Aluminum and its alloy materials are one of the most common metal materials in life. And the aluminum CNC machine has therefore become the most commonly used equipment for CNC aluminum machining. Especially in the industrial field of batch processing, aluminum CNC machines have replaced manual aluminum machining tools.

The aluminum CNC machine can be divided into multiple categories. For example, CNC router for aluminum, waterjet cutting machine, plasma cutting aluminum machine, and aluminum laser cutting machine. Each type of CNC machine has its own advantages and applications in the CNC aluminum machining process.

This article briefly introduces you to the four types of aluminum CNC machines and their basic information. It also helps you choose a suitable one. If you are in hesitation, you can also look directly at the recommended machines at the end of this article.

Table of Contents

- Aluminum: CNC aluminum machining

- What can an aluminum CNC machine do?

- What does the aluminum CNC machine include?

- Advantages of using an aluminum CNC machine

- How much does an aluminum CNC machine cost?

- How to choose an aluminum CNC machine?

- How to buy an aluminum CNC machine?

- Ways to improve CNC aluminum cutting

- Aluminum CNC machine recommendation

- Words in the end

Aluminum: CNC aluminum machining

Before understanding aluminum CNC machines, let’s take a look at aluminum materials. Aluminum products can be seen everywhere, from aviation, automobile, equipment manufacturing, to household doors and windows, kitchen utensils, etc. Aluminum has extensive usage in all walks of life because its material properties make it highly workable.

Properties of aluminum material include:

- Lightweight

- High conductivity

- Reflectivity

- High ductility

- Weldable

- High strength to weight ratio

- Corrosion resistance

- Easy finish treatment

- Recyclable

In addition, aluminum is rich in reserves in the earth’s crust and has many advantages over other metals. Aluminum will still have an extremely wide application prospect in the future. For example, automakers are currently discussing the use of aluminum alloys to replace steel in large areas, thereby making cars lighter.

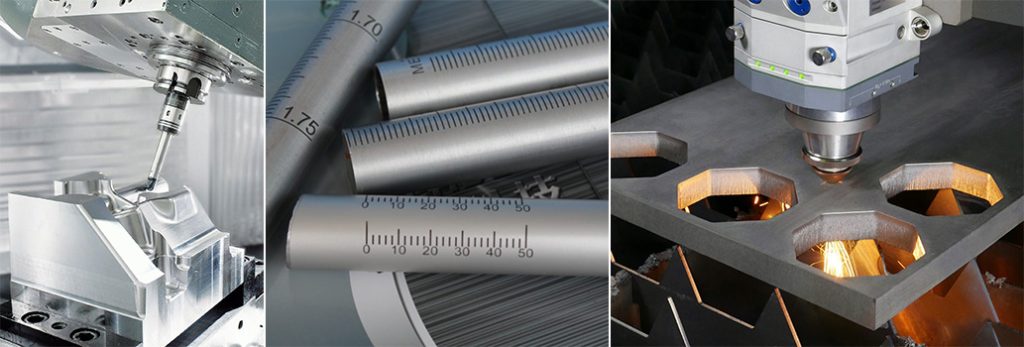

Correspondingly, the aluminum CNC machine has become more popular in CNC aluminum machining. The aluminium CNC machine can cut, engrave, turn, mill, pocket, face, and drill aluminum and its alloys quickly and effectively. The machining process is done automatically and controlled by a computer, avoiding human errors. It can improve the quality of aluminum products significantly.

What can an aluminum CNC machine do?

Aluminum materials have excellent machinability, so there are many processes for CNC aluminum machining. The aluminum CNC machine can realize multiple processing techniques, including cutting, engraving, milling, punching, etc. Let us briefly understand these processes.

CNC aluminum cutting

CNC aluminum cutting is the most basic and common processing method in the CNC aluminum machining process. Many aluminum products, especially mass-produced parts, are processed from a large aluminum plate. And then cut into individual parts by an aluminium CNC machine. Therefore, most aluminum CNC machines have the function of cutting aluminum sheets.

CNC milling

Milling operation is also one of the most common operations in CNC aluminum machining. This operation involves the rotation of multi-point cutting along its axis, while the workpiece remains stationary along its own axis.

CNC engraving and carving

The CNC engraving and carving refers to the process of using aluminum CNC machine tools to remove parts of the surface material of aluminum. A CNC router for aluminum can complete the engraving process accurately and quickly.

Marking

The CNC marking process leaves shallow marks on the aluminum surface. A marking CNC machine for marking can leave various marks on aluminum nameplates, parts, tools, etc. Even black marks. The commonly used aluminum CNC machine for marking is a fiber laser marking machine. It can mark not only aluminum materials but also aluminum alloys.

Drilling

This refers to the process of making a hole on aluminum sheets. The shapes may not only include circle holes or square holes.

Apart from the above processes, other aluminium CNC machine models can also realize pocketing, facing, turning, and other processes.

What does the aluminum CNC machine include?

As I mentioned above, there are many types of aluminum CNC machines to realize CNC aluminum parts machining. Its types include the CNC router for aluminium, plasma cutting aluminum machine, aluminum laser machine, waterjet cutting machine, etc. They can achieve multiple functions, such as aluminum cutting, engraving, marking, welding, and so on.

Blue Elephant provides multiple types of CNC machines to meet the aluminum machining demands of individuals and factories. I’ll simply introduce the aluminum CNC machines that Blue Elephant offers.

CNC router machine for aluminum

With dedicated CNC bits for aluminum, the CNC router machine for aluminum is capable of realizing multiple CNC aluminum machining processes. For instance, CNC aluminum cutting, engraving, drilling, and milling. Of course, besides aluminum, the CNC router for aluminum can also process wood, plastic, acrylic, and other materials.

The aluminum CNC machine has extensive use in aluminum window and door engraving, aluminum parts machining, 3D mold carving, CNC aluminum cutting, and other fields.

Based on the processing capacity, the aluminum CNC machine falls into the hobby type and industrial type machines. The hobby aluminium CN machine usually has a small working size, simple structure, and small power. So it is more suitable for CNC hobbyists or home use. The sizes of the hobby aluminium CNC machine can be 400*400mm, 600*600mm, and 600*900mm. However, the industrial ones are often in big size and good at heavy-duty and long-term CNC aluminum machining.

When divided by the number of working axes, the aluminum CNC machine can have 3 axis, 4 axis, and 5 axis models. A 3 axis CNC router machine can cut and engrave the top surface of an aluminum sheet. A 4 axis CNC router is capable of 2D and simple 3D engraving of aluminum parts. While a 5 axis CNC machining center can realize aluminum parts machining, 3D aluminum mold engraving, and other complicated work.

Basic parameters of CNC router for aluminum

| Model | ELE CNC router for aluminium |

| Types | 3 axis, 4 axis, 5 axis |

| Materials | Aluminum, aluminum alloy |

| Worktable size | 6090, 1325, 1530, 2040, 2060, customized |

| Functions | Cutting, engraving, carving, milling, pocketing |

| Capacity | 2D cutting, 3D carving, and engraving |

| Optional parts | Linear or carousel ATC, rotary device, auto loading and unloading |

| Price range | $2,000 -$100,000 |

Table 1 Basic Parameters of CNC Router for Aluminum

Although a CNC router can cut aluminum sheets, it only applies to thin sheets. The maximum cutting thickness for CNC router cutting aluminum is about 5mm. And the cutting efficiency and quality may decline when increasing the cutting thickness.

CNC bits for aluminum

CNC router cutting aluminum requires appropriate CNC bits for aluminum to conduct the CNC aluminium cutting and engraving. Aluminum materials belong to soft metal. So it means the CNC bits for aluminum will not be subjected to hard force during work. And the key is to keep the CNC bits sharp.

We usually use the dedicated single flute CNC bits for CNC router cutting aluminum sheets. Because it does not stick to the material during the cutting process, with fast speed and high efficiency. Besides, the 2 flutes or 3 flutes CNC bits for aluminum are also recommended to cut aluminum sheets.

As we all know, the softer the material, the high the cutting speed. The CNC aluminum machining has the feature of a high spindle rotating speed. Therefore, the aluminum CNC machine must make a balance between the high rotating speed and the slow feed speed.

As wearing parts, we suggest replacing the CNC bits for aluminum regularly to maintain good cutting accuracy and quality.

Aluminum laser cutting machine

The second type of aluminum CNC machine is a fiber laser cutting machine. Because laser cut aluminum sheet is also a common method of aluminum CNC machining. Aluminum is a highly reflective metal material with a low light absorption rate. In the past, laser cutting aluminum had certain technical limitations. However, as the technology develops, the current fiber laser machines can cut aluminum, brass, and other highly reflective metals easily.

The aluminum laser cutting machine can cut and engrave aluminum materials. But the processing thickness of the two processes is different. So the required laser power also varies. If you only need to engrave or mark aluminum plates, a low-power laser machine can achieve it. While if you need to cut a large number of aluminum sheets, you may need a larger laser power. Therefore, customers should choose the appropriate laser power according to the specific material thickness and other requirements.

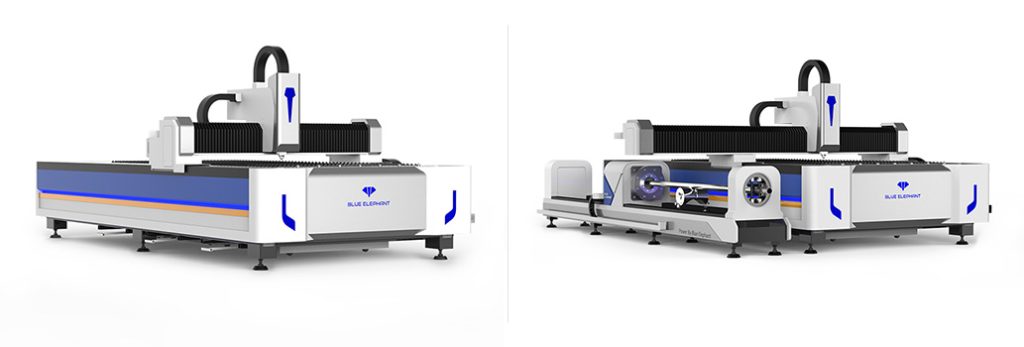

Blue Elephant offers many types of aluminum laser cutting machines. There are laser cutters with single functions of cutting aluminum sheets or pipes. And there are also dual-function laser cutters cutting both sheets and pipes. Meanwhile, we also provide upgraded options for aluminum parts machining companies with large production volumes. For example, exchange platforms, auto loading, and unloading equipment.

Cutting thickness

The cutting thicknesses of an aluminum sheet under different fiber laser power are shown in the table below.

| Laser power | Laser cut aluminum sheet thickness |

| 1000W | 3mm |

| 1500W | 4mm |

| 2000W | 5.5mm |

| 3000W | 7.5mm |

| 4000W | 10mm |

| 6000W | 12mm |

Table 2 Laser Cut Aluminum Sheet Thicknesses with Different Laser Power

It shows that the laser cut aluminum sheet thickness has a close relationship with the laser power. The greater the power, the greater the cutting thickness. In addition, the above values are theoretical numbers. During the specific operation, the cutting thickness may be different due to the different cutting conditions and the situation of the laser machine itself. Therefore, when cutting aluminum plates with the above thickness, it is recommended to select the next level of power. This can better ensure the cutting speed and quality.

Major models and parameters of aluminum laser cutting machine

| Brand | Blue Elephant aluminum laser cutting machine | ||||||

| Model | Sheet fiber laser cutter | Sheet and tube fiber laser cutter | Full cover fiber laser cutter | High precision fiber laser cutter | |||

| Work size | 1530/1540/1560/2040 | 1530/1540/1560/2040 | 1530/1540/2040/2560 | Small/medium/large | |||

| Laser power | 1kW-8kW | 1kW-8kW | 1kW – 20kW | 1kW – 20kW | |||

| Laser | Raycus/MAX/GW/IPG | ||||||

| Laser head | Raytools/Precitec/WSX | ||||||

| Options | Exchange platform Auto coil fed machine | Exchange platform | Exchange platform Auto loading & unloading device | / | |||

Table 3 Basic Aluminum Laser Cutting Machine Types and Parameters

Other laser aluminum CNC machines

Except for cutting and engraving, some other fiber laser machines can realize aluminum marking, welding, and cleaning. They are fiber laser marking machines, welding machines, and cleaning machines. The common features of these machines include small size, easy operation, and high cost performance.

Blue Elephant fiber aluminum marking machine can mark various letters, codes, and patterns on aluminum, aluminum alloy, and alumina materials. For example, aluminum nameplates, tools, tableware, medical equipment, crafts, etc. Optional laser power includes 30W, 50W, 80W, and 100W, etc. In addition, the fiber laser marking machine can also mark other metal materials and certain plastic materials.

Blue Elephant also offers an aluminum handheld fiber welding machine. It has high processing flexibility and high cost performance. This fiber welding machine can realize aluminum splicing welding, inside fillet welding, spot welding, etc. And the aluminum CNC machine is easy to operate, has high welding efficiency, and has little thermal influence. It is widely used in the CNC machining of aluminum.

An aluminum fiber laser cleaning machine is used to clean oil stains, attachments, oxide scale, rust, etc. on the surface of aluminum and aluminum alloys. This hand-held aluminum CNC machine for cleaning has high flexibility. So, the cleaning process has no grinding, non-contact, no thermal effect, and no damage to the raw materials.

All these small aluminum laser machines are suitable for home use or small workshops. They can realize small-scale mass production.

Aluminum CNC plasma cutting machine

The third type of aluminum CNC machine is CNC plasma cutting aluminum machine. Plasma cutting aluminum also has a wide range of applications in the metal cutting industry, especially for cutting thick sheets.

Plasma cutting aluminum is a fast, economical, and simple CNC aluminum cutting method.

Aluminum plasma cutting machines provided by Blue Elephant adopt gantry type and can meet industrial cutting needs. With the help of different auxiliary gases, the plasma cutter can cut metals that the oxygen cutting finds hard to cut. Besides, it can also cut highly reflective metals effectively and accurately, such as aluminum, copper, etc.

Many people think that plasma cutting aluminum may not get clean and precise cutting results. Of course, this is an outdated idea. Because plasma cutting technology has been greatly improved. The current plasma cutting provides not only excellent cutting results but also lower production costs.

However, compared to laser cutting aluminum, plasma cutting aluminum has lower accuracy. But it has a wider range of cutting thickness, lower machine costs, and lower operating costs.

Major parameters of plasma cutting machine

| Brand | Blue Elephant plasma aluminum CNC machine |

| Cutting method | Plasma technology |

| Worktable size | 4x8ft, 5x10ft, 6x10ft, customized |

| Voltage | 380V, 50Hz, 3P |

| Plasma current | 60A, optional |

| Cutting thickness | 2-100mm, depending on power and material |

| Cutting speed | 0-8000mm/min, depending on power and material |

Table 4 Basic Parameters of Aluminum CNC Plasma Cutting Machine

Auxiliary gases for cutting aluminum with plasma cutter

When cutting aluminum with plasma cutter, air or air + nitrogen will be selected as auxiliary gas in most cases. Because the air is the most cost-effective cutting gas. But it may leave a rougher cutting surface when cutting alumina. Therefore, when using plasma cutting aluminum, it is best to choose a suitable gas combination to achieve better cutting quality. For example, air & nitrogen, nitrogen & CO2, etc. These are relatively inexpensive options.

If your budget is sufficient, you can also choose a gas combination of H35 and N2. Using this gas combination to cut aluminum can obtain a larger cutting range, smoother cutting experience, and more vertical cutting edges.

Advantages of using an aluminum CNC machine

Compared with other processing methods, using an aluminum CNC machine for aluminum processing has many advantages. These characteristics are also the reason why they are gradually replacing other aluminum processing equipment.

- CNC aluminum machining is simple and reduces the processing steps. And it can process complex aluminum products without complicated tooling and fixtures.

- The aluminium CNC machine can guarantee processing quality, precision, and repeatability.

- Using an aluminum CNC machine can reduce the number of production equipment, machine adjustment, preparation time, and inspection processes. This can improve working efficiency greatly.

- An aluminum CNC machining center is able to process the complex faces that other common equipment cannot make.

- The aluminium CNC machine has strong adaptability to the processing object. Operators merely need to reprogram to process another workpiece, without any other complex adjustment. Thus it shortens the production preparation cycle.

How much does an aluminum CNC machine cost?

The aluminium CNC machine is available in many types, and the prices vary greatly as well. The aluminum CNC machine price is affected by multiple factors, depending on the specific machine type and configuration. For example, you may be able to buy a hobby aluminum engraving machine for only $2,000. While an industrial-grade aluminum laser cutting machine could cost you $20,000. The price can be ten times different.

Therefore, the price range in the following table is for reference only. The specific aluminum CNC machine price is subject to negotiation between you and the manufacturer.

| Machine type | Price range |

| CNC router for aluminum | $2,000 – $50,000 |

| Aluminum laser cutting machine | $17,000 – $90,000 |

| Aluminum laser marking machine | $3,000 – $5,000 |

| Aluminum laser cleaning machine | $5,000 – $25,000 |

| Aluminum laser welding machine | $5,000 – $20,000 |

| CNC plasma cutter | $5,000 – $30,000 |

Table 5 Aluminum CNC Machine Price Range

The above table only gives a general range of the aluminum CNC machine price. Even for the same type of machines, their prices can be several times different due to different specifications. In general, the higher configuration, the more expensive the aluminum CNC machine price. Similarly, the CNC machine with more functions and better cutting results has a higher price.

How to choose an aluminum CNC machine?

We have discussed three major types of aluminum CNC machines in the above text. But they have a lot of uncommon functions respectively. So it’s easy to choose among them.

The top consideration to choosing a CNC aluminum machine is to figure out your processing requirements.

When to choose a CNC router for aluminum?

Let’s assume that your work involves not only cutting and engraving aluminum but also wood, plastic, and other materials. The CNC router for aluminum is your first choice. Because it can perfectly meet your demands on both aluminum cutting and non-metal material cutting. At the same time, you need to choose appropriate CNC router bits for cutting aluminum and wooden boards. Then you can choose the appropriate model and configurations based on your own material size, thickness, etc. In case that you have a sufficient budget, you also have multiple upgraded options to choose from. For instance, auto loading and unloading platform, auto labeling equipment, linear or carousel ATC, aggregate head, drilling head, etc.

If you process complex and precise aluminum parts or models, the 5 axis aluminum parts machining center is your best choice. A five axis CNC machining center is an advanced CNC router working on 5 axes. It is good at CNC machining complicated curved and irregular surfaces.

When to choose a laser cutting machine?

Using CNC router cutting aluminum sheets for a long time is not an ideal choice. But laser cutting aluminum is. Let’s say you need to cut a large number of aluminum parts, and the accuracy requirements are high. I recommend you the aluminum laser cutting machine. The fiber laser aluminum CNC machine has advantages that other metal cutting machines cannot compare. With fast speed, high precision, and good cutting effect, it is the best choice for precision CNC aluminium cutting.

When to choose CNC plasma cutter?

Please consider a CNC plasma cutter when you cut aluminum sheets over 30mm thick but with less precision. Cutting aluminum with plasma cutter has wider cutting ranges, and it can cut metal sheets with a thickness of over 100mm. But as we mentioned before, its cutting precision is inferior to the fiber laser machine. If you are not on a tight budget, with appropriate argon hydrogen, you can also obtain good cutting edges.

Choose other aluminum CNC machine

It is easier to choose among the laser welding, marking, and cleaning machines. Because these small aluminum CNC machines have a relatively single function. When you need to weld aluminum sheets, choose the laser welding machine. And if you want to clean oil stains on the aluminum surface, select the laser cleaning machine. That’s so simple.

How to buy an aluminum CNC machine?

Although you have figured out the machine type, you still have other things to consider to buy an aluminum CNC machine.

Find a suitable CNC machine manufacturer.

It could be energy-consuming work to choose a suitable CNC aluminum machine manufacturer. You need to fully understand the manufacturer’s information from multiple channels. For example, you can browse the manufacturers’ website to see if it is properly organized. And check if their products are complete and website content is genuine. Big companies usually have a well-organized and formal website, showing their strength and capacities. Or, you can learn the manufacturer’s information from other industry users.

Negotiate and discuss with the manufacturer.

Negotiation is an indispensable process of buying any product. After you choose a suitable manufacturer, you need to discuss the details about the machine. All purchase information related to the aluminum CNC machine will be determined during this process. This includes inquiry, quotation, bargaining, and information about the machine price, delivery time, services, configurations, technical support, etc.

Place an order and sign a sales contract.

It would be best to sign a sales contract with the aluminum CNC machine manufacturer after settling all things down. The contract shall specify matters concerning the purchase of the CNC machine. For example, general and special terms and conditions, including detailed information about the machine, manufacturing time, delivery, price, services, etc. So signing a formal contract helps protect the rights and interests of both the buyer and the seller.

Stay in touch and wait for your machine.

After you placing an order, you need to keep in touch with the manufacturer to know the production progress. Due to different production capacities, the production cycle or delivery time may vary for different manufacturers. But qualified companies, like Blue Elephant, will try every effort to ensure their production and delivery. Besides, the whole production procedure will be under regular inspection and strict quality control. We also carry out debugging and testing runs to make sure the CNC machine can work well before being out of the factory.

Check the packaging to see if there is any damage once you received your machine. In case of damage, contact your manufacturer. Install and conduct test runs of the aluminum CNC machine to ensure it can work normally. For any questions or doubts in this process, be sure to ask the manufacturer for solutions.

Ways to improve CNC aluminum cutting

- Use high-quality aluminum and its alloy materials. And different aluminum materials are suitable for different products. So be sure to use the appropriate raw materials.

- Select materials without internal stress. A common method to eliminate internal stress is to use natural or artificial aging and vibration treatment. Afterward, cut the excess part in advance and continue processing after 1-2 hours of natural aging.

- Remember to choose the right CNC router bits. The material and geometric parameters of the bits had an important influence on the cutting results.

- Be sure to replace the worn or damaged CNC router bits on a regular basis. Because this could affect the CNC aluminum cutting and engraving.

- Use correct clamping method, appropriate feeding speed, spindle speed, and cutting depth.

- Maintain the aluminum CNC machine regularly to make sure it always stays in good condition.

Aluminum CNC machine recommendation

You can find the aluminum CNC router machine, laser machine, and plasma cutting machine introduced above on this website. Try to click on the above name to jump directly to the machine page. Alternatively, you can check the following recommended hot-selling aluminum CNC machine. These machines can meet your different needs for CNC aluminum machining.

CNC router for aluminum

This aluminum CNC machine can cut aluminum sheets with thickness less than 5mm and engrave patterns on the aluminum surfaces. Apart from aluminum sheets, the CNC router machine for aluminum is also good at processing various wood materials. It can carry 8 CNC router bits and can achieve 8 different processes. This aluminium CNC machine has wide applications in the cabinet, door, home furniture, office furniture, and other furniture industries.

The following video shows the working process of an aluminum CNC router with a working area of 2700*12000mm. It can cut and engrave thin aluminum sheets with smooth operation, clean edges, and good precision.

All you need to know is that we also provide CNC router for aluminum of other working sizes. Click the CNC Router column to know more sizes. Besides, you can also customize the CNC router specifications and configurations according to your specific demands.

Aluminum laser cutting machine

As a cost-effective laser CNC machine, it can realize two functions in one machine. The power for laser cutting aluminum can be chosen from 1kW to 20kW. Low-power models can meet most aluminum cutting requirements for small and medium factories. And high-power models can satisfy industrial and large volume laser cutting aluminum demands of big companies.

Here’s a video showing Blue Elephant aluminum laser cutting machine cutting 6mm thick aluminum sheet. The laser cutting machine can cut with high speed and accuracy.

In addition to the dual-use laser aluminum CNC machine, we also offer other models of laser cutting machines. For example, flatbed sheet fiber laser cutter, full cover fiber laser cutter, high-precision laser cutting machine. To know more details about the laser cutting machine, please click the FIBER LASER CUTTER column to see more.

CNC plasma cutting aluminum

Many metalworking factories select a CNC plasma cutting machine to develop their businesses. Especially those manufacturers who have not rigorous precision on their products, like the metal gate, screen, window, fence makers. Because compared with laser cutting machines, the plasma cutting aluminum has less precision and operation cost, but a larger thickness range.

To know more details about cutting aluminum with plasma cutter, please check the PLASMA CUTTERS page on this site.

Words in the end

Aluminum and aluminum alloy products will continue to grow rapidly not only in traditional applications but also in new areas. For example, aerospace, transportation, electronic power, construction, and other fields. In addition, aluminum products are also essential in daily life. Thus, the application of aluminum CNC machine will also grow in CNC aluminum cutting and machining.

This article introduces you to three types of aluminum CNC machines, which can realize a variety of aluminum machining processes. For instance, cutting, engraving, pocketing, drilling, cleaning, welding, marking, etc. Each type of aluminum CNC machine has distinctive characteristics and functions. Therefore, it is easy to choose among them.

You only need to make clear your detailed processing requirements before choosing the type of aluminium CNC machine. Blue Elephant provides the CNC router for aluminum, aluminum laser cutting machine, and plasma cutting machine. If you still have any doubt about selecting which type of aluminum CNC machine, feel free to CONTACT US. We can recommend one that can best suit your demands.