A few years ago, I was running a job that had to be delivered the next morning. Everything was going smoothly—until the CNC controller started acting up.

Commands were delayed, movements weren’t precise, and I had no idea how to fix it fast. I knew right then, it was time for an upgrade.

I’ve worked with CNC machines for years. I’ve seen the headaches of outdated controllers, and I’ve helped businesses make the right retrofit choices.

If you’re reading this, you’re probably facing the same challenge: your machine is still solid, but the controller is holding you back.

This guide will help you fix that. I’ll break down what to look for in a retrofit CNC controller, how to compare options, and how to avoid costly mistakes.

By the end, you’ll know exactly what you need to upgrade your CNC machine without overpaying or wasting time.

Let’s start!

1. What is Retrofit CNC Controller?

Ever had a CNC machine that worked fine—until it didn’t? I’ve been there. The machine itself was still solid, but the controller felt outdated, sluggish, and unpredictable. Buying a new machine wasn’t an option, but I knew something had to change. That’s when I discovered retrofitting.

A retrofit CNC controller is a modern upgrade for your existing machine. Instead of replacing the whole thing, you swap out the outdated control system for a new one. It’s like giving your CNC machine a fresh brain while keeping the body intact.

How Does a Retrofit CNC Controller Work?

Think about your CNC machine like a car. The frame, engine, and wheels may still be in great shape, but if the dashboard and controls are old, performance takes a hit. Upgrading to a retrofit CNC controller is like installing a new dashboard with digital gauges, GPS, and better control.

When you retrofit a CNC machine, you typically upgrade:

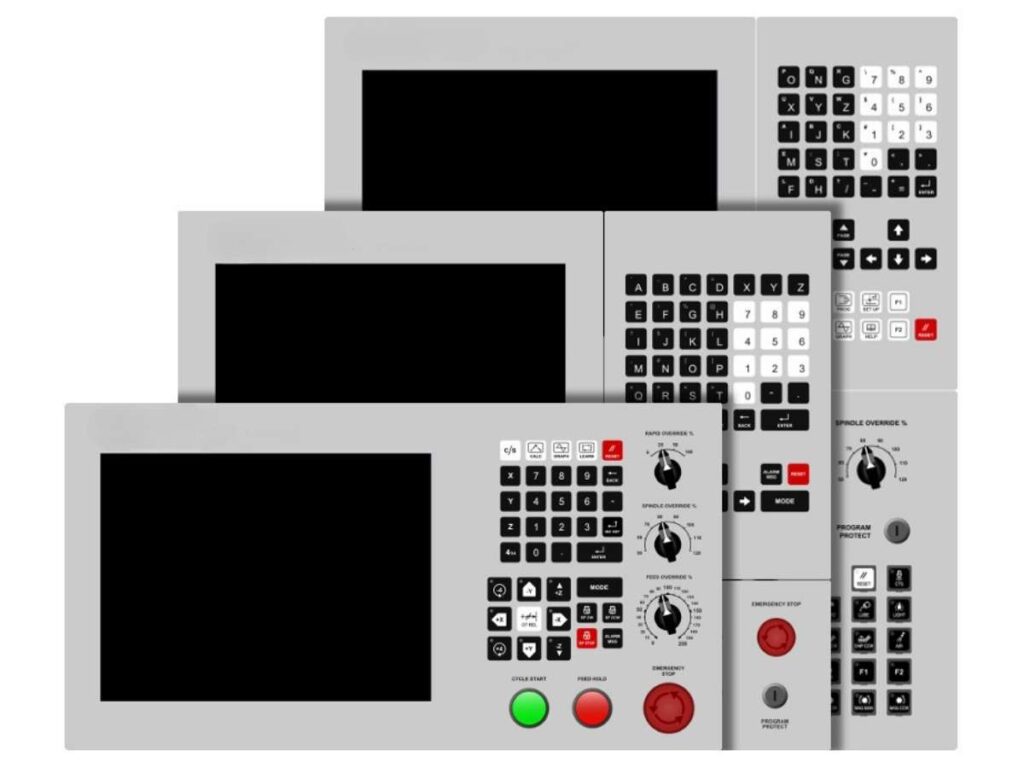

- Control Panel: The interface where operators input commands and adjust settings

- Servo Drives And Motors: These control movement and improve precision

- Software: Modern systems that improve efficiency and user experience

With these upgrades, your machine runs smoother, operates faster, and avoids costly breakdowns.

2. Benefits of Retrofit CNC Controller

A retrofit CNC controller brings modern technology to your existing machine, making operations smoother, faster, and more precise. But what exactly does that mean for your business? Let’s break it down.

Improved Performance and Accuracy

Older controllers struggle with speed, precision, and advanced programming. A retrofit gives you faster processing, better motion control, and higher accuracy, allowing your machine to run complex programs with tighter tolerances. Operators will notice smoother movements, fewer errors, and improved part quality, making production more efficient.

Minimized Downtime and Fewer Breakdowns

An outdated controller can lead to unexpected failures, stopping production when you need it most. A retrofit reduces these risks by upgrading the electronics, software, and diagnostics to modern standards. With fewer system crashes and easier troubleshooting, your machine stays operational longer, cutting downtime and maintenance costs.

Better Compatibility with Modern Software

Many older controllers lack integration with CAD/CAM software, automation systems, and remote monitoring tools. A retrofit allows your machine to connect with modern manufacturing processes, improving programming efficiency and production tracking. This upgrade makes it easier to work with newer file formats, automate operations, and optimize workflows.

Extended Machine Life

If your CNC machine is still mechanically sound, there’s no reason to replace it just because the controller is outdated. Retrofitting extends the life of your machine by bringing its controls up to current industry standards. Instead of scrapping a reliable system, you give it a second life with enhanced capabilities.

3. Types of Retrofit CNC Controller

Choosing the right retrofit CNC controller depends on your machine, production needs, and budget. But don’t worry—I’ll break it down so you can find the best fit for your business.

There are several types of retrofit CNC controllers, each designed for specific applications. Let’s go over the most common ones and how they can transform your machine’s performance.

PC-Based CNC Controllers

A PC-based CNC controller runs on a standard computer, using specialized software to control the machine. Instead of relying on dedicated hardware, this system processes commands through a high-performance PC.

- Why Choose It? PC-based controllers are affordable, easy to upgrade, and support a wide range of software.

- Best For: Shops that need flexibility, advanced CAD/CAM integration, and real-time data tracking.

- Potential Drawbacks: Requires a stable computer system and regular software updates.

A machine repair technician I once worked with swore by PC-based controllers. He liked that they could be easily customized, but he also warned that a poorly maintained PC could cause crashes.

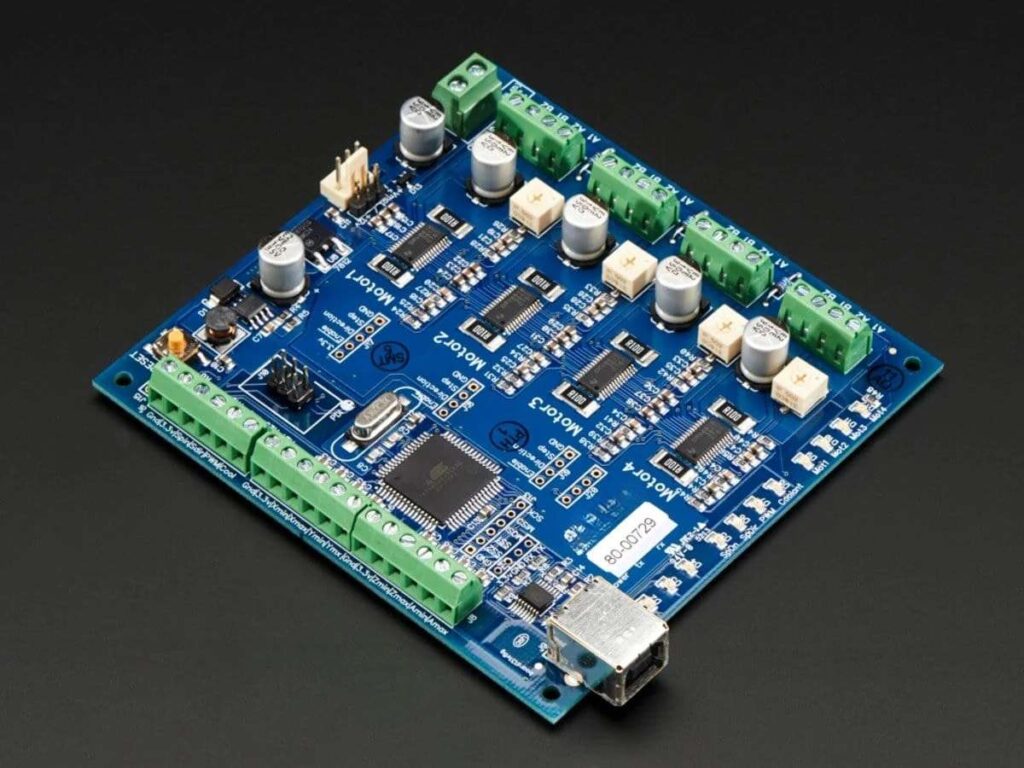

Microcontroller-Based CNC Controllers

A microcontroller-based CNC controller uses a dedicated embedded system to execute commands. Unlike PC-based systems, it doesn’t rely on an external computer, making it more stable and less prone to software failures.

- Why Choose It? These controllers are compact, reliable, and optimized for efficiency.

- Best For: Small to mid-sized businesses that need a straightforward, no-fuss CNC upgrade.

- Potential Drawbacks: Limited customization compared to PC-based controllers.

If you prefer a system that “just works” without needing frequent updates, a microcontroller-based controller could be the right choice.

PLC-Based CNC Controllers

A PLC-based CNC controller (Programmable Logic Controller) is designed for industrial automation. These systems are built to handle complex multi-step operations, making them ideal for large-scale production environments.

- Why Choose It? PLC-based controllers are extremely durable, scalable, and work well with automated production lines.

- Best For: Factories and production facilities needing precise, repeatable machining.

- Potential Drawbacks: More expensive and requires expert programming to set up.

A factory I worked with retrofitted their CNC machines with PLC-based controllers and immediately saw improved efficiency. The only challenge? Training their staff to operate the new system.

4. Key Features to Look for in a Retrofit CNC Controller

Ever installed new equipment only to realize later that it doesn’t fully meet your needs? I’ve seen it happen. A shop owner once upgraded his CNC controller, excited about the new features—only to discover it lacked essential compatibility with his existing software. That mistake cost him both time and money.

Choosing the right retrofit CNC controller isn’t just about picking the most expensive or feature-packed option. It’s about finding the right balance between performance, ease of use, and compatibility with your current setup. Here are the key features to look for when making your decision.

User-Friendly Interface

A complex system slows down productivity, especially if your team has to spend hours figuring it out. Look for a CNC controller with:

- Touchscreen or Intuitive Display: A well-designed interface makes setup and operation easier.

- Customizable Controls: Operators should be able to modify functions based on workflow needs.

- Easy-to-Use Software: A controller with clear menus and navigation speeds up programming and reduces errors.

Processing Speed and Memory

Slower controllers lead to delays, reduced accuracy, and longer production times. Key things to check:

- High-Speed Processing: Faster controllers execute commands without lag, reducing cycle times.

- Adequate Memory: Enough storage to handle large programs without crashing.

- Multi-Tasking Capability: The ability to process multiple commands simultaneously for efficiency.

Automation and Connectivity

CNC machines are becoming smarter. If you want to stay ahead, look for controllers with:

- Remote Monitoring: Allows you to track machine performance from anywhere.

- IoT Integration: Connects with other smart factory systems for better workflow.

- Automated Tool Changer Support: Speeds up production by reducing manual intervention.

5. Signs Your CNC Machine Needs a Retrofit CNC Controller

A CNC machine should be reliable, precise, and efficient. But over time, an outdated controller can start causing problems that slow down production and increase costs. If your machine isn’t performing like it used to, a retrofit might be the right solution.

Upgrading the controller can restore efficiency and extend the life of your equipment. Here are the key signs that it’s time to make a change.

Frequent Errors and System Instability

Old controllers often struggle to keep up with modern machining demands. If your machine:

- Freezes unexpectedly or requires frequent restarts

- Displays recurring error codes with no clear fix

- Produces inconsistent results even with the same program

A shop I worked with had to reboot their CNC system several times a day just to finish jobs. Once they upgraded the controller, production ran smoothly without interruptions.

Slow Processing and Lag Between Commands

A CNC machine should respond instantly to commands, but an outdated controller can cause delays. Signs of slow processing include:

- Hesitation between movements, leading to longer cycle times

- Inability to run complex programs without slowing down

- Noticeable lag between input commands and machine execution

Limited Compatibility with Modern Software

As technology evolves, older controllers often become incompatible with new software. If you experience:

- Difficulty importing files from updated CAD/CAM systems

- Lack of support for modern programming languages

- Limited connectivity with other shop-floor automation tools

Increased Downtime and Higher Maintenance Costs

If your CNC machine is spending more time being repaired than producing parts, the controller could be the cause. Common issues include:

- Frequent service calls due to failing electronic components

- Difficulty finding replacement parts for outdated controllers

- Unpredictable breakdowns causing lost production time

A furniture shop I advised was dealing with long downtimes because their CNC controller’s spare parts were discontinued. A retrofit gave them access to modern support and reduced repair costs.

6. Common Mistakes to Avoid When Retrofitting

Upgrading a CNC controller should improve performance, not create new problems. But I’ve seen businesses make costly mistakes when retrofitting—errors that led to downtime, compatibility issues, and wasted money. Retrofitting is an investment, and making the right decisions upfront will save you from headaches later.

Whether you’re retrofitting for the first time or upgrading multiple machines, here are the most common mistakes to avoid.

Choosing the Wrong CNC Controller for Your Needs

Not all CNC controllers work the same way. Some are designed for high-precision machining, while others are better for basic operations. Picking the wrong one can lead to poor performance or unnecessary costs.

- Match the controller’s features with your production needs

- Check compatibility with your machine’s motors, drives, and software

- Avoid controllers with features you’ll never use but still have to pay for

Overlooking Compatibility Issues

A new controller won’t work if it doesn’t communicate properly with your existing equipment. Common compatibility issues include:

- Servo motors that don’t match the new controller’s output signals

- Communication protocols that don’t integrate with your software

- Electrical connections that require costly adapters or rewiring

Skimping on Technical Support and Warranty

CNC controllers are long-term investments, and choosing one without proper support can be a mistake. Before buying, make sure:

- The manufacturer provides technical support when needed

- Spare parts are available to avoid long downtimes

- The warranty covers key components in case of failure

At Blue Elephant, we offer 24/7 online support, spare parts supply, and on-site servicing when needed in order to make sure that CNC machines performs at its best.

7. Tips on How to Choose the Right Retrofit CNC Controller

I’ve seen too many businesses make costly mistakes when upgrading their CNC controllers. Some pick a model that’s too advanced for their needs, while others buy a controller that isn’t even compatible with their machine. The right retrofit CNC controller should improve efficiency, reduce downtime, and fit seamlessly into your workflow.

Here’s how to make the best choice without wasting time or money.

Tip #1 Identify Your Machine’s Requirements

Every CNC machine operates differently, so choosing a controller without considering your specific needs can lead to frustration. Think about what type of machining you do daily and whether you need advanced automation or just a basic upgrade. A shop I worked with once installed a high-end controller with unnecessary features, only to realize they could have saved thousands by choosing a simpler option.

Tip#2 Check Compatibility with Your Existing Hardware

A new controller is useless if it doesn’t work with your current machine setup. Always verify that the controller supports your motors, drives, and communication protocols before purchasing. I once helped a manufacturer who bought a controller without checking if it supported their spindle drive, leading to unexpected costs and installation delays.

Tip#3 Look for a User-Friendly Interface

A CNC controller should make life easier, not harder. Touchscreen displays, intuitive menus, and customizable settings help operators work efficiently without struggling with complicated controls. At Blue Elephant, our user-friendly machines come with pre-configured software and training support.

Conclusion

So now you know—what retrofitting is, why it’s smart, how to do it right, and which traps to avoid.

I’ve made the mistakes so you don’t have to. That night job? I missed it. But I never let that happen again—and neither should you.

This article is your roadmap to smarter upgrades and longer machine life.

Ready to stop wasting time and money? Let Blue Elephant help.

Contact us today and take control of your shop’s future.

Recommended Reads for You

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.