In recent years, customized furniture has been recognized by more and more furniture producers and consumers not only for that it can satisfy the individualized and diversified processing needs of customers, but also to its convenient transportation and easy assembly.

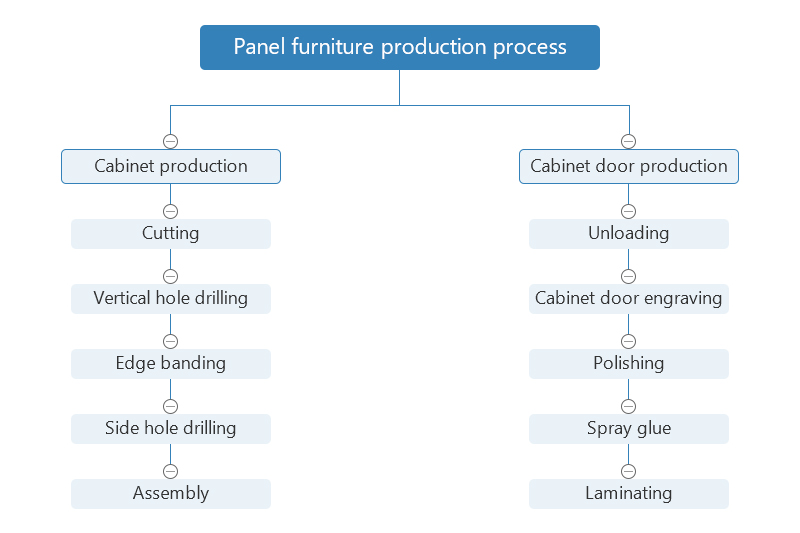

So what are the process for the panel furniture production?

The production of panel furniture is mainly divided into two parts: one is the production of customized wardrobe and cabinets, and the other is the production of customized wardrobe door and cabinet doors.

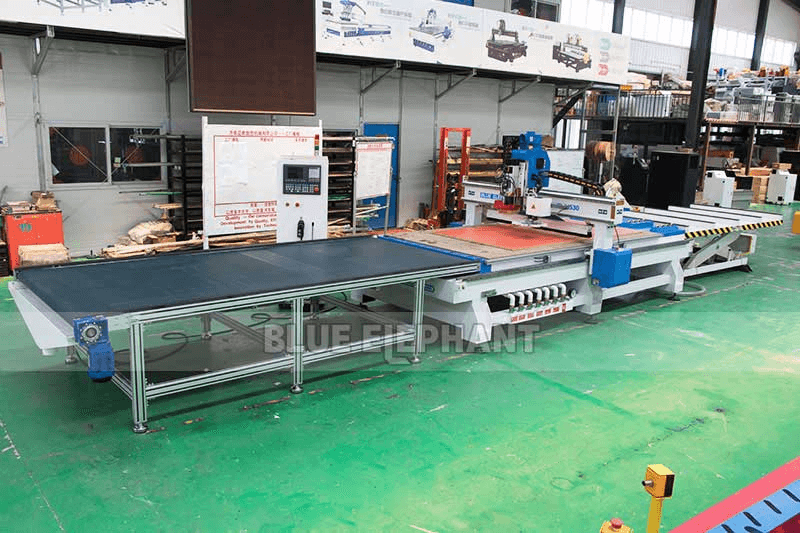

The main mechanical equipment used in custom closet cabinets include the cutting machine, edge banding machine and side hole drilling machine.

The main function of the cutting machine is the process of cutting, punching and grooving. Generally, it can realize easily the design of various cabinets by the design of intelligent software.

The main function of the edge banding machine is to seal the edge of the plate after cutting various shaped materials to make the processed plate more beautiful. And it mainly includes fully automatic edge banding machine, a semi-automatic edge banding machine and a manual edge banding machine depending on the main functions.

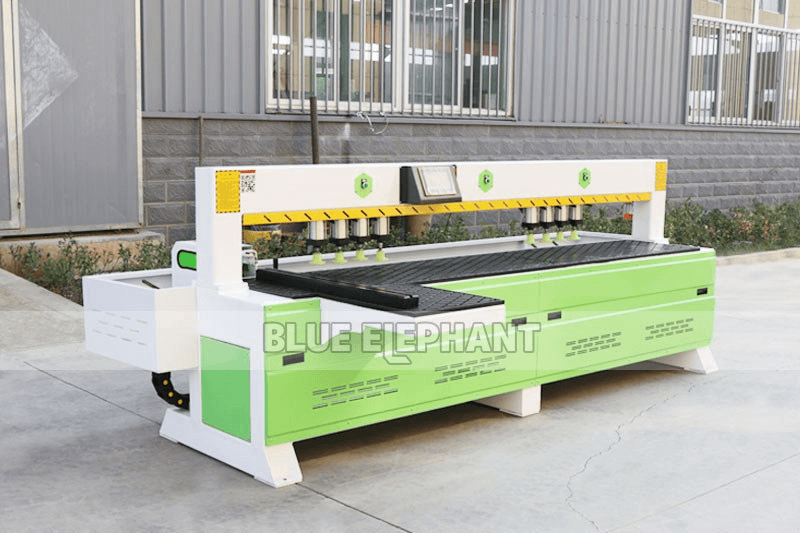

The main function of the side hole drilling machine is the side hole drilling function after the plate is cut, such as various alloy holes and wooden pin holes. According to different functions, there are two main types commonly found in the market such as fully automatic side hole drilling machine and portable side hole drilling machine.

The main equipment for customized closet door and cabinet doors also include the cutting machine. In addition, some factories also need polishing and grinding machines to make the processing more convenient and labor-saving. Moreover, after the finished plate is polished and grind, it can be placed in the vacuum press machine for vacuum coating after being dried by spraying glue. Finally, the final product is the wardrobe door that we often see with different patterns and beautiful appearance.

The above is the equipment needed to produce panel furniture production line, as well as a simple process. If you still want to know other aspects of the panel furniture production line. Please feel free to ask online or leave a message.