What laser can a 100 watt laser cleaning machine adopt?

Fiber Laser

Fiber lasers are popular choices for laser cleaning due to their high efficiency and precise beam quality. They are reliable, compact, and capable of delivering high power levels. Fiber lasers are often used for industrial applications such as cleaning metal surfaces.

CO2 Laser

CO2 lasers are another option, especially for organic materials and certain plastics. They operate at longer wavelengths compared to fiber and solid-state lasers and are effective for removing paint, grease, and other contaminants.

Pulsed Laser

Pulsed laser delivers high-energy pulses in short durations. It is effective for removing surface layers without causing excessive heat buildup or damage to the substrate.

YAG Laser

It can offer good beam quality and are suitable for various materials, including metals and ceramics.

What is the lifespan of a 100W laser cleaning machine?

The lifespan of a 100W laser cleaning machine can vary widely based on several factors, including the quality of the machine, how well it’s maintained, the frequency and intensity of its usage, and the specific components used in its construction. Laser cleaning machines are relatively complex systems with various moving parts, optical components, and electronics that can wear out over time.

On average, a well-maintained industrial-grade laser cleaning machine can last anywhere from 10,000 to 30,000 hours of operation. However, some machines might experience shorter lifespans if they are used more intensively or if they are subjected to harsh operating conditions. Regular maintenance and proper usage can significantly extend the lifespan of the machine.

It’s important to note that technological advancements and improvements in manufacturing can also influence the lifespan of such machines. As technology evolves, newer models with better components and designs might have longer lifespans compared to older models.

What can laser cleaning machines do?

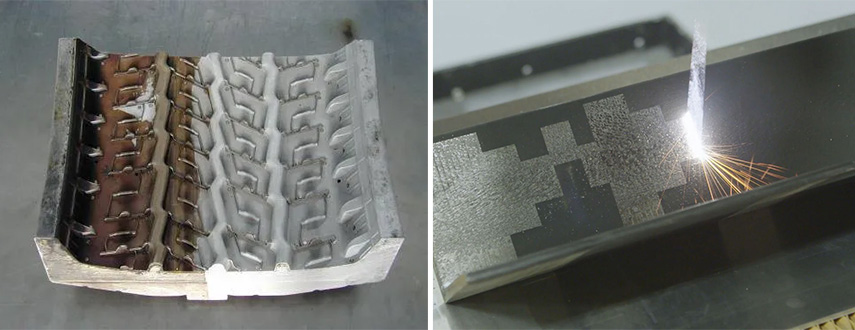

- mold cleaning

- industrial rust removal

- old paint and film removal

- re-welding pretreatment and post-welding treatment

- deesterification of precision parts

- decontamination and oxide layer removal of electronic components

- cleaning of cultural relics

It is widely used in metallurgy, mold tools, automobiles, hardware tools, transportation, construction appliances, machinery and other industries.

How is the laser cleaning machine constituted?

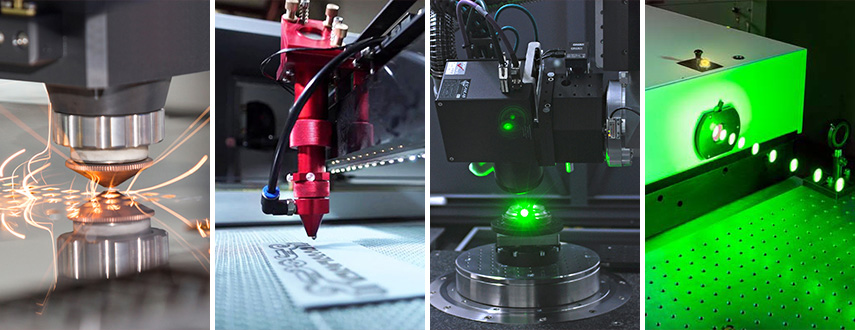

1. Laser generator: it is the main core component, which is used to generate high-energy laser beams.

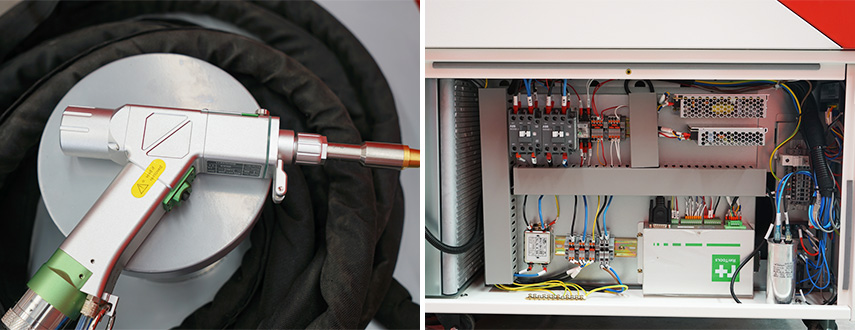

2. Cleaning head: mainly includes collimation system, galvanometer system and focusing system.

3. Control system: generally used to control lasers, galvanometers, actuators, boards and other systems.

4. Water cooler: provide cooling for laser and cleaning head ( water cooling pulse or air cooling pulse ).

5. Air pump: effectively purify the exhaust gas and solid dust particles produced by laser cleaning, and the effect of nitrogen and argon is the same.

6. Vulnerable parts: mainly the protective mirror.

7. fiber optical cable: the longest support is 20 meters. The longer the length, the more serious the laser attenuation.

What is the efficiency of laser cleaning machine?

The cleaning efficiency of the professional laser cleaner machine is 2-3 times that of the 3-in-1 laser cleaning machine. The cleaning scanning width determines the cleaning efficiency. The three-in-one cleaning width is fixed at 80mm. The normal cleaning width of the special cleaning machine is 300mm. When the light intensity achieved in the unit is the same, the larger the cleaning width, the higher the cleaning efficiency.

Can I change to higher-energy laser cleaning power?

How high power you can choose will depend on the machine design. For example, Blue Elephant 100 watt laser cleaner can provide customers with more choices. They can change the laser cleaning power from 100w to 500w or even much higher laser power. Usually, our customers will select 100w, 200w, 300w laser cleaning machine to remove rust and other stains.

How to use and maintain a laser cleaning machine?

It’s very important to correctly use and maintain a laser rust removal machine. Because, if we don’t properly use the metal laser cleaning machine, it may lead to serious consequences, including safety risks, equipment damage, and environmental pollution. Keep the following using rulers in mind, you may avoid these dangers.

Before using a fiber laser cleaner, ensure that employees have received proper training and understand the characteristics of the laser cleaning equipment as well as operating procedures, safety procedures, and maintenance methods. Familiarize yourself with the owner’s manual and manufacturer’s recommendations. Second, when operating, operate the fiber optic cleaner in a controlled environment that is well ventilated and free of flammable materials. Finally, test on a small area before machining to determine proper laser power and settings.

Regularly clean the optical components of the laser cleaning machine, such as lenses and mirrors, to ensure laser transmission efficiency. Especially the optical components of the laser cleaning machine, such as lenses and mirrors, should be cleaned regularly to ensure the efficiency of laser transmission. Keep the environment around the device clean and tidy to prevent dust and dirt from entering the device.

Blue Elephant 100W Laser Cleaning Machine Recommendation

How to choose the best laser cleaning machine that suits you?

Want to find your best suitable laser cleaner but have no ideas at all? Keep the following choosing steps to get the best idea.

Application and Cleaning Requirements

Determine the specific applications for which you need the laser cleaning machine. Different machines are designed for different tasks, such as rust removal, paint stripping, surface preparation, and more. Understand your cleaning requirements in terms of material, surface area, and the type of contaminants you need to remove.

Laser Power and Wavelength

Laser cleaning machines come with different power levels and wavelengths. The power level affects the speed and efficiency of the cleaning process, while the wavelength determines the material compatibility. Choose a machine with a power level and wavelength suitable for your cleaning tasks.

Safety and Environmental Concerns

Consider the safety aspects of laser cleaning. Some lasers can generate hazardous fumes, so make sure the machine you choose has appropriate safety features and environmental controls. Ensure that the machine complies with safety standards and regulations.

Ease of Use and Automation

Look for a machine that is user-friendly and easy to operate. Automation features like programmable settings, adjustable parameters, and pre-set cleaning patterns can improve efficiency and consistency in the cleaning process.

Maintenance and Service

Consider the maintenance requirements of the machine. Some machines might require more frequent maintenance than others. Also, check the availability of service and technical support from the manufacturer or distributor.

Budget and Cost of Ownership

Set a budget for your laser cleaning machine purchase. Keep in mind that the initial cost is just one part of the total cost of ownership, which also includes maintenance, consumables (like laser optics), and operational costs.

Demo and Testing

Whenever possible, request a demo or perform a test of the machine on your specific cleaning tasks. This can help you evaluate the machine’s performance and determine if it meets your requirements.

Supplier Reputation

Choose a reputable supplier or manufacturer with a history of producing reliable and high-quality laser cleaning machines. Look for certifications, industry recognition, and customer feedback.

Customization Options

Depending on your unique requirements, you might need a machine with customizable features or attachments. Discuss customization options with the supplier if needed.