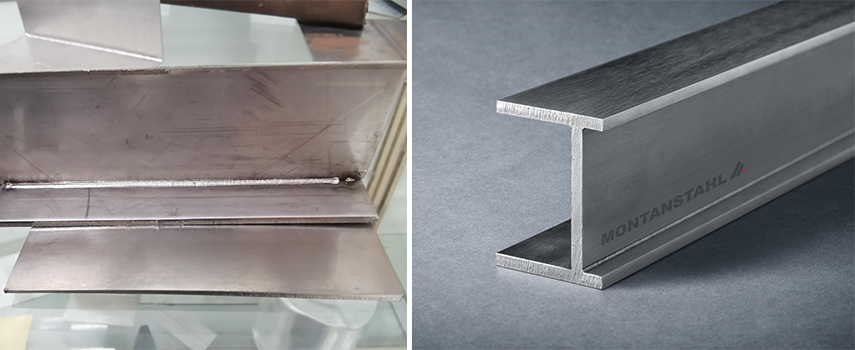

Aluminum Alloy Laser Welding

When laser welding aluminum alloys, many pores, and cracks will be generated during the laser welding process, which will affect the welding quality. Aluminum has low ionization energy and poor welding stability, and also causes welding discontinuities. Moreover, aluminum oxide and aluminum nitride will be produced in the high-heat laser welding process, which will pollute the environment.

For different aluminum alloys, the difficulty of laser welding varies. Therefore, for the laser welding of aluminum alloys, you should adopt an appropriate laser welding method so as to obtain a better laser welding effect. For example, the surface of the aluminum alloy plate can be polished before welding to increase its absorption of laser energy. At the same time, inert gas can be used during the laser welding process to prevent pores. Or you can control the laser welding parameters, change the laser welding structure, etc. They are all effective welding methods.

Laser Hybrid Welding

5 Common Laser Welding Problems & Solutions

With the advantages of high efficiency, high precision, good effect, and easy automation integration, laser welding machine plays a pivotal role in various industries. However, if any processing method does not master its principle and technology, it will produce certain defects or defective products. Laser welding technology is no exception. Only by learning how to avoid these problems, can we better utilize the value of laser welding machines and process products with beautiful appearance and high quality. Through the long-term accumulation of experience, Blue Elephant has summed up some solutions to common welding defects, hoping to give you some help.

1. Crack

The cracks generated in laser welding are mainly thermal cracks, such as crystallization cracks, liquefaction cracks, etc. While the main reason is that the weld produces a large shrinkage force before it is completely solidified. Solutions like wire filling and preheating can reduce or eliminate cracks.

2. Porosity

Porosity is a defect that is easily generated in laser welding. The molten pool of the laser welding machine is deep and narrow, and the cooling rate is fast. And the gas generated in the liquid molten pool does not have enough time to escape, which easily leads to the formation of pores. Cleaning the surface of the workpiece before laser welding can reduce porosity. In addition, the direction of blowing will also affect the generation of porosity.

3. Spatter

The spatter produced during laser welding seriously affects the surface quality of the weld. At the same time, it will also contaminate and damage the lens. Spatter is directly related to power density. Therefore, you can appropriately reduce the laser welding energy to avoid spatter.

4. Undercut

If the welding speed is too fast, the liquid metal will not have time to redistribute. So it will solidify on both sides of the weld to form an undercut. And if the joint assembly gap is too large, the molten metal of the caulking is reduced, which is also easy to produce undercuts. Controlling the power and speed to match can be a good solution to the generation of undercuts.

5. Collapse

If the welding speed is slow, and the molten pool is large and wide, the number of molten metal increases. Thus, the surface tension is difficult to maintain with the heavier liquid metal and the center of the weld will sink. Then it will form collapses and pits. At this time, it is necessary to appropriately reduce the energy density to avoid the collapse of the molten pool.

Laser Welding Kits

1. The laser welding host is composed of main parts such as a power supply, laser generator, optical path, and control system.

2. A cooling system can cool the laser. And the chiller will be equipped with different powers if the laser power is different.

3. The laser welding automatic workbench is also called the motion system, which is used to realize the automatic welding function of the laser. And it is very simple to operate. Moreover, there are three forms of motion control: workpiece movement but the laser head fixed; laser head movement while the workpiece fixed; and both laser head and workpiece move.

4. A fixture is mainly used to fix the workpiece to be welded, so that it can be repeatedly loaded and unloaded, and repeated positioning, so as to facilitate the automatic welding of the laser. Especially in mass production, fixtures will directly affect the efficiency and yield of production.

5. The observation system can conduct real-time microscopic observation of the workpiece, which is conducive to accurate positioning and inspection of the welding effect. Generally, a CCD display system or a microscope is configured.

Laser Welding Machine Price

Now, we have three types of laser welding machines on hot sale. According to different configurations and functions, each laser welding machine has various laser welding machine price. For example, the 3D automatic laser welding machine price usually ranges from $4,000 to $8,000. The handheld laser welding machine price is the most economical. It sells for a price ranging from $3,000 to $5,000 with the fiber laser power of 1000w to 2000w. And because the three-in-one fiber laser welder is the most multifunctional laser machine, the handheld laser welding machine price is much higher than that of the ordinary one. The three-in-one handheld laser welding machine price ranges from $5,000 to $10,000.

What Can You Weld with a Laser Welder?

The following videos show the demonstration of processing different metal materials with different fiber laser welders for sale.

First, the handheld laser welding machine can realize the inside or outside fillet welding of stainless steel, carbon steel, and aluminum. Besides, the handheld laser welder for sale can also complete carbon steel and aluminum splicing welding.

Second, you can freely and easily switch 3 different laser processing modes of the best 3-in-1 laser welder for sale. Then you will make metal laser welding, metal laser cleaning, and metal laser cutting at the same time. Therefore, the laser welding machine for sale is a very ideal choice for people who wants higher efficiency with lower laser welding cost.

Third, through the welding spot monitor of the automatic handheld laser welder, it is a sample for workers or beginners to operate. The 3D laser welding machine for sale can realize stitch welding and splicing welding of metal materials.

What are Laser Welding Machines Used for?

Applied industries

Manufacturing industry, aerospace industry, shipbuilding industry, automobile industry, electronics industry, IT industry, battery industry, jewelry industry, biomedicine industry, powder metallurgy industry, optical communication industry, sensor industry, hardware industry, glasses industry, home appliance industry, solar energy industry, electric heating industry, precision parts manufacturing industry, etc.

Applications

Laser welding machines are widely used in the automotive industry. Besides, laser welding machines can realize flexibly welding. And the welds of the welded products are firm and beautiful. In addition to the welding of automotive thin-plate structural parts, laser welding machines can also be seen in many other applications. For example, the laser welding machine for sale can be used to weld automotive parts, such as engine cylinder gaskets, hydraulic tappet sealing welding, automotive high-voltage relays, filters, torque sensors, turbochargers, fuel rails, cylinder head gaskets, spark plugs, block motor stators, seat adjustment screws, air bags, etc.

Laser welding equipment can also be widely seen in the current electronics industry. Such as sealing and breaking welding of solid state relays, welding of connectors, welding of metal shells and structural components like mobile phones and MP3, welding of motor shells and connectors, welding of fiber optic connector joints, etc.

Hermetically sealed electronics in medical devices such as pacemakers and other electronics have made fiber laser welding the process of choice for applications. In addition, fiber laser welding machines can weld nickel and titanium based aerospace alloys in many aerospace applications.

How to Weld at Home for a Beginner?

You shouldn’t use the arc welding machine at home. Because the current required for arc welding is less than tens of amps, which will make your protector jump. So TIG, MIG, and MAG can be ruled out. Electric resistance welding (ERW) and hot press welding are too big for home use. The disadvantage of oxyacetylene gas welding is that the flame temperature is more than 3000°. If you’re not careful, your home can be set on fire. Therefore, the most reliable method of welding at home is braze welding. Braze welding requires high frequency heating, so soft soldering is more suitable. However, you also need to consider what you’re welding, as the metal bond isn’t as strong that way. Laser welding, plasma welding, and electron beam welding (EBW) are a bit expensive, but they can be used at home. And their welding quality is good and the speed is fast.

Word at Last

After carefully reading this article, you will get some answers about the fiber laser welding machine that you want to know. Because this article makes an overall introduction to laser welding technology. You will not only know the differences between the fiber laser welding machine fo sale and the traditional welding machine, but also learn the application, advantages, price, problems, and solutions of the laser welding machine.

Due to the wider use and popular trend of laser welding machines, in the future, we will continue to make more introductions of laser welding technology and Blue Elephant CNC laser welders for sale. If you have interested in our laser welding machines or laser welding technology, please keep following us.