As a professional CNC router manufacturer, Blue Elephant CNC has provided customized machines for thousands of users at home and abroad, and has also provided customized production solutions for users with various needs. Has rich experience in the production of woodworking engraving machine models and selection of engraving machines. Today we will talk about which machines are the best CNC router most popular among the customer base and why are these best CNC machine popular with customers? Follow me to learn with the editor.

The First Best CNC Machine Recommended-an Entry-level 1325 CNC Wood Router

This 1325 CNC wood router is also known as cheap CNC router, cheap CNC machine or affordable CNC machine by users for its lower procurement and maintenance costs. From the processing path, this is also a three-axis engraving machine. During the processing of the 3 axis CNC wood machine, the work piece always remains stationary, while the cutting tool moves along the three axes to process the work piece.

When the three-axis CNC engraving machine is engraving, whether it is flat carving or round carving, it can be imagined as a plane carving. It is mainly suitable for engraving plane and bilaterally symmetrical, uncomplicated patterns, such as olive core, 461 brand, etc.The reason why this woodworking CNC machine is considered to be an entry-level engraving machine in the woodworking machinery industry is because this CNC machine is simple to operate and does not require special training. The operator can complete the machine operation independently.

In addition, the procurement cost is low, and maintenance and repair are relatively simple. Therefore, both in operation and maintenance, it is more suitable for new users.

Parameters of 1325 3 Axis CNC router:

| X,Y,Z Working Area | 1300*2500*200mm |

| Working Area | 1300*2500mm |

| Working Voltage | 380V/3PH/50Hz |

| Control System | Mach3 control system· |

| Spindle | CSwater cooling spindle |

| Spindle Speed | 0-24000RPM |

| Inverter | Fuling inverter |

| Drive Motors | FL118Motor and YAKO 2811 |

| Frame | New Type Heavy Duty Body |

| Lubrication | Manual Lubrication System |

| Gantry structure | Steel Gantry |

| Spray/ Flume | Automatic Oil Mist Cooling |

| X, Y Structure | ABBA/PMI 20#Guide Rails |

| Z Structure | TBI Ball ScrewBall ScrewTransmission |

| Tool Sensor | Automatic Tool Sensor |

| Limited Switch | Soft limit switch |

| Software | Artcam software |

Check this video to see our entry-level 1325 CNC router engraving patterns on a MDF board.

Four Reasons Why This Entry-level 1325 CNC Wood Router Sells Well.

- 1. High cost performance. Processing requirements can be met without high procurement and training costs. This type of CNC wood engraving machine can help users save 30% purchase cost. It also can be used as CNC wood cutting machine, especially for MDF, wood panel cutting.

- 2. Wide range of applications. This CNC wood machine can be widely used in advertising industry, craft industry, mold industry, electronics industry, construction industry, printing and packaging industry, wood industry, decoration industry, tombstone industry, etc.

- 3. Extensive processing materials. CNC wood machine can meet the processing of most of non-metal materials like acrylic, PVC board, hibiscus board, two-color board, wood board, density board, marble, fire board, rubber board, glass, crystal.

- 4. Longer service life. The core components of this machine are all imported from international brands, with perfect after-sales service and guaranteed quality. Therefore, the service life of the whole machine is greatly improved.It should be noted that this 1325 engraving machine is only a basic model.

Of course, if you have other processing requirements, we can upgrade the accessories on the basis of this engraving machine.If you need 3D work pieces, curved surface processing of complex work pieces, we also provide 4-axis engraving machine, rotary axis engraving machine. If you need high precision and mass production processing, we can provide you with ATC CNC machine and multi-head engraving machine for your choice.

The Second Best CNC Machine Recommended-2040 ATC CNC Router with Press Roller

We all know that the ATC CNC router is specially designed for users with high precision and high efficiency processing requirements. Compared with the traditional manual tool change production method, this type of CNC engraving machine has an independent tool magazine with different tool bits. It can be controlled by computer program to automatically change the required tools without stopping the work during the process, complete a series of cutting, hollowing, grooving, stamping, milling, milling and other processing needs. From the point of view of tool change, this engraving machine is also called a disc-type automatic tool change engraving machine.

This kind of CNC machine is also one of the machines most selected by users. You can also choose the location of the disc tool magazine according to user needs. On the one hand, the disc tool magazine can be placed next to the spindle. The biggest advantage of this machine is the rapid tool change. However, the number of tools should be guaranteed within 20 tools. If the number of tools exceeds 20, the weight of the cutter head will increase, which will affect the load capacity of the Z axis and the frame, especially the load capacity of the Z axis screws and rail sliders.

All these will affect the machining accuracy. On the other hand, the disc tool magazine can be placed on the side of the rack. This automatic tool changer engraving machine is not limited by the number of tools and has better stability. It also guarantees the machining accuracy of the machine, and ensures that the ATC CNC milling machine can be used for a long time, and the machining accuracy is not affected.

Parameters of 2040 Carousel ATC CNC Router:

| Description | Parameters |

| Model | ELECNC-2040ATC |

| Working size | 2000*4000*200mm |

| WorkingVoltage | 380V, 3Phase, 50Hz |

| Control system | Taiwan SYNTEC 6MBControl System |

| Spindle | 9kw Italy HSD ATC spindle |

| Inverter | 11kw Delta Inverter |

| Motor & Driver | Japan YASKAWA 850W servo motor and driver |

| Table surface | T-slot and vacuum working table, 6 zones, with two pressure rollers |

| Lubrication system | New Auto Lubrication system |

| Automatic tool magazine | 12 Tools |

| Rail | Taiwan ABBA 25# |

| Vacuum pump | 7.5kw water circulation vacuum pump (380V, 3Phase, 50Hz) |

| Tool sensor | Automatic tool sensor calibration |

| Reducer | SHIMPO Reducer |

This video shows our 2040 carousel ATC CNC router cutting and engraving aluminum panels. The ATC function greatly reduces the non-production time and increases work efficiency. Besides aluminum, it is also good at processing various non-metal materials.

Five Reasons Why This 2040 Carousel ATC CNC Router Sells Well.

- 1.High productivity. Equipped with automatic tool changing device, which can meet the tool changing requirements during processing without manual participation. With simple and easy operation mode to learn, which can help users quickly grasp the use of methods and greatly improve production efficiency.

- 2.Adopting the automatic tool changing spindle, it has the advantages of good starting performance, fast processing speed, large torque and high processing efficiency.

- 3.Adopting Italy HSD spindle motor, and spindle bearings with high-precision ceramic bearings, it has the advantages of low noise and long service life.

- 4.Equipped with the imported high torque servo motor, it has the advantages of low noise, fast speed and high positioning accuracy.

- 5.Equipped with a unique tool changing device and a dedicated tool setting table, it can realize automatic tool changing without intermittent with fast tool changing speed, and can accurately compensate for tool length errors.

- 6.Adopting Taiwan linear guide and ball screw, it has the advantages of high bearing capacity and accurate cutting.

The Third Best CNC Machine Recommend- Oscillating CNC Cutter Machine for Leather

The oscillating CNC cutter machine is a new type of engraving machine assembly produced to meet more processing requirements of users. And this type of CNC cutter machine has automatic patrol edge positioning function. This type of engraving machine mainly processes soft materials, such as PVC, KT boards in the advertising production industry, as well as cloth cutting, tablecloth cutting, stickers, leather cutting in the clothing industry, and flexible materials such as automotive interiors and floor mats.

The finished product has the characteristics of clean and tidy, smooth edges, accurate chip size, tasteless and environmentally friendly. Therefore, this type of oscillating cutter machine is selected by more and more users at home and abroad.

Parameter of This 2050 Oscillating CNC Cutter

| Description | Parameter |

| X,Y,Z Working Area | 2000*5000mm |

| Knife | Vibrating knife and creasing |

| Working Voltage | 400V ,3phase,50HZ |

| Operating System | Blue elephant control system |

| Software | Ruida software |

| Y axis | Servo system with reducer for Y axis |

| Transmission | Helical rack gear 1.25M for X and Y |

| Linearguide | Taiwan #20linear square guide way for X,Y axis |

| Table | Vacuum table |

| Vacuum pump | 9KW vacuum pump |

It is ELE 2050 CNC router with an oscillating knife in the following video. The CNC router spindle cut and engrave various wood materials and some soft metals, like aluminum. And the oscillating knife is good at cutting soft materials, like cloth, foam, leather, fabric, etc.

Reasons Why This Oscillating CNC Cutter Machine for Leather Sells Well.

- 1.The cutting speed is up to 2000mm/s, which greatly improves the production efficiency. The processing efficiency of one cutting machine is equivalent to 10 workers.

- 2. Cutting precision reaches 0.01mm, and the improvement of precision can maximize product quality and competitiveness.

- 3. Intelligent processing. Automatic cutting can be done by simply entering the graphic to the computer.

- 4. It can be customized according to different processing needs, free to choose CCD camera, projector, double cutter head, double gantry, working area, etc.

- 5. The imported high-precision ball screw Z axis moves smoothly to ensure the high precision of the machine tool.

- 6. The famous Italian HSD water-cooled spindle spindle is used, and there are many after-sales service departments around the world. It is a water-cooled spindle with lower noise.

- 7. Equipped with high-performance Japanese Yaskawa servo motor, high working accuracy. The servo motor runs smoothly, there is no vibration even at low speed, and the overload capacity is strong.

- 8. It has the function of continuation of engraving at a break-point, and engraving continues after a power outage, thereby minimizing the failure rate.

- 9. Adopting advanced Taiwan Syntech handle control system, it is easy to operate.

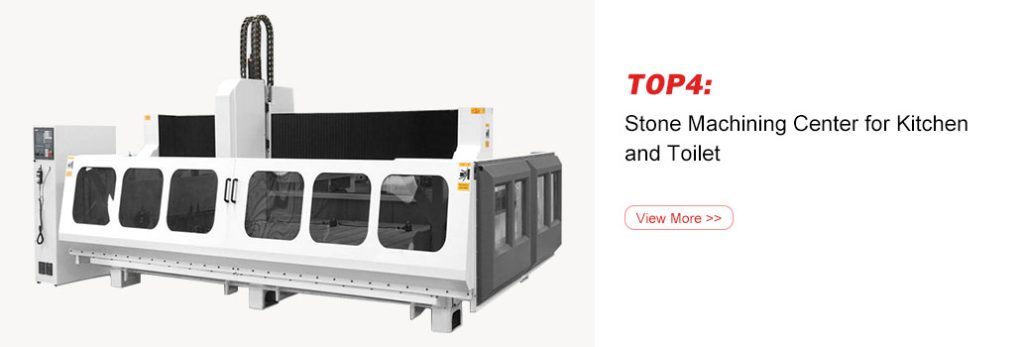

The Forth Best CNC Machine Recommended-Powerful Stone Machining Center for Kitchen and Toilet Industry

This CNC router machine is a stone processing center. And this type of stone CNC router is specially designed for all kinds of stone processing. It is suitable for the processing of various types of stone, metal, jade, crystal, wood, man-made materials, synthetic materials, etc. The main functions of the stone CNC router include embossing, lettering, hollowing out, cutting, seamless stitching, surface treatment, table milling and so on. And it is widely used in inscriptions, garden engineering, large-scale sculptures, handicraft carvings, home improvement, film and other industries.

Parameters of This Stone Machining Center :

| Model | ELECNC-3015 |

| Working area | 3000*1500*500mm |

| Spindle | 5.5kw Changsheng ATC water cooling spindle |

| Inverter | Taiwan Fuling inverter |

| Tool magazine | 12 linear tool changer with 12 BT 30 tool holder |

| Control system | NC 60A control system |

| Motor and driver | 1kw Weihong servo motor and driver |

| Reducer | Japan Shimpo reducer |

| Tool sensor | Automatic tool sensor |

| Limit switch | OMRON limit switch |

| Lubrication system | Automatic lubrication system |

| Vacuum pump | 7.5kw water circulation vacuum pump |

| Frame structure | Welded structure,heavy duty T-structure |

This is our new 3015 quartz stone CNC machining center for stone processing in the following video. It can make stone kitchen sinks, stone countertops, basins, bathroom countertops, bar island countertops, coffee table tops, stone tabletops, etc. It is good at cutting, milling, and engraving letters.

8 Reasons Why This Stone Machining Center Sells Well.

- 1. Automatic leveling function: It can correct the concave, convex and uneven slope of any stone surface. The software automatically generates a new program based on the floating of the stone surface, which conforms to the surface characteristics of the stone.

- 2. Stable bed structure: The bed adopts high-quality steel structure and double beam design, and the gantry and work surface are respectively supported by reinforced beams. Therefore, it has the advantages of bearing load, no deformation, and high stability.

- 3. Super cutting ability: Adopting high-power drive system coordinated with the spindle’s stable engraving, it has the features of greater torque force, smoother operation, precise and powerful cutting point. And Y-axis uses dual motor synchronous drive, it has the features of strong power, high stability, and can realize the process of 70mm Granite thickness.

- 4. Longer service life: Use stainless steel sink, protection plate and other parts to fully protect the transmission parts and electrical components, so that the machine has a long service life.

- 5.Complete function. One machine is multi-purpose, and it can meet the processing requirements of cutting, edging, polishing and engraving of different materials.

- 6.High degree of automation. The machine automatically changes the tool during the whole process without manual intervention, which reduces the labor cost and improves the production efficiency for the enterprise.

- 7.The bed is welded seamlessly with thick-walled steel pipes to ensure higher machining accuracy.

- 8.The working table is made of steel plate, which has the advantages of anti-rust, good load bearing performance and long service life.

The fifth best CNC Machine Recommended-4×4 Mini ATC CNC Router

This is a small CNC router who also called home CNC router, home CNC machine and hobby CNC machine. Compared with other ordinary CNC machines, this best hobby CNC router has a relatively small CNC router table. Due to its small CNC router table and high degree of integration, this small CNC router is very convenient in operation and transportation. The small footprint requires relatively little space for users, so it has always been a small best cnc router for small shop among users. In addition, this mini CNC router is also equipped with an in-line tool magazine. The engraving machine can automatically complete the tool change instruction according to the processing requirements without stopping the work during the processing. The time for manual tool change is greatly saved, and the production efficiency is correspondingly improved. Mini CNC engraving machine is mainly used for engraving and milling of PVC, acrylic, two-color board, plastics, bake-lite, solid wood and soft metal materials like graphite electrode processing, and is also suitable for engraving PCB circuit boards, model molds, crafts, plastic boxes with limited specifications, aluminum alloy chassis, openings in the panel. Besides that it also can do some processes like 3D engraving, drilling and milling of metal materials such as aluminum alloy and copper.

Parameters of 4×4 Mini ATC CNC Router

| Model | ELECNC-1212 |

| Working area | 1200*1200*500mm |

| Spindle | 4.5KW HSD air cooling spindle |

| Control system | German Siemens 828D control system |

| Motor and driver | Siemens 1000w servo motor and 1000w servo driver |

| Working Table | T-slot & aluminum table |

| Structure | Heavy duty thicker structure |

| limit switch | Japan OMRON limit switch |

| Working Table | T-slot working table |

| Limit switch | Japan Omron limit switch |

| Lubrication system | Automatic oil lubrication system |

The video below shows our 1212 ATC CNC router engraving on a MDF board. It is equipped with a linear tool magazine and an automatic tool calibrator. Besides, it also has a rotary device for making cylindrical workpieces.

8 Reasons Why This – 4×4 Mini ATC CNC Router Sells Well.

- 1. The floor space is relatively small, which is more convenient for operation and transportation, and requires less space.

- 2. Low noise. Because the machine is small, the power requirement is not high, so the sound is very small. Simple and convenient operation.

- 3. High precision. Very small badges or small characters can also be carved out. The cut surface is also very smooth and smooth, and there will be no burrs or scum on the surface.

- 4. The cutting speed of the small laser engraving machine is also very fast, and the corresponding production efficiency is high.

- 5. The small laser engraving machine can ensure a smaller cutting width, and is more suitable for processing some small pieces, such as advertisements and kitchen utensils.

- 6. The cost is relatively low. It does not require high purchase and maintenance costs to meet the normal processing work requirements. Very suitable for small businesses or those with tight funds.

- 7. Adopting the automatic tool changing spindle, it has the advantages of good starting performance, fast processing speed, large torque and high processing efficiency.

- 8. Complete function. Equipped with a rotary device, this CNC router can not only carry out plane engraving, but also process cylindrical work pieces.

The Sixth Best CNC Machine Recommended-1530 Stainless Steel Fiber Laser Cutting Machine

This is a fiber laser cutting machine for processing metal materials such as stainless steel, carbon steel, alloy steel, silicon steel, aluminum, aluminum alloy, galvanized sheet, aluminum-plated zinc sheet, copper, silver, gold, titanium and other metal plates and pipe cutting. And it can be widely used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, food machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration , advertising, metal external processing, kitchenware processing and other manufacturing and processing industries. Compared with other CNC machine tools, the fiber laser cutting machine can complete the processing of various complex structures. As long as any image can be drawn on the computer, the machine can complete the processing without opening the mold and can produce the product immediately. That is, new products can be developed quickly and costs can be saved. No matter how complicated the process requirements are, fiber laser cutting machines can do it.

Parameters of This 1530 Stainless Steel Fiber Laser Cutting Machine:

| Model | ELECNC-1530F |

| Working Area | 1500*3000mm |

| Laser Power | 1000W |

| Cutting Thickness | 0-12mm |

| Control System | FSCUT cutting system |

| Driver system | Fuji servo motor made in Japan |

| Liner guider system | PMI made in Taiwan |

| Rack system | VASTUN made in TAIWAN |

| Water Chiller | Guangzhou TEYU |

| Pneumatic components | SMC made in Japan |

| Electrical components | Schneider made in France |

| Reducer | SHIMPO |

| Laser head | Empower raytools laser cutting head |

| laser | Raycus 1000W |

| bed frame | High temperature quenching stress relief(Standard bed) |

http://www.elephant-cnc.com/pro/fiber-laser-cutting-machine

This video displays our newly designed sheet metal fiber laser cutting machine. It can cut various metal sheets, like stainless steel, carbon steel, steel, aluminum, brass, etc. in various thickness with right laser power.

8 Reasons Why this 1530 Stainless Steel Fiber Laser Cutting Machine sells well

- 1. Excellent beam quality: the focus spot is smaller, the cutting line is finer, the work efficiency is higher, and the processing quality is better.

- 2. Extremely high cutting speed: 2 times of the same power CO2 laser cutting machine.

- 3. Extremely high stability: the use of the world’s top imported fiber lasers, stable performance, the life of key components can reach 100,000 hours.

- 4. High electro-optical conversion efficiency: the photoelectric conversion efficiency of fiber laser cutting machine is about 30%, which is 3 times higher than that of CO2 laser cutting machine, energy saving and environmental protection.

- 5. Low cost of use: the power consumption of the whole machine is only 20-30% of the similar CO2 laser cutting machine.

- 6. Low maintenance cost: no laser working gas; optical fiber transmission, no need for reflective lenses; can save a lot of maintenance costs.

- 7. Convenient product operation and maintenance: optical fiber transmission, no need to adjust the optical path.

- 8. Super flexible light guide effect: small size, compact structure, easy to flexible processing requirements.

The Seventh Best CNC Machine Recommended-1530 Professional Plasma Cutting Machine

This is a plasma laser machine. With different working gases, it can cut various metals that are difficult to cut with oxygen, especially for non-ferrous metals (stainless steel, carbon steel, aluminum, copper, titanium, nickel). The main advantage is that when cutting metals with small thickness, the plasma cutting speed is fast, especially when cutting ordinary carbon steel sheets, the speed can reach 5-6 times of the oxygen cutting method, the cutting surface is smooth, the thermal deformation is small, and there is almost no Heat affected zone. It is widely used in various industries such as automobiles, locomotives, pressure vessels, chemical machinery, nuclear industry, general machinery, construction machinery, steel structure and so on.

Parameters of This 1530 Professional Plasma Cutting Machine

| Working Area | 1500x3000x200mm |

| Generator | 120A LGK plasma generator |

| Control System | Fangling F2300 controller system |

| Linear guide | Taiwan PMI Square guide rails |

| Software | Fastcam software |

| Working Voltage | 415V, 3Ph, 50Hz( can be customized) |

| Others | Dust proof on X axis |

The video below shows our plasma cutting machine cutting shapes from a steel square tube. Plasma cutting machine is especially designed for cutting metal materials of medium thickness.

9 Reasons Why This 1530 Professional Plasma Cutting Machine Sells Well

- 1. The frame adopts all-welded structure, strong and reasonable, simple operation, durable.

- 2. Fast cutting speed and high precision. The cutting port is small, neat, and there is no dross. Based on the traditional numerical control system, the control method for cutting is improved to avoid secondary trimming.

- 3. Suitable for low carbon steel plate, copper plate, iron plate, aluminum plate, galvanized plate, titanium gold plate and other metal plates.

- 4. The CNC system configuration is high. Automatic arc starting, stable performance, and successful rate of arc starting reaches over 99%.

- 5. Support standard G code path files generated by Wentai, Beihang Haier, ARTCAM, Type3 and other software. The control system uses U disk to exchange processing files, which is convenient and fast to operate.

- 6.It has the advantages of small size, light weight, low noise, low power consumption and convenient carrying.

- 7.The slit is narrow and smooth, the size error is small, and the problem of excessive material waste is effectively improved.

- 8.Flexible and convenient feeding, there is no need of special supporting loading equipment.9.The operation is simple, the difficulty of manual operation is reduced, and the processing efficiency is correspondingly improved.

The Eighth Best CNC Machine Recommended-1325 4 Processes CNC Router for Cabinet Production

This is a 4 processes CNC engraving machine,and this multi-process engraving machine is also known as a simple ATC CNC router. This type of engraving machine can process multiple processes on one engraving machine. Moreover, these different processes cannot be performed at the same time. According to the different processing requirements issued by the control system, the engraving machine can realize the automatic tool change function. Without manual intervention, and no need to find the origin again, the engraving machine can automatically complete a variety of processing requirements. A CNC engraving machine can complete the production of multiple machines at a time, which greatly improves the production efficiency. But this type of engraving machine has a limited number of tool changes, generally within 4 tools, so it is more suitable for users who need to replace less than 4 tools. In addition, compared with the ATC CNC engraving machine, this type of multi-process engraving machine also has the advantages of low cost, high production efficiency, and various processing methods, which are welcomed by users at home and abroad. And widely used in antique furniture, European furniture and other furniture industries. This type of multi-head CNC engraving machine is also suitable for processing cabinet doors, embossed screens, craft windows, embossed craft gifts, solid wood murals, carpentry calligraphy carving, art photo frames, sports equipment, etc.

Parameters of This 1325 4 Processes CNC Router for Cabinet

| Model | ELECNC-1325 |

| Working area | 1300*2500*200 |

| Spindle | HQD Air Cooling Spindle |

| Inverter | Taiwan BEST inverter |

| Control system | Taiwan LNC 2200 |

| Motor and driver | Dongling 1500w servo motor |

| Working Table | Full absorption vacuum table |

| limit switch | Japan OMRON limit switch |

| Reducer | Japan Shimpo reducer |

| Lubrication system | Automatic lubrication |

| Vacuum pump | Water circulation vacnnm pump |

| Voltage | 380V, 50HZ |

| Dust collector | 3.0kw Double bags dust collector system |

Here is our economical four-process CNC router machine in the video below. It is designed to cut, drill, engrave, groove, and slot wooden panels to make panel furniture. It can perfectly solve the nesting and vertical drilling work during panel furniture production process.

5 Reasons Why This1325 4 Processes CNC Router for Cabinet Sells Well

- 1. Multi-purpose machine, economical and affordable. When the production volume is relatively large, multiple spindles can be processed simultaneously to complete the processing requirements of multiple machines at one time. When the production volume is small, a single spindle can also work independently, which can effectively and reasonably control production costs.

- 2. High production efficiency, high cost performance and good processing quality. Especially when batch processing of products, the product has good consistency and high quality, which greatly reduces the purchase cost of production equipment.

- 3. Longer service life. The multi-head engraving machine body adopts an overall thick-walled all-steel structure design. After welding and tempering, the machine’s body has the characteristics of strong rigidity, high strength and smooth rotation, which can ensure that the machine will not deform and shake under long-term high-speed operation.

- 4. Humanized design. The embedded PCI numerical control system makes the machine tool and computer seamlessly combined, and the operation is simple. The unique intelligent budget rule enables the motor to fully realize its high-speed potential, and the curved and linear synchronous processing is more perfect, and it has a worry-free operation for a long time. In addition, it has functions such as power off, break point re-engraving, and processing time prediction to realize a truly humanized design.

- 5. Good software compatibility. Adopting open software interface, it can be compatible with the processing codes generated by various CAD / CAM design software, such as type3 / Art cam / Cast mate / Wentai, to ensure the realization of various design functions.

The Ninth Best CNC Machine Recommended-The Most Popular Rotary Axis CNC Router Machine

This rotary axis CNC router is also known as 4 axis CNC router, which refers to these wood CNC machines with rotary devices. It mainly processes cubic or cylindrical work pieces. During the processing of the rotary axis engraving machine, there is no need to manually rotate and process the work piece, which reduces the number of clamping and completes the processing at one time. Compared with the ordinary CNC wood engraving machine, the rotary axis engraving machine reduces the manual workload and improves the production efficiency. In addition, since the tools of the rotary axis can be layered, higher processing quality can be ensured. In addition, the rotary axis can also achieve the processing requirements of local processing, without being limited by the size of the object.

Parametes of Popular Rotary Axis CNC Router Machine

| Model | ELECNC-1530 |

| Working area | 1500x3000x600mm |

| Spindle | 4.5KW china HQD air cooling spindle |

| Spindle speed | 24000rpm |

| Control system | SYNTEC 6MB 4 axis control system |

| Motor and driver | 850W leadshine servo motor and drivers |

| Working Table | T-slot working table |

| limit switch | Japan OMRON limit switch |

| Lubrication system | Automatic lubrication system |

| Rotary device | 300mm diameter rotary device |

| X,Y,Z Transmission | X,Y-helical rack pinion,Z ball screw |

| X,Y,Z Rail | Sweden SKF ABBA linear guide/Taiwan PMI,25mm |

| Frame structure | New type thicker and bigger heavy duty 10-12mm |

| Voltage | 220V/380V,3phase(customized) |

| Dust collector | 3.0kw Double bags dust collector system |

| Software Compatibility | ARTCAM 2018/Powermail/UG |

This video shows our 1325 ATC rotary axis CNC router engraving and milling a large diameter wood cylindrical workpiece. The diameter could be 200mm or 300mm based on your working demands.

5 Reasons Why This Rotary Axis CNC Router Machine Sells Well

- 1.The rotary CNC router can make the spindle always face the machining surface at the most suitable angle, so that the force on the tool side is reduced, the machining stability is increased, and the machining accuracy is improved.

- 2.The rotary axis engraving machine does not need to repeatedly rotate the work piece, it reduces the clamping times and manual participation, and can complete the tool path calculation at one time to ensure higher machining accuracy and efficiency.

- 3.This type of rotary axis CNC machine can be processed multiple times in layers, reducing the number of finishing operations, and correspondingly improving the processing quality and processing efficiency.

- 4.Rotary axis engraving machine adopts the whole way of rotary axis to automatically generate closed rotary engraving processing path. It is not affected by the accuracy of the fixture, especially for irregular work pieces, the rotary axis engraving machine has higher processing accuracy compared with other processing methods.

- 5.This 4th axis CNC machine can realize local processing of the work piece by setting the angle range and length range of the tool.

The Tenth Best CNC Machine Recommended-Nesting CNC Machine with Automatic Feeding

This nesting CNC machine is a numerical control equipment specially designed for the production of panel furniture. It is mainly used to cut various wooden boards. In terms of processing functions, the cutting machine mainly includes cutting, punching, grooving and other processes. Generally, through the design of intelligent software, nesting CNC machine can automatically optimize the typesetting design, generate the effect map, and perform operations such as modification intuitively, and automatically generate various paths. Therefore, it can save sheet and improve sheet utilization. The nesting CNC machine is widely used in the furniture industry such as cabinet doors, wardrobe doors, solid wood doors, paint-free doors, solid wood composite doors, and suite doors. If you are a manufacturer of furniture production lines, This nesting CNC machine is definitely one of your indispensable CNC equipment.

5 Reasons Why this Nesting CNC Machine with Automatic Feeding Sells Well

Parameters of This Nesting CNC Machine with Automatic Feeding

| Model | ELECNC-1325 |

| Working area | 1300*2500*200 |

| Spindle | HQD Air Cooling Spindle |

| Inverter | Taiwan BEST inverter |

| Control system | Taiwan LNC 2200 |

| Motor and driver | Dongling 1500w servo motor |

| Working Table | Full absorption vacuum table |

| limit switch | Japan OMRON limit switch |

| Reducer | Japan Shimpo reducer |

| Lubrication system | Automatic lubrication |

| Vacuum pump | Water circulation vacnnm pump |

| Voltage | 380V, 50HZ |

| Dust collector | 3.0kw Double bags dust collector system |

The following video shows our new 1632 ATC CNC router with Auto loading and unloading platforms. It is one of the core machines in a automatic panel furniture production line. It can cut, drill, load and unload panels with high speed and precision.

6 Reasons Why This Nesting CNC Machine with Automatic Feeding Sells Well

- 1.Plate utilization increased by 40%. The nesting CNC machine adopts a milling cutter to cut the material, which can be arbitrarily turned to cut special-shaped work pieces and improve the utilization rate of the plate.

- 2.Labor saving. one person can operate multiple nesting CNC machine , which greatly saves labor costs and reduces production costs.

- 3.Reduce labor intensity. The nesting CNC can be equipped with automatic loading and unloading equipment, making the operation easier and simpler. Which greatly reduce the labor intensity of workers.

- 4.High safety factor. If you do not pay attention to the table saw when using the table saw, it is easy to hurt your hands and cause unnecessary accidental injuries. The safety factor of the opener is higher, which will basically not cause personal injury.

- 5.Better vacuuming effect. The nesting CNC machine is equipped with double-cylinder vacuum cleaner, and the vacuuming effect is 3-5 times higher than that of the table saw.

- 6.Higher productivity. The nesting CNC machine adopts full automatic loading and unloading, in the same time, the opening workload is 1.5 times that of ordinary manual opening. In addition, manual labor can be used during machine processing to greatly reduce labor intensity and improve production efficiency.

The above-mentioned best CNC machine for woodworking are also popular with customers at home and abroad. In summary, the best CNC machines favored by customers have the following common characteristics. First, high practicality. In other words, the wood CNC machine can really meet the different processing needs of users and achieve the ideal processing effect of customers. Second, cost-effective. In other words, a series of purchase costs, maintenance costs and use costs of the machine itself are within the users acceptance. Third, the operation is simple. In other words, after receiving the machine, the user can complete the installation and use of the machine independently without special training. Fourth, perfect after-sales service. After purchasing the CNC machine, customers can enjoy a series of after-sales services provided by the machine manufacturer, including tips on installation, operation, repair and maintenance of the CNC machine. Sixth, the machine has a long service life. It means that the CNC router kit and some wearing parts are produced by regular large-brand manufacturers, which effectively ensures the machine has a long service life. Seventh, the processing materials are diverse. Whether it is carbon steel, stainless steel, galvanized sheet and other metal materials, or acrylic, wood, plastic, glass, rubber and other non-metallic materials, these CNC wood router can achieve their processing. Eighth, a wide range of applications. It can be widely used in kitchenware industry, furniture industry, fitness industry, handicraft industry, packaging industry, clothing industry, mold industry, decoration industry and other large and small industries. As a professional CNC machine manufacturer, Blue Elephant is favored by hundreds of users at home and abroad. Whether you are interested in the above best CNC router or other diy CNC router or customized CNC router, please contact us and let us I know your needs.