Laser Cleaning Machine

Blue Elephant: Your Reliable Laser Cleaning Machine Manufacturer

Blue Elephant delivers advanced laser cleaning machines designed for efficient, precise, and environmentally friendly surface treatment. Suitable for rust, paint, grease, and oxide removal, these machines offer a contact-free cleaning method that preserves the integrity of the base material. Commonly used in industries like manufacturing, restoration, and metal processing, they ensure clean surfaces with minimal waste or abrasion.

As a trusted machine company, we offer customizable laser cleaning systems with options for power levels, mobility, and automation. Built for stability, ease of use, and long-term performance, Blue Elephant machines help businesses reduce labor costs and maintain high cleaning standards.

Explore Our Product Range

Reduce Costs 30%, Increase Profits 42%

with Our CNC Machine.

Connect With Us

For any inquiries, don’t hesitate to contact us at:

- manager@elephant-cnc.com

- +86 186 6899 1371

Explore More via Video

Related Products

-

E200 Double Head Side Hole Drilling Machine

Read more -

Double Head Hinge Hole Drilling Machine

Read more -

ET6 6 Sided CNC Drilling Machine with a Return Table

Read more -

420 Computer Beam Saw Machine for Sale

Read more -

CNC-32TA Sliding Table Saw with Digital Control

Read more -

EM3.2-1126 Through-type Double-channel Door Lock Making Machine

Read more -

EM2.1-1128 CNC Through Type 4 Sides Wood Door Cutting Saw

Read more -

EK2-1328 Linear ATC CNC Machining Center

Read more

Customization Options

Blue Elephant provides versatile customization options to suit a wide range of industrial cleaning tasks. From power output and scanning modes to design enhancements and logo integration, each laser cleaning machine is built for maximum performance, seamless workflow compatibility, and a distinctive brand presence.

Specs & Functions

CNC machines tailored in size, power, and system to meet your needs

Aesthetic Design

Custom colors and styling to enhance your brand identity

Branding Service

OEM solutions with your logo for market distinction

What Sets Blue Elephant Ahead

Superior Quality

100% inspection and 160 checks ensure precision and zero issues.

Cost Effectiveness

Efficient manufacturing meets ISO9001, SGS, CE, BV standards at competitive prices.

Precision Custom

Advanced CNC technology with yearly upgrades keeps products at the cutting edge.

Innovation Focus

Advanced CNC and annual upgrades ensure innovation and top performance.

Reliable Support

A dedicated 50+ team provides 24/7 pre-sales, installation, and maintenance support.

Global Reach

A 75,000㎡ modern factory supports direct sales, regional optimization, and fast delivery.

Certified Excellence

International certifications and over 8,000 satisfied users build trust and credibility.

Extended Warranty

A 12-month warranty, along with a 60-day trial, ensures lasting peace of mind.

Real-World CNC Solutions

Discover how businesses across industries overcome production challenges with Blue Elephant CNC solutions. From improving precision to enhancing efficiency, our machines help companies achieve their manufacturing goals.

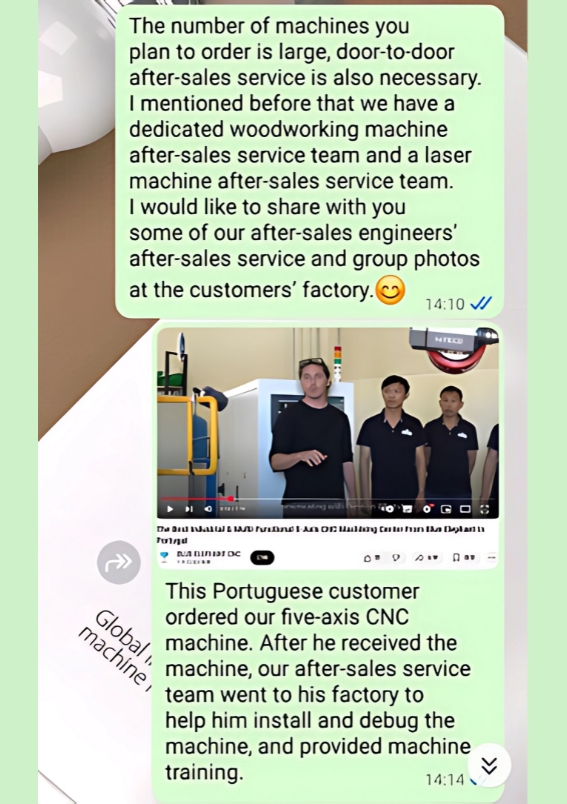

Portugal | Metal and Non-Metal Processing

Customer Challenges

- Needed a tool for cutting both metal and non-metal

- Limited budget, required affordable, high-quality equipment

- Concerned about support for complex fiber laser systems

Our Solution

- Recommended the 1325 CO2 Laser and 1325 Fiber Laser for diverse material processing.

- Assured that discount doesn't compromise machine quality.

- Committed to thorough after-sales service, including on-site training by expert technicians.

- Showed proven reliability through case studies and customer feedback from Portugal.

Final Results

- Delivered machines to Portugal with comprehensive support

- Customer pleased with the machine quality and cost

- Established trust in our professional service, hinting at a lasting partnership

Israel | Label Engraving Business

Customer Challenges

- Hard to find a reliable local engraving machine

- Needed efficient, precise label engraving

- Worried about machine durability and performance

Our Solution

- Suggested the ELECNC1390L Engraving Machine for its precision and efficiency.

- Features CW5200 water chiller for optimal cooling and minimal downtime. Includes an electric lifting table for stable operations.

- Machine has a fully enclosed design with anti-corrosion paint for safety and durability.

- Offered real-time technical support and dedicated after-sales service, ensuring customer confidence.

Final Results

- Machine delivered to Israel, with installation and training included

- Customer highly satisfied with performance and service

- Reliable operation and enhanced productivity boosted the customer’s business

Cyprus| Aluminum and Steel Processing

Customer Challenges

- Unclear about fiber optic welding machine options

- Needed help choosing the right machine for aluminum and steel

- Debated between a dedicated welder or a multi-functional machine

Our Solution

- Evaluated customer’s material and thickness needs to determine suitable machine power.

- Recommended a 1.5KW fiber optic welding machine for best performance with aluminum and steel.

- Explained the benefits of a three-in-one machine that offers welding, cutting, and descaling, though cutting is limited to 1-2mm.

- Advised choosing the three-in-one machine for its versatility and small price difference.

- Customer decided on the three-in-one machine, adding a woodworking machine for a complete setup.

Final Results

- Prepared and ordered the machine for shipment

- Customer pleased with the guidance and versatile machine choice

- Enhanced production flexibility and efficiency with the three-in-one machine

What Our Customers Say about Edge Banding Machine

SAUDI ARABIA

E-70JDSR Edge Banding Machine

After unloading the machines, the staff also placed, organized, adjusted and set them up diligently until we finally completed the work.

The quality of the finished products I saw was also very good and satisfactory. Hopefully this is a good start.

AMERICA

E-80 Edge Banding Machine

The customers purchased our CNC machine two years ago. This time, they came to purchase another edge banding machine.

" Actually we are using that machine for two years and we have a very good experience with it. They have very professional salesteam and customer service. Definitely we will be their customers again."

MAURITIUS

E-80L Edge Banding Machine

We are from Mauritius and we came here to look at some work machines. We got an edge banding machine and a beam saw.

And we see that the factory is really good. They have very nice production, great engineer. And overall so far we' re very happy with what we've seen. And we look forward to having the machines and starting to use them.

Montenegro

E-60 Edge Banding Machine

Our after-sales technicians went to Montenegro to debug the machine and provide guidance on machine operation.

The customer said the machine was very good and was grateful for our service.

About Our Factory

15+ years in business as an industry leader

75000+㎡ High-level Production Base

25+ Dedicated Production Bays

10 technical service centers around the world

30+ locations worldwide

500+ emplovees for service you

8000+ client' Trust and recognition

Exported to 180+ countries and regions

Our Valued Certifications

Blue Elephant CNC machines comply with internationally recognized standards, holding certifications such as CE, ISO9001, BV, SGS, and TUV. Our strict quality control processes and precision engineering ensure high-performance, durable, and reliable solutions that meet the demands of global industries.

Real Feedback from Our Laser Cleaning Machine Users

TURKISH

This laser cleaning machine has been a reliable part of our maintenance workflow. It easily removes rust, paint, and oxide layers from steel, aluminum, cast iron, rubber molds, and even delicate stone surfaces

AUSTRALIAN

We’ve used this laser cleaner on everything from machinery to restoration work. It strips rust, grease, and coatings from stainless steel, copper, stone, and iron components with incredible accuracy and zero abrasive contact.

SAUDI ARABIAN

Perfect for prepping weld joints and cleaning old metal parts. This laser cleaning machine handles corroded tools, pipe exteriors, stone facades, and painted surfaces with ease—efficient, low-maintenance, and safe for sensitive materials.

25 Ways to Make Money with a Laser Cleaning Machine

- Precision engraving for furniture parts

- Made-to-order home decor items

- Production of custom business signboards

- Fabrication of decorative props for events and weddings

- Custom wooden gift crafting services

- Woodcutting and carving for toys and crafts

- Crafting wooden parts for instruments

- Hand-assembled wooden model structures

- Bespoke wood accessories for pets

- Wooden casing development for electronics

- Wood-based replicas of art and calligraphy

- Puzzle and brain game wood fabrication

- Engraving instruction and hands-on training

- Resale and repair of second-hand equipment

- Showcasing at artisan and handicraft exhibitions

- Personalized packaging for brand identity

- Creating retro-themed decorative pieces

- Handcrafted wooden shelves and storage units

- Supplying wooden educational materials

- Producing handcrafted religious wooden goods

- Custom-designed wooden pins and awards

- Designing wood elements for outdoor decor

- Producing artisan wooden keychains

- Restoration and artistic renewal of furniture

- Partnered mass production capabilities

Frequently Asked Questions

A laser cleaning machine is used to remove rust, paint, oil, oxides, and other contaminants from metal and industrial surfaces. It’s widely applied in automotive, aerospace, manufacturing, and cultural heritage restoration industries.

A laser cleaning machine is suitable for metals like stainless steel, aluminum, brass, copper, and even delicate surfaces like molds or sculptures. It effectively cleans without abrasive wear or chemical corrosion.

Yes, a laser cleaning machine is an eco-friendly solution as it requires no chemicals, solvents, or blasting media. It produces minimal waste and dust, making it safe for operators and the environment.

No, when configured correctly, a laser cleaning machine selectively removes surface contaminants without harming the substrate. It’s perfect for preserving surface quality, even on precision parts.

Yes, laser cleaning machines can be customized in power level, portability (handheld or fixed), automation options, and lens types. Blue Elephant offers tailored solutions for both industrial and delicate applications.

Connect With Us

For any inquiries, don’t hesitate to contact us at:

- manager@elephant-cnc.com

- +86 186 6899 1371