How to choose your first wood engraving machine as a CNC novice? Here, we will provide you with a detailed CNC woodworking engraving machine purchasing guide and reference to help you choose your first satisfactory wood carving CNC machine. Below I will introduce the following 7 chapters:

| What you should know before purchasing a wood engraving machine? |

| Customer feedback of the Blue Elephant wood engraving machine? |

| How much does a wood engraving machine cost? |

| Start your business with wood engraving machine |

| Best wood engraving machine for beginners |

| Steps to choose a suitable wood engraving machine for beginners |

| Precautions after buying a wood engraving machine |

The content covers a complete introduction of CNC wood engraving machines. Next, let’s take you to a comprehensive understanding of automatic wood engraving machines.

Chapter 1: What You Should Know Before Purchasing a Wood Engraving Machine?

I.What machine can you use to engrave wood?

Now the CNC wood cutting and engraving machine has gradually replaced the traditional wood etching machine. And it is loved by more and more business people in the woodworking industry. According to the different processing needs of customers, wood carving CNC machines are continuously upgraded and the types become more and more diverse. In general, CNC wood engravers are divided into two categories: laser engraving machines for wood and ordinary CNC wood carving machines.

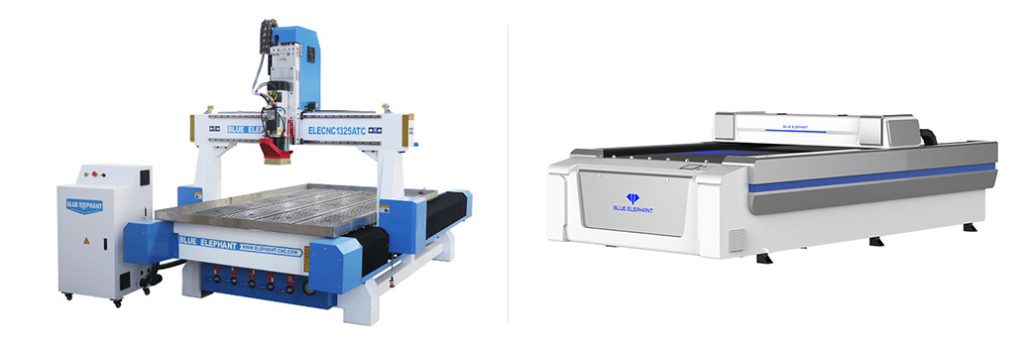

1.CNC engraving machine for woodworking

CNC wood carving engravers are mainly composed of three parts: computer, control system, and engraving machine body. The CNC wood engraver uses the special engraving software configured in the computer for design and layout. And then the computer automatically transmits the design and layout information to the control system of the wood etching machine. Next, the control system converts this information into a pulse string that drives a stepper motor or a servo motor and controls the CNC woodcarving machine to generate X, Y, and Z axis engraving paths. Thus it can complete the processing of the material fixed on the worktable and realize the user’s various wooden projects processing requirements.

Wood etching machines can cut and engrave a variety of materials, such as plywood, two-color board, rubber, density board, crystal, acrylic, plexiglass, wood, etc. This CNC wood carving machine is widely used in the furniture industry, decoration industry, woodworking industry, musical instrument industry, wood handicraft industry. Besides, the CNC wood engraver is very suitable for large-area plate carving, furniture CNC carving, art mural etching, solid wood engraving, density board carving, kitchen window, and door engraving, etc.

The main types of CNC router engravers are ATC wood carving CNC machine, 5-axis CNC wood etching machine, 4-axis CNC wood engraver, 3-axis wood engraving machine for beginners, rotary CNC router engraver, multi-head wood 3D carving machine, hobby wood etching machine, and so on.

2.Laser engraving machine for wood

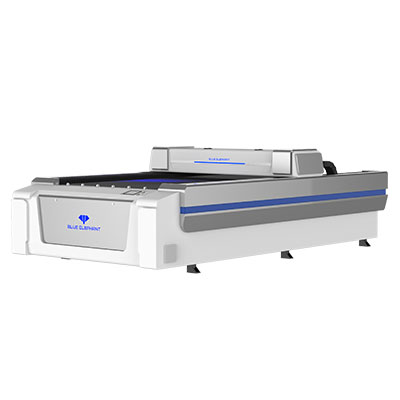

As a beginner first using the best wood laser cutter for sale, you may want to know what laser can engrave wood. We all know that the best wood laser cutters are divided into two categories: fiber laser cutting machines and CO2 laser wood cutting machines. Among them, the fiber laser engraver machine is suitable for cutting and engraving metal materials. While the CO2 laser wood cutting machine is fitful for CNC cutting and engraving non-metal materials. The laser machine for wood here mainly refers to the CO2 laser wood cutting machine.

A CO2 wood laser cutter is also called a plywood laser cutter and a laser cutter for MDF. It uses CO2 laser technology to quickly vaporize the surface of the processed material through a laser beam to achieve engraving functions. It can engrave more complex patterns. In addition, the CO2 laser wood cutting machine also has a strong anti-interference ability. So it is not susceptible to interference from other external factors. It can cut and engrave almost all non-metallic materials, such as wood, paper packaging, plastic products, label paper, leather cloth, glass ceramics, resin plastic, bamboo and wood products, PCB boards, etc. In addition, the CO2 laser engraver for wood can also engrave some soft metals, such as brass, aluminum, gold, silver, and so on. It is mainly used in the mold industry, printing industry, clothing manufacturing industry, and jewelry manufacturing industry.

II.What is the easiest wood engraver machine to use?

In my opinion, the CO2 laser engraving machine for wood is much easier to use for beginners and novices. Next, I will take the hot sale 1390 CO2 plywood laser cutter(laser cutter for MDF) for an instance.

First, it has a moderate working table size, which is convenient for you to put and move. And it is enough to cut and engrave larger and thicker materials. Second, with a very simple operation, even a novice can use it within an hour. Besides, you are safer to operate this laser wood cutting machine for its safety cover. Third, it is flexible to freely adjust the engraving sequence. Moreover, the laser power, laser cutting speed, and focal length can also be adjusted according to your requirements.

III.What tool is used for wood engraving machines?

What tools are used to engrave designs into wooden pieces? And What is the best tool for engraving wood? There are many tools used to assist wood engraving machines to carve letters and patterns on wood panels, such as metal cutting heads, laser heads, rotary devices, automatic tool changers, etc. But the best engraving tools are the rotating devices and the automatic tool changers. The rotary device is flexible and can be independently installed on the side of a wood carving CNC machine for easy disassembly. At the same time, it can assist in the processing of column objects, such as table legs, chair legs, stair handrails, wooden posts, and so on. The automatic tool changer can automatically change tools according to different materials, with different thicknesses and shapes. Thanks to the fast tool change speed, short tool change time, and high processing efficiency, you will save more time.

Chapter 2: What Do Customers Say About Blue Elephant Wood Engraving Machine?

Blue Elephant has been in the CNC engraving machine industry for more than ten years. Its wood engraving machines are widely sold at home and abroad and are well received by customers all over the world. For example, customers in Australia, the United Kingdom, the United States, Canada, India, Chile, the Netherlands, Hungary, Peru, Eldogua, South Korea, New Zealand, Portugal, the Czech Republic, and other countries have purchased our CNC wood carving engravers and laser engravers for wood recently.

Some of them are used to make large wooden products such as furniture, molds, and advertising boards. Others are used to make small products such as handicrafts, decorations, and gifts. Customers who have bought the Blue Elephant machine also sent us some feedback, such as the machine operation videos and the sample pictures the machine produced. Among them, the Portuguese customers left a very deep impression on me.

Not long ago he bought one of our 1212 plywood and MDF engravers and used it to make beautiful handicrafts and wood painting panels. He not only sold them in his store but also displayed pictures and videos of the products on social accounts. Because of the very exquisite product, it has been praised by many followers. And the local TV show interviewed him. The Portuguese customer told us such good news at once and then expressed his sincere gratitude to us. He thanks our excellent CNC wooden engraving machines for enabling him to produce such successful and beautiful works. His friends also want to buy the Blue Elephant wood carving CNC machines, and he will continue to buy back if needed. We are proud of him and expressed our warm congratulations to him. The following is the interview video broadcast.

Chapter 3: How to Start Your Business with Wood Engraving Machine?

If you want to start your own business, then using a wood etching machine to start your business is a very good idea. Because wood engraving machine has a wide range of applications and can provide you with many entrepreneurial ideas. Or you are working in the woodworking industry, want to make some breakthroughs in your work, or want to get better profits, then you should also choose a high-quality wood etching machine to help you.

Some people think that CNC wood carving engraving machines are only suitable for mass processing production in large factories. This is wrong. You don’t have to be a big company to use a wood router engraving machine. Even if you are just a wood crafts enthusiast or run a small shop or a small workshop, you can also buy a wood CNC engraving machine, such as the mini CNC wood engraver, desktop wood engraving machine, portable wood engraving CNC machine, or wood engraving machine for home depot.

Then we will talk about how to use a wood engraving machine for beginners to make some exquisite and practical products. Hope to give you more inspiration to start your business.

1.Wood engraving machine for small business

Now more and more young people like to use environmentally friendly wooden gifts to give friends or decorate the room, so you can seize such a good business opportunity and choose to buy a mini CNC woodworking engraving machine or small 3D wood engraving machine to make some popular wood engraving projects for small business. For example, you can use a wood engraving machine to make door hangers, wood decoration frames, cup mats, wooden photos, wood plugs, world wood push pin maps, mobile phone cases, switch Surrounds, etc.

These small crafts have low cost, high profit, short production cycle, and mass production. They are a very good choice for people who are engaged in small businesses. In addition, people pay more attention to the packaging bags, so the engraving design of the packaging bags cannot be ignored, which is a hidden selling point.

The recommended Small business wooden engraver machine is ELE6090 wooden engraving machine, ELE1325 CNC engraving machine for wood, ELE1212 automatic wood engraving machine, etc. This woodcarving machine handles a wide range of materials. It can cut and carve birch, camphor, pine, willow, mahogany, paulownia, plywood, two-color board, density board, acrylic, plexiglass, crystal, etc.

Moreover, it is with high performance-price ratio, low cost, good processing effect, and can save manpower and improve processing efficiency. The processing system of the wood engraving machine is flexible. And the CNC automatic engraving can be realized by adopting numerical control technology. With parameter backup and parameter recovery functions, it can effectively prevent the loss of important data parameters. Some also have an intelligent processing memory function, and support breakpoint engraving. Surprisingly, it can continue processing even when the machine encounters a sudden power outage.

2.Wood laser engraver for home decoration

A wood laser engraver is also called a wood laser cutter, laser wood cutting machine, laser engraving machine for wood, laser engraver for wood, woodworking laser engraver, and laser machine for wood. The use of laser engraving machines for wood is more extensive. And the production carved and engraved by wood laser cutter cover all areas of our lives. Especially many young people or petty bourgeoisie pursue a relatively high quality of life and hope that their rooms can be decorated beautifully and generously. So a lot of expenditure will be spent on the house and room decorations.

For example, there are large flora embellished floor mats, wooden tableware, wooden dining tables and chairs, plywood decorative paintings, plywood clocks in our dining room; wardrobes, shoe cabinets, bookshelves, and candle holders in the bedroom; Acrylic LED light, exquisite plywood art wall, decorative woodworking screens in the living room; the glass kitchen canister, kitchen utensils, and cabinets in the kitchen. These large and small home decorations can be realized with a laser engraving machine for wood.

More suitable wooden laser engraver machines for home decoration are 1390 CO2 wood laser cutters and customized CO2 laser engraving machines for wood. This home laser engraver for wood is easy to operate, even a novice can quickly learn to operate it. Using automatic laser positioning and non-contact processing, the processing accuracy can reach 0.02mm. In addition, the heat-affected area of the wood laser cutter is small, so the cutting surface is not damaged. Many woodworking laser engravers sold are equipped with PVC protective covers. This not only guarantees the stable operation of the machine but also protects the personal safety of the operator.

3.DIY wood engraving machine for crafts

If you are a wooden crafts hobbyist or want to DIY some jewelry, knitted decorations, woodworking gifts, wood assembling toys, etc., you can build your own designed wood laser engraver, such as desktop laser engraver for wood, hobby laser engraver for wood, portable wood laser carver, and mini laser carving machine for wood. These are just part of the DIY laser wood engraving machine projects. As long as you have enough imagination, you can design more interesting and practical ideas with the laser engraving machine for wood. It can help you develop your business well and bring you many unexpected benefits.

Chapter 4: Best Wood Engraving Machine for Beginners

1. Entry-level 1325 wood engraving machine for beginners

The following video shows the Blue Elephant entry-level 1325 woodworking CNC engraving machine engraving patterns on MDF boards.

2.Popular 4-axis wood engraving machine with an automatic tool change

This kind of plywood CNC engraving machine has a front-end rotary device, which can greatly save your space. It is usually used to engrave short-length cylindrical parts, such as columns, desk legs, wooden armrests, and chair legs. The ATC spindle takes the tool from the tool magazine according to your settings, which can better complete complex 3D wood carvings. Those popular woodworking machine models are 1212 ATC CNC engraving machines for woodworking, 1325 ATC wood etching machines, 1530 ATC wood carving CNC machines, 2040 ATC CNC wood engravers, 2060 ATC CNC router engravers for wood, etc. Of course, the wood 3D carving machine can also be customized according to your processing needs.

A wood engraving machine with an automatic tool change is the first choice for large enterprises and industries. The automatic tool-changing wood engraving machine is a major category of CNC router engraver. To some extent, it also represents the highest technology engraving machine equipment. It has an independent tool magazine, which can automatically change the required tools during the processing of the workpiece without stopping the work. When you can engrave complex patterns, you can choose different tools, which greatly accelerates work efficiency and improves product quality. The automatic tool-changing engraving machine is also the final trend in the development of CNC engraving machine equipment.

3.High-precision 3D 5-axis wood engraving machine for sale

This kind of wood engraving machine is the most high-end wood etching machine. It has the best machining accuracy and can complete difficult processing of curved surfaces, such as exquisite irregular stair handrails.

Compared with the 3-axis wood engraving machine, the 5-axis wood etching machine is more flexible and changeable. 5-axis wood carving CNC machine means that the processing spindle can work in 5 different directions at the same time. The five axes refer to X+Y+Z+A (rotating around X) + B (rotating around Y) + C (rotating around Z).

4.Multifunctional 1326 CO2 wood laser cutter for sale

The following is a video of the 1326 CO2 laser cutting machine for wood engraving. This carving and engraving process is very smooth and stable.

Chapter 5: How Much does a Wood Engraving Machine Cost?

Before buying a 3D automatic wooden engraver, many customers will be very concerned about the wood engraving machine price. After all, everyone has a different budget. Next, I will take a brief introduction of wood carving machine price.

1.ELECNC1325 wood carving machine price

| Models | Costs |

| 3-axis wood engraving machine | $3,500-$8,000 |

| 3-axis ATC CNC wood engraver | $10,000-$20,000 |

| 4-axis CNC wood engraving machine for wood | $14,000-$20,000 |

| 4-axis ATC CNC wood engraving machine | $16,000-$27,000 |

| 5-axis CNC wood 3D carving machine | ≥ $85,000 |

2.CO2 laser wood carving machine price

The price of a CO2 laser wood cutting machine is higher than the CNC engraver for wooden pieces, ranging from $3,000-$150,000. Among them, the cheaper CO2 wood laser cutter is the ELECNC1390 laser engraver for wood. It is sold in the range of $3,000-$9,000. However, the ELECNC1326 CO2 wood laser cutter with an exchange platform has an expensive price of $6,000-$150,000.

3.Factors affecting wood carving machine price

First of all, we must understand that it is not that the higher the price, the more suitable the machine is for you. In addition, don’t blindly pursue a cheap wood engraving machine price. You should know that sometimes, the cheap machines will have not a good enough processing effect. So what are the factors that affect the price of the wood engraving machine?

One of the most important factors is the difference in the configuration of the CNC wood carving machine. Because there are many types of wood carving CNC machines with different sizes, configurations, and performances, there must be a big price difference. For example, the price of the best laser engraver for wood is much higher than that of ordinary CNC wood carver. And the best wood laser cutter machine price is generally $25,000-$12,000, while the CNC wood carving machine price is $2,500-$5,000. Imported ones are more expensive than domestic ones. And large wood engraving machine price is more expensive than mini wood engraving machine price. For that, the small 6090 CNC wood engraver only costs you $2,000. In addition, the wood engraving machine price is also affected by many other external factors, such as freight fees, packaging fees, and taxes.

Chapter 6: How to Choose a Suitable Wood Engraving Machine for Beginners?

I.Processing needs

Don’t be delusional to buy an all-around wood engraving machine to do whatever you want to process. Because it is impossible to process all products with only one wood etching machine. Therefore, you must be very clear about your processing requirements before buying a woodworking engraving machine. This is very essential. As the Chinese saying goes: Only the targeted medicine must be prescribed. That means only knowing your emergent requirements can you quickly and correctly find your best wood engraving machine.

First, know what material you need to process. Second, clear what is the thickness and size of the material to be processed. Third, whether the engraving patterns are 2D or 3D. For example, if you often engrave some thin wooden boards, and do not require a large processing depth, then you can choose a CO2 laser engraving machine for wood with lower power. I think it is sufficient to complete your task well. But if you plan to engrave solid wood or hardwood furniture, you’d better find a CNC wood engraver with high power to realize a deep engraving depth. And if you just make some tiny handicrafts, the small 6090 CNC engraving machines for wood and other mini wood engraving machines can meet your needs. Therefore, only the wood engraving machine that suits our processing needs is the best wood engraving machine.

II.Configuration

The machine configuration is closely related to the specific processing requirements, so this can also be used as a criterion for choosing a wood engraving machine. All Blue Elephant CNC wood engraving machines can be customized according to your carving needs. So you can assemble the machines according to your own preferences. You can specify different brands of parts, or choose whether to use imported parts, such as different spindles, work surfaces and sizes, motors, drives, control systems, etc.

III.Price

You need to know exactly what your budget is and don’t wait until the machine is determined to find that the budget is insufficient. Otherwise, all previous efforts will be lost, and you will spend a lot of time and power. So inform the seller of your budget requirements in advance. And ask them to recommend the wood engraving machine that best meets your processing requirements within your budget.

If your budget is sufficient, and you don’t have much demand for the price, or you care more about the overall performance of the machine than the price, then we recommend you to buy a CO2 laser engraving machine for wood or a five-axis wood engraving machine. These two kinds of CNC wood engraving machines have high precision, fast speed, and good carving effect. But if you are more pursuing a good price or a performance ratio, then the 1325 wood engraving machine and 1530 wood carving CNC engraving machine are good choices. These two are also the more popular CNC wood engraving machines, they can complete excellent wood processing.

IV.Operation capability

In addition to processing performance, you have to consider whether you have enough ability and expertise to run the CNC wood engraving machine smoothly. If you have no operating experience or limited operating ability, then you’d better choose an easy-to-operate CNC woodworking engraving machine, such as a CO2 best laser engraver for wood. After all, being able to produce and bring you income and benefits is your ultimate goal.

Chapter 7: After-sale Service Support

I.How do you start engraving on wood?

Operators should strictly follow the usage instructions of wood engraving machines for beginners and comply with safety regulations:

1)Before using the wood etching machine, first determine whether all connections between the machine tool and the computer are normal. And then turn on the power supply. After the system is started, enter the CNC system.

2)After opening the control system, select the “Back to Machine Origin” menu, the machine tool will automatically return to the machine origin and correct the system coordinate system.

3)Select the “Open” menu to load the engraving file into the system.

4) Manually move the X and Y directions of the wood engraving machine to the origin position on the workpiece. Next, select the “Set the current point as the origin of the workpiece” menu, so that the current position is the starting point when the processing program is executed Processing.

II. How to maintain the wood engraving machine for beginners?

We have a complete after-sales service system that can solve all your difficult problems through online and offline technical support. For example, we can help you with how to maintain wood engraving machines. To keep the parts of the wood engraving machine always in good condition, it is very important to insist on regular maintenance, so that many hidden troubles can be eliminated in the bud. In general, the maintenance of wood engraving machines includes the following aspects:

1)Check whether the voltage is stable before starting up every day. And then turn on the power supply to operate the wood engraving machine to move it back and forth to ensure that the woodworking machine can run normally before starting work.

2)Regularly check whether the screws of each part of the wood engraving machine are loose.

3)The woodworking engraving machine equipped with a water cooling spindle should ensure that the recycling water is clean and the water pump is working normally. Regularly replace the recycling water and prevent the water temperature from becoming too high.

4)Frequently clean the guide rails and sensors of the wood engraving machine to prevent dust, powder, and oil from affecting its sensitivity.

5) After use, move the cutting head of the wood engraving machine to the lower left or lower right position to prevent collisions. And then cut off the power. Pay attention that does not pull the plug when the power is on.

CONCLUSION

The above content takes you to understand the basic knowledge, buying guide, operation method, and maintenance guide of wood engraving machine in detail. It’s clear that CNC wood engraving machine occupies a large part of the market, and it will become more and more popular in the future. As one of the leaders in the CNC machine industry, Blue Elephant has professional knowledge and an excellent work team. If you have any needs, please contact us. We promise to give you the most professional advice.