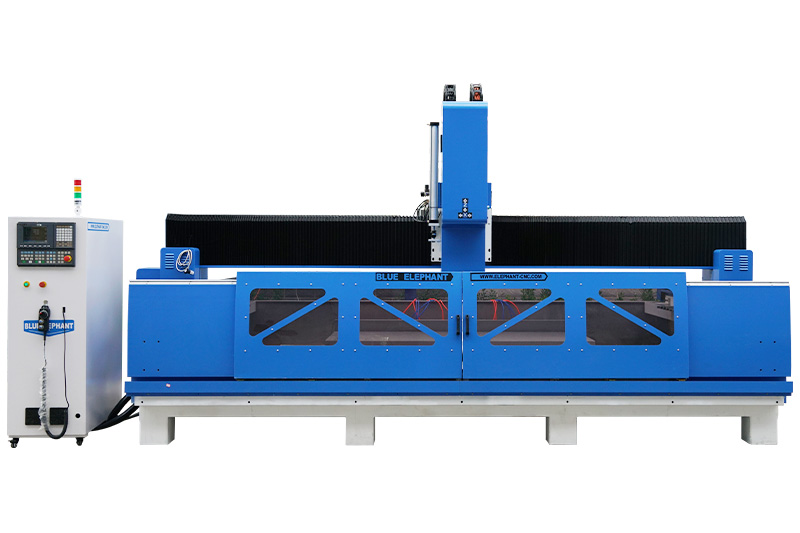

Stone CNC Machining Center

Blue Elephant: Your Reliable Stone CNC Machining Center Manufacturer

Blue Elephant stands out as a reliable stone CNC machining center manufacturer, offering advanced machines engineered for precision, strength, and durability. Our stone CNC machines are built to handle demanding materials like granite, marble, and quartz with ease, ensuring high-quality results for engraving, cutting, and shaping.

With strict quality control and user-friendly features, we meet the needs of custom workshops and industrial manufacturers. As a trusted CNC factory, we provide tailored solutions and professional support to help you streamline operations. Choose Blue Elephant for efficient, long-lasting stone CNC machining center performance.

Reduce Costs 30%, Increase Profits 42%

with Our CNC Machine.

Connect With Us

For any inquiries, don’t hesitate to contact us at:

- manager@elephant-cnc.com

- +86 186 6899 1371

Explore More via Video

Related Products

-

1228 Stone CNC Router with Horizontal Saw Spindle

Read more -

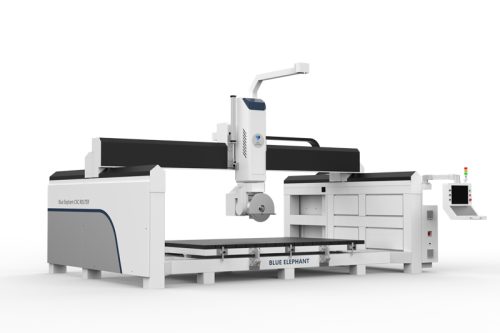

1325 5 Axis CNC Router for Sale

Read more -

KR 210 R2700-2 6 Axis Robot

Read more -

ES4-3220 4 Axis CNC Bridge Saw Machine

Read more -

ES5 5 Axis CNC Stone Bridge Saw Machine

Read more -

1530 EPS Foam CNC Engraving Machine

Read more -

1821 8 Spindles CNC Router with Rotary Devices

Read more -

1325 4 Axis ATC CNC Router with 4 Divisions T-slot & Vacuum Table

Read more

Customization Options

We offer custom stone CNC machines designed around your specific requirements. From enhanced cutting power to unique dimensions and branded details, Blue Elephant ensures every machine fits perfectly into your workflow and business identity.

Specs & Functions

CNC machines tailored in size, power, and system to meet your needs

Aesthetic Design

Custom colors and styling to enhance your brand identity

Branding Service

OEM solutions with your logo for market distinction

What Sets Blue Elephant Ahead

Superior Quality

100% inspection and 160 checks ensure precision and zero issues.

Cost Effectiveness

Efficient manufacturing meets ISO9001, SGS, CE, BV standards at competitive prices.

Precision Custom

Advanced CNC technology with yearly upgrades keeps products at the cutting edge.

Innovation Focus

Advanced CNC and annual upgrades ensure innovation and top performance.

Reliable Support

A dedicated 50+ team provides 24/7 pre-sales, installation, and maintenance support.

Global Reach

A 75,000㎡ modern factory supports direct sales, regional optimization, and fast delivery.

Certified Excellence

International certifications and over 8,000 satisfied users build trust and credibility.

Extended Warranty

A 12-month warranty, along with a 60-day trial, ensures lasting peace of mind.

Real-World CNC Solutions

Discover how businesses across industries overcome production challenges with Blue Elephant CNC solutions. From improving precision to enhancing efficiency, our machines help companies achieve their manufacturing goals.

America

Tile and Floor Processing

Customer Challenges

- Needed better equipment for high-quality product cuts.

- Concerned about installation and training support in the U.S.

- Wanted reliable after-sales service and simple machine setup.

Our Solution

- Strong U.S. after-sales support with on-site engineer service.

- Showed evidence of frequent engineer visits to U.S. clients and positive review.

- Offered flexible online support for quick troubleshooting.

- 5-Axis Bridge Saw ships mostly assembled; only sheet metal needs setup.

- Shared past U.S. efficient delivery and setup examples.

- Shared U.S. client positive reviews on setup and use.

Final Results

- Smooth delivery and installation of the 5-Axis Bridge Saw.

- Engineer provided door-to-door setup and training; customer satisfied.

- Customer praised machine quality and support; deal successful.

America

Kitchen Countertop and Wall Processing

Customer Challenges

- Switching to kitchen countertop and wall processing and have no experience.

- Unsure about the necessary machinery and specs.

- Limited budget, high cost performance required.

- The customer's workers had no experience in CNC.

Our Solution

- Recommended the 5+1 Bridge Saw, perfect for various materials.

- Demonstrate the actual cutting process through live video.

- Engineer installed machine door-to-door and guided customer first project.

- Establish an after-sales service group for 24/7 support.

Final Results

- Highly satisfied with the machine's quality and after-sales support.

- Daily output: 10 countertops; accuracy ±0.3mm.

- Labor costs are reduced by 30%, with 2 people replacing 4.

- The payback period is shortened from the expected 12 months to 6 months.

Saudi Arabia

Bathroom and Kitchen Furniture

Customer Challenges

- 30+ Years of experience in bathroom and tile work and expanding into kitchen and bathroom furniture.

- Needs suitable CNC, considering bridge cutting saws.

- Price sensitive, comparing 4 +1 and 5 +1 Bridge Saws.

- Seeks dependable suppliers for new operations.

Our Solution

- Recommended 4+1 Bridge Saw for efficient, budget-friendly work, and the customer does not need the bevel function.

- Explained galvanization of critical parts and use of antirust paint for others.

- Arranged customer agent’s visit to verify quality and reliability.

- Offered discount to encourage fast decision, highlighting value.

Final Results

- Customer chose the 4+1 Bridge Cutting Saw, suitable for their needs.

- Smooth process with clear communication.

- Customer confident in product quality and supplier partnership.

What Our Customers Say about Stone CNC Machining Center

US

5 Axis Bridge Saw

This CNC machine performs incredibly well with all types of stone. We've used it mainly for marble and quartz.

Clean cuts, stable operation, and very precise results make it a great addition to our workshop.

BRAZILIAN

5 Axis Bridge Saw

We've used this stone CNC machine for over five years now. It's highly dependable,

especially for engraving and carving stone. It runs consistently without issues and has improved our production speed and product quality significantly.

BRAZILIAN

3415 Stone CNC Machining Center

The machine easily handles hard materials like granite and marble. Setup was simple, and it operates smoothly.

We're really happy with the finish quality—it’s helped us offer more detailed, professional stonework to our clients.

Oman

5+1 CNC Bridge Saw

Thank you Blue Elephant for this nice machine. It’s easy to operate, and CNC after engineer is very helpful and quickly.

About Our Factory

15+ years in business as an industry leader

75000+㎡ high-level production base

25+ dedicated production bays

10+ technical service centers around the world

30+ locations worldwide

500+ employees for service you

8000+ clients' trust and recognition

Exported to 180+ countries and regions

Our Valued Certifications

Blue Elephant CNC machines comply with internationally recognized standards, holding certifications such as CE, ISO9001, BV, SGS, and TUV. Our strict quality control processes and precision engineering ensure high-performance, durable, and reliable solutions that meet the demands of global industries.

25 Ways to Make Money with Stone CNC Machining Center

- Wall skirt cutting

- Window sill processing

- Stair tread processing

- Washing table processing

- Island/bar customization

- Background wall carving

- Reception desk customization

- Kitchen countertop customization

- Bathroom countertop processing

- Commercial space desktop customization

- Elevator door cover/wall processing

- Chamfering and polishing of countertop edges

- Irregular shape cutting

- Souvenir stone carving

- Personalized pattern carving

- Artistic countertop carving

- Parquet/splicing processing

- Advertisement base processing

- Hospital/laboratory countertops

- Quartz stone drilling service

- Old countertop renovation service

- Small batch processing service

- Cabinet factory countertop processing

- Buddha shrine/shrine stone table carving

- Undertake building materials market processing

Frequently Asked Questions

Blue Elephant stone CNC machining centers can process a wide range of materials including granite, marble, quartz, limestone, artificial stone, and more. They are built for heavy-duty use and consistent performance across different hardness levels.

Industries like construction, interior design, monument production, furniture, art sculpture, and custom décor commonly use stone CNC machining centers. Blue Elephant serves all these sectors with customizable and efficient CNC solutions.

Yes, Blue Elephant offers flexible customization options. From working table size, spindle power, and tool configurations to automation features, each stone CNC machining center can be tailored to match your specific production goals.

Yes, Blue Elephant machines are designed with user-friendly controls and intuitive software. We also provide training, manuals, and technical support to help operators get started quickly and safely, even with minimal experience.

We offer comprehensive after-sales support, including online guidance, video tutorials, spare parts, and remote troubleshooting. Our technical team is always ready to help you maintain and operate your stone CNC machining center efficiently.

Explore Related Resources

Connect With Us

For any inquiries, don’t hesitate to contact us at:

- manager@elephant-cnc.com

- +86 186 6899 1371