A few years ago, I worked with a manufacturer struggling to meet demand. Their manual processes led to inconsistent quality and delays. Then, they switched to CNC machining, and everything changed, higher output, fewer errors, and faster production.

That shift wasn’t just a trend; it was a necessity. Businesses across industries are relying on CNC machines to stay competitive.

If you’re exploring how CNC machines can impact your operations, this article will give you practical insights. It’s built on industry knowledge, not marketing fluff.

You’ll discover the key applications of CNC machines and how they’re used to optimize production. No vague explanations, just clear, useful information.

Let’s get started!

1. Manufacturing and Metalworking

I once worked with a supplier who struggled with consistency in their metal parts. Some pieces were flawless, while others had minor but costly defects. They relied on manual machining, and human error was inevitable. It wasn’t until they switched to CNC machining that things changed, every part came out identical, cutting down on waste and improving efficiency.

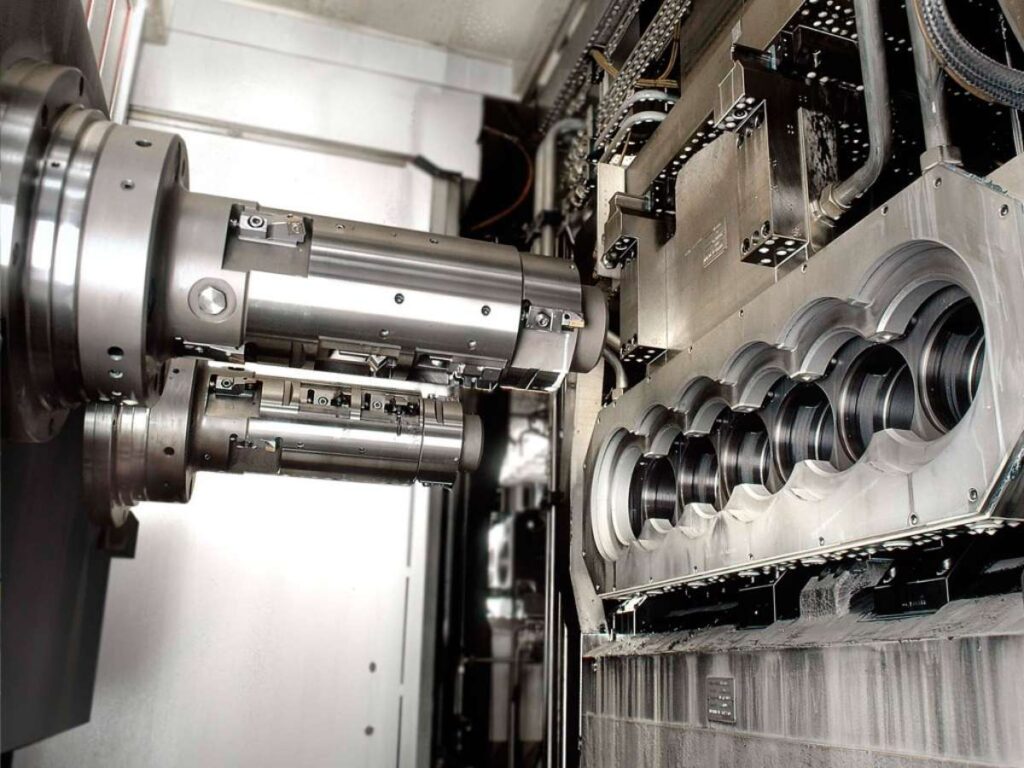

Manufacturing and metalworking rely heavily on CNC machines because precision and repeatability are non-negotiable. These machines handle everything from cutting and milling to grinding and drilling, ensuring every piece meets exact specifications.

How CNC Machines Optimize Metalworking

- Precision and Consistency: Unlike manual machining, CNC machines execute the same process repeatedly with microscopic accuracy. Whether it’s a simple bracket or a complex aerospace component, every unit meets strict tolerances.

- Increased Production Speed: Time is money in manufacturing. CNC machines work around the clock with minimal supervision, speeding up production without sacrificing quality.

Applications in Metalworking Industries

- Fabrication and Prototyping: Many manufacturers use CNC machining to create prototypes before full-scale production. It allows them to test designs and make adjustments before mass production.

- Mass Production of Metal Parts: From screws and bolts to automotive and aerospace components, CNC machining ensures uniform quality across large production runs.

2. Aerospace and Defense Applications

Aerospace manufacturing isn’t forgiving. A fraction of a millimeter off, and a component may not fit or function correctly. I once visited an aerospace facility where engineers relied on CNC machining to craft turbine blades. The precision wasn’t just about quality, it was about safety.

CNC machines play a crucial role in aerospace and defense, where every component must meet strict regulations and performance standards. From jet engines to missile components, precision is non-negotiable.

Why CNC Machining is Essential in Aerospace

- Extreme Precision Requirements: Aerospace parts must meet incredibly tight tolerances. CNC machining achieves precision down to the micron level, ensuring flawless fit and function.

- Complex Geometries: Many aerospace components, like turbine blades and fuselage structures, have intricate designs. CNC machines handle complex cuts and contours that manual processes cannot replicate.

Key Aerospace Applications

- Aircraft Structural Components: CNC machining is used to produce lightweight yet durable parts like wing spars, landing gear components, and fuselage frames.

- Engine and Turbine Components: Jet engine parts require exact tolerances to function under extreme conditions. CNC machining ensures these components perform efficiently and safely.

3. Automotive Industry

When automakers ramp up production, precision and efficiency matter more than ever. I remember speaking with a parts manufacturer who struggled to meet demand using traditional machining methods. Switching to CNC machining allowed them to scale up without sacrificing quality.

CNC machines are essential in the automotive industry, producing everything from engine components to custom body parts. The ability to create consistent, high-quality parts at scale keeps production lines running smoothly.

How CNC Machines Benefit the Automotive Sector

- High-Speed Production: CNC machining drastically reduces cycle times, allowing manufacturers to produce thousands of components per day with minimal manual labor.

- Custom and Prototype Manufacturing: Whether designing a new model or testing performance parts, CNC machines allow for quick prototyping and iteration.

Applications in the Automotive Industry

- Engine and Transmission Parts: CNC machining produces critical powertrain components like cylinder heads, camshafts, and transmission gears with exact precision.

- Chassis and Suspension Components: Structural elements require both strength and precision. CNC-machined parts improve vehicle durability and performance.

In the fast-paced automotive industry, CNC machining is a game-changer for companies looking to balance speed, cost, and quality.

4. Medical and Healthcare Equipment

Medical equipment isn’t something you can afford to get wrong. I once spoke with a manufacturer who struggled with inconsistencies in surgical tool production. After switching to CNC machining, they achieved the precision required for medical-grade instruments.

CNC machines play a crucial role in healthcare, where accuracy and safety are top priorities. From implants to diagnostic devices, CNC machining ensures medical equipment meets the highest standards.

Why CNC Machining is Critical in Healthcare

- Strict Regulatory Standards: Medical devices must meet FDA and ISO standards, which CNC machines help achieve through precise manufacturing.

- Biocompatible Materials: CNC machining allows for the precise cutting of materials like titanium and stainless steel, commonly used in medical implants.

Key Medical Applications

- Surgical Instruments: Scalpels, forceps, and orthopedic tools require extreme precision to function effectively in medical procedures.

- Custom Implants and Prosthetics: CNC machining creates patient-specific implants, improving comfort and functionality.

5. Electronics and Semiconductors

I once toured a semiconductor facility where the precision of CNC machining was the backbone of production. With components measured in microns, even the smallest deviation could lead to a faulty circuit board.

Electronics manufacturing demands extreme precision, and CNC machining ensures consistency in intricate designs and delicate components.

How CNC Machines Support Electronics Manufacturing

- Micro-Precision Capabilities: CNC machines handle the tight tolerances required for circuit boards, connectors, and casings.

- High-Speed, High-Volume Production: The ability to produce thousands of identical parts efficiently keeps up with the fast-paced electronics industry.

Key Applications in Electronics

- Printed Circuit Boards (PCBs): CNC machining precisely drills and engraves boards for various electronic applications.

- Device Enclosures and Heat Sinks: Custom casings and cooling systems require exact machining for optimal performance.

6. Energy and Renewable Resources

Minor inconsistencies in machining led to significant performance issues. When they transitioned to CNC machining, their failure rates dropped dramatically, improving efficiency and longevity.

The energy sector depends on CNC machining for precision manufacturing, especially in renewable energy. Whether it’s wind turbines, solar panels, or oil and gas infrastructure, accuracy is critical for operational efficiency.

How CNC Machines Support the Energy Industry

- Extreme Durability Requirements: Energy components must withstand harsh environmental conditions. CNC machining ensures high-precision, wear-resistant parts.

- Customization for Specialized Equipment: Many energy systems require highly specific components that CNC machining can produce with exacting detail.

Applications in Energy Production

- Wind and Hydro Turbine Components: CNC machining fabricates precision parts like turbine blades, generator housings, and drive shafts.

- Oil and Gas Infrastructure: From pipeline connectors to drilling equipment, CNC-machined parts improve durability and performance in demanding environments.

7. Marine and Shipbuilding Industry

The shipbuilding industry operates on a massive scale, where even the smallest parts must be incredibly precise. I once met a shipbuilder who explained how manual machining led to assembly delays because parts didn’t fit as expected. After adopting CNC machining, they saw a dramatic improvement in efficiency and accuracy.

How CNC Machines Benefit Shipbuilding

- Corrosion-Resistant Components: CNC machining enables the use of specialized alloys that withstand harsh marine environments, reducing maintenance costs.

- Large-Scale Precision: Whether cutting steel for hulls or fabricating custom propellers, CNC machines ensure accurate manufacturing at scale.

- Reduction in Production Time: CNC machining automates complex manufacturing tasks, reducing the overall build time for ships and marine structures.

Applications in Shipbuilding

- Propulsion Systems: CNC machining produces high-precision propeller shafts, gears, and rudder components, ensuring smooth operation at sea.

- Structural Components: Hull reinforcements, support structures, and deck fittings require accurate machining for long-term durability and safety.

- Marine Engine Components: CNC machining helps produce high-performance engine parts that can withstand extreme marine conditions.

8. Jewelry and Fashion Industry

Precision isn’t just for industrial applications, I once visited a jewelry manufacturer who used CNC machining to create intricate custom designs. Before adopting CNC technology, hand-carved pieces took weeks to complete. With CNC, they reduced production time to days while maintaining fine details.

CNC machining is becoming a game-changer in high-end jewelry and fashion accessories, offering unparalleled precision and repeatability.

How CNC Machines Are Transforming Jewelry Making

- Intricate Designs with Perfect Symmetry: CNC technology allows for fine details that would be impossible to achieve consistently by hand.

- Mass Production of High-Quality Pieces: Brands can produce hundreds of identical, flawless pieces without sacrificing quality.

Key Applications in Jewelry and Fashion

- Custom and Luxury Jewelry: CNC machining carves detailed patterns into gold, silver, and platinum with precision.

- Watchmaking and Accessories: High-end watches rely on CNC machining for case, bezel, and gear production.

9. Woodworking and Furniture Manufacturing

I once worked with a furniture maker who spent hours hand-cutting intricate patterns into wood. It was a slow, labor-intensive process. When they invested in CNC routers, production time was cut in half, and every piece maintained the same level of craftsmanship.

CNC machining has revolutionized woodworking by blending traditional craftsmanship with modern efficiency.

How CNC Machines Enhance Woodworking

- Automated Precision Cutting: CNC routers cut complex patterns with unmatched accuracy, reducing waste and manual labor.

- Faster Production for Custom and Mass Orders: Whether for one-off designs or bulk production, CNC machines streamline the process.

Applications in Woodworking

- Custom Cabinetry and Furniture: CNC machining allows for precision joinery, decorative engravings, and seamless assembly.

- Architectural Woodwork: Intricate panels, moldings, and doors benefit from CNC precision.

For woodworking businesses, CNC technology enables both creativity and efficiency, making high-quality craftsmanship scalable.

10. Customization and Artisanal Production

The rise of CNC machining has changed the way businesses approach customization. I’ve seen small shops scale their production without losing the personal touch that makes their products special.

From one-off prototypes to personalized consumer goods, CNC machining enables businesses to offer high-quality customization without sacrificing efficiency.

How CNC Machines Drive Customization

- Precision Without Human Error: CNC ensures every custom piece is made exactly to specification, reducing rework and waste.

- Scalability for Small and Large Orders: Businesses can produce one item or thousands with the same level of quality.

Applications in Artisanal Production

- Custom Engraving and Personalization: CNC machining is used to engrave logos, names, and intricate designs onto metal, wood, and acrylic.

- Limited-Run and Bespoke Products: From custom bike frames to high-end kitchenware, CNC machining allows artisans to scale production while maintaining quality.

Conclusion

Remember that company I told you about—the one drowning in delays? They’re now booked out six months, thanks to CNC.

In this guide, you’ve learned:

- What CNC machines are capable of

- How different industries rely on them daily

- Why precision = progress

It’s time for your business to get that same edge. You don’t need a big team. You just need the right machine.

Are you ready to take control of your production?

Contact us today at Blue Elephant. Let’s talk about what’s possible.

Dive Deeper Into Our Resources

We’ve gathered a few more articles that could help you out. Check them out for more great advice:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.