Choosing the right CNC drilling machine is crucial for achieving high precision and efficiency in woodworking. Whether you’re involved in furniture making, cabinetry, or custom wood designs, selecting a reliable CNC machine from a top manufacturer can significantly improve productivity and product quality. In this article, we highlight the top 5 best wood CNC drilling machine manufacturers, known for their advanced technology, exceptional craftsmanship, and commitment to customer satisfaction.

What Is A CNC Drilling Machine?

CNC drilling machine is a precise and efficient processing technology that can automatically drill holes in fixed workpieces (wood, metal, plastic or composite materials). CNC drilling machine uses computer programs to control the movement of the drill with high precision. In CNC drilling, the machine follows the instructions of the computer software to drill holes according to specific sizes and patterns.

The following two machines are the best-selling six-sided drilling machines and side hole machines on the market.

Six-sided CNC drilling machine:

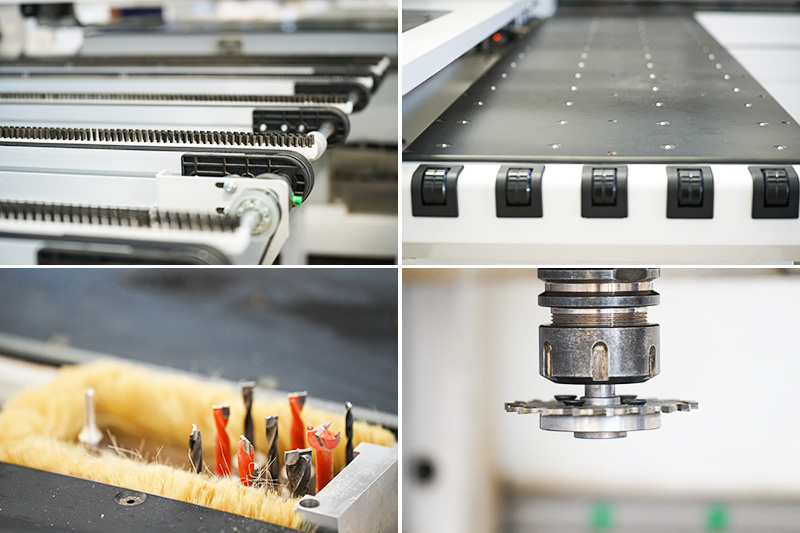

Six-sided drilling parts:

Side hole drilling machine:

Side hole drilling parts:

Manufacturers Overview

| Company Name | Established Year | Location |

| Blue Elephant | 2013 | China |

| Biesse | 1969 | Italy |

| Felder | 1956 | Austria |

| Homag | 1960 | Germany |

| SCM | 1952 | Italy |

Top 5 Best Wood CNC Drilling Machine Manufactures for Wood Working

Blue Elephant(China)

Jinan Blue Elephant CNC Machinery Co., Ltd. is a high-tech enterprise located in Jinan, Shandong Province, China. It was established in 2013 and focuses on the research and development, production and sales of CNC machinery and equipment. It has focused on the research and production, manufacturing and sales of panel furniture production line equipment, providing professional CNC equipment and services to tens of thousands of customers at home and abroad.

The production scale continues to expand, and the factory covers an area of 10,000+ square meters. The company will continue to uphold the entrepreneurial spirit of innovation, pragmatism and efficiency, continuously improve product quality and service level, and create greater value for customers.

Blue Elephant provides an overall solution for the digital production of customized furniture. Its main products include a variety of CNC equipment such as woodworking engraving machines, stone engraving machines, metal engraving machines, laser cutting machines and plasma cutting machines. In addition, it also includes customized furniture production lines, CNC cutting series, edge banding series, CNC drilling equipment, stone processing series, mold processing series, etc.

In the past decade, Blue Elephant has continuously strengthened its scale and strength. It was recognized as a high-tech enterprise in 2020, a Jinan Gazelle Enterprise in 2021, and a well-known brand in Shandong Province in 2023. In addition, it has also passed the ISO9000 quality management system certification.

Established Date:2013

Company Image:

Factory Image:

Product Image:

Review:

Blue Elephant has rich CNC experience and a large number of products. The CNC wood drilling machine series currently has 8 products, covering various CNC drill products and models, with guaranteed quality.

As a company committed to technological innovation and customer service, Blue Elephant CNC Machinery Co., Ltd. adheres to the business philosophy of “quality first, customer first”, actively expands the global market, and continuously promotes the development and application of CNC technology. If you need to buy a CNC drill, Blue Elephant is undoubtedly the most cost-effective choice.

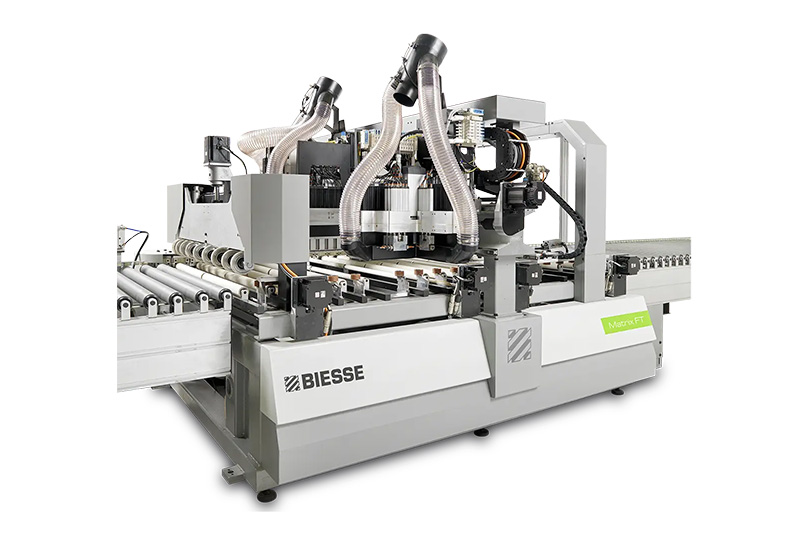

Biesse(Italy)

Biesse is a well-known Italian machinery manufacturing company, founded in 1969 and headquartered in Pesaro, Italy. It mainly focuses on providing high-tech machinery and automation solutions for the wood, glass, stone and composite materials processing industries. Biesse’s product line covers CNC machining centers, automated cutting, wood drilling machine and milling equipment, which are widely used in furniture manufacturing, construction and other industrial fields.

Established Date:1969

Company Image:

Factory Image:

Product Image:

Review: Biesse has a very extensive global business network. In addition to its R&D and manufacturing base in Italy, the company also has branches, service centers and training centers in many countries and regions around the world. Through continuous technological innovation and global expansion, Biesse provides its customers with customized solutions and comprehensive after-sales support.

However, Biesse’s products are relatively expensive and have high maintenance costs, making them unsuitable for customers with limited budgets. At the same time, some high-end machines are complex to operate and require professional training.

Felder(Austria)

Felder Group is a well-known machinery manufacturing company headquartered in Austria, focusing on providing high-quality processing equipment for the woodworking industry. Felder is committed to the research, development, manufacture and sale of multi-functional machinery and equipment for the woodworking industry, including sawing machines, planing machines, milling machines, drilling equipment and CNC machining centers.

Felder Group has three sub-brands, Felder, Hammer and Format-4, which are aimed at different levels of the market to ensure that its product line can fully cover the needs of all types of users. Among them, the Felder and Hammer series are more aimed at small and medium-sized woodworking companies and individual users, while the Format-4 series is the first choice for the high-end and professional market, with advanced CNC technology and automation functions.

Established Date:1956

Company Image:

Factory Image:

Product Image:

Review: The Felder Group’s factory is located in Innsbruck, Austria, where all products are designed and manufactured, ensuring the consistency and precision of product quality. Felder not only has an important share in the European market, but also provides efficient technical support and after-sales service to global customers through a global sales and service network.

However, Felder products are relatively expensive, and after-sales service in some areas is not perfect enough.

Homag(Germany)

Homag Group is a world-leading wood processing machinery manufacturer headquartered in Schopfloch, Germany, founded in 1960. Homag Group mainly provides advanced machinery and equipment and fully automated solutions for furniture manufacturing, woodworking and construction industries.

Homag’s product line is very extensive, covering everything from wood cutting, edge banding, drilling, painting to fully automated production lines. Its core technologies include CNC machining centers, automated production solutions and smart factory systems, helping customers achieve a high degree of production automation and flexibility.

Established Date:1956

Company Image:

Factory Image:

Product Image:

Review: As a global enterprise, Homag has multiple subsidiaries and distribution networks around the world, serving more than 100 countries and regions. In addition to its production base in Germany, Homag also ensures that it can provide customers with timely technical support and after-sales service through a global sales and service network. However, Homag has a smaller market in some regions, and professional training is required for operation and maintenance.

SCM(Italy)

SCM Group is a world-leading machinery manufacturing company headquartered in Rimini, Italy, and was founded in 1952. SCM focuses on providing high-tech machinery and automation solutions for the processing industries of materials such as wood, plastic, glass, stone and metal.

SCM’s product portfolio covers a wide range, including CNC machining centers, planers, cutting machines, cnc drill machines, sanding machines, edge banding machines and fully automated production lines specifically for the furniture and construction fields.

Established Date:1952

Company Image:

Factory Image:

Product Image:

Review: SCM has a wide global market coverage, with important business layouts in Europe, Asia, North America and South America. With its rich experience in precision machinery manufacturing and global market network, SCM Group has become an indispensable and important player in the international manufacturing industry. Its core concept of “quality, innovation and reliability” enables SCM to maintain its competitive advantage in the global market.

However, the product does not have an advantage in price, and the purchase cost is high. Especially for small and medium-sized enterprises, the initial investment cost is high and it is not suitable for investment.

How to Evaluate A CNC Drilling Machine Manufacturer?

Brand Background and History

When purchasing a CNC drill, the manufacturer’s brand background and history are crucial, directly affecting the quality of the equipment, technical support, and after-sales service. First of all, manufacturers with a long brand background usually have a deep accumulation in technology research and development. They have continuously improved and innovated through years of experience and are able to provide stable and efficient equipment.

Secondly, experienced manufacturers pay more attention to product quality control, have mature manufacturing processes and strict quality inspection processes. Manufacturers with international market experience usually have a better understanding of global industry standards and can produce CNC equipment that meets international quality certifications (such as CE, ISO, etc.). This is especially important for companies that need to expand international markets.

Jinan Blue Elephant CNC Machinery Co., Ltd. is a well-known brand at home and abroad. Its products are exported to many countries and regions such as Europe, America, Southeast Asia, the Middle East, Africa, etc., and have been highly praised and trusted by customers around the world.

Product Quality and Technical Level

In the selection of CNC drilling machines, product quality and technical level are the key factors that determine the production efficiency, product accuracy and long-term economic benefits of enterprises. The core advantage of CNC drilling machines lies in their high precision and consistency. High-quality equipment can ensure that drilling is completed accurately in every operation, whether it is a complex pattern or a high-precision hole position requirement.

High-quality and technologically advanced wood drilling machines can improve accuracy, reduce downtime, increase production efficiency, and reduce long-term operating costs. Therefore, investing in a high-quality wood drilling machine can not only improve current production capabilities, but also lay a solid foundation for the future development of the company.

After-sales Service and Technical Support

After-sales service and technical support are the key guarantees to ensure the stable and efficient operation of CNC drilling machines and other equipment. It can help enterprises solve problems quickly, reduce maintenance costs, improve the ability of operators, and ensure that the equipment is always in the best condition through continuous technical support and equipment upgrades. High-quality after-sales service not only directly affects the production efficiency and economic benefits of enterprises, but also creates greater value for enterprises in long-term cooperation.

Blue Elephant has a complete and efficient after-sales service system. It provides an online service platform and a professional after-sales service team. It can provide technical guidance in the country where the customer is located. Whether it is product consultation, troubleshooting or repair and replacement, it can provide professional and efficient solutions.

Field Trip

When purchasing a CNC wood drilling machine, it is very important to conduct a field visit to the manufacturer. This not only helps the company to have a more comprehensive understanding of the manufacturer’s strength, production process and technical level, but also reduces procurement risks and ensures that the selected equipment meets production needs.

Through field visits, companies can intuitively understand the manufacturer’s production scale and equipment manufacturing capabilities. During the field visit, the company can directly observe the production process of the equipment.

The CNC drilling machine is a precision equipment, and the refinement of the production process directly determines the quality and performance of the equipment. Through field visits, you can intuitively understand the production capacity of the CNC drilling machine.

The Blue Elephant factory covers an area of 30,000+ square meters and produces more than 10,000 machines annually. It currently has two major factories in Jinan and Tai’an, and a large number of customers come to visit every year.

Conclusion

In conclusion, choosing the best wood CNC drilling machine manufacturer is crucial for achieving precision, efficiency, and long-term reliability in woodworking projects. The top 5 manufacturers highlighted in this article are recognized for their cutting-edge technology, robust machine performance, and strong customer support.

If you have any questions about CNC drilling machines, you can consult Blue Elephant at any time.

Email: [email protected]

Whatsapp/mobile: +86-15064026772