Wood CNC machines offer many advantages over traditional manual cutting methods for woodworking. Wood CNC machines come in various sizes, from small tabletop models for hobbyists to large industrial-grade machines used in the furniture manufacturing industry. They can also use different cutting tools, including router bits, drills, and saw blades, to achieve different effects on the wood material. With the help of computer-aided design (CAD) software and computer numerical control (CNC) technology, wood CNC machines can produce complex designs and patterns quickly and accurately. Next, I will take you through a comprehensive understanding the features, size, and price ot woodworking CNC machine, and the business you can use it for.

What kind of wood can be used with a CNC router?

A CNC router can be used with a wide range of woods, including hardwoods, softwoods, and engineered woods. Here are some examples of woods commonly used with CNC routers:

Hardwoods

Hardwoods such as oak, maple, mahogany, cherry, ash, hickory, birch, teak, and walnut are popular choices for CNC routing because they are strong and durable, and they have attractive grain patterns.

Softwoods

Softwoods such as pine, cedar, fir, redwood, cypress, and spruce are also commonly used with CNC routers. They are generally less dense and weaker than hardwoods, but they are often more affordable and easier to work with.

Engineered woods

Engineered woods, such as plywood, MDF, particleboard, OSB, LVL, are also commonly used with CNC routers. These materials are made from wood fibers or particles that are glued together, and they are often used in furniture manufacturing.

What are the different types of wood CNC routers?

3 Axis CNC Router

A 3 axis CNC wood router operates along three axes: X, Y, and Z. The X-axis runs from left to right, the Y-axis runs from front to back, and the Z-axis runs up and down. It is typically consists of a cutting spindle, a bed or table where the material is placed, a gantry or frame that moves the spindle along the X and Y-axis, and a vertical column that moves the spindle along the Z-axis. The machine is controlled by a computer and uses specialized software to execute the cutting, carving, or drilling tasks. And it can create 2D and 3D designs on a wide range of materials like wood, acrylic, PVC, and foam.

4 Axis CNC Router

In addition to the three axes of the 3 axis CNC router, the 4 axis CNC wood cutting machine also includes a rotary axis which can rotate 180 degrees. This allows for the creation of more complex shapes and designs, such as those needed for curved surfaces, columns, or spirals. Furthermore, it can also increase production efficiency by reducing the need for manual repositioning of the material.

5 Axis CNC Router

The 5-axis router adds two more axes of movement, typically referred to as A axis and B axis. The A-axis rotates the cutting tool around the material, and the B-axis tilts the cutting tool at an angle. This allows for even greater flexibility and precision, as the machine can work on more complex shapes and contours in 3D CNC objects.

Multi-head CNC Router

A multi-head CNC router has multiple cutting spindles or heads, typically 2-8, that can work simultaneously or independently. Each spindle can be equipped with a different cutting tool, allowing for different types of cuts or carvings to be performed on the same material at the same time. Therefore, it reduces setup time and increase the variety of cuts that can be performed on a single piece of material.

Rotary Axis CNC Router

This type of CNC router machine is typically used for three-dimensional carving or engraving applications, where the material being machined needs to be rotated along an axis while being cut. The rotary axis can rotate the material in any direction, allowing for complex shapes to be created.

What is the best CNC router for small shops?

Blue Elephant hobby CNC router is a versatile and affordable wood carving machine that is perfect for small shops. Hobby CNC router is also known as small CNC router, mini CNC router, and desktop CNC router. It is a smaller version of a full-sized CNC router and is ideal for small-scale projects, hobbyists, and home workshops.

Hobby CNC router has small footprint, making it easy to fit in tight spaces. At the same time, they are also easy to use and comes with a variety of advanced features, including vacuum adsorption and a touch-screen interface. In addition, it comes in different sizes, such as desktop 2×3 CNC router and 4×4 hobby CNC router. Moreover, you can also customize a small working area according to your specific requirements like 1310 mini CNC router or 3018 small CNC router.

What kind of software is needed to operate a wood CNC router?

To operate a wood CNC router, you will need two types of software: CAD (Computer-Aided Design) software and CAM (Computer-Aided Manufacturing) software.

CAD software

This type of software is used to design the part or component you want to create. You can use CAD software to create a 2D or 3D model of the part or component, which can then be exported as a file format that can be read by the CAM software. There are many different CAD software options available, including free and paid options.

Some popular CAD software options for woodworking include SketchUp, Fusion 360, and SolidWorks.

CAM software

This type of software is used to create toolpaths that will guide the CNC router in cutting the part or component. CAM software takes the 2D or 3D model created in the CAD software and generates the toolpaths needed to cut the part or component. CAM software is typically specific to the CNC router being used and may be included with the router or purchased separately.

Popular CAM software options for CNC routers include Vectric Aspire, ArtCAM, and BobCAD-CAM.

Best selling CNC wood projects to make money

Wooden signs

Customized wooden signs are always popular, especially for weddings, events, and home decor.

Wall art

Unique and eye-catching wall art can be created with a CNC router. Designs can range from simple patterns to intricate, detailed designs.

Picture frames

Customized picture frames are a popular item for displaying photos and artwork.

Coasters

Personalized coasters make great gifts for any occasion. They can be engraved with names, dates, or designs.

Clock

A CNC wood clock is a clock made from wood that has been cut and shaped using a CNC machine. CNC wood clocks can be a beautiful and unique addition to any home, and they can also make great gifts for friends and family.

Lamp

Wood lamps are often used as decorative pieces in homes or offices, adding a natural and warm element to a space. They come in a variety of styles and designs, from simple and minimalistic to ornate and decorative. They can be made from a variety of woods, such as oak, walnut, birch, or maple, and finished with different stains or paints to match the decor of a room.

Guitar

The top of the guitar, or soundboard, is usually made of spruce, which is a common choice due to its strength and tonal qualities. The back and sides of the guitar may be made of mahogany or rosewood, which are known for their warm and rich sound. The neck and fretboard are typically made of maple, which is a dense and durable wood that provides a smooth surface for playing.

Sculpture

A wood sculpture is a three-dimensional artwork created by carving or shapingwood. The wood can be left natural or finished with stains, paints, or varnishes to enhance its color and texture. Some wood sculptures are also assembled from multiple pieces of wood or combined with other materials, such as metal or glass. Wood sculptures can be representational or abstract, with subject matter ranging from figures and animals to landscapes and abstract shapes. They can be displayed indoors or outdoors and are often used as decorative pieces in homes, gardens, or public spaces.

Jewelry

Jewelry pieces such as earrings, pendants, and bracelets can be created using CNC woodworking techniques.

Wooden toys

Wooden toys are timeless and can be created in a variety of designs, such as puzzles, blocks, and cars.

Furniture

Customized furniture pieces such as tables, chairs, and shelves can be created using CNC woodworking techniques.

Home decor items

Home decor items such as vases, candle holders, and decorative boxes can be created using a CNC router.

What are the advantages of using a CNC router machine for Woodworking over traditional woodworking tools?

Precision

A wood CNC router can make precise cuts and shapes with a high degree of accuracy, which is difficult to achieve with traditional woodworking tools. This precision is particularly important when creating intricate or complex designs.

Speed

A wood CNC router can work much faster than traditional woodworking tools, which can save time and increase productivity. This is particularly important for large-scale production runs.

Consistency

A wood CNC router can produce identical parts or components with a high degree of consistency, which is difficult to achieve with traditional woodworking tools. This consistency is particularly important when creating products that need to fit together precisely.

Automation

A wood CNC router can be programmed to perform a variety of tasks automatically, which can save time and reduce the need for manual labor. This is particularly important for repetitive tasks or for creating large quantities of parts or components.

Versatility

A wood CNC router can work with a variety of materials, including wood, plastics, and metals, which makes it a versatile tool for many different applications. This versatility allows woodworkers to create a wider range of products and designs.

What is the maximum size of wood that a CNC router can handle?

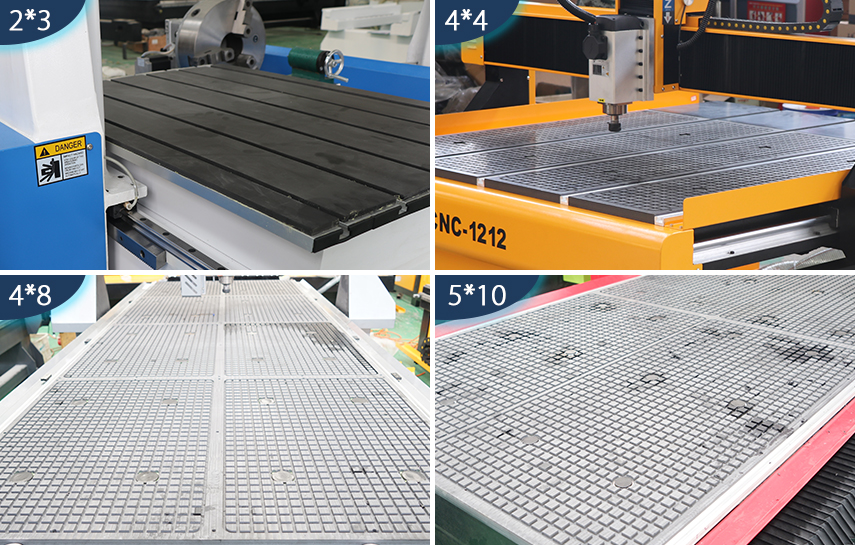

CNC router table sizes can vary widely depending on the type and model of the machine. Generally speaking, CNC routers come in three main categories based on their bed size: desktop, hobbyist, and industrial.

Desktop CNC routers are the smallest and most affordable option, with bed sizes typically ranging from around 12″ x 12″ to 24″ x 24″. These machines are suitable for smaller projects or for working with smaller pieces of wood or other materials.

Hobbyist CNC routers are a step up from desktop models, with bed sizes ranging from around 2′ x 3′ to 4′ x 8′. These machines are larger and more powerful than desktop models, and can handle larger and more complex projects.

Industrial CNC routers are the largest and most powerful option, with bed sizes that can range from 4′ x 8′ to 10′ x 50′ or larger. These machines are designed for heavy-duty use in commercial or industrial settings, and can handle large-scale production runs and complex projects.

It’s important to choose a CNC router with a bed size that is appropriate for the size and type of projects you will be working on. A larger bed size can allow you to work with larger pieces of wood or other materials, but it can also increase the cost and complexity of the machine.

What kind of safety precautions should be taken when operating a wood CNC router?

1. Wear protective equipment

When operating a CNC router, always wear safety glasses or goggles to protect your eyes from flying debris, as well as a dust mask or respirator to protect your lungs from dust particles.

2. Secure the workpiece

Make sure the workpiece is properly secured to the router bed before beginning any cuts. This will prevent the workpiece from moving or shifting during the cutting process, which can be dangerous.

3. Use proper router bits

Use the appropriate router bit for the material being cut, and make sure the router bit is securely fastened in the collet. Dull or damaged router bits should be replaced immediately.

4. Keep hands clear

Keep your hands and fingers away from the moving parts of the router at all times. Never attempt to adjust or touch the router while it’s in operation.

5. Monitor the cutting process

Keep a close eye on the cutting process at all times, and be prepared to stop the router if necessary. If you notice any unusual noises or vibrations, stop the router and investigate the problem.

6. Keep the workspace clean

Regularly clean up dust and debris from the workspace to prevent it from accumulating and creating a fire hazard.

7. Follow manufacturer’s instructions

Always follow the manufacturer’s instructions for operating the CNC router, and never modify the router without first consulting the manufacturer.

Word at Last

It’s important to carefully consider the advantages and disadvantages of CNC routers before deciding whether to invest in one. And different types of wood have different properties, so it’s always a good idea to test a new type of wood on a CNC router to determine the best settings and techniques for cutting and machining it. A wood CNC router can be used to create a wide variety of designs and shapes, limited only by the imagination and skill of the user. The versatility and precision of a wood CNC router make it a valuable tool for creating a wide variety of designs and shapes in woodwork.