CNC router machines have become one of the most commonly used CNC machines in the woodworking industry. Because it has high efficiency, good precision, and long service life. The CNC router machine is mainly for cutting, engraving, drilling, and pocketing a wide range of non-metal products as well as soft metals. For instance, wooden doors, cabinet doors, cabinets, beds, office furniture, advertising signs, letters, and foam, acrylic, and other materials.

If you find this article, you must have some questions and want to know more about CNC router machine. You may first check the table of contents to see if there is an answer you are interested in. Besides, if you are new to CNC woodworking machines and want to buy one, this article will help you a lot.

Table of Contents

- 1. How much does a CNC router cost?

- 2. What’s a CNC router controller

- 3. What software can a CNC router machine use?

- 4. Can I choose to DIY CNC router?

- 5. Is the used CNC router reliable?

- 6. How to choose CNC router bits?

- 7. What is the CCD CNC router machine?

- 8. What are Blue Elephant’s best-selling CNC routers?

You will have a clear understanding of the CNC router machine after figuring out the following 8 questions. These answers can be some of the basis for your choice and use of CNC routers for woodworking.

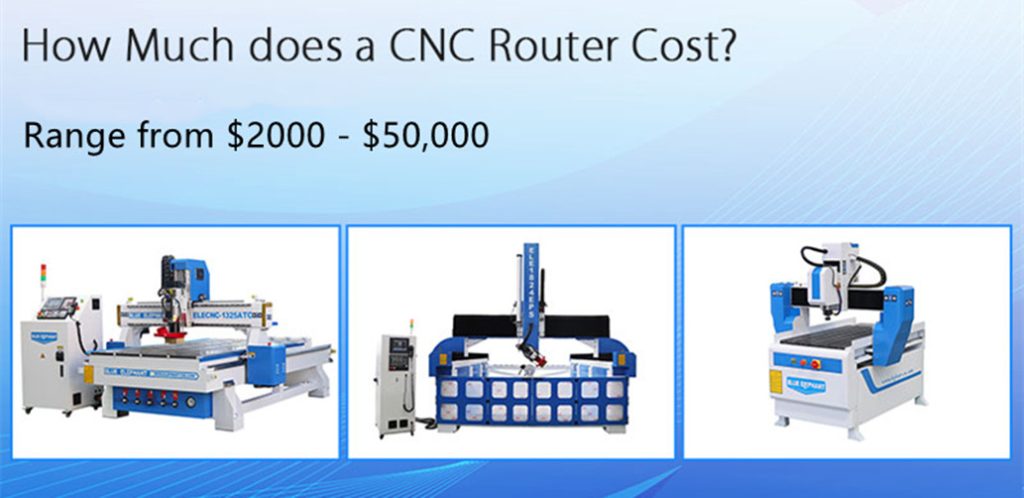

How much does a CNC router cost?

The prices of different models of CNC woodworking machines vary widely. The CNC router machine price ranges from $2,000 to $50,000 generally. I have written an article about the CNC Router Machine Price before. It gives an approximate price range for different types and uses of woodworking machines. Besides, it also briefly lists several factors that affect the CNC router machine price. Click the hyperlink to know more details.

Blue Elephant does not currently provide the desktop CNC router with a simple structure. For example, a desktop CNC router machine with a table area of 300x400mm or 300x180mm. You may spend only $500 or less to buy a desktop CNC router on some online shopping websites. That’s the reason why our CNC router machine price starts from thousands of US dollars.

All Blue Elephant’s CNC routers have a strong and rigid structure and can realize mass production. There are 6090 CNC routers for beginners and home use and also advanced 5 axis wood CNC machine for complex processing. Furthermore, we also have 4 axis and rotary axis CNC routers for woodworking with appropriate prices.

The factory cost of a common 3 axis 6090 CNC router machine is about $2700. And you need to pay more if you’d like to upgrade its configurations. The CNC router machine price of a 5 axis machine could reach $30,000 or more on average. It realizes much more functions than a home use 6090 CNC router machine.

Price ranges for different types of CNC machines

Therefore, it’s hard to give you a clear answer to the CNC router machine price immediately. I can only offer general prices ranges, as shown in the table below.

| Model | CNC router machine price range |

| 3 axis CNC router | $2500-$30,000 |

| 4 axis CNC router | $5000-$40,000 |

| 5 axis CNC router | $20,000-$60,000 |

Nonetheless, the prices ranges in the above are for reference only. The specific CNC router machine price is subjected to the quotation made by our salesperson after negotiation. This quotation is more accurate and includes the detailed price for each specification, instead of a general range.

This wood CNC machine for furniture production may cost you over $10,000. But it is worthwhile considering its high accuracy and good performance.

Factors affecting CNC router machine price

Various configurations

This is the most direct factor affecting the CNC router price. Everyone’s industry and processing needs are different. So everyone’s requirements for the CNC wood router are also distinct. In general, the more advanced the configuration, the more expensive the CNC wood router will be.

Increased international shipping fees

Anyone who has recently made an international trade knows that shipping costs fluctuate greatly. Recently, sea freight has risen a lot than before due to the global epidemic and various other factors. As a result, you may pay hundreds or thousands of dollars more than usual to buy a CNC wood router.

Fluctuating exchange rate

Our woodworking machines are billed in US dollars. Thus, fluctuations in international exchange rates will have an impact on the CNC router price if your currency is not USD. Generally speaking, exchange rate fluctuations are not too large. Therefore, its impact on the CNC router machine price will not be great.

Other fees

The other costs mentioned here refer to some operating costs. For example, maintenance costs, labor costs, software costs, training costs, and so on. Some of them may not be necessary according to the actual situation of different individuals. Although most of the parts of our machines are from well-known brands of good quality, there are bound to be various problems in daily use. Addressing these issues can sometimes add an expense to the production cost of the CNC router machine.

What is a CNC router controller?

All operations of a CNC router machine are under the control of a CNC router controller, or control system. The CNC router controller is like the human brain, receiving, processing, and transmitting various signals. In short, it gives orders to drive the CNC wood cutting machine to complete various tasks.

At present, the CNC router controller roughly falls into three categories: computer control, handle control and all-in-one machine control.

Computer control

This control method needs to install a control card on the computer motherboard. Besides, it requires installing the corresponding software driver on the computer to control the movement of all axes and the rotation of the spindle motor. You can preview the processing effect through the computer and see the processing track at any time. What’s more, you can correct any program loading error at any time on the computer.

The disadvantage is that you need a separate computer to connect the CNC router machine. But fortunately, the requirements for computer configuration are extremely low. A second-hand computer works fine for customers with tight budgets.

Common computer control system — NCstudio

NCstudio CNC router controller is one of the most widely used systems in the wood CNC machine at present. It has a user-friendly interface, simple and convenient operation, complete functions, and high program compatibility. Meanwhile, it can import various engraving CAM software directly or indirectly.

NCstudio’s greatest features and competitive advantages lie in its high speed, high precision, multitasking, network interconnection capability, and excellent user interface. It can realize three-dimensional dynamic tracking and display of tool processing paths. Moreover, the man-machine interface is easy to operate and intuitive, and it is convenient to find processing instruction files.

NCstudio CNC router controller system has complete G commands and PLT commands. The G instructions cover the complete G and M instruction sets. In addition, it also supports PLT format. So users can directly output PLT format files from AutoCAD software for processing.

Now NCstidio has launched various versions of different control software and hardware, including multi-axis linkage.

Handle control

Handle control refers to controlling the movement of the CNC wood engraving machine with a single handwheel. This control method saves space and does not need a computer. All functions are integrated into one control panel. So you may press the wrong function keys if you are not skilled in operation.

The handle CNC router controller is widely used in various CNC wood engraving machines (including four-axis linkage). Without a separate computer, it greatly reduces the footprint of the CNC router machine. And it is also more convenient to calibrate the cutter. However, there is no preview function and the interface is not as intuitive as the computer control system.

DSP CNC router controller

- The handle controller of the CNC wood carving machine is compatible with G codes generated by various CNC router software. For example, Type3, Artcam, Castmate, ProE, UG, Wentai, etc.

- You can use the handwheel offline without a computer to control the movement of the CNC router machine.

- There is a large memory space in the handle system, such as 128M which can be extended as required. The handle CNC router controller can save 9 processing files at the same time, and read and process arbitrarily.

- It adopts intelligent prediction algorithms to give full play to the potential of the motor. It can achieve high-speed continuous processing, synchronization of curves and straight lines, and smoother curves.

- The DSP control system has the ability to pre-check processing documents and prevent G code writing errors. It can also prevent the placement of materials beyond the processing range.

- With good self-diagnosis ability, it can diagnose input and output, parameters, pulses, return signals, etc. This can improve the ability of remote maintenance of the CNC router machine.

- It has a reliable power failure protection function and breakpoint recovery function.

All-in-one control system

With independent integrated design, the all-in-one control system uses the industrial computer, PLC and other integrated control modes. It has rich interfaces and complete functions and can realize multi-axis control and automatic tool change.

The integrated CNC router controller is mainly used for high-end CNC wood engraving machines and machining centers. Its anti-interference ability, as well as other aspects of performance and control accuracy, are superior to other control systems. So, this type of CNC router controller is relatively expensive compared with the above two types.

Common all-in-one control system — SYNTEC

SYNTEC CNC router controller is a completely independent control system. You can copy the created files to the CF card, then connect the CF card to the system through the interface. Or you can load the designs from the computer through the network program. SYNTEC control system can deal with complex machining paths.

Besides, as a closed-loop control system, it is suitable for servo systems. Therefore, it is mainly applied to large CNC router machines with servo motors. For instance, large mold CNC carving machines or ones with the automatic tool changing function.

The most widely used control system in the ATC CNC router is the Taiwan SYNTEC control system. 6MA and 6MA are the two most commonly used SYNTEC control system models in the CNC router machine. In addition, the upgraded FC-60WA model is also available. Other all-in-one control systems also include LNC, NCstudio, FANUC, etc.

Besides, as a closed-loop control system, it is suitable for servo systems. Therefore, it is mainly applied to large CNC router machines with servo motors. For instance, large mold CNC carving machines or ones with the automatic tool changing function.

The most widely used control system in the ATC CNC router is the Taiwan SYNTEC control system. 6MA and 6MA are the two most commonly used SYNTEC control system models in the CNC router machine. In addition, the upgraded FC-60WA model is also available. Other all-in-one control systems also include LNC, NCstudio, FANUC, etc.

This wood CNC machine adopts an LNC control system with a handwheel to control the machine’s operation. Click to see more operation instructions of the LNC control system.

What software can a CNC router machine use?

The CNC router software also plays an essential role in the operation of a CNC router machine. Because it turns our CNC router ideas into files and converts these files into signals. Thus, our CNC router machine can work based on these signals.

I’ve written a blog about the CNC router software. Click to read in case you are interested in it. I’ll introduce the CNC router software briefly below.

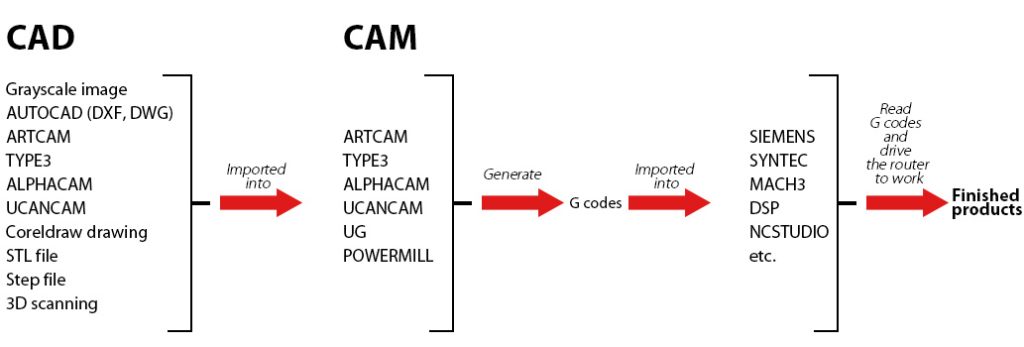

Generally, we divide the CNC router software into two types, CAD software and CAM software. There is now a type of CNC router software combining both the CAD and CAM functions. The CAD CNC router software stands for computer-aided design and turns your ideas into electronic files. CAM refers to computer-aided manufacturing, which converts the design files into a language that the machine can understand.

Therefore, the whole workflow of a CNC router machine can be summarized as the following chart:

Blue Elephant will provide certain CNC router software for free when you buy a CNC router machine. The software can be the English version. But you need to pay for the post-processors for 4 axis or 5 axis CNC machines. Alternatively, you can use your own CNC router software that is suitable for your work.

CNC router software that Blue Elephant offers includes AutoCAD (multiple versions), CAXA (multiple versions), Solidworks, Coreldraw, JD, Powermill, etc. Besides, we also provide ArtCAM, Ucancam, Type3, UG (NX), Pro/E, ZW 3D, AlphaCAM, and other software combining CAD and CAD functions.

Can I choose to DIY CNC router?

Nowadays, many people choose to DIY CNC router machine. Especially CNC machine hobbyists who like to create machines by hand.

DIY CNC router is fun

DIY CNC router machine has some benefits. For example, you will have a lot of fun and learn many CNC knowledge throughout the DIY process. Once a CNC machine is successfully completed, the sense of accomplishment and satisfaction you get from it is unparalleled.

DIY CNC router does not necessarily cheap

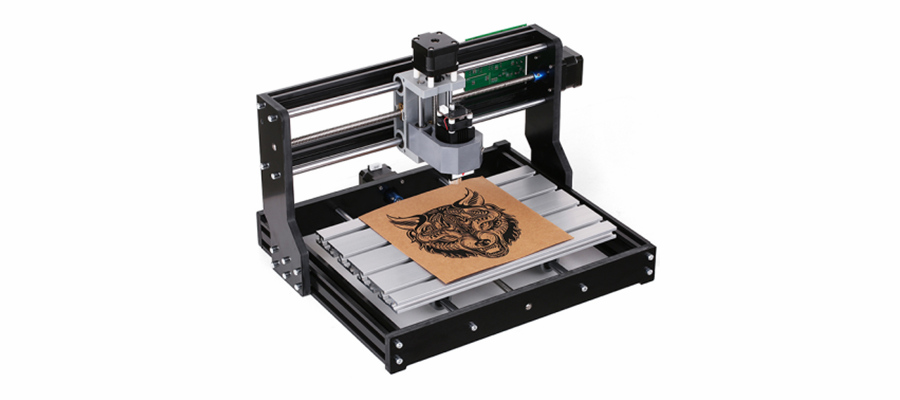

Many people may feel that DIY CNC router machine is cheaper than buying a complete one. But it’s not always the case. I think it is more suitable for DIY simple models. For example, a desktop CNC router machine with a small cutting area, or a machine made of MDF or plastic material with low precision. These DIY woodworking machines are difficult to do delicate work.

If you want to build a CNC router that is accurate with repeated positioning less than ±0.03mm, a DIY CNC router might not be cheap. For example, buying components can cost a fortune, especially stepper motors, linear slides, and frame materials. Because when you want a machine that’s precise and durable, these are three areas you shouldn’t ignore at all. You may regret in the future if you buy cheap parts due to inaccuracy or frequent downtime.

DIY CNC router consumes a lot of knowledge, time, and energy

Furthermore, building a CNC router machine requires certain CNC knowledge. So it may take much time to learn and build a CNC router for CNC beginners. Meanwhile, DIY CNC router needs plenty of time and energy. So building a CNC machine from scratch may not be a good choice if you need one urgently.

In addition, you will also encounter a lot of trouble in the process of DIY. The more precise the machine you want to build, the more precise the selection of spare parts should be. For instance, some surfaces appear to be flat, but they are not. You need to figure out a way to level it out. Similar things will appear many times in the process of DIY CNC router. So it’s not easy to build a CNC router machine from scratch.

When to choose DIY CNC router?

All in all, the answer to the question of whether to DIY CNC router is clear. If you are a CNC enthusiast and want to create machines, DIY CNC router is a great opportunity to exercise. Besides, it is also a good choice if you are not in a hurry to use it, or do not plan to use it to process precise parts.

However, building a CNC router machine from scratch is obviously not a good option when you own a factory or workshop. Especially for mass production of wooden furniture, big advertising signs, artworks, etc. Industrial CNC routers for woodworking can realize long-time and heavy-duty work with excellent precision and accuracy.

This hobby CNC router machine has a working area of 600x900mm, occupying a small floor area. You can put it in your garage, basement, tool house, or any small room. Its price is affordable. So, it is quite popular with individual users for home use. Besides, its major applications include cutting and engraving wooden and acrylic signs, letters, trays, characters, double-color boards, etc.

A Dutch client has bought three 6090 hobby CNC routers for his workshop and was satisfied with the process quality. Watch the following video to see what’s his opinion on this hobby CNC router.

Is the used CNC router reliable?

Many people choose to buy a used CNC router to save money. However, the low price may be the only advantage of the used CNC router machines. Because some used CNC router machines may look new on the outside but could have many problems in operation.

You are lucky if your seller is reliable and willing to tell you the actual conditions of the used CNC router. But what if the seller is reluctant to take responsibility when the used CNC router you bought is not as described? Thus, buying a second-hand CNC wood router could be risky.

We have also met many customers who purchased Blue Elephant used CNC machines. They encountered problems when using their CNC wood carving machines that their sellers couldn’t fix, or didn’t fix. So they found the original manufacturer, which is us. Generally, we will find a way to solve this situation. After all, he bought a machine from Blue Elephant. We will try out best to solve all problems whether you bought a brand new or a used CNC router.

But imagine that there is something wrong with the used CNC router you bought. While your seller refuses to fix and at the same time you can’t contact the manufacturer. What should you do now?

However, you will not have the above worries if you buy a new CNC woodworking machine. Especially buy from a good CNC machine manufacturer. Hence, I recommend buying a new CNC wood carving machine than a used one. But if you’ve decided to buy a used CNC machine, keep your eyes open and don’t blindly pursue low prices.

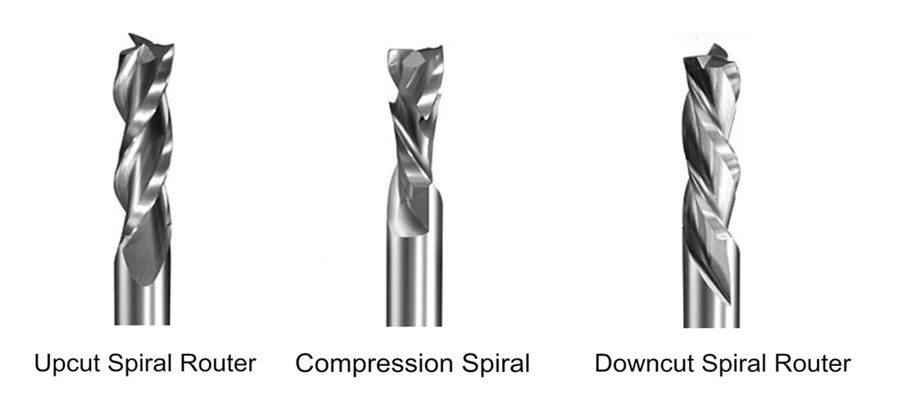

How to choose CNC router bits?

We all know that the cutting, engraving, milling and other work of a wood router machine are all realized by the bits. Choosing the right CNC router bits can help improve work efficiency and ensure processing results.

A previous article has already introduced the types of commonly used CNC router bits. Different tools can realize distinctive

Below are the different CNC router bits recommended for machining different materials. Of course, these are for reference only. The selection of specific CNC router bits shall be based on the actual processing situation.

1. Single-edged spiral cutter is recommended for acrylic cutting. Besides, a double-edged milling cutter or a cylindrical cutter can also be used to cut thin acrylic heets.

2. We recommend using dedicated single-edged aluminum CNC router bits for aluminum machining. Meanwhile, we can also use double-edged milling cutters for metal in case of low cutting requirements or hard aluminum sheets.

3. Round bottom CNC router bits are mainly for engraving relief patterns on non-metal materials.

4. Single- or double-edged spiral milling bits can be used to engrave softwood, MDF, original wood, PVC, and acrylic materials.

5. We can use tungsten steel-coated metal-specific single- or double-edged milling cutters and special flat-bottomed bits to engrave metals.

6. It is recommended to use straight groove milling cutters or double-edged large-flute milling cutters to process MDF, solid wood, multi-layer board and plywood.

7. Diamond engraving CNC router bits are a good choice for engraving and carving jade or other stone materials.

Why does the bit break?

Many customers happen to break CNC router bits during processing. This problem can appear due to several factors. You can check the machine step by step according to the following suggestions. Furthermore, you can focus on the relevant reasons to avoid tool breakage in the subsequent processing.

Processing program

As the instructions to operation, the processing program includes the position instruction and the speed instruction. They are the basis for the CNC engraving machine movement. So, whether the machining program is correct and reasonable directly affects whether the tool will break.

Machine itself

The CNC wood carving machine is the executor of the engraving process and also the provider of engraving power. Whether the CNC engraving machine is appropriate and whether the machine is in a proper state will influence the CNC router bits.

Clamping of tools

This is also an important factor that affects the operation of CNC router tools. For instance, improper clamping of tools may result in large radial ran-out. Besides, the tool may break if the length of the tool is too long.

Material

CNC router Tools may break if the processing materials have nonuniform hardness or impurities.

Surrounding environment

The working environment may also have an influence on the tool breakage. For example, the vibration source near the wood CNC machine will affect the processing state and lead to tool breakage. Besides, the unstable or excessive voltage could cause an abnormal working state of the machine, causing tool breakage.

What is the CCD CNC router machine used in the advertising industry?

The CCD CNC router machine engraving machine is also known as the automatic edge detecting CNC wood cutting machine. It is a CNC router machine specially developed for punching and cutting UV prints.

The CNC wood cutting machine with a CCD camera provides a complete solution for cutting special-shaped boards. With the popularization of UV printing equipment and the continuous transformation of the advertising industry, the application of UV panels, PVC, and KT boards has been continuously expanded. Therefore, the CCD CNC router machine has become essential equipment in the advertising industry for cutting panels with special-shaped images. It can greatly improve processing efficiency and save human labor.

The CCD CNC router machine can complete the cutting work with automatic edge detection. It can quickly cut the special-shaped patterns from the KT boards and PVC boards. Let’s watch the video below to see how the CCD camera works.

Compared with the ordinary 3 axis CNC router machine, this type of CNC wood router has a CCD camera. Therefore, it can do all the work that a 3 axis CNC router machine can do. In addition, the CCD camera can automatically identify the edge of the images and then cut along the edges. It is with fast positioning speed and high precision. That’s the reason why it is very popular in the advertising industry.

Features of CCD CNC router machine

- It can automatically generate the cutting path based on the patterns through the CCD system. This saves the time and workload of manual path making.

- The CCD CNC router machine can recognize and cut large-area graphics. One person can take care of multiple machines at the same time, which saves a lot of labor and is cost-effective.

- Support a variety of positioning methods, such as feature matching, two-point positioning, multi-template positioning, contour extraction, etc.

- It is able to complete graphic editing, typesetting, control, and export in a one-stop operation.

- Support multiple data formats: BMP, AL, PLT, DXF, DST, etc.

- It can cut printed images with high precision and rapid speed without missing or errors.

Application of CCD CNC router machine

The CCD CNC woodworking machine is the same as the ordinary wood CNC machine. It can cut wood, plastic,PVC, acrylic, polyethylene, plexiglass, etc.

The CCD router machine is widely used to cut or engrave UV, PVC, KT boards, and molds and templates in the advertising, decoration, construction and template industries.

What are Blue Elephant’s best-selling CNC routers?

Blue Elephant has been committed to the research and development and production of CNC machines for more than 10 years. More than 50,000 CNC routers for woodworking have been exported to more than 130 countries. There are also many customers who choose to buy multiple times.

According to the different functions that can be achieved, Blue Elephant provides 3-axis, 4-axis, rotary-axis, and 5-axis CNC woodworking machines. In terms of processing materials, we have wood CNC machines, stone CNC routers, styrofoam CNC machines, etc. Each type of CNC machine has different specifications and configurations. If you have special needs, we can also customize the CNC router machine according to your needs.

We will recommend the most suitable machine configuration for you according to your processing needs. For example, the number and power of spindles, motor drive power, table type and size. Besides, you can also add loading, unloading, or labeling platforms, rotating spindle, oscillating cutter, CCD camera, etc.

Nesting CNC router for furniture production

Various types of nesting CNC routers for woodworking are our flagship products. They can be equipped with multiple additional CNC router kits to complete a lot of processes for furniture production. You can choose these kits based on your own processing needs to realize the highest cost-performance ratio.

The nesting CNC machines are the best solutions for the mass production of wooden furniture. For example, cabinets, wardrobes, shelves, doors, beds, etc.

This nesting CNC router machine is also equipped with an HSD drill head and a saw blade spindle. The drill head comes with 9 different types of vertical drill bits, which can drill 9 types of vertical holes. The saw blade spindle can process the slotting of invisible connectors and three-in-one connectors. Panel furniture linked with invisible connectors has a better appearance and better stability.

These three automatic platforms are upgraded configurations that can greatly improve work efficiency. You can also choose the CNC wood cutting machine without them to save money.

Wondering how the three spindles work during operation? Check the following video.

Hobby CNC router for advertising use

The 1212 and 6090 CNC router machines are our best-selling hobby CNC machines. They are most popular with small businesses and woodworking enthusiasts. Because of their small size, simple operation, and most importantly, cost-effective.

All three axes of a hobby CNC router can adopt ball screw-driven mode. This ensures the high precision of the hobby CNC router. It can complete a lot of work, such as advertising signs engraving and cutting, relief engraving, acrylic letter cutting, toys, crafts manufacturing, etc.

Our hobby CNC router falls into two structures. One is the ground type shown in the above link. The other is the common structure. The biggest difference between the two structures is the position of electrical parts. Worktable of the ground type hobby CNC router machine is close to the ground, which is convenient to load and unload workpieces. But it has no room to install the electrical devices. So it usually has an independent control cabinet. However, the common hobby CNC router has more room under the worktable to install the electrical devices.

Words in the end

This article gives answers to the most asked 7 questions about the CNC router machine. It also simply recommends several best-selling CNC routers for woodworking. CNC woodworking machines are widely used in the woodworking industry. With so many brands on the market, choosing a suitable CNC machine manufacturer is never an easy task.

Don’t hesitate to contact us when you still have doubts about CNC router machine basics or want to know more about a certain machine. We are looking forward to your inquiry.