If you want a CNC router, do you prefer to buy a CNC router kit to DIY CNC router, or to buy a complete CNC router machine? Nowadays, the use of CNC router machines has taken up an increasing proportion in the modern woodworking industry. We all know that a CNC router machine is composed of a complete CNC router kit, which consists of various CNC router parts. The quality and service life of the CNC machine kit determines the quality and service life of the complete CNC engraving machine. Whether buying a complete CNC router or DIY CNC router, you need to choose the right CNC router kit and CNC router parts.

This article simply introduces the pros and cons of the major CNC router kit and the complete CNC router. It also offers an opinion on which one to choose and recommends two complete CNC router machines with outstanding CNC router kit.

Introduction of major CNC router kits

At present, many CNC machine manufacturers offer complete CNC router kit for DIY CNC router. When you want to DIY CNC router, you can buy a set of CNC router kit and assemble the CNC router parts according to instructions. Or, you can buy individual CNC router parts based on your requirements. CNC router beginners may have no idea about choosing what type of CNC machine kit or parts.

You may ask yourself a few questions before understanding the CNC router kit or CNC router parts. For example, what do you expect your CNC router to do? What’s your goal? This will lead you to the machine type and functions you need. In other words, you need to make sure that the CNC router kit you choose should meet your expectations. Let’s take a look at the major CNC router parts below.

Bed frame

The bed frame of the CNC engraving machine is the basic support of the entire machine tool. It is generally used to place other important CNC router kits, such as CNC router rails, gantry, spindle, motor, and CNC router table.

The CNC router bed frame should have higher static and dynamic stiffness, vibration resistance, and good thermal stability. So it can meet the requirements for high speed, precision, productivity, reliability, and a high degree of automation.

Currently, the bed falls into two types, seamless welded and cast iron. The welded bed is flexible and changeable, and the process is relatively simple and the price is moderate. The cast iron bed is less liable to deform, but its complicated casting process and special feature of the cast iron determine its higher price than the welded bed.

Movable worktable or movable gantry

The CNC router machine can equip a movable router table kit and a fixed gantry, or a movable gantry and a fixed router table kit. The latter one is the most commonly used model. Compared with the movable router table kit, although the movable gantry increases the driving power, it greatly increases the engraving precision and efficiency.

Spindle

A spindle is a CNC router kit used to carry the CNC router tools to do engraving, cutting and drilling work.

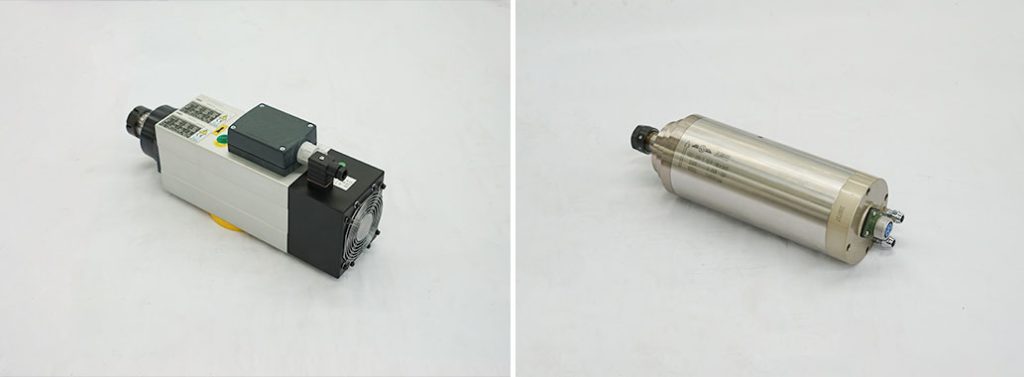

Air cooling or water cooling

Based on the cooling method, the CNC router spindle mainly has two types: water cooled spindle and air cooled spindle.

The water cooled spindle adopts water circulation to cool the heat generated after the spindle rotates at a high speed. This method will have a good cooling effect, because the temperature after circulation will not exceed 40℃. The air cooled spindle uses a fan to dissipate heat, and its effect is definitely not as good as the water cooled spindle.

Comparison between air cooled spindle and water cooled spindle

| Air cooled spindle | Water cooled spindle | |

| Cooling agent | Air | Water |

| Cooling effect | Good | Better than air cooled spindle |

| Noise | Large | Small |

| Torque | Large | Small |

| Precision | Good | Better than air cooled spindle |

| Price | Expensive | Cheap |

| Maintenance cost | Low | High |

| Service life | Short | Long |

| Usage | Requires a fan Easy to accumulate dust, requiring regular cleaning | Requires a water pump or chiller, and water pipes Easy to freeze under 0℃ |

From the above comparison, the air cooled and water cooled spindle have their respective pros and cons.

You can choose an air cooled spindle if you are looking for simple operation and convenient installation. The air cooled spindle is less affected by environmental factors and has a lower maintenance cost. However, the fan is prone to dust accumulation, affecting the accuracy of cutting and engraving, so it is necessary to clean the dust frequently.

For high-temperature work on solid wood, stone and soft metals, the water cooled spindle is your better CNC route kit choice. It has low noise, affordable price and excellent cooling effect. But if you live in a place of a high latitude, you need to reconsider the water cooled spindle. Because the water is easy to freeze when the temperature is below zero. This will affect the operation. Therefore, remember to add antifreeze to the cooling water when the temperature is below zero to prevent freezing.

ATC tool change spindle or ordinary spindle

Based on the tool changing method, the CNC router spindle falls into ATC to change spindle and ordinary spindle.

The ATC tool change spindle can be used with a linear tool magazine or a disc tool magazine. Such ATC tool change spindle can automatically change the required tools during the processing without stopping the operation. This greatly accelerates work efficiency and improves product quality.

The ordinary CNC router spindle can only change tools manually by stopping the CNC router machine. So the ordinary spindle CNC router kit is suitable for simple woodworking without many complex processes.

In case that your products include multiple engraving styles, the ATC tool change spindle is your best CNC router kit choice.

Small power spindle or high power spindle

The power of the CNC router spindle affects the processing effect. For most cutting processes, it is recommended to use a high-power spindle, which has a fast cutting speed and good effect.

For example, the four-process nesting CNC usually adopts two 6.0kW CNC router spindle in the middle and two 4.5kW ones on the left and right. Many can also equip a CNC router kit spindle of 9.0kW. However, if your work mainly involves surface engraving, the spindle of small power, like 2.2kW or 3.0kW, can meet your requirements.

Worktable

At present, the common router table kit falls into three types: aluminum T-slot CNC router table, full vacuum CNC router table, and T-slot vacuum CNC router table.

The aluminum T-slot router table kit uses high-quality aluminum, which is high-temperature resistant, oxidation and corrosion resistant. It is mainly used for materials that are not easy to be adsorbed, hollowed out, thicker or thinner materials, and special-shaped materials. It requires additional fixtures to position and fix the workpieces.

The full or T-slot vacuum CNC router table adopts high cost effective PVC material, having features of high hardness, high-temperature resistance, corrosion resistance and tiny deformation. It requires connecting to a vacuum pump. The full vacuum router table kit is suitable for processing a whole board. While the T-slot vacuum CNC router table has several zones and each zone can be controlled by a manual control value independently.

For choosing the right CNC router table kit, you can refer to a previous article CNC Router Table Complete Guide.

Transmission system

Most of the current CNC router machines use the following transmission mode:

Ball screw

Pinion and rack

The ball screw transmission mode is mainly used in small CNC routers, like 6090, 1212 CNC router, or the Z-axis of large CNC routers. It has features of low speed but high precision. However, when the travel is too long, the ball screw may vibrate affecting the engraving precision.

So the large CNC routers, like 4×8, 5×10 or above dimension, usually adopt the pinion and rack transmission method. It has features of large speed and stable performance. The rack falls into the linear type and helical type. The helical rack is adopted in most of the CNC router machines due to its larger contact area with the pinion, greater stability and lower noise.

Round rails or square rails

CNC router rails are also one of the important CNC router kits. There are two types of CNC router rails available at present: round rails and square rails.

| Pros | Cons | |

| Round CNC router rails | Low friction coefficient Low price Short production circle Simple installation | Ordinary bearing capacity Ordinary precision Low rigidity |

| Square CNC router rails | Uniform bearing capacity High precision Low friction resistance No idling skid | High price Requiring frequent lubrication High maintenance cost |

In conclusion, the square CNC router rails are better than the round ones in terms of friction resistance, bearing capacity and precision. So the price of the square CNC router rails is higher correspondingly. Certainly, the choice of CNC router rails relies on the customers’ processing materials and requirements.

Generally, the small CNC routers (6090, 6015, 1212, etc.) may adopt round CNC router rails, and the large CNC routers would choose square rials.

Motor

As a core CNC router kit, the motor plays an important role in the CNC router machining.

There are two types of CNC router motor: stepper motor and servo motor. The major differences between the stepper motor and servo motor lie in the control precision, frequency-torque characteristics, overload capacity and operating performance, and speed response performance.

| Stepper CNC router motor | Servo CNC router motor | |

| Advantages | Without losing step during work Up to 30% speed-up ratio Good cooling effect Smooth operation Small vibration Energy saving Low price | All advantages of the stepper motor Without losing step under great load High precision Fast progress |

| Disadvantages | Relatively small torque and small overload Low control precision Slow response of progress Loss of steps or stalls will occur during operation when the load is too large. | high price Only the matching driver can be used. |

Common CNC router motor brands

YASKAWA

Delta

Leadshine

YAKOTEC

Generally speaking, our CNC engraving machine mainly adopts the stepper motor. In case of high machining requirements and adequate budget, servo motor is definitely a better CNC router kit choice. Besides, the hybrid servo motor is also a good CNC router kit choice when you don’t want the stepper motor but have a limited budget.

Driver

The driver is the CNC router kit used to coordinate with the motor. The stepper motor shall equip a suitable stepper driver, while the servo motor shall equip a matching servo driver. Besides, the power of the driver shall also match the power of the selected motor.

The common brands of the driver include Delta and Fuling. What calls for special attention is that the stepper motor and the stepper driver can come from different brands, but the servo motor can only be used with the matching servo driver.

Inverter

As long as you use a CNC router spindle, there must be an inverter. As a necessary CNC router kit, the major function of the inverter is to regulate the speed of the spindle. The control system gives an analog voltage to control the output frequency of the inverter. Then it will change the rotating speed of the spindle motor, thereby the rotating speed of the spindle is changed.

The power of the inverter shall be greater than that of the spindle, in order to control the spindle speed effectively. Our CNC routers mainly use two brands of inverters. One is from Delta, which can coordinate with the HSD spindle. The other is from a Chinese brand Best, which can be used with the Chinese domestic spindle.

Control system

The control system is one of the core CNC router kits of a CNC wood router. It is like the brain and the whole mechanical part of the CNC wood router is like the body. To move the body to do the required work, it needs a clever brain. The mainstream control system at present includes the computer control system and handle control system.

The computer plays a major role in the computer-based control system. An operator shall program the path on the computer to connect the computer and the CNC router machine. And then the computer controls the machine to move along the given path. The computer-based control system includes Mach3, NCStudio, SYNTEC, SIEMENS, etc.

The handle control system also needs a computer. But the path programmed on the computer is saved into a storage device, like a USB. Then plug the storage device into the handle and use the handle to control the movement of the CNC wood router. The commonly used handle control system is DSP, for example, DSP A11, A15, B18, B58.

Introduction of complete CNC router

Some people may find it troublesome and time-consuming to purchase a CNC router kit or individual CNC router parts for assembly. Therefore, they prefer to make an inquiry to a CNC router manufacturer and buy a complete CNC router machine.

CNC router is the computer numerical controlled machine used to cut, engrave, carve or drill wood, plastic, stone, foam and other materials. CNC routers are available in many models and specifications. For instance, 3 axis CNC router, 4 axis CNC router, rotary axis CNC router, 5 axis CNC router, nesting CNC, stone CNC router, foam CNC router, etc. All the CNC engraving machines contain the above-mentioned major CNC router kits or CNC router parts of different brands, types and power.

Advantages of CNC routers

Although with different configurations and functions, they all have the following 5 advantages:

High efficiency and precision

One of the major advantages of the CNC wood router is to perform precise cutting and engraving with high efficiency. Compared with manual woodworking equipment, the high-level automation of CNC routers makes the difficult cutting and engraving work easier and more precise.

Outstanding repeatability

A CNC wood engraving machine can route the exact same thing over and over again with speed and accuracy, saving time and money by reducing waste and expediting work. It is quite suitable for mass production due to its outstanding repeatability.

Multiple functions and applications

CNC router machines can not only cut and engrave materials, they can also drill, pocket, route and groove. In addition, CNC routers can process multiple materials and have wide applications in various industries.

Ease of operation

The wood CNC router can complete most of the work automatically, minimizing manual operation. This also ensures more safe working conditions for the operators.

Reduced labor cost

One operator can work with one or two CNC router machines at the same time because of its simple and automated operation. This saves an amount of money for the factory.

Pros and cons of buying a CNC router kit

Pros

You can choose the CNC router kit according to your specific machining requirements. You don’t have to pay for the functions that you don’t need.

It can save an amount of money to buy the CNC router kit instead of a complete machine.

Assembling the CNC router kit and debugging the DIY CNC router can really exercise your hands-on ability.

After completing the DIY CNC router, you can obtain a strong sense of satisfaction and accomplishment.

Cons

It requires you to conceive and design a machine model or type first. This requires you to be very familiar with the CNC machine, which is quite difficult for beginners.

It will take much time and energy to pick, buy and assemble all the necessary CNC kit you need.

Except for the CNC router kit, you should also buy other small auxiliary parts or tools, like wire, connectors, bolts, nuts, etc.

Assembling all the CNC router kit or CNC router parts also requires certain technical knowledge and skills.

The DIY CNC router may only in small sizes, like 3040, 3018, 6090, 1212, etc. and have simple functions. It can’t realize heavy-duty or long-term cutting and engraving work.

Pros and cons of buying a complete CNC router

Pros

The complete CNC router machines with heavy-duty configurations can achieve large scale, long-term and high-strength work.

A specially assigned person will answer all your questions before buying a complete machine. He/she can also introduce and recommend the CNC router kits that meet your specific demands.

You can tell all your requirements to the CNC machine manufacturer instead of conceiving and designing the machine personally. So you can buy all the CNC router kit and also other auxiliary CNC router parts at one stop.

Signing a purchase contract with the CNC machine manufacturer can better protect your rights and interests.

The complete CNC wood router has already been installed, debugged and tested before leaving the factory. You just need to assemble the machine simply after receiving it.

The complete after-sales service can solve all your problems encountered in the course of using the complete wood CNC router.

Cons

It may cost much than buying a CNC router kit.

The complete CNC router machine may have some functions that you don’t use often.

If you buy from an overseas CNC machine manufacturer, you also need to pay additional shipping costs, customs fees, etc. Besides, this requires a long time for production and shipment.

In case of an unreliable CNC machine manufacturer, you’ll get a poor-quality product and may find it difficult to safeguard your rights. Therefore, it’s necessary to spend time and energy to find a right CNC machine manufacturer.

Which one to choose, CNC router kit or CNC router?

As I mentioned above, both buying a CNC router kit or a complete CNC machine have respective advantages and shortcomings. But in my opinion, buying a complete machine has more benefits than buying a CNC router kit.

If you don’t mind the troublesome, have enough time and technical knowledge, and are willing to DIY CNC router, buying the CNC router kit could be a good choice. It can exercise your design ability and hands-on capacity in the processing of assembling the CNC router parts. At the same time, this may save you an amount of money.

Buying a CNC router kit and assembling the CNC router parts personally may only apply to small size or simple structure machines. Therefore, if you are a hobbyist or just want to DIY CNC router for home uses, buying CNC router kits can be enough to meet your demands.

However, if you own a factory or a workshop engaging in mass production, a complete CNC router machine could be your best choice. The complete machine has a strict production and testing process to ensure its good quality and stable operation. Even if you’re a large furniture making company with high output, the CNC router machine can realize the long-term, heavy-duty, and high strength cutting work. The complete CNC router machine is available in various specifications, and allows customization according to your needs.

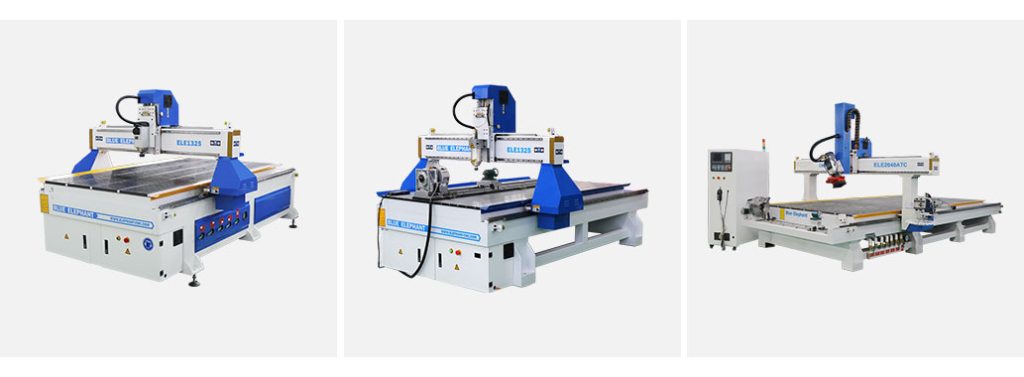

Recommendation of complete CNC engraving machine

The CNC router table size is 1500x3000mm, which is about 5ft x 10ft. This router table size is suitable for processing common wood panels of 1220x2440mm. Other CNC machine kit, including auto lubrication system, cast iron bed frame, SYNTEC 21MA control system and auto tool sensor, also helps upgrade this CNC router machine. With high performance CNC router kit, it has wide applications in wooden furniture, decoration, molding, craft and other industries.

There are also other CNC router parts of good quality, for example, heavy-duty welded steel tube frame, auto lubrication system, square CNC router rails, helical rack, etc. The CNC router kit 4×8 ensures excellent performance, stable operation and reliable processing of the CNC router machine. The rotary device CNC machine kit is quite suitable for engraving cylindrical parts, like columns, pillars, handrails, 3D statues, etc.

Conclusion

Both buying CNC router kits or a complete CNC machine have own advantages and shortcomings. It’s hard to tell which one is absolutely better, but they tends to apply to different customers. Nowadays, an increasing number of industry users choose to buy a complete wood CNC router. Because it’s more convenient and energy-saving, and can include all the CNC router kit or CNC router parts you prefer.

But if you just use the CNC router for hobby or making things at home instead of mass production, you can choose to buy a CNC router kit. Assembling the CNC router kit one by one can also be a very pleasant and rewarding process.

As a professional CNC router manufacturer, Blue Elephant also provides many other CNC router machines with high-quality CNC router kit. We can also select the CNC router kit for your CNC engraving machine based on your personal requirements. If you feel confused about choosing which CNC router parts, you can contact us. We will assign a professional salesperson to solve all your confusion and recommend a wood engraving machine with the CNC router kit that suits your demands best.