As the furniture CNC machine becomes increasingly mature, many factories intend to choose furniture CNC machine to realize mass production. Furniture makers can also choose different furniture making machines to form an automated furniture production line.

Nowadays, panel furniture has gained more popularity due to its simple style, easy assembly, and favorable price. To meet mass production requirements, many panel furniture factories choose the furniture CNC machine.

This article will introduce to you the furniture making machines used in three different production lines. Besides, these machines can be combined freely according to your specific demands.

Panel furniture production process

The production process varies for different furniture lines. And the furniture CNC machine used will also be different. In addition, if you have a sufficient budget, you can choose a more advanced furniture CNC machine. For example, computer panel saw machine, six-sided CNC drilling machine, etc.

Considering many factors, most panel furniture makers choose to produce the cabinet and cabinet door separately. The production process of the cabinet body mainly includes cutting, edge banding, and hole drilling.

However, the production of cabinet doors may be relatively complicated. Some cabinet doors require decorative designs, and some need to be coated with PVC film. Therefore, the production process of cabinet doors includes cutting, drilling, edge banding, polishing, vacuum pressing, etc.

Below are three different furniture production lines for CNC cabinet making, high-gloss door making, and thermofoil door making. I’ll introduce the furniture making machines used in these lines.

Furniture CNC machine in the entry-level cabinet production line

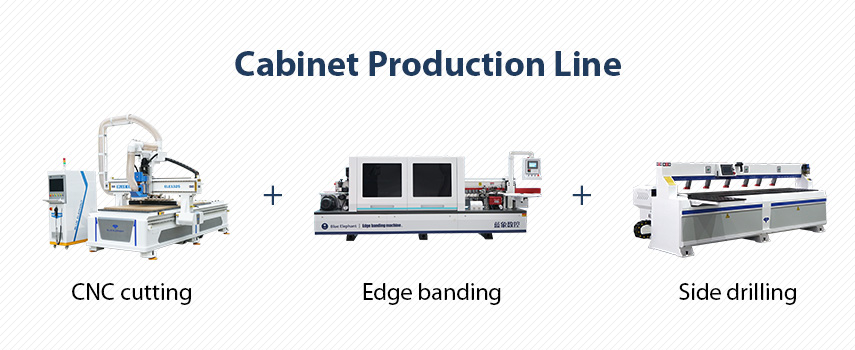

As mentioned above, the production process of the cabinet is relatively simple, mainly including cutting, sealing, and drilling. Therefore, the cabinet CNC machine used in the cabinet production line mainly includes three types, CNC cutting machine, edge banding machine, and side hole drilling machine.

CNC cutting machine for wood furniture

There are multiple choices for the cabinet CNC machine for cutting boards. Among them, the nesting CNC router is the most popular with cabinet makers.

Recently, labor costs have been rising year by year, and raw material and transportation costs have also been rising. Therefore, many furniture makers are looking for ways to effectively control production costs.

The emergence of nesting CNC machines properly solves the problem of increasing labor costs. Besides, the nesting CNC machine significantly reduces the amount of manual work and improves production efficiency. Traditional furniture manufacturing originally required 10 or even more positions, now just two or three people will be able to fully operate.

This nesting CNC machine adopts a 9KW air-cooled ATC spindle with a 12-pcs linear tool magazine. So it can complete at least 12 processes automatically without stopping for manual tool change. This improves work efficiency and reduces the manual operation risk greatly. The computer numerical control method improves accuracy, increases panel utilization rate, and improves quality for the CNC cabinet making.

Let’s take a look at the machining process of this nesting CNC router.

Cheap panel saw machine for cutting boards

The price of the above automatic tool changing nesting CNC machine ranges from $10,000 to $15,000. This is relatively expensive for a small woodworking shop. However, don’t worry. We also have other affordable furniture making machines for cutting boards fast and accurately.

The sliding table saw adopts two saw blades to cut wooden panels with fast speed and good precision. The small saw blade makes a slot on the board and then the big saw cuts through it. This cutting method can help reduce the burrs and chippings of the panel. Except for cutting at 90 degrees, you can adjust the height and angle of the saw blades to cut boards at other angles.

Furthermore, the price of this panel saw machine is cheaper than the ATC nesting CNC router. It only costs about $4,000 on average, saving much cost.

Watch the following video to see how the sliding table saw works.

Edge banding machine

The edge banding machine is the furniture CNC machine dedicated to banding panel edges. We provide both manual and automatic edge banding machines to meet the demands of both small and big businesses.

We have multiple models of edge banding machines to complete different edge banding functions. For example, the E-50 series, E-60 series, and E-70 series. The higher the level, the more functions the edge banding machine has. Accordingly, the edge banding machine price is higher.

I’d like to introduce the most popular E-60 edge banding machine.

Rough trimming and fine trimming functions can remove the excess banding tape and glue, making the penal edge smoother. The banding speed of this furniture CNC machine is about 15-23m/min, which can improve production efficiency effectively.

You can choose PVC or veneer materials with a thickness of 0.4-3mm as the banding tape. The price of this E-60 edge banding machine is about $10,000 on average, which is for reference only.

In addition, we also provide cheap manual or semi-auto edge banding machines with simple functions. They can band irregular-shaped panel edges with basic gluing, banding, and end cutting functions. Therefore, the banding result is far less than the automatic edge banding machine. That’s why I strongly recommend the automatic edge banding machines.

Let’s watch the operation video of the E-60 edge bander.

Side drilling machine

The CNC cabinet making process also requires punching various holes and making slots for the installation of connecting parts, hinges, hidden parts, etc. As for vertical holes, you can directly use our ATC furniture CNC machine for punching. But it may not be able to complete horizontal drilling. At this point, you need another cabinet CNC machine that specializes in drilling horizontal holes – a side drilling machine.

When processing small-sized boards, three boards can be placed on the workbench at the same time. This can reduce clamping times and realize simultaneous loading and unloading. This furniture CNC machine greatly improves the horizontal punching efficiency, improves the punching accuracy, and saves labor costs.

A double head side drilling machine may cost you about $4,300. The final price shall be subject to the specific configuration.

The video below shows how our double-head side drilling machine drill holes and make grooves.

Furniture CNC machine in the high-gloss door production line

The high-gloss board is a new type of environmentally friendly decorative material with MDF as the base material and polyvinyl chloride as the veneer. It is formed by high-temperature hot pressing, and the surface is cured by ultraviolet light. The high-gloss wardrobe door has high reflectivity and is beautiful. This style is more popular with young people nowadays because it is fashionable and looks energetic.

The production process of high gloss cabinet doors mainly includes cutting, edge banding, and drilling hinge holes. The furniture CNC machine used in this furniture production line mainly covers three types: CNC wood cutting machine, edge banding machine, and hinge drill.

CNC router machine for cutting panels

You can choose the above-mentioned ATC 4×8 CNC router machine for cutting high gloss panels. It can meet the demands of cutting with fast speed and high accuracy. However, for a large production volume, we recommend the furniture CNC machine with higher efficiency for cutting panels in a large amount.

We provide multiple models of CNC router machines with automatic loading, unloading, and labeling platforms, drill bank, aggregate head, and other devices to improve work efficiency.

Let me introduce a nesting CNC machine with two platforms for cutting high gloss wooden panels.

Working with two worktables greatly reduces the shutdown time between operations and improves work efficiency. Besides, this furniture CNC machine has an automatic tool changing function. Carrying 12 tools in the linear tool magazine, the cabinet CNC machine can realize multiple processes. For example, vertical punching, cutting, milling, chamfering, etc.

The price of this automatic tool changing nesting CNC machine could be around $18,000 to $25,000 based on different specifications.

Cabinet making machine for edge banding

Generally, the banding requirements for cabinet doors are higher than that for cabinet bodies. So many cabinet makers intend to choose the fully automatic edge banding machine with better banding results.

Here I recommend our E-70 series of edge bander. Compared with the above-mentioned E-60 edge bander, the E-70 J has additional pre-milling and profile tracking functions.

The diamond pre-milling cutter removes corrugated marks and excess burrs from the board. So the banding tape can fit the edges better, resulting in a stronger and more beautiful bond. The pre-milling seat is under pneumatic control, which is more accurate and convenient.

Its profile tracking function can trim the sharp corners of a board into arc shapes, making them smoother and safer. All these two additional functions ensure better banding results. The E-70J edge banding machine price is $20,000.

CNC furniture Hinge boring machine

The cabinet door and the cabinet body need to be connected by hinges. Cabinet makers previously choose manual tools to punch hinge holes, which is inefficient and poor in precision. But now, as CNC technology develops, many furniture making machines can be used to drill hinge holes and make slots.

For small CNC furniture makers, we offer the hinge boring machine with a single drill bit and double drill bits.

This hinge drill machine is provided with two drill bits and has two workstations. It can process two wooden panels in one operation. Besides, it is simple and labor-saving to operate the machine with a foot switch.

This type of furniture CNC machine is very cost-effective, which may only cost you $2,000.

High-end CNC drilling machine

For mass production of large-sized CNC furniture factories, the hinge drilling machine definitely can’t meet the processing demands. So we launched the six-sided CNC drilling machine. It is a high-end furniture CNC machine dedicated to punching various holes and making slots for CNC furniture production.

This significantly improves the drilling efficiency. In addition, the six-sided drilling machine can process panels of a variety of sizes. Therefore, it can meet all your drilling demands even if you need to process different panel furniture products. Correspondingly, the price of this furniture CNC machine will be more expensive than the above hinge drill. It may cost you over $20,000.

To know more working details of the six-sided drilling machine, please watch the following video.

Furniture CNC machine in the thermofoil door production line

The thermofoil door is very popular in home decoration. It adopts the density board as the substrate, and is covered with a PVC film by vacuum pressing. Various colors and patterns of PVC film make the wooden door more beautiful. In addition, thermofoil doors have good wear resistance, moisture resistance, corrosion resistance, and are not easy to deformation.

The production process of thermofoil doors includes cutting, polishing, vacuum filming, drilling, etc. So the furniture making machines used in this production line cover the nesting machine, wood sanding machine, vacuum press machine, etc.

Furniture CNC machine for sizing panels

Any of the above two nesting CNC machines can complete the cutting of door panels. These two furniture making machines are good at cutting panels and engraving complex patterns on the panels. Here I’d like to introduce another furniture CNC machine used for sizing panels with two saw blades.

The saw spindle has one big saw blade and one small saw blade, which run in the opposite directions during operation. The small saw cuts a slot of 3-5mm deep and then the big saw cuts through the board. This cutting method can reduce burrs and crackings to the largest extent. In addition, cutting panels with saw blades is faster than using CNC router tools. This can greatly improve working efficiency for the CNC furniture makers. The CNC router price of this furniture CNC machine is about $18,000 on average.

Watch the following video to see the cutting demonstration of the saw blades.

Furniture CNC machine for panel polishing

After sizing panels and engraving patterns, you’ll need to polish and sand the panels. This step helps the further vacuum filming process. Because bubbles will occur during the vacuum pressing operation if the panel surface is not smooth. This will have negative effects on the beauty of the doors. So the wood polishing machine comes into being to solve this problem.

This furniture making machine adopts frequency control to adjust the speed freely and choose the right feeding speed. It is equipped with multiple round sanding discs and longitudinal sanding rollers, which can polish the panels carefully from multiple directions. The surfaces of the sanded wood panels are smooth and can be directly proceeded to the next process. The furniture CNC machine for pressing may cost you about $5,000.

Let’s see the operation process of the wood polishing machine together.

Vacuum press machine

This process is to use high temperature and vacuum to laminate various PVC films, wood veneers, etc. onto the door panels. The furniture CNC machine used is the vacuum press machine.

The smart digital heating system can ensure even heating and ensure the consistency of the filming quality while saving energy and power. Its high-power vacuum pump has a strong adsorption capacity and automatic control of vacuum pressure, which is durable. This furniture CNC machine is suitable for processing shallow patterned door panels, deep carved door panels, hollow door panels, relief door panels, etc. The cost of this machine is $7500 approximately.

If you are interested in this vacuum press machine, please watch the following video.

Smart production line furniture making machines

The furniture production lines mentioned above are not fixed. You can increase or decrease the types or configurations of furniture CNC machine according to your own processing needs. By combining different furniture making machines, you can form a furniture production line that is most suitable for your business. This maximizes efficiency, reduces labor, and brings more benefits.

If you have a sufficient budget, you can consider the smart furniture production line to start your business. The smart furniture production line aims to maximize work efficiency by using the least human labor. Generally, the furniture CNC machine used in the production line is highly automated and intelligent. Except for the furniture CNC machine, the furniture production line also includes robot arms, conveyor platforms, gantry, loading and unloading platforms, etc.

Furthermore, the smart furniture production line has certain requirements in the factory area. You must have enough space to put all the furniture making machines and connect them into a complete line. In addition, the whole smart furniture production line is very expensive.

Therefore, the smart production line solution is more suitable for large-sized furniture factories.

The video above shows a furniture production line for mass production of cabinets. It consists of three major units: CNC nesting unit, edge banding unit, and CNC drilling unit. Under the central control system and with auxiliary devices, the whole production line can complete panel cutting, edge banding, and drilling work automatically.

How much does it cost to open a panel furniture factory?

A variety of furniture making machines are required to start a panel furniture factory. Most modern furniture manufacturers choose the furniture CNC machine to improve efficiency and increase production.

As mentioned above, the cabinet body production line may cost you about $15,000 to $30,000 on average. The high-gloss door production line price ranges from $25,000 to $45,000. And the total furniture CNC machine price of the thermofiol door production line is around $30,000 on average. All the costs above are for reference only. The detailed price depends on which machine and what configuration of the machine you choose.

So you can contact us to get quotations of the furniture CNC machine if you plan to open a furniture factory.

Conclusion

Different furniture production lines require different furniture making machines. Therefore, it is necessary to choose the furniture CNC machine according to your specific needs. For instance, to produce cabinet bodies, you will need a CNC cutting machine, an edge bander, and a hole punching machine. If you produce thermofoil doors, the wood sanding machine and vacuum press machine are your must choice.

When your budget is enough to build a large-scale furniture factory, you can choose a complete smart furniture production line. We also provide advanced computer panel saws, six-sided drills and other intelligent equipment. Combined with a furniture CNC machine such as nesting CNC machine and automatic edge banding machine, they can form a highly automated production line.

Blue Elephant provides various types of furniture CNC machine to meet the needs of furniture factories of different sizes. If you are interested, don’t hesitate to contact me.