During CNC router maintenance, the CNC lubrication system with right CNC machine lubrication oil is very important, it affects the life of gear/screw transmission and rails, then affects the CNC router working precision and wood carving & engraving quality.

In this article, we will also give a basic maintenance checklist for CNC.

The right use of the CNC lubrication system and daily CNC router maintenance checklist is the assurance of CNC router working for a longer time.

Part A: CNC Router maintenance checklist and tips:

CNC Router machines mainly process wood, stone, soft metal(Aluminum, copper, etc), plastic, MDF, acrylic, etc., there is always a lot of dust brings potential damage, we need to do the maintenance of CNC machines and CNC kits on time regularly.

1 CNC Router tips

Here are some daily tips and things that need to be checked when using and maintenance:

- 01, The control box need well-ventilated, and avoid high-temperature;

- 02, The machine itself needs a dry and well-ventilated place, avoid exposure of the fuselage);

- 03, A reliable voltage regulator is along with your machine from the buyer;

- 04, Some CNC router needs a computer, make sure it is only for CNC;

- 05, Check Maintenance every week; lubricating every day, clean the screw & rail from dust, add or replace the lubrication oil;

- 06, Avoid machines working in the same position every time;

- 07, Check electric circuits and screws every week;

- 08, Do not place debris (magnetic materials, corrosive items, overweight items, liquids, etc.) on the table, gantry or head of the router machine;

The above is the basic daily tips of CNC router using.

2 CNC Router maintenance checklist:

- Dust cleaning check, air cooling check, water cooling check, oil lubrication check, belt tighten check, screw fixed check, safe check.

- In order to make the CNC router machine work better, you are suggested to contact the after-sale staff.

Here you also need a checklist like this to check your CNC router maintenance:

Dust cleaning check:

Dust should be cleaned on time;

Especially dust on or in the spindle shell, transmission gears or rail, electric cabinet, control cabinet;

Dust-against cover for rail and gear is recommended;

Air cooling check:

Make sure the cooling fans working well and there is no dust covering;

Check the temperature of Spindle in the right range;

Water cooling check:

Make sure the cooling pump and water pipe, water running working well and there is no dust covering;

Check the temperature of Spindle in the right range;

Oil lubrication check:

If it is a manual lubrication system, don’t forget to press the handle to send oil;

Check and make sure there is enough oil, oil pump, oil pipe working well and CNC kits get oil;

Belt tightens check:

Check whether the belt is tightened enough and worn out or not;

Screw fixed check:

Check the screws of all running parts, make sure they are tightened and working well;

Safe sensor check:

Check the safe sensor, make sure they are working well;

Note: when check & maintenance of electric parts, shut off the power.

3 Protection of frost for water cooling router

Water cooling CNC router works with water running by the spindle and taking away heat. If the temperature is too low in winter, water may freeze in the pipe, there are 3 points for your reference:

- Consider some antifreeze additive;

- Take measures against low temperature;

- Blow out water from cooling pipe when every day’s work ends;

- Consult our after-sale manager for advice;

Part B: CNC lubrication system:

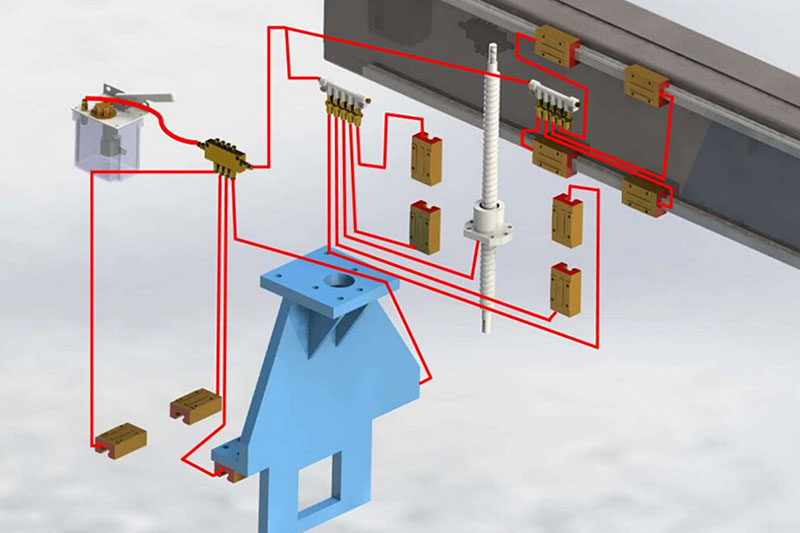

First, let us talk about CNC lubrication system, it has a CNC lubrication pump to send CNC machine oil to the right kits;

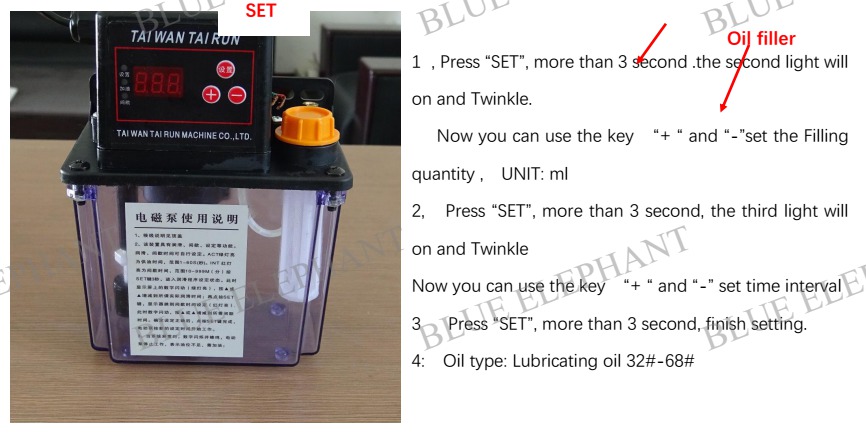

The CNC lubrication oil, we choose Normal Engine oil Lubricating oil 32#-68#.

Some maintenance tips for CNC lubrication system as follows:

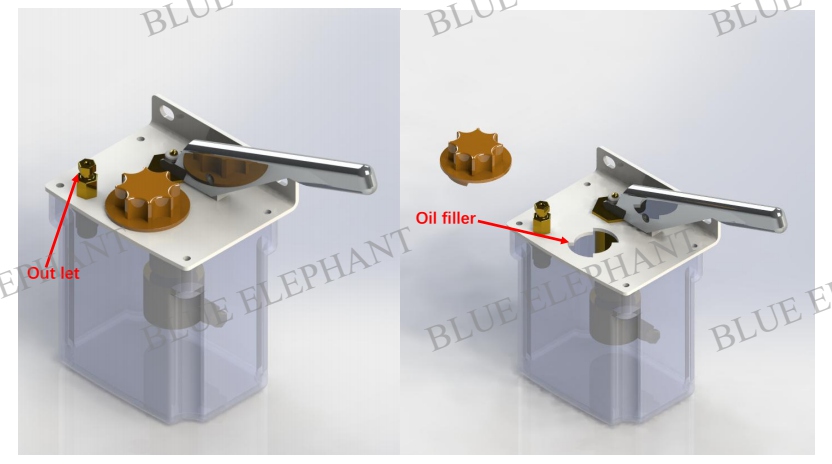

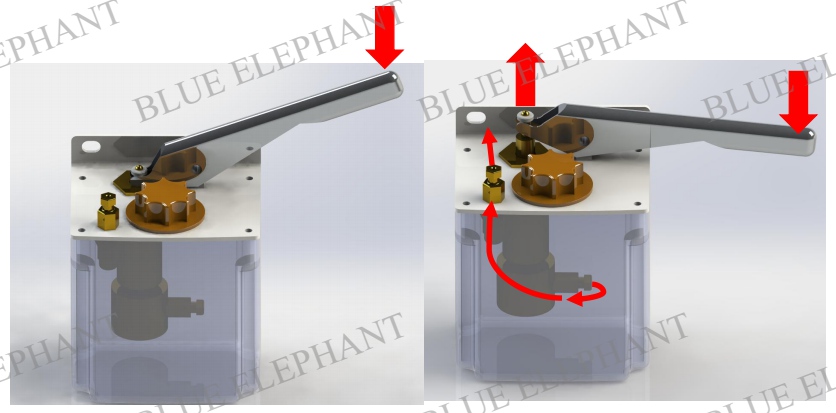

1 Manual lubrication pump for CNC machine:

- Check the Manual lubrication system every day, cap covered to prevent dust, and oil enough to pump into oil pipe;

- Press the hand lever on time as requirements to make oil sent out;

- Check CNC kits, make sure they get lubrication oil;

2 Auto lubrication pump for CNC machine:

- Auto lubrication system needs no maintenance in theory;

- Pay attention to dust and oil level;

- Make sure the pump is working, nothing wrong with oil pipes and CNC kits get oil;

3 Protection of frost for CNC Lubrication system

In someplace, the temperature is too low in winter, and lubrication oil may freeze, there are three things for your reference:

- Every day when the working ends, clean dust from rails and gears;

- Take some measures against low temperature;

- Consider to choose 0w series oil;

- Consult our after-sale service;

4 Attention of lubrication system in CNC machine:

- Requirements of lubrication oil for CNC machine: CNC machine oil, or CNC lubrication oil 32#-68#, it has a low price;

- Before first use of the machine, we need the rail, gear and the ball screw get lubrication oil;

- After the first use, we need everyday press the Manual lubrication pump once before starting work;

- Avoid CNC router working without CNC kits get oil;

- Clean dust from rails and gears every day, because dust waste oil and abrase CNC kits;