Oscillating Knife Cutting Machine

Blue Elephant: Your Reliable Oscillating Knife Cutting Machine

Blue Elephant specializes in oscillating knife cutting machines engineered for high-precision cutting of flexible, soft, and composite materials. Perfect for foam, leather, textiles, rubber, and packaging boards, these machines offer smooth, burn-free edges and high-speed performance. Widely used in industries such as automotive, signage, garment, and insulation, they are ideal for both custom and batch production.

As a leading supplier, we configured to match unique material and workflow requirements, from tool selection to bed size and software integration. Backed by advanced technology and reliable support, Blue Elephant’s oscillating knife cutting solutions help manufacturers reduce waste and streamline production with ease.

Reduce Costs 30%, Increase Profits 42%

with Our CNC Machine.

Connect With Us

For any inquiries, don’t hesitate to contact us at:

- [email protected]

- +86 186 6899 1371

Explore More via Video

Related Products

-

E-90 Aluminum-Wood Integrated Edge Bander

Read more -

UV Laser Marking Machine for Sale

Read more -

1390 CO2 Laser Cutting Machine with Rotary Device

Read more -

1212 CNC Router Machine for Sale

Read more -

ET6 Double Stations 6 Sided CNC Drilling Machine

Read more -

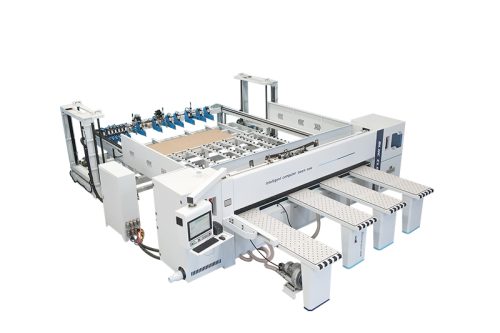

330C Rear Feeding Computer Beam Saw Machine

Read more -

1325 4×8 ATC Nesting CNC Machine

Read more -

1325 4 Axis CNC Router Machine for Sale

Read more

Customization Options

Blue Elephant provides adaptable customization options to support diverse material processing needs. From tool head options and precision settings to design enhancements and brand integration, each oscillating knife cutting machine is built for maximum efficiency, seamless workflow integration, and a distinct visual identity.

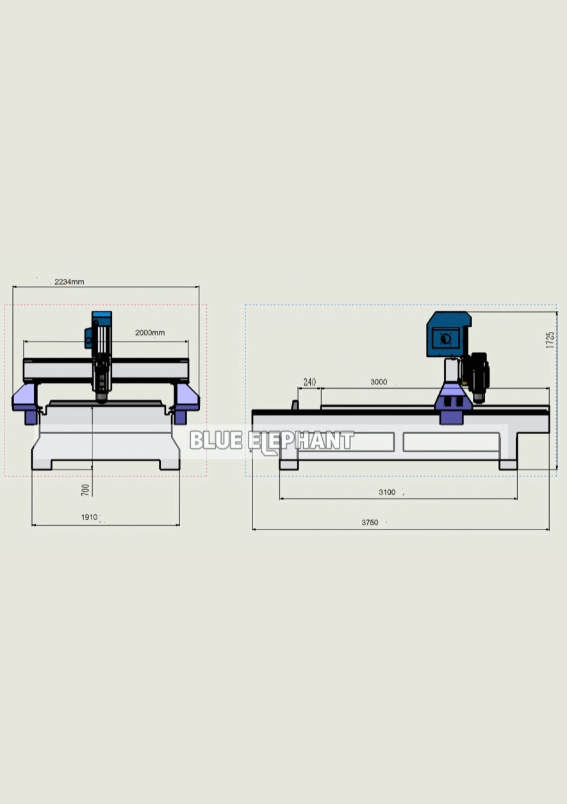

Specs & Functions

CNC machines tailored in size, power, and system to meet your needs

Aesthetic Design

Custom colors and styling to enhance your brand identity

Branding Service

OEM solutions with your logo for market distinction

What Sets Blue Elephant Ahead

Superior Quality

100% inspection and 160 checks ensure precision and zero issues.

Cost Effectiveness

Efficient manufacturing meets ISO9001, SGS, CE, BV standards at competitive prices.

Precision Custom

Advanced CNC technology with yearly upgrades keeps products at the cutting edge.

Innovation Focus

Advanced CNC and annual upgrades ensure innovation and top performance.

Reliable Support

A dedicated 50+ team provides 24/7 pre-sales, installation, and maintenance support.

Global Reach

A 75,000㎡ modern factory supports direct sales, regional optimization, and fast delivery.

Certified Excellence

International certifications and over 8,000 satisfied users build trust and credibility.

Extended Warranty

A 12-month warranty, along with a 60-day trial, ensures lasting peace of mind.

Real-World CNC Solutions

Discover how businesses across industries overcome production challenges with Blue Elephant CNC solutions. From improving precision to enhancing efficiency, our machines help companies achieve their manufacturing goals.

Venezuela | Leather and Carpet Sign Making

Customer Challenges

- Needed a machine for cutting leather and carpet for signs.

- Lacked experience with automated cutters, needed reliable guidance.

- Desired high-quality performance with cost-effectiveness.

Our Solution

- Suggested the ELECNC-1625 Oscillating Knife Machine, ideal for leather, carpet, and signage.

- Showed samples and videos to demonstrate the machine's cutting quality and efficiency.

- Provided weekly production updates with photos to keep the customer informed.

- Tested materials thoroughly before shipment to meet the customer’s standards.

Final Results

- Installed the ELECNC-1625 Oscillating Knife Machine at the client’s factory.

- Provided comprehensive training; the client quickly mastered the machine.

- The machine boosted production efficiency, increasing revenue.

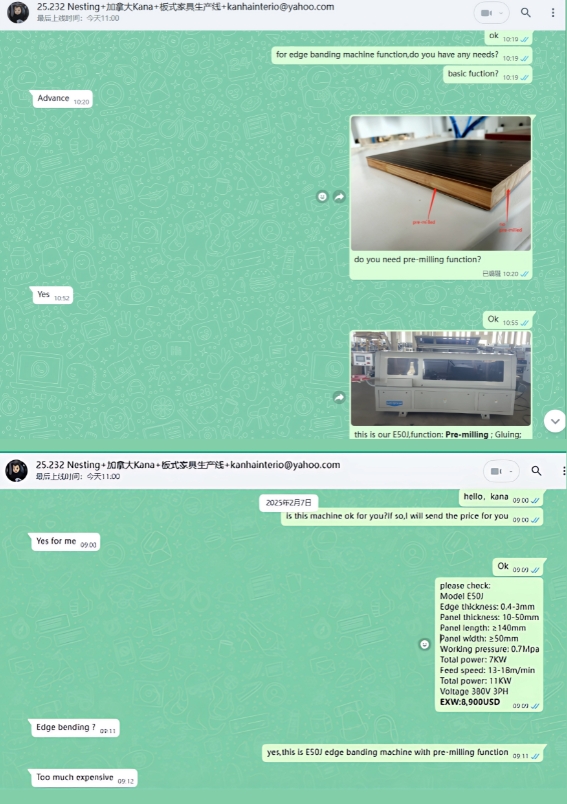

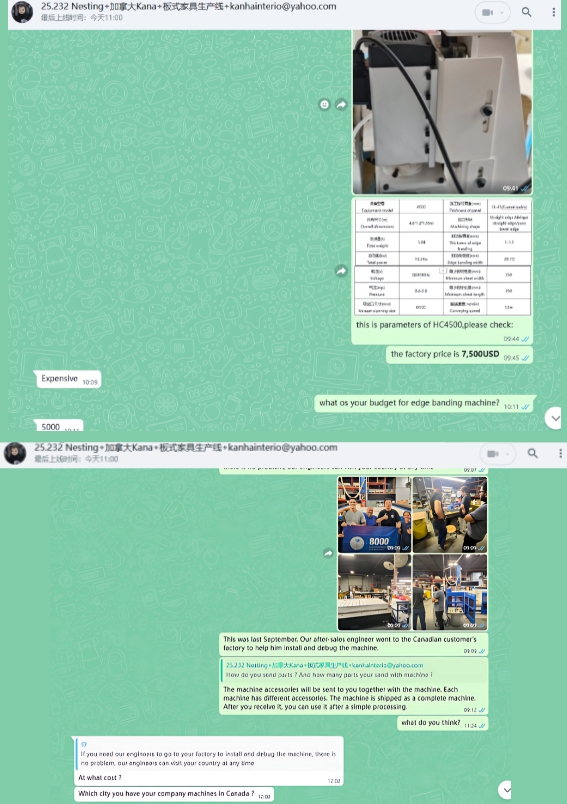

Canada | Cabinet Manufacturing Business

Customer Challenges

- New to cabinet manufacturing, needed various machines.

- Concerned about machine quality, support, and affordability.

- Sought detailed guidance on technical support, spare parts, and machine noise.

- Had a tight budget, preferred cost-effective and reliable options.

Our Solution

- Identified needs for a ripper, edgebander, drill, vacuum, and feeder machine.

- Recommended the 1530 Feeder for a 5x10 ft operation, and the HC4500 Edge Sealing Machine for cost-effectiveness, after the E50J was deemed too costly.

- Advised on a 7.5KW air compressor with efficiency features.

- Provided negotiable pricing and arranged a transparent credit order.

Final Results

- Purchased essential machines including the 1530 Feeder, HC4500 Edge Sealing Machine, Single-Head Hinge Drill, Table Saw, and 7.5KW Air Compressor.

- Customer pleased with our transparent, professional service, fostering future business relations.

- Provided machine details and quotes, learned the customer's $5000 budget for an edge banding machine. The machine fits well within this budget and the price is negotiable, so continued to market this machine to the customer.

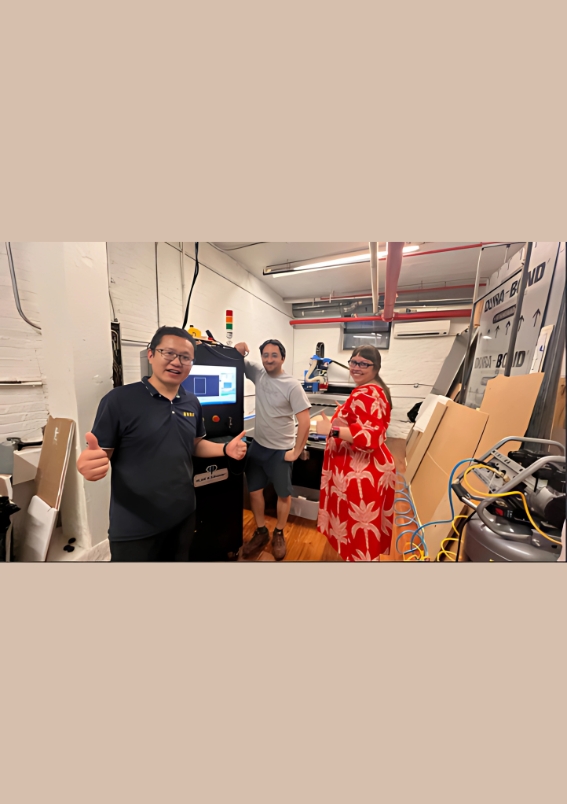

USA | Print Store

Customer Challenges

- Needed an ATC machine with oscillating knives for aluminum composites and plexiglass.

- Unsure if a 5x10 ft machine would fit in their workspace.

- Concerned about machine cost and available configurations.

Our Solution

- Confirmed need for cutting specific materials with precise cuts.

- Ensured oscillating knife functionality was included.

- Provided a size chart and detailed quotation to match space and function needs.

- Offered two configurations with similar features at different price points for cost flexibility.

- Shared positive U.S. customer feedback and included door-to-door installation and training for reassurance.

Final Results

- Customer opted for the more affordable configuration and placed their order.

- Machine was delivered and set up successfully in their print store.

- Customer very satisfied with the machine’s performance and our comprehensive support.

- Customer plans to recommend our machines to other printing industry contacts.

What Our Customers Say about Oscillating Knife Cutting Machine

ITALIAN

2040 ATC CNC Router

We were hesitant at first, but this knife cutting machine exceeded our expectations.

It handles leather and vinyl with high precision and zero fray. Maintenance is straightforward, which is a bonus.

Dutch

1337 Digital Knife Cutting Machine

The knife cutting machine has been a game-changer for our custom metal signage work.

It delivers precise edge finishes without burrs or secondary processing. Clean cuts, fast cycles—just what we needed.

United Arab Emirates

2137 ATC CNC Router

We really appreciate the quality of cutting from Blue Elephant. We have bought the excellent cutting quality machine.

Mr. Tian is very professional in training the machine and the software. This machine is a really nice machine.

BOSNIA AND HERZEGOVINA

1540 ATC CNC Router

From ordinary cutters to four-axis, five-axis, machining centers, stone processing, beam saw cutting,

they basically have everything. We were seduced by what we saw. And we recommend that you come to.

About Our Factory

15+ years in business as an industry leader

75000+㎡ High-level Production Base

25+ Dedicated Production Bays

10 technical service centers around the world

30+ locations worldwide

500+ emplovees for service you

8000+ client' Trust and recognition

Exported to 180+ countries and regions

Our Valued Certifications

Blue Elephant CNC machines comply with internationally recognized standards, holding certifications such as CE, ISO9001, BV, SGS, and TUV. Our strict quality control processes and precision engineering ensure high-performance, durable, and reliable solutions that meet the demands of global industries.

25 Ways to Make Money with a Oscillating Knife Cutting Machine

- Sofa cushion design

- Wall soft decoration

- Wooden Model Making

- Artwork Replication

- Small batch custom packaging

- Soft furniture cutting

- Hollow KT Board 3D Letters

- Acrylic/PVC Letter Cutting

- Giant Outdoor Billboard Cutting

- Luxury Cardboard+Felt Packaging Boxes

- Cutting leather fabrics for bags

- Automotive Interior Parts Processing

- New Energy Battery Insulation Cutting

- Wooden Badges & Awards

- Wooden Puzzles Production

- Wooden Keychains Making

- Precision Carpet Trimming

- Wooden Electronics Casings

- Commercial Signage Production

- Brand Packaging Customization

- Educational Tools Manufacturing

- Musical Instrument Parts Processing

- Children’s Toys/Educational Tools

- Custom Furniture Component Engraving

- Wallpaper/Wall Fabric Art Mosaic Cutting

Frequently Asked Questions

Oscillating knife cutting machines are ideal for non-metal, soft materials such as EVA foam, corrugated paper, fabric, gasket materials, fiberglass, and PVC. They are perfect for intricate shapes and layered cuts.

Yes, Blue Elephant offer customization options for table size, blade type, tool head combinations, conveyor systems, and auto-feeding setups. This helps meet various production needs, from prototyping to mass production.

Yes, our oscillating knife machines feature user-friendly software interfaces, touchscreen controls, and support for common design files like DXF or AI. With basic training, even first-time users can operate them efficiently.

Regular maintenance includes cleaning the cutting area, replacing worn blades, and checking the tool head for proper alignment. It’s also important to inspect moving parts and keep the software updated.

Our machines are ISO9001-certified and built with high-quality components for durability and precision. We test every unit before shipping and provide videos, customer references, and global case studies.

Connect With Us

For any inquiries, don’t hesitate to contact us at:

- [email protected]

- +86 186 6899 1371