Table of Contents

In the wood processing industries, the factories often receive the orders of customizing the wood products with different patterns and various sizes. And some woodworking fanciers would like to design the graphics or letters that they create. On such occasions, a CNC wood router, or specifically, a wood design machine can meet their needs.

What is the wood design machine?

The wood design machine is actually a kind of CNC wood engraving machine under the CNC Router. CNC router includes the CNC wood engraving machine, advertising engraving machine, and stone engraving machine. The CNC wood engraving machine has numerical control technology to allow users to use the software within the computer to design as required. Therefore, the CNC wood engraving machine is also named as the wood design machine.

The wood design machine is specially designed for the engraving, hollowing, milling, and other processing of wooden doors, cabinet doors, solid wood doors, embossed doors, and craft wood products. It has fast engraving speed, high precision, large bearing capacity, and long service life. CNC woodworking engraving machine is must-choice equipment for the wood door industry, cabinet industry, furniture industry, and other industries.

Categories of the wood design machine

According to different applications, the wood design machine can be further subdivided into four types. They are respectively wooden door engraving machine, furniture engraving machine, handicraft engraving machine, and wood carving machine.

The wooden door engraving machine is specially used in the wood door, cabinet door, and closet door processing industry. The configuration of the wood engraving machine for doors is higher than the ordinary woodworking engraving machine. Because of the frequent loading and unloading, it is generally equipped with a vacuum adsorption table.

The furniture engraving machine is mainly used in the production of modern furniture, European style furniture, antique furniture, and office furniture. In order to improve processing efficiency, it is generally equipped with multiple spindle motors.

Wood furniture machine

Handicraft engraving machine can be called the relief engraving machine, and generally equipped with multiple spindles for processing. It can reduce costs and improves production efficiency.

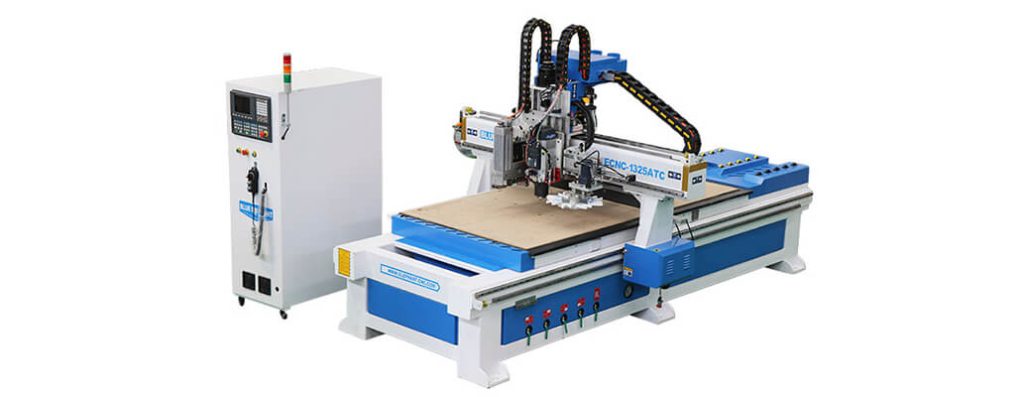

Finally, the wood carving machine is the wood engraving machine model 1325 with the standard configuration. Its internal configuration can be selected on the basis of the specific needs of users and is generally suitable for customers in the decoration industry.

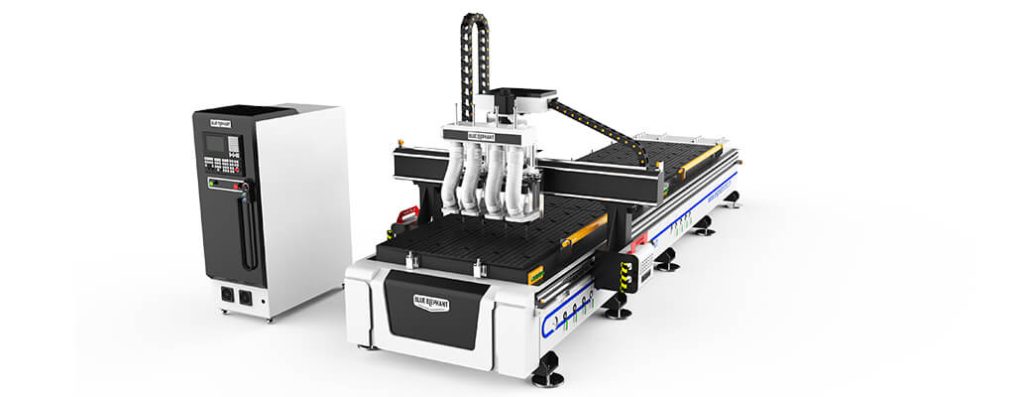

CNC Router 1325 Multi-process

Advantages of the wood design machine

1. Blue Elephant’s CNC wood router machine adopts the linear guide rail. The slider has the pre-tensioner, which can adjust if there is any clearance. And the machine frame owns high rigidity. The whole machine has good processing stability, high control accuracy, and very small machine vibration.

2. The CNC wood router is very suitable for wooden panel processing. For example, there are many users from woodworking furniture manufacturing, woodworking handicraft manufacturing, and advertising sign processing industries.

3. The CNC Router machine has a unique three-dimensional scanning system. It can quickly scan the shape of a complex template into an editable data curve.

4. Blue Elephant also manufactures the CNC Router machines with 4 axes or 5 axes CNC router kit system. Such a system allows the wood CNC machines to process four or five work-pieces at the same time. This is suitable for mass production and achieves fast and easy operation.

Wood design projects

As the name suggests, the wood design machine is mainly used for the CNC wood router projects. For example, there are the processing of various doors, windows, cabinets, craft wooden doors, paint-free doors, screens, craft fan windows, wave plate processing, and other furniture. It is not only suitable for many different kinds of CNC wood router projects. Additionally, the CNC wood router projects can also include the applications in the musical instrument industry, advertising industry, decoration industry, and the building model industry.

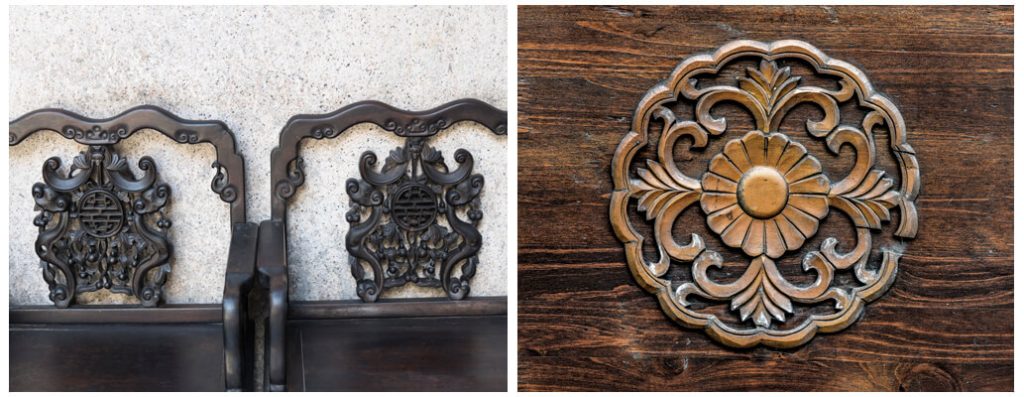

Wooden door and furniture decoration industry

The wood design machine is mainly used for the processing of solid wood and composite doors, and cabinet doors. It can also be used as the wood carving machine for large-size plate carving, solid wood carving and milling, panel furniture carving, antique mahogany furniture carving, and solid wood art mural carving.

The following introduces some common wood products needing CNC routers in this industry.

Cabinet and closet door processing

In the woodworking industry, the production of cabinets and closet doors is one of the most popular applications of CNC router. The manufacturers of wood cabinets prefer to use CNC wood engraving machines to reduce the costs and increase production quantity. In addition, these highly effective CNC routers are very popular in processing drawers, shelves, table boards in different sizes at the same time.

Chairs, sofa legs, and stair handrails

CNC wood design machine improves production time is are no longer limited to mold processing and plane engraving. Some factories are using CNC routers as a production method for manufacturing chairs of various designs. Due to the digital characteristics of the numerical control system, the current digital curve model of the chairs is designed by using computer software. The software supports the 3D format, which can be modified on the computer according to the woodworking processing needs of customers.

The CNC router is the numerical control technology instead of a traditional CNC machine. Therefore, the users can design the engraving curves and set up processing parameters of the chairs, sofa legs, and stair handrails. And then they can produce the shape as designed or as required by the customers. The use of the CNC wood design machine is more a creative and intelligent machining process for the engraving and cutting of the chairs. The CNC wood router also inspires manufacturers to create different kinds of shapes and designs.

Musical instrument production and processing industry

The CNC wood design machine owns the functions of the wood carving machine. Especially in the musical instrument industry, the wood carving machine equipped with the rotation axis to become a 3D wood carving machine. The users can operate the wood carving machine to carve the three-dimensional surface of musical instruments and complete shape cutting. For example, many manufacturers use the 3D wood carving machine to produce the front, scroll, and fingerboard of cello and violin.

Wooden crafts processing industry

Clock and watch frames, craft photo frames, thin aluminum plate crafts engraving, milling and engraving, electric appliance cabinet boards, sports goods.

Advertising and decoration industry

The CNC wood router can also be taken as the wood design cutting machine in the advertising industry. The users can design the cutting patterns to cut acrylic boards, aluminum-plastic panels, decorative materials, and MDF boards.

EVA processing industry

The wood design machine can cut and engrave EVA materials, such as, EVA material packaging tools, medical packaging, and electronic products.

What factors affect the wood design machine price?

The wood design machine price is influenced by a lot of factors. There are the price fluctuation of raw materials, different machine configurations, and different labor costs of the CNC router suppliers in different countries. What factors affect the CNC router cost mostly? The following introduces three important factors that affect the CNC wood design machine price.

Brand influence

The brand influence factor has a great influence on the wood design machine price. This is also due to the significant differences in the market competitiveness of different brands. The suppliers have accumulated a rich market experience for CNC wood router in the process of creating a brand. Therefore, it can more effectively guarantee product quality and performance, and provide consumers with better wood CNC machines and services. And customer satisfaction will be higher. Therefore, the quality and the added value of the CNC wood engraving machine have been rising. And the prices of the CNC Routers with well-known brands are also higher than that of ordinary CNC wood routers.

Configuration of the wood design machine

When the customer understands and prepares to purchase the wood design machine, the sales staff of the CNC router manufacturer will always provide different configuration schemes. There is a significant difference in the price of woodworking engraving machines with different models and configurations. Even for the CNC carving machine with similar functions, the prices of the wood routers with different configurations are also significantly different. This is also because different configurations mean the differences of materials, performance, design, and work efficiency of CNC Router. Therefore, it is normal to cause price differences. The following takes the different configurations of the important part, the motor, in the wood CNC machine as an example.

The motor is one of the indispensable parts of the CNC wood engraving machine. And the commonly used motors are mainly divided into stepper motors and servo motors. Both of then are widely used in many industrial processing workshops. The servo motor configuration is relatively more expensive than the stepper motor. The starting torque of the servo motor is very large, that is, it starts fast. The rated speed can be reached in a short time. It is suitable for frequent starts and stops conditions and the requirements of large starting torque. At the same time, the power of the servo motor can be relatively larger. The wood carving machine is usually equipped with the servo motor. The start of a stepper motor is relatively slow and has to go through a process from low to high frequency.

Differences in different purchasing methods

The customers may purchase the wood design machine or CNC wood router from different sales channels. The different sales channels will have an influence on the wood design machine price. With the development of technology, purchasing methods are becoming more and more diversified. In addition to traditional face-to-face procurement, purchasing a CNC wood router through various international network platforms has also become a popular trend. Especially under the current situation, it is unfeasible for international buyers to travel around the world. Online procurement has become an important trading method. And sometimes it is more favorable to buy from the supplier’s online store through the network than from local factories or through the trade agent. Because the network saves a part of the operating cost and service fee. This also provides a good channel and method for customers to purchase wood CNC wood routers.

In addition, different suppliers have different quotations on the wood engraving machine or wood carving machine with similar functions. The customers must first attach importance to the quality and service of the wood CNC machine. In this way, the buyers can operate the machine smoothly and achieve a high processing efficiency after purchasing. And it also guarantees the high-quality products made by the wood design machine.

When buying a wood design machine, what should you consider?

CNC wood design machines have various sizes, functions, and numbers of axes, as well as different quality and automation levels. If the buyers purchase a CNC router that suits their manufacturing needs for wood processing, they should consider the following four aspects.

Firstly, understand the requirements of the wood router project

First of all, the buyers need to make a clear assessment of current and future production needs to avoid buying too small working tables or too many machines. And then, they can ask themselves the following questions. For example, what parts and materials that they hope the CNC wood router produces. What are the size and complexity of the materials they will use? What level of accuracy do they need when manufacturing these parts and materials. And try to achieve a balance between speed, accuracy, flexibility, and price. In some cases, choosing a slower model may mean getting higher processing accuracy at a lower price.

By asking themselves these questions, the buyers can determine the performance and functionality required at the next stage.

Secondly, consider the appropriate wood CNC machine type

There are so many types of CNC wood routers on the market. The buyers need to consider to choose the model suitable for their daily manufacturing demands.

We have many years of experience in manufacturing and selling high-performance CNC wood router machine. And we have found that experienced customers usually consider the following factors before buying a wood CNC machine.

- The size, shape, and materials of the parts for CNC router processing.

- Production cycle and turnaround time, such as the small-batch and large batch processing.

- The size of the working space. For example, the size of the working space shall also match the size of the working table. And it also needs to consider the cycle of tool replacement.

- The length, width, height of the fixture, the number of parts produced in one cycle, and the number of operations in one setting

- Tool capacity, machine tool spindle power, and performance (engraving or cutting force)

- Compatibility with existing CAM software or other design programs

- The number of machining axes depends on the complexity of the work-piece to be manufactured.

- The adaptability of the cutting or engraving tool with the materials, and the service life of the tool.

And thirdly, consider the wood design machine price

The wood design machine price varies largely. Customers usually think that purchasing a good wood engraving machine is not a small investment.

When making the budget for the wood design machine, you need to consider the options you need. Most of CNC routers come with common options. If you have higher manufacturing requirements, there are other options and other costs.

You also need to weigh the pros and cons of price, quality, and production output. Lower-cost wood CNC machines may be easier to adapt from the start. But they may not provide the speed and performance that your business requires. Conversely, paying more for the features you don’t need may affect your bottom line. Therefore, the buyers could inquire and compare the wood design machine price and configuration from several suppliers. And then they can choose the CNC Router with the acceptable price and performance of the wood engraving machine.

Fourthly, Know the spare parts and maintenance costs

Usually, when the customers are selecting a CNC wood router, it is easy to overlook the components and parts and maintenance costs. When choosing the right wood engraving machine, the customers need also to calculate the life cycle cost of the investment.

The machine at a cheaper price may be more expensive throughout their service life. The reason is that the poorer quality of their machine parts may cause faults frequently, higher replacement, and repair cost. Frequent failure of the CNC Router can also frustrate the machine operators and owners. And it also leads to lost opportunities and reduces revenue.

Conclusion

In summary, with the wood design machine, you can make various designs on the computer and engrave, carve, and cut materials. The machine expands your business scope and improves machining quality. Blue Elephant manufactures the wood design machine and many other kinds of wood CNC machines. The supplying scope covers all series of CNC routers. We can also provide a high-quality CNC machine and processing solution according to the specific demand of customers.

If you would like to know more about the wood design machine, please contact us or leave a message.