Speaking of wood cutting machine, many people first think of various saws. For example, table saw, jigsaw, sawmill, handsaw, etc. With the development of technology, the woodworking industry has gradually adopted more efficient and precise automatic wood cutting machine.

Automatic wood cutting machines fall into many types. For instance, handheld electric cutting device, CNC wood cutting machine, laser wood cutter, computer beam saw, etc. Their appearance greatly improves the wood cutting efficiency and precision and brings more benefits to the woodworking industry.

This article provides a buyer’s guide for the most popular wood cutting machines. It covers the brief information and recommendation of the wood CNC router, laser engraving machine, computer beam saw and sliding table saw. If you are considering buying a wood cutter to start your woodworking work, you must not miss this article.

CNC wood cutting machine

A wood cutting machine can be a manual or an automatic cutting machine according to the driving mode. Manual wood cutters include hacksaws, coping saws, bowsaws, crosscut saws, chisels, and other handheld tools. These hand tools are wood cutting machine for home use. They have relatively low efficiency and poor precision and are only suitable for cutting a small amount of wood. Now woodworking factories are gradually using CNC cutting machines instead of manual saws and ordinary electric saws.

What is a CNC wood cutting machine?

A CNC wood cutting machine refers to the computer numerical controlled wood cutting equipment. Compared with ordinary electric saws, the CNC wood cutting machine is faster, more efficient, more precise, and has less waste. Once the program is set, the whole cutting process will complete according to the given path. Less human intervention avoids material wastes and errors.

Blue Elephant offers many types of CNC wood cutting machines, including CNC router machine, laser wood cutting machine, computer panel saw, etc. Each CNC wood cutting machine has various models and configurations. Besides, we accept personal customization of both the size and specifications. Users can customize the wood CNC machine to meet their processing requirements at most.

Advantages of CNC wood cutting machine

Efficiency and precision

High efficiency and precision are the biggest advantages of the CNC wood cutting machine compared to manual tools. Handheld operation may give you close contact with the material to cut, but its fault tolerance rate is much higher. Even the most skilled worker makes some mistakes. But the CNC wood cutting process is controlled by a computer program. The machine runs strictly according to the given route and automatically completes the cutting. This greatly reduces manual errors. Due to the increased accuracy, waste will be greatly reduced, which will also save money and time.

Repeatability

Due to the above-mentioned high precision feature, the repeatability of a CNC wood router is much higher than that of manual tools. A wood CNC router can cut exactly the wood boards over and over again quickly and accurately. It saves time and money by reducing waste and speeding up work. The repeatability potential is excellent.

Ease of operation

The CNC wood cutting machine adopts an automatic system and is very easy to operate. An operator can learn how to use CNC router software to operate the machine only after simple training. Most CNC router software has a human-friendly interface and is easy to learn. With the help of router software, you can realize various even complex pattern engraving and cutting.

Reduced labor cost

CNC wood dividing machine greatly reduces labor costs due to its ease of operation, high precision, and fast speed. Using the automatic CNC cutting system can quickly and accurately complete the work that requires multiple technicians to use the handheld routers. CNC router software programming requires a much smaller team. One person can operate two or even three machines, greatly reducing labor costs. And you can buy another wood CNC router by the saving costs.

Safety

CNC cutting is much safer than handheld cutting saws. Because operators do not need to keep close to the saw blade or tool. All the operators need to do is to properly install the CNC router bits and make a cutting design on the computer. This has greatly reduced occupational injury and increased working safety.

CNC wood cutting machine recommendation

Nesting CNC router machine

Users can also add auto loading and unloading platforms or other higher configurations to this plywood cutting machine.This wood CNC machine has such features as durable structure, powerful cutting ability, fast speed, multiple functions, etc. It is a good choice for factory and workshop use.

Major parameters

| Cutting area | 1300x2500x200mm |

| Wood cutter machine price | $10,000-$20,000, for reference only |

| Spindle | HQD 9kW air-cooled spindle, 24000RPM |

| Tool magazine | 12-tool carousel magazine |

| Materials | Various wooden boards, plastic |

| Support | multiple CNC router software, auxiliary compression rollers, auxiliary loading rollers |

Check this video for the cutting demonstration of this CNC cutting machine. Both the spindle and the saws can cut wooden boards quickly and neatly.

ATC wood CNC router

It is provided with an 8-tool linear tool magazine. So it can engrave complex patterns on the wooden boards without changing CNC route bits manually. The spindle can swing 180 degrees, which makes the machine can process some three-dimensional objects and molds. Users can add other configurations to this CNC cutting machine according to their specific needs.

Major parameters

| Cutting area | 1500x3000x200mm |

| Wood cutter machine price | $10,000-$20,000, for reference only |

| Spindle | HSD water-cooled spindle, 24000RPM |

| Tool magazine | BT30 ISO30, 8-tool linear magazine |

| Materials | Various wooden boards, plastic, soft metal |

| Control system | SYNTEC |

| CNC router software | Ucancame V9/Artcam/TYPE3 |

Computer beam saw

It can cut density boards, particle boards, fiber boards, gypsum boards, large core boards, light guide boards, aluminum boards, aluminum-plastic boards, solid wood, and other boards.

Major parameters

| Overall dimension | 6400x6300x1800mm |

| Wood cutter machine price | $20,000-$30,000, for reference only |

| Cutting length | Max. 3700mm |

| Cutting thickness | Max. 100mm |

| Auto feeding speed | 100mm/min |

| Main saw power | 16kW |

| Total power | 23kW |

With the features of high efficiency, excellent precision, and easy-to-operate, the computer beam saw is quite suitable for mass cutting of wooden panels. The panels cut by this CNC machine have smooth and clean surfaces and can be used for the next processing directly without any further treatment. It is the best wood cutting machine for factories with large production volumes.

Let’s see the video below together to understand how the computer beam saw cuts boards.

CNC wood cutting projects

CNC wood sawing machines are widely used in various industries. For example, panel furniture, construction, decoration, crafts, toys, advertisements, etc. Our wood CNC router customers are from all walks of life. They use our CNC woodworking machine to make their own unique cabinets, toys, billboards, etc. Exquisite products have also brought them considerable income.

The picture below is the feedback of our CNC cutting machines from our Kenyan and American customers. The Kenyan customer uses ELE1530 three-process CNC router machine to cut MDF and make wall decorations. The American customer uses our ELE1325-R plywood cutting machine to make cool dinosaur models. Such toys are very popular with children.

In addition to the above, many of our customers choose our wood cutter machines for cabinets, doors, and other panel furniture. The picture below shows various cabinets made by our customers. These exquisite cabinets are cut with our wood CNC machine.

Laser wood cutting machine

What is a laser wood cutting machine?

A laser wood cutting machine refers to the CNC machine using laser technology to cut wood materials. Different from cutting wood directly with the CNC router bits, the wood laser cutter adopts a non-contact processing method. The laser head does not contact the wood directly. Instead, it uses a high-density laser beam to burn the wood, thus realizing the cutting effect.

At present, the most commonly used laser machines are fiber laser cutter and CO2 laser cutter machines. Fiber laser cutters are mainly for cutting various metal materials. The wavelength of a CO2 laser cutter is 10.64um, which is more easily absorbed by the wood. Therefore, the CO2 laser machine is widely used for cutting and engraving wood.

Laser processing wood has high precision, fast speed and simple operation. It is suitable for the precise processing of wood products and other non-metallic materials. The software can draw any pattern graphics. And the high energy density of the laser beam projects on the surface of the workpiece to complete the cutting and hollowing of the graphics. There is no tool wear during laser processing, so the material loss is small and the yield is higher.

Why choose a wood laser cutter?

Excellent precision: Positioning precision can be 0.05mm and that of repeated positioning can be 0.02mm.

Narrow cutting slit: The laser beam is focused on a tiny spot and the cutting slit is about 0.10-0.20mm.

Smooth cutting surface: Without burrs, the roughness of the cutting surface is controlled under Ral2.5.

Fast speed: The cutting speed could reach 10m/min and the maximum positioning speed can reach 70m/min.

Good quality: With a small heat-affected area, the workpieces have no deformation and avoids any damages. The cutting slit generally requires no second working.

No damage to workpieces: The laser head does not contact the material physically, so it causes no damage to the material.

Reduced waste: The laser machine adopts computer programming, which can cut products of different shapes on the whole board material. This maximizes the utilization rate of materials.

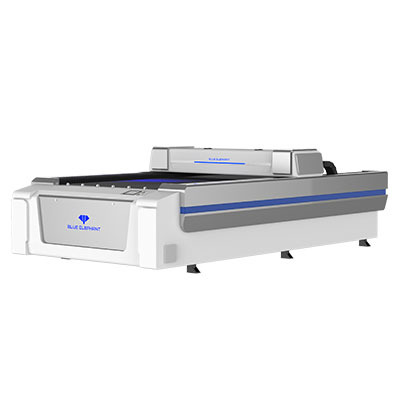

Laser wood cutting machine recommendation

Laser cutting can provide precision for customized parts within a tenth of a millimeter, even for small or thin shapes. Compared with other technologies, laser systems can save time and can process the thinnest materials through non-contact processing.

The laser engraver for wood has a working area of 1300x900mm. So it can only process relatively small wood items. For example, gifts, crafts, jigsaw puzzles, artworks, etc.

Major parameters

| Working area | 1300x900mm |

| Laser power | RECI 130-150W |

| Laser type | Sealed CO2 laser source |

| Cooling | CW5200 water cooling |

| Cutting speed | 1-1000mm/min |

| Cutting thickness | 0-20mm |

| Wood laser cutter machine price | $3,000-$9,000 |

Check the following video to see this laser engraver for wood cutting various four types of non-metal materials. This plywood laser cutter has a protection cover, which can be closed during the cutting process. It not only protects the operator’s safety but also protects the environment. It is an ideal wood cutting machine for home use.

The flatbed structure worktable of this laser wood cutting machine is suitable for cutting and engraving thin wood panels. The wood laser cutter generally does not cut wood deeply. The maximum cutting depth depends on the wood material and the power of the laser. If you want to cut very thick wood, you can slow down the cutting speed, but it may cause the wood to burn.

Major parameters

| Working area | 1300x2600mm |

| Laser power | RECI W6 |

| Control system | RUIDA |

| Laser type | Sealed CO2 laser source |

| Cooling | CW5200 water cooling |

| Cutting speed | 1-1000mm/min |

| Cutting thickness | 0-20mm |

| Laser wood cutter machine price | $5,000-$10,000 |

The video below shows our 1326 CO2 laser cutter machine processing different materials with high efficiency.

Sliding table saw for wood cutting

Sliding table saw is also a popular wood cutting machine in the woodworking industry apart from the above machines. The sliding or precision table saw is a woodworking machine suitable for cutting various boards, such as wood boards, PVC boards, and wood-based panels. It also refers to a sliding panel saw. Its main structure includes a sliding table, a work surface, a horizontal ruler, a sliding seat, a main panel saw blade, an auxiliary saw blade, etc.

Advantages of cutting wood with a sliding panel saw

It has a mobile workbench. The operation is light and labor-saving, and the pushing stroke is large. So it can cut large wooden boards

Equipped with a stable and portable trailer, it runs smoothly.

The angle of the saw blade can be adjusted to achieve 22.5° or 45° cutting and grooving.

It is equipped with a 5.5kw pure copper motor, which is more powerful. It can cut smoothly, and has better stability, so the sawing efficiency is quite high.

The sliding table saw can cross-section and longitudinally cut a variety of boards. For example, density boards, polished boards, man-made boards, solid wood boards, ABS boards, PVC boards, etc.

Sliding table saw recommendation

A sliding panel saw is easy to operate and suitable for businesses with a small production volume. Compared with CNC wood cutting routers, it is obviously less effective and precise.

Major parameters

| Overall dimension | 3200*2540*900mm |

| Sliding table size | 3200*375mm |

| Main saw diameter | 300mm |

| Auxiliary saw diameter | 120mm |

| Motor power | 5.5kW |

| Saw blade angle | 0-45° |

Please see this video to check how our sliding panel saw works and change the saw blade angle.

How to choose a wood cutting machine?

If you are a cabinet, door or other panel furniture manufacturer, your job involves not only cutting but also engraving, drilling, etc. Then CNC router machine is your best choice. The CNC wood router customized according to your requirements has various functions you required. It can best meet your cutting, engraving, drilling, milling, and other requirements.

Although the wood laser cutter is of high efficiency and precision, it can’t cut wood boards as much as a CNC router machine. The plywood laser cutter is more likely to cut and engrave small wooden ornaments such as gifts, artworks, toys, etc. It is not suitable for the mass production of wooden furniture. Besides, the maximum cutting thickness may only be 20mm. If cut thicker panels, it may burn the wood.

As a smarter product, the computer beam saw can cut panels more quickly and accurately. It can even cut four boards at a time. But it can’t carve or punch. Therefore, for other operations such as engraving patterns or drilling holes, users still need to purchase other production line machines.

The sliding table saw is a semi-automatic wood sawing machine. Its efficiency and accuracy are less than those of the above-mentioned three cutting machines. So, if your workshop has a small production volume and a limited budget, a sliding table saw is an ideal choice. But if you are a large woodworking factory, the sliding panel saw may not be able to meet the fast and efficient needs.

Conclusion

This article briefly introduces 4 popular types of wood cutting machine, including CNC wood router, wood laser cutter, computer saw, and sliding table saw. They all are the best wood cutting machine in the woodworking industry. But each of them also has a different focus on the cutting process. When choosing a wood cutting machinery, users need to figure out the machine functions and their own processing needs.

In short, wood cutting machine, especially CNC wood cutting machine, is more and more widely used. With the development of technology, the price of wood cutting machine will gradually decrease. And more people will be able to afford CNC cutting machines. If you are interested in any of the above machines, please contact us. We will give you the most preferential price.