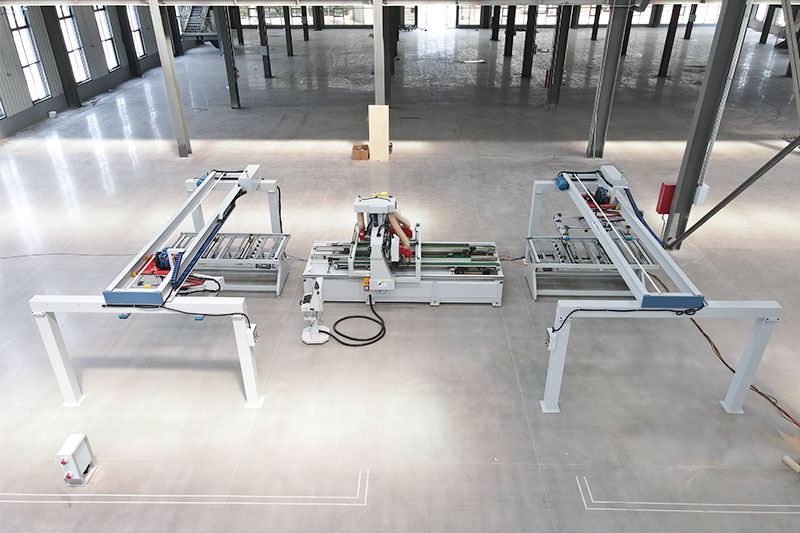

4 sides cutting saw machine is also called wooden door 4 side edge cutting machine, 4 sides cutting machine for wood doors, four sided cutting machine for sale, four sides sawing machine, etc. CNC wooden door four-sided saws are mainly used to cut the length of the four sides of fixed wooden doors to meet the size requirements. At the same time, they can drill two process holes such as keyholes and hinges. They have high processing accuracy and high efficiency. They are indispensable automatic CNC equipment for wooden door companies.

Key features of wood door edge cutting machine

Precision

High Accuracy: Ensures precise cuts on all four sides of the door, maintaining consistent quality.

Digital Controls: Often equipped with digital interfaces for setting exact measurements and adjustments.

Automation

CNC Technology: Many machines are computer numerical control (CNC) operated, allowing for automated and programmable cutting processes.

Automatic Feed: Includes automatic feeding mechanisms to move doors into position for cutting.

Versatility

Adjustable Cutting Heads: Allows for different types of cuts and profiles on the door edges.

Multi-Material Capability: Can handle various materials such as wood, MDF, and composite doors.

Efficiency

High Speed: Capable of cutting multiple doors per hour, increasing production efficiency.

Multi-Side Cutting: Cuts all four sides of the door in a single pass or cycle.

Safety

Emergency Stop: Equipped with emergency stop buttons for immediate halting of operations.

Guarding: Safety guards and shields to protect operators from moving parts.

User-Friendly Interface

Touchscreen Controls: Intuitive touchscreen interfaces for easy operation and programming.

Pre-Set Programs: Stores multiple pre-set cutting programs for different door styles and sizes.

Durability and Maintenance

Robust Construction: Built with durable materials to withstand heavy use in industrial environments.

Easy Maintenance: Designed for easy access to components for maintenance and repairs.

Dust and Waste Management

Dust Collection: Integrated dust collection systems to maintain a clean working environment.

Waste Disposal: Efficient disposal systems for cutting waste and off-cuts.

Benefits of four sides cutting saw machine

Consistency: Delivers consistent quality and precision, reducing the need for rework.

Productivity: Increases overall productivity and throughput in door manufacturing processes.

Labor Efficiency: Reduces the need for manual labor and minimizes human error.

Customization: Allows for customized cuts and profiles to meet specific design requirements.

Working video of 4 sides CNC cutting machine for sale

In the following video, you will see how the auto loading and unloading 4 sides cutting machine process wooden doors. For example, you will see it automatically load wood panels and convey it to cut four sides. After cutting, the finished panel will be automatically unload without any manual operation.

Applications of 4 sided cutting machine

Door Manufacturing: Ideal for manufacturers producing wooden, MDF, and composite doors.

Cabinet Making: Useful in cutting and shaping edges of cabinet doors and panels.

Furniture Production: Can be adapted for use in other furniture parts requiring precise edge cuts.