The wood laser cutter has gradually become the first choice of related woodworking industry due to its unparalleled processing characteristics. The wood laser cutting machine is available in various sizes and powers. In terms of woodworking, the laser wood cutting machine can perform marking, engraving, and cutting with amazing results.

Laser cutting is an amazing technology that is now widely used for precise cutting on flat materials. It uses a movable laser head to emit a focused beam to cut, mark or engrave materials. Applicable materials include wood, acrylic, plastic, paper, cloth, rubber, stone, etc.

This article focuses on the basic knowledge you need to know when buying and using a wood laser machine. I hope to provide some ideas for you if you are hesitant to buy a laser wood cutter for sale.

What is a wood laser cutter?

A wood laser cutter is a laser cutting machine used to cut, engrave and etch wood. In addition to wood, it can also process other non-metallic materials, such as plastic, acrylic, fabric, leather, rubber, stone, glass, etc. Therefore, it is also called plywood laser cutter, acrylic laser cutter, laser wood engraver for wood. The wood laser machine is suitable for cutting simple to complex designs into flat materials.

Nowadays, the mainstream laser wood cutting machine is a CO2 laser cutter. Its beam wavelength is 10.64um, suitable for processing wood and other non-metal materials. The other mainstream laser cutting machine is the fiber laser cutter. Its beam wavelength is one-tenth of that of the CO2 laser. The fiber laser cutter is more suitable for cutting metals, so it is also known as the metal laser cutter.

Compared with a fiber laser cutting machine for metal, a wood laser cutter requires much less power to cut wood. We have 80W, 100W, 130W, 150W, and other power options. This laser power determines the cutting ability of the wood laser cutter.

Advantages of a wood laser cutter

Whether a laser wood cutting machine or a metal laser cutter, laser cutting has advantages that other traditional machines cannot match.

High precision

The laser wood engraver adopts computer-controlled operation, and no manual cutting is required. This greatly avoids errors or wastes caused by manual cutting. The positioning accuracy can reach 0.03mm, and the repeat positioning accuracy can reach 0.02mm.

High efficiency

Once the program is set, the plywood laser cutter machine will automatically and quickly complete the wood cutting. The cutting speed can reach 2000mm/min. The high level of automation greatly improves cutting efficiency.

Good effect

Laser cutting adopts a non-contact processing method and has a very small heat-affected area. The cutting slit is narrow with a width generally 0.10-0.20mm. In addition, the cutting surface is smooth and free of burrs. And the surface roughness of the incision is generally controlled within Ral2.5. Laser cutting will not cause thermal deformation of the workpiece and will not damage the workpiece.

Save materials

The optimized software can properly layout the wood board according to the cutting shapes. This maximizes the utilization of materials. Besides, it’s safer to use a wood laser machine than to cut with a manual tool.

Shortcomings of a wood laser cutter

Every coin has two sides. Although the laser wood cutting machine has many outstanding advantages, it can not cut all kinds of materials. Due to the limitation of its own composition, the wood laser cutter also has some disadvantages.

The photoelectric conversion rate of a CO2 laser cutter is relatively low, which is only about 10%. So the wood laser cutting machine consumes more electricity when in use.

The use and maintenance costs of a wood laser cutter are relatively high. Because it uses a glass CO2 laser generator, optical mirrors and other vulnerable parts which require regular replacement.

It may emit toxic smoke to the air when cutting certain materials, such as plastic.

The maximum thickness cut by a plywood laser cutter is about 20mm. It is harder to cut thicker or denser wooden plates. Cutting a wooden board thicker than 20mm leads to very low speed, and it may cause the burning of wood.

Depending on the thickness and density of the material, the processing speed is not always continuous.

Major technical parameters of a wood laser cutter

Table 1 Major Parameters of Wood Laser Cutter Machine

| Name | Parameters |

| Laser type | Sealed CO2 laser tube |

| Laser wavelength | 10.64um |

| Power | 100W, 130W, 150W, 180W, 200W |

| Control system | RUIDA |

| Working table size | 900*600mm, 1300*900mm, 1300*2500mm or as requested |

| Positioning accuracy | ≤±0.1mm/m |

| Repeatability positioning accuracy | ≤±0.1mm |

| Processing materials | Acrylic, glass, leather, MDF, paper, plastic, sponge, plexiglax, plywood, rubber, stone, wood, crystal, etc |

| Voltage | 220V/50Hz/100A (customized) |

| Support graphic format | DST, PLT, BMP, DXF |

| Optional parts | Rotary device, Auto focus, CCD camera |

Wood laser cutting machine price and factors affecting the price

With the popularity of laser technology in the woodworking industry, more small businesses and individuals can afford a wood laser cutter. The wood laser cutter price is about $3,000-$15,000. Of course, this is just a reference price range. The specific price depends on the specific configurations of the laser wood cutter for sale.

There are many factors that could affect the wood laser cutting machine price. The most important factor is the configurations and specifications of the laser machine itself. For example, the size, laser power, and cost of parts and components of the CO2 laser cutter. The greater the laser power, the thicker the wood that can be cut, and the higher the wood laser cutter price. The price of a large-sized laser machine is also higher than that of a small-sized one. Besides, imported parts will also cause extra to the laser cutter price.

Other factors include shipping costs, software fees, training fees, etc. In addition, you also need to freight, customs clearance fees, taxes, etc. if you buy a machine from overseas.

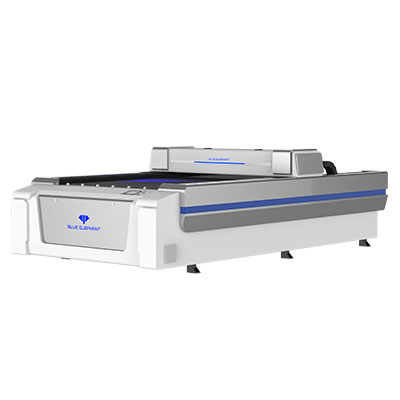

Best wood laser cutter recommendation

This laser engraving machine for wood uses a honeycomb worktable. This kind of worktable is more suitable for flexible materials such as leather, cloth, and paper. It usually has an adsorption device to fix the soft materials and keep them flat during the cutting process. The rotary device automatically rotates the workpiece, making it suitable for engraving cylindrical items. For instance, engraving letters and patterns on glasses.

The following video shows the process of laser engraving patterns on the surface of a glass goblet.

The laser power is available from 80W to 180W. And the thickness of the wood it can cut depends on the selection of the laser power. The protective cover can not only protect operators’ safety but also prevent the smoke generated from being emitted into the air.

You may choose a knife strip table for this best laser cutter for wood. The gap between the knife strips is large and the contact area with the material is relatively small. The density of the strips is adjustable, which is very suitable for cutting acrylic, MDF, and other hardwood boards.

The following video is the feedback of an American customer using a Blue Elephant CO2 laser cutter to cut wooden signs and boards. It can be seen from the video that through the optimized layout of the software, the wood laser cutter can make the greatest use of the board. This helps reduce the waste of materials. This wood laser cutter is very suitable for craft companies.

This laser head has the function of auto-focusing, which adjusts the depth of cutting and engraving automatically. So there is no need to making the second processing. It also adopts the famous RUIDA laser control system, ensuring smooth and safe operation.

The video below shows the processing demonstration of acrylic, MDF, leather, and corrugated board materials with a wood laser cutter.

Applications of a wood laser cutter

As mentioned above, different laser powers can cut wooden boards of different thicknesses. The table below shows the maximum thicknesses of the wood, acrylic, and MDF that a CO2 laser cutter can cut.

Table 2 Max. Thickness of Wood, Acrylic and Density Boards that a Blue Elephant Wood Laser Cutter can Cut

| Power | Wood | Acrylic | Density board |

| 80-100W | 10mm | 10mm | 5mm |

| 100-130W | 13mm | 15mm | 7mm |

| 130-150W | 18mm | 20mm | 9mm |

| 150-180W | 23mm | 25mm | 10mm |

Can a laser wood cutting machine cut all kinds of wood?

Yes. The laser machine can cut all kinds of wood materials of different thicknesses and density. The type and density of the wood may affect the laser wood machine’s speed and cutting quality. Besides, the cutting and engraving effect of softwood obviously differs from that of hardwood materials. Therefore, you’d better check the detailed processing parameters of a plywood laser cutter to make sure it suits your laser cut wood projects. For instance, the max. cutting depth.

Will a plywood laser cutter cause damage to the wood?

There will be no risks to damage the wood materials if you set all parameters correctly. This is the unique aspect of CO2 laser machines and their ability to work with great precision. So it is important to set all things correct in order to protect the wood surrounding the cuts. You should carefully read the operation manual or consult the machine manufacture before start working with a wood laser cutter.

Laser cut wood projects

The laser wood cutting machine has a wide range of applications in various industries, such as:

Advertising

Crafts

Artworks

Decoration

Models

Jewelry

Toys

Packaging

Laser cut and engraved projects are everywhere in life. In the previous blog, I have listed some of the best laser cutter projects for beginners. Except for metal projects, a CO2 laser cutting machine can achieve plenty of non-metal wood projects.

Laser cut

Wood arts, crafts, jewelry, organizers, holders, puzzles, models, racks, medals, etc.

Acrylic lamps, racks, letters, crafts, jewelry, toys, etc.

Paper name-cards, invitation cards, packages, arts, crafts, etc.

Fabric dresses, shirts, towels, pillows, artworks, decorations, etc.

Leather purses, wallets, gloves, keychains, packages, etc.

Laser engraved

Glass cups, coasters, medals, crafts, jewelry, etc.

Stone crafts, souvenirs, medals, profile boards, etc.

Things to consider before buying a wood laser cutter

First, understand your processing needs. As a woodworker, you should look for an engraving and cutting machine that can process wood and related materials such as cardboard and paper. It would be better if the laser wood cutter you choose can process many kinds of materials.

Then you may initially determine your requirements for the machine configuration based on your processing needs. If you just engrave images on wood, a small power such as 40W can meet this requirement. But when you want to cut wood, you need to consider a high-power wood laser cutter. Selection of the machine size relies on the maximum size of the materials you need to cut. In case that your project requires a lot of details, accuracy is the key metric. The engraving quality of a laser engraver for wood depends on various factors. For example, the beam width and the spacing between the lines it can engrave.

In the event that you need to cut wood panels over 20mm thick for a long term, you’d better use a CNC router.

Don’t forget the budget. The price of a wood laser cutter for home and factory use varies greatly. You can expect to spend between $2,000 and $10,000 on one machine. Before purchasing, please determine your maximum budget and select the most suitable machine accordingly.

Security is also a critical factor especially if you are working at the beginner level. You also need to pay special attention when you keep the machine in a high-traffic area of your home or workshop. The best laser cutter for wood with a protective cover can be an ideal choice. It not only protects the operator’s safety but also protects the environment.

You should also consider the maintenance and repair of the laser cutter. It should be easy to clean. Ask about the maintenance frequency and the whole process before investing. In addition, you should be able to easily find its parts in the market.

Buying a wood laser cutter or laser cutting service

If you do not need laser cut wood projects frequently, you can choose the laser cutting service. There are many online laser cutting service providers now. You only need to tell them your needs and send them design documents, and they can make laser-cut products according to your needs. So, you don’t need to invest in an expensive wood laser cutter machine. Instead, you only pay the corresponding processing costs, freight, and other costs. Choosing the laser cutting service also has certain risks. That’s because the quality of laser cutting service varies from good to bad. And it is possible that the project produced does not meet your needs.

However, if you need a large number of laser wood projects, or your company’s business is to sell laser-cut products, buying a wood laser cutter is the best choice. Because with a wood laser cutter, you will have a lot of flexibility. You can decide the time and quantity of cutting by yourself. If you are not satisfied, you can pause the cutting process at any time and change the corresponding parameters. Although buying a wood laser cutter is not a small investment, the income it brings is considerable.

Precautions when using a wood laser cutter

The CO2 laser is a powerful laser that can burn your skin and retina through direct or reflected radiation. So, do not stare at the laser for a long time during the cutting process. You can wear protective goggles or close the protective cover of the wood laser cutter during work.

Cutting certain materials, such as plastic, can cause the emission of toxic smoke. So, pay attention to the ventilation of the studio or garage. If your place has strict environmental requirements, I recommend you choose a laser wood engraver with a protective cover. Or use a vacuum cleaner to absorb the smoke.

Before using the CO2 laser cutter, be sure to read the instruction manual carefully or consult the manufacturer for the relevant parameters. Find out whether the laser machine can complete your own cutting or engraving needs.

When not using for a long time, remember to cut off the power and conduct the dustproof and lubrication work properly. You also need to frequently check the condition of all parts and replace the aging and worn parts.

Tips to make more clean laser cut wood projects

Keeping the workpiece elevated helps prevent the molten sap from sticking to the bottom of the workpiece. This can be achieved with a honeycomb worktable or by using pins to fix the workpiece.

Cutting wood with a laser may leave burn marks. Putting painter’s tape on the top and bottom of the workpiece helps protect the edges of the cut from burning. Besides, the auxiliary air can also help prevent the burning of wood.

You can use sandpaper to sand off any burn marks left on the wood surface after cutting.

You can also dye or add other decorations to the workpiece to make it more professional.

Summary

The wood laser cutter is the optimized choice for small wooden crafts, artworks, toys, etc. Most wood laser cutter machines can process materials 0.5-12mm thick. A CO2 laser cutter is good at processing all kinds of wood materials. There are no restrictions when marking or engraving wood, although some wood types will look better than others. The only limitation of cutting is the thickness and density of the wood.

Laser cutting wood has unparalleled advantages compared with traditional cutting tools. For instance, excellent precision, narrow slit, high efficiency, and good quality. More and more companies and individuals can afford a wood laser cutter to carry out their projects. Although highly automated, using a wood laser cutter still need to pay attention to many precautions.

If you have any doubt about a wood laser cutter, feel free to contact us. We will provide you with complete consult, purchase and after-sales services.