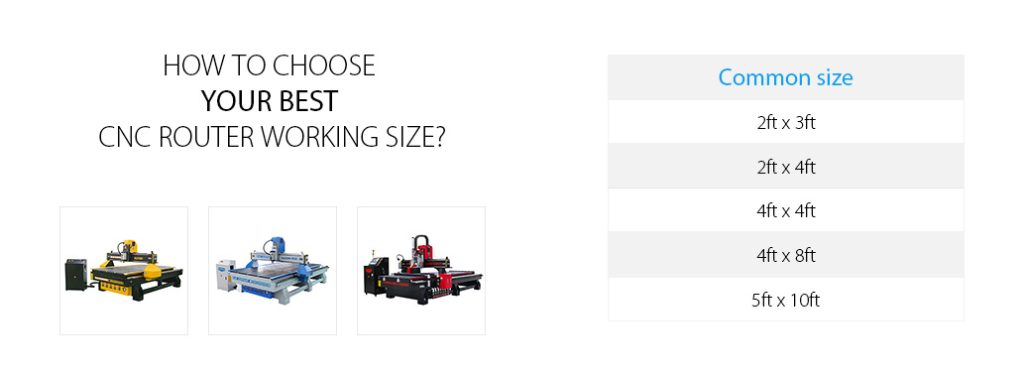

CNC routers are good tools for workers. Choosing the most suitable CNC router table size can help you finish your work with only half the effort. You can conduct the cutting, engraving, routing, pocketing, milling, and grooving process with your CNC router as long as choosing the right CNC router kits and tools. The CNC router table is available in various sizes, such as 4×4 CNC router, 4×8 CNC router, 5×10 CNC router, etc. CNC routers with different router table sizes have different purposes, but they all can improve working efficiency and save labor and time. CNC router sizes are an important factor when choosing your best CNC router.

In this article, I’ll list some commonly used CNC router sizes to help you find the CNC router table dimensions that suits you best.

Whether you are just a beginner or a professional, a furniture manufacturer or a craft hobbyist, you can find the most suitable router table dimension for your business here.

Small CNC router table size

As suggested in the name, the small CNC router has a relatively small CNC router table, occupying a small floor area, and is easy to move or operate. The small CNC router is also known as the mini CNC router, desktop CNC router or hobby CNC router. In terms of transmission mode, the X, Y and Z axis of the small CNC router all adopt the lead-screw transmission. Since the travel of all three axes is short, the lead-screw transmission mode will complete the cutting or engraving work with high precision.

The small CNC router table is available in many router table dimensions, such as 3018 CNC router, 3040 CNC router, 2x3CNC router, 2×4 CNC router, and 4×4 CNC router.

| CNC router size | Router table size | Optional CNC router kits |

| Small CNC router table | 2×3 CNC router | Rotating spindle Rotary device Linear ATC magazine Vacuum worktable High-power spindle |

| 2×4 CNC router | ||

| 4×4 CNC router | ||

| 3018 CNC router 3040 CNC router 9015 CNC router 6015 CNC router |

CNC router table size: 3018 CNC router, 3040 CNC router

Both the 3018 CNC router and 3040 CNC router belong to the desktop CNC router. They have small effective working sizes, which are 300x180mm and 300x400mm. Such CNC routers are simple in both structure and in function, and easy to operate. The 3018 CNC router and 3040 CNC router machines can engrave wood, bamboo, PCB, PVC, PMMA, plastic, ABS, stone, and other non-metallic materials. They can also engrave soft metals, such as gold, silver, brass, aluminum, etc. The 3018 CNC router and 3040 CNC router are quite suitable CNC router sizes for small handicraft studios or enthusiasts.

As the simplest structure and configuration, the price of 3018 CNC router and 3040 CNC router is the cheapest. Their price ranges from $300 to $1,000. With a small investment, you’ll get a multifunctional CNC router machine!

CNC router table size: 2×3 CNC router or 2×4 CNC router

2×3 CNC router, i.e. 2ft x 3ft CNC router and 6090 CNC router, is one of the most commonly used CNC router sizes. It is also the best CNC router table size for advertising industry customers. As the CNC router machine adopting lead-screw transmission mode, the 2×3 CNC router has slow speed but high precision. It can complete various woodworking, letter cutting, and pattern engraving work. Processing materials of the 2×3 CNC router include wood, acrylic, PVC, plastic, stone, double-colored boards, aluminum, gold, etc.

The basic 2×3 CNC router uses an overall cast iron frame, DSP control system, 3kw Changsheng water cooling spindle and other corresponding parts. However, if you have higher demands, you can upgrade the 6090 CNC router. For example, adding a rotary device, replacing the ordinary spindle with a rotating spindle, using a high-power spindle, adding ATC function, etc.

Below shows several 6090 CNC routers with the CNC router table size of 2ft x 3ft in different configuration.

Basic 3 axis 2×3 CNC router for woodworking beginners

Although this 6090 CNC router has simple functions, it can process small wooden furniture, signs, logos, letters, crafts and can also engrave patterns on wood, acrylic, aluminum and stones.

2×3 CNC router with rotary device for cylindrical parts

The latest 6090 CNC router with linear tool changer

It is deemed as the best CNC router table size making various advertising signs, logos, molds, toys, crafts, souvenirs, gifts, medals, trophies and so forth.

Besides, if required, the spindle can also be replaced with a rotating spindle, making it a real 4 axis CNC router. In this case, the 2×3 CNC router is able to make 3D products.

As for the 2×4 CNC router, its CNC router table size is about 600×1,200mm and it is also an excellent CNC router size for craft hobbyists and CNC beginners. If customers have requirements, we can also customize 2×4 CNC router or other CNC router sizes, such as 9015 or 6015 CNC routers.

CNC router table size: 4×4 CNC router

4×4 CNC router has an effective CNC router table size of 1,200×1,200mm, so we also call it the 1212 CNC router. It also adopts the lead-screw transmission mode and has the features of high processing precision but relatively slow speed. The 4×4 CNC router has extensive use in wood furniture, advertising, mold and craft industries. It can make larger wooden furniture, signs, letters, molds, sculptures or crafts than the 2×3 CNC router and the 2×4 CNC router.

Cheap 4×4 CNC router for sale in advertising industry

Heavy duty 4×4 CNC router

Similar to the 2×3 CNC router, we can also upgrade or improve the 4×4 CNC router in many ways. Replacing with a rotating spindle, the 1212 CNC router can realize multiple-side processing, such as side drilling or engraving, 3-dimensional sculpture carving, etc. When your products involve cylindrical workpieces, we can also add a rotary device on the side of the worktable. If the customer required, we can also add the ATC function to the 1212 CNC router.

Best CNC router of 1212 4 axis ATC CNC router for 3D workpieces

It can engrave more complex patterns and complete more processes at a time without stopping the machine for changing another tool manually. This best CNC router improves working efficiency greatly.

Large CNC router table size

The large CNC router adopts racks as transmission mode. That’s because the ball screw would vibrate causing deviation in precision if the stroke is too long. However, the rack transmission solves the problem of vibration well. Even if the working stroke is 3,000mm, it will not generate vibration and affect the accuracy of the CNC router.

The large CNC router table is available in multiple CNC router sizes and purposes. The common CNC router table sizes include 4×8 CNC router, 5×10 CNC router, 2030 CNC router, 3050 CNC router, etc. All these large CNC routers have basic 3 axis models and can be upgraded according to specific customer’s needs. For instance, adding linear or disc auto tool changer, oscillating knife, aggregate head, saw blades, rotary device and other assemblies.

The large CNC router table is good at processing large-size boards instead of small-size boards. One of the most extensive use is the production of panel furniture. With the help of automatic loading, unloading and labeling platforms or other auto devices, the CNC routers of large CNC router sizes can complete multiple processes in furniture making. For example, loading, feeding, nesting, labeling, vertical drilling, side drilling and unloading.

These CNC routers can also form a complete fully automatic furniture production line with our auxiliary furniture making machines. For instance, edge banding machine, side drilling machine, polishing machine, vacuum press machine and so forth.

| CNC router size | Router table size | Optional CNC router kits |

| Large CNC router table | 4×8 CNC router (1325 CNC router) | Rotating spindle Rotary device Linear or disc ATC magazine Auto loading and unloading platforms Auto labeling device Aggregate head Drill unit Oscillating knife Saw spindle Detachable bed Others |

| 5×10 CNC router (1530 CNC router) | ||

| 2030 CNC router | ||

| Customized sizes e.g. 1824, 2040, 2646, 2060, 3050, etc. |

CNC router table size: 4×8 CNC router

4×8 CNC router is the 1325 CNC router that we often say. It has a CNC router table in the size of 1,300×2,500mm. The 1325 CNC router is suitable for making small and medium-sized wood furniture. For example, cabinet doors, cupboards, kitchen cabinets, coffee tables, chairs, stools, etc. You can also choose different types of CNC router table. For instance, the common T-slot CNC router table, the vacuum absorption CNC router table, and the aluminum T-slot CNC router table.

Cost-effective 4×8 CNC router for woodworking purposes

This 1325 CNC router is the most cost-effective CNC router for CNC woodworking beginners and small businesses.

As I mentioned above, the CNC machine manufacturer can upgrade the 1325 CNC router on the basis of the common 3 axis model according to customers’ needs. Below I will show you 3 upgraded 1325 CNC routers.

Four-process 4×8 CNC router with rotary device

Only one spindle can work every time. So even though one of the four spindles malfunctions, it will not affect the operation of the other three ones. This 4×8 CNC router has wide applications in the furniture making, advertising and decoration industry.

1325 CNC router woodworking machine with 8 spindles

These high-performance water cooling spindles and rotary devices are suitable for engraving various patterns on cylindrical objects. For example, table and chair legs, stair handrails, armrests, bed frames, building columns and posts, 3D sculpture, etc. It is the best CNC router for mass production.

Auto tool change 1325 CNC router with two saws

This 1325 CNC router can also equip additional loading, feeding and unloading platforms or devices to increase working efficiency. It also has two pressing rollers to help secure the boards during the cutting process.

CNC router table size: 5×10 CNC router

5×10 CNC router has an effective CNC router table size of 1,500×3,000mm, so it is also called the 1530 CNC router. This is also one of the most suitable working sizes for wooden furniture manufacturers. The 5×10 CNC router can also be customized in its working area and CNC router kits according to customers’ requirements.

1530 ATC CNC router with auto loading and unloading platforms

If you required, you can select other high-quality CNC router kits for the 5×10 CNC router. For example, Italy HSD spindle, YASKAWA servo motor, Syntec control system, etc.

1530 CNC router for marble engraving and carving

All parameters and accessories of this 1530 CNC router can be customized according to your specific requirements.

1632 ATC CNC router with an aggregate head

The aggregate head and drilling head can meet various drilling requirements on five sides of the boards. It also has a high-power YASKAWA servo motor to ensure high speed and stable operation and a dust cover to make the machining cleaner and safer. This CNC router is also available in 1530 CNC router table.

CNC router table size: 2030 CNC router

2030 CNC router with an oscillating knife and automatic tool changer

The height of Z axis could be 500mm or any height you want. It also adopts a vacuum absorption worktable with strong absorption ability, which can secure the workpieces firmly. The large size of 2030 CNC router allows it to process most sizes of panel materials.

CNC router table size: 3050 CNC router

4 axis 3050 foam CNC router with rotary device

In addition, if you have many processing styles requiring more types of tools, you can also add an automatic tool changing function to this foam CNC router.

CNC router table size: 5 axis CNC router

The latest 5 axis CNC router for all purposes

As a CNC router with high-level technology, the 5 axis CNC router offers better process results in whether efficiency or precision. It can realize complex machining in one clamping. The 5 axis CNC router is the best CNC router machine for automotive, aerospace, military, scientific and technological, and medical industries.

Apart from the listed best CNC router sizes, we also produce CNC routers in customized sizes, like 2040, 2060, 2137, etc. These CNC router machines can equip various additional functions in accordance with your requirements, making them the best CNC router meeting your demands.

Which CNC router table size do I need?

There is a wide range of CNC router sizes available. Do you know how to choose a CNC router table size that suits your business best?

The most important thing is to determine your processing needs. For example, the size of the workpiece, the thickness or height of the material, the type of machining, etc. The most suitable CNC router table size you choose should be slightly larger than the maximum size of your processing materials.

For example, if you just make small crafts, gifts and badges, you can choose a 2×4 CNC router or a 4×4 CNC router. In case that you mainly produce interior doors, the 1530 CNC router machine can meet your needs. But if you produce customized furniture of various sizes and your budget is sufficient, you can choose a large CNC router, such as 2030 CNC router or 2646 CNC router.

The best size of CNC router table suitable for your business shall be the one that can perfectly meet or surpass all your processing demands. Big size may not always be good for every manufacturer.

How much space does a CNC router occupy?

The 2×3, 4×4 or 1530 and other figures I mentioned are the effective working sizes or the CNC router table sizes of the CNC routers. The overall size of the complete CNC router is a bit larger than these figures.

In addition, some CNC routers are equipped with a dust collecting system, control cabinet, loading and unloading platforms, labeling platform or other external equipment. So it may require more additional space. Besides, it is best to have enough space to ensure good ventilation, which can also increase the service life of the CNC routers.

Conclusion

Regardless of the CNC router table sizes, all the CNC router machines can realize cutting, engraving, vertical drilling, grooving, and other processes. According to customers’ processing requirements, other CNC router kits can be added to expand its functions and improve its efficiency. For example, automatic tool change, drill head, rotating device, etc.

Small CNC routers, such as 2×3 CNC router, 2×4 CNC router, 4×4 CNC router, are widely used in advertising and handicraft industries. These sizes are also the best CNC router sizes for CNC beginners and enthusiasts. Large CNC routers, such as 4×8 CNC router, 5×10 CNC router, 2030 CNC router or 3050 CNC router, are good at producing panel furniture, decorations, and molds. Large CNC routers can also form a complete automatic furniture production line combined with other auxiliary equipment. It can greatly improve furniture production efficiency.

Size of the CNC router table is an important factor when it comes to choosing a CNC router. It’s not that the bigger the size, the better the choice. You should choose the best size of CNC router table according to the maximum size of your materials to avoid waste of resources.

Blue Elephant has been deeply involved in the CNC machinery industry for more than ten years. It has devoted itself to the R&D of CNC routers. We can provide you with the best CNC router machines of various sizes. We welcome the inquiries of customers from anywhere.